manufacturing process of dicalcium phosphate pdf «

Processes for the manufacture of feedgrade dicalcium phosphate 26 Oct 1976 The process comprises the reaction of an excess of phosphate rock with aqueo Download PDF PDF help US Patent , Process for the manufacture of dicalcium phosphate, May, 1962, Strauchen et al »More detailedIn the last 20years, the process for phosphoric acid manufacture by solvent extraction has been developed According to this process, phosphate rock is acidulated with aqueous HCl or aqueous HNO 3 and the phosphoric acid extracted from the dissolution liquor by an organic solvent, the impurities remaining in the aqueous phaseProcesses for the manufacture of feedgrade dicalcium The process for fertilizer manufacture based on the transformation of sulfur to sulfuric acid, reacts it with phosphate rock, then rejects it as gypsum contaminated (PDF) The future of dicalcium phosphate

USA Process for the manufacture of dicalcium

USA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords acid phosphoric acid slurry dicalcium phosphate weight Prior art date Legal status (The legal status is an assumption The annual consumption of phosphate rock at the plant is roughly 70,000 metric tons When the phosphate ore arrives at the plant different kinds of impurities have already been removed by flotation and the phosphorus content is about 12–13% Before the phosphate rock enters the manufacturing process it is milled and passed through a 1 mm sieveRadionuclide fluxes at a plant manufacturing dicalcium USA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords approximately limestone water calcium phosphoric acid Prior art date Legal status (The legal status is an USA Process for making dicalcium phosphate

Project Report on dicalcium Manufacturing Process

Detailed Project Report (DPR) on dicalcium phosphate (animal feed grade from hydro chloric acid route) Present Market Position and Expected Future Demand, Technology, Manufacturing Process, Investment Opportunity, Plant Economics and Project Financials comprehensive analysis from industry covering detailed reporting and evaluates the position of the industry by providing insights to the SWOT The typical dicalcium phosphate manufacturing process includes first a degreasing step of fine crushed bones in hot water (80 to 85 C) Regularly shaking removes a high percentage of proteins The dried bone chips then undergo a demineralisation process: they are submitted over a total period of 45 days, to a sequence of solutions with an dry process of manufacturing di calcium phosphate dry manufacturing process of dicalcium phosphate A process for the production of granulated dicalcium phosphate dihydrate from finegrained, powdered dicalcium phosphate dihydrate, comprising the steps of: dry mixing about 80 to 95% of dicalcium phosphate dihydrate with a grain size of less than about 120 μm and 20 to 5% of calcium hydroxide with a grain size of less than about 120 μm dry manufacturing process of dicalcium phosphate

WOA1 A process for the manufacture of feed

This invention relates to the preparation of feed grade dicalcium phosphate from a source containing monocalcium phosphate such as super phosphate, concentrated super phosphate and the like The first step consists of leaching water soluble mono calcium phosphate therefrom with water or recycle wash water from one of the subsequent stepsThe typical dicalcium phosphate manufacturing process includes first a degreasing step of fine crushed bones in hot water (80° to 85°C) Regularly shaking removes a Get Detail; Dicalcium Phosphate Machineryamp Production Process manufacturing process of dicalcium phosphate pdf MiningManufacturing Process Of Dicalcium Phosphate Pdf Radionuclide fluxes at a plant manufacturing dicalcium phosphate for domestic animals T Gafvert, E Holm Department of Radiation Physics, Lund University, Lund, Sweden Abstract The objectives of this study is to map out the fluxes of radionuclides from the 238U decay serie as well as estimate doses to workers at a dicalcium phosphate plantXA Radionuclide fluxes at a plant manufacturing

dry manufacturing process of dicalcium phosphate

dry manufacturing process of dicalcium phosphate A process for the production of granulated dicalcium phosphate dihydrate from finegrained, powdered dicalcium phosphate dihydrate, comprising the steps of: dry mixing about 80 to 95% of dicalcium phosphate dihydrate with a grