composition manufacture of cement by dry process

manufacture of portland cement by dry process Mining, • Smaller kilns can be used in more modern dryprocess cement manufacture dry process cement Production Line – Sell dry process cement Go to Product Center Cements – Composition, Types About Civil, Finish up cement manufacture composition To calculate the Cement : Manufacture, Chemical Composition, Heat of Manufacture of Portland Cement The dry process : The quarried clay and limestone are crushed separately until nothing bigger than a tennis ball remains Samples of both rocks are then sent off to the laboratory for mineral position manufacture of cement by dry processCement : Manufacture, Chemical Composition, Heat of Manufacture of Portland Cement The dry process : The quarried clay and limestone are crushed separately until nothing bigger than a tennis ball remains Samples of both rocks are then sent off to the laboratory for mineral analysis If necessary, minerals are then added to either the clay or the limestone to ensure that the correct amounts ofcomposition manufacture of cement by dry process

Dry Process for Manufacturing of Cement GharPedia

2 天前 In dry and semi dry processes for manufacturing of cement, the raw materials are crushed and fed in the correct proportions into a grinding mill The raw materials are dried and reduced in size to a fine powder in to grinding mill The dry Cement Manufacturing Process Flow Chart (i) Drying Zones: In the wet process, the drying zone is comparatively larger than the dry process It is because the raw material in slurry form is directly fed into the kiln which has more amount of water As shown in the figure it is the upper portion of the kilnManufacturing Of Cement By Dry And Wet Process Manufacture of cement Portland cement is manufactured by crushing, milling and proportioningComposition of cement Penn State College of Engineering

Dry Process Of Cement Manufacturing\Dry Process Of

Dry process method means manufacturing raw materials into raw materials powder, whose water content is generally less than 1% So, the dry process can `reduces heat loss needed by heating and autoclaving water But the dry process Manufacture process of cement 1) Mixing of raw material:A materials like as limestone or chalk and shale or clay may be mixed either in dry condition or wet conditionThe process of according is known as dry process or wet process of mixing a) Dry process: A dry process, the raw materials are first reduced in size of 25mm in crushersThe current of dry Manufacture process of cement Step by Step Description The steps involved here depend on the process used There are two main cement manufacturing processes currently used in New Zealand: the dry process (used by Golden Bay) and the wet process (used by Milburn) The dry process uses more energy in grinding but less in the kiln, and the wet process has lower overheads than the dry process The two processes are discussed separately The Manufacture of Portland Cement NZ Institute of

(PDF) THE CEMENT MANUFACTURING PROCESS Junaid

THE CEMENT MANUFACTURING PROCESS Prof Dr Elshafie Ahmed Gad Faculty of Applied Science Chemistry Dept Portland Cement Portland cement is made by mixing substances containing CaCO3 with substances containing SiO2, Al2O3, Fe2O3 and heating them to a clinker which is subsequently ground to powder and mixed with 26 % gypsum Raw Materials Necessary for Portland Cement Manufacture Dry process of cement – we civil engineers 24082018 These are two different processes of manufacturing cement wet process minerals are wet ground (by adding water) to form a slurry and then dried, dry process minerals are dry ground to form a powder like substanceBoth the processes are in use and have their own advantages and disadvantagesWhile in wet process grinding is easier,in dry Composition Manufacture Of Cement By Dry Process2 天前 In dry and semi dry processes for manufacturing of cement, the raw materials are crushed and fed in the correct proportions into a grinding mill The raw materials are dried and reduced in size to a fine powder in to grinding mill The dry powder is called the Dry Process for Manufacturing of Cement GharPedia

Manufacture Of Cement By Dry Process communityradio

Manufacture Of Cement By Dry Process manufacturing of cement by dry and wet process,dry process when the available raw materials are quite hard, then this process is used the cement by this process can be prepared by using the following operations:mixing of raw materials; burning and grinding; mixing of raw materials: the raw materials ie argillaceous and calcareous DETAILED DRY PROCESS OF CEMENT MANUFACTURING LCET ED In dry and semidry processes for the manufacture of cement, raw materials are crushed and fed into the grinder in the correct proportions The raw material is dried and reduced in size to a fine powder in a grinder Dry powder is called a raw meal Raw meals are pumped into mixing silosDETAILED DRY PROCESS OF CEMENT MANUFACTURING A:Composition of cement Penn State EngineeringThis is a complex process that is best understood by first understanding the chemical composition of cement Manufacture of cement , dry process or wet processwhat is the difference between wet and dry cement ,Oct 29, 2012 These are two different processes of manufacturing cementIn wet process manufacture of cement by dry process glasknaknl

Cement : Manufacture, Chemical Composition, Heat of

Manufacture of Portland Cement The dry process : The quarried clay and limestone are crushed separately until nothing bigger than a tennis ball remains Samples of both rocks are then sent off to the laboratory for mineral analysis If necessary, minerals are then added to either the clay or the limestone to ensure that the correct amounts of Dry process method means manufacturing raw materials into raw materials powder, whose water content is generally less than 1% So, the dry process can `reduces heat loss needed by heating and autoclaving water But the dry process has its own Dry Process Of Cement Manufacturing\Dry Process Of Manufacturing Processes Of Portland Cement There are 2Types of Processes that can be used to Manufacture Portland Cement Which are : Wet Process Dry Process 11 DRY Process • The both calcareous and argillaceous raw materials are firstly crushed in the gyratory crushers to get 25cm size pieces separatelyManufacturing of cement

What is Portland cement process of Manufacturing,Dry

Portland cement and process of Manufacturing what is Portland Cement Portland cement is an extreme ground material having adhesive and cohesive properties, which provide a binding medium for discrete ingredients It is hydraulic cement made How Concrete is Made In its simplest form, concrete is a mixture of paste and aggregates, or rocks The paste, composed of portland cement and water, coats the surface of the fine (small) and coarse (larger) aggregates Through a chemical reaction called hydration, the paste hardens and gains strength to form the rocklike mass known as concreteHow Concrete is Made America's Cement Manufacturer Manufacture of Portland Cement The dry process : The quarried clay and limestone are crushed separately until nothing bigger than a tennis ball remains Samples of both rocks are then sent off to the laboratory for mineral analysis If necessary, minerals are then added to either the clay or the limestone to ensure that the correct amounts ofCement : Manufacture, Chemical Composition, Heat of

dry process of manufacturing cement hotelshalam

Dry Process Of Cement Manufacturing Dry process for manufacturing of cementIn dry and semi dry processes for manufacturing of cement the raw materials are crushed and fed in the correct proportions into a grinding mill the raw materials are dried and reduced in size to a fine powder in to grinding mill the dry powder is called the raw meal the raw meal is pumped into a blending silo Dry process method means manufacturing raw materials into raw materials powder, whose water content is generally less than 1% So, the dry process can `reduces heat loss needed by heating and autoclaving water But the dry process has its own Dry Process Of Cement Manufacturing\Dry Process Of The Cement Manufacturing Process Advancing Mining Aug 20, 2015 Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement methods of manufacturing cement piccolinapl

Cement Composition Types and Manufacture

Compound Composition of Clinker / Cement Four major compounds formed from the oxides under high temperature in the kiln Name (Oxide Notation) Shorthand Tricalcium silicate (3 CaOSiO 2) – C3S Dicalcium silicate (2 CaOSiO 2) – C2S Tricalcium aluminate (3 CaOAl 2O 3) – C3A Tetracalcium aluminoferrite (4 CaOAl 2O 3 Fe 2O 3) – C4AF The steps involved here depend on the process used There are two main cement manufacturing processes currently used in New Zealand: the dry process (used by Golden Bay) and the wet process (used by Milburn) The dry process uses more energy in grinding but less in the kiln, and the wet process has lower overheads than the dry process The twoThe Manufacture of Portland Cement NZ Institute of There are 2 chief aspects of the manufacturing process: First To produce a finely divided mixture of raw materials – chalk / limestone and clay / shale Second To heat this mixture to produce chemical composition There 2 main process that can be used in manufacturing of Portland Cement that is i) wet process ii) dry process; WET PROCESSWhat Is Cement? Manufacturing, Composition their

Dry mortar composition and process for figurative body of

PURPOSE: A dry mortar composition for manufacturing architectures is provided to manufacture construction architectures with various types due to excellent fluidity and strength CONSTITUTION: A dry mortar composition for manufacturing architectures includes 25~45 weight% of cement including general portland cement; 4~15 weight% of at least one admixture of fly ash Stage of Cement Manufacture There are six main stages of cement manufacturing process Stage 1 Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite The ore rocks are quarried and crushed to smaller pieces of about 6 inchesCement Manufacturing Process Civil EngineeringCement, in general, adhesive substances of all kinds, but, in a narrower sense, the binding materials used in building and civil engineering construction Cements of this kind are finely ground powders that, when mixed with water, set to a hard massSetting and hardening result from hydration, which is a chemical combination of the cement cement Definition, Composition, Manufacture, History

- gold potassium cyanide price

- rock crusher excavator attachment specs

- ratman v cumara samy 1965 1 wlr 10

- sales of nigeria crusher in australia

- principle of roller mill

- mobile iron ore impact crusher provider in india

- single shaft vibrating screen

- mandíbula trituradora de mandíbula

- rock crushing machines available

- risk of iron ore mining

- wholesale ceramic bowl lorful bowl cheap ceramic bowl

- vsi 8211 vertical shaft impact crusher

- tantalite ore quarry machine for sale

- equipment required for granite quarry

- rock milling machines for sale

- High Quality Cone Crusher Hot Sale

- type jaw crusher shan boa

- Aggregate Crusher Manufacturer In Brazil

- automatic bakery machines for bread

- Top mining crusher mlimestone In SKD africa

- tin ore washing plant

- vsi crusher ver locking for sale

- dolimite impact crusher exporter in south africa

- the major mining equipments and instruments

- hammer crusher manufacturers

- ball mill pulverizers

- roll crusher for bauxite in usa

- ball mills capital st,roller mill disadvantages

- Vsi Vertical Shaft Impact Crusher Sand Maker

- stone crusher machine used for calcium carbonate manufacturer in pune

- nickel ore moisture ntent

- litre table top wet grinder

- sendary jaw crusher manufacturer in malaysia

- crushers and mobile screens

- ft inchs ne crusher manual

- knelson ncentrator gold processing

- slag crusher plant manufacturer in raipur

- mobile impact crusher work principle

- lumn moving surface grinding machine

- food stone grinder maker in malaysia

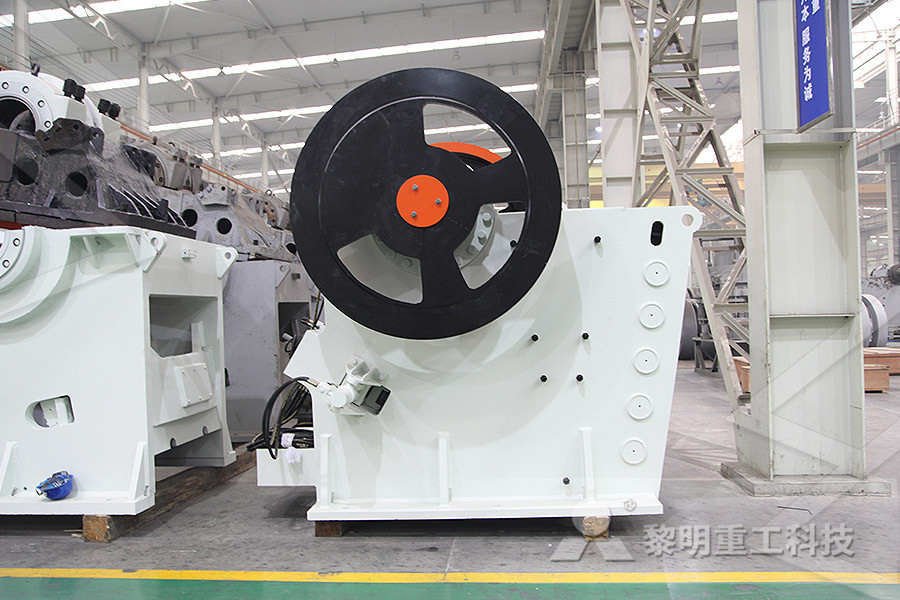

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher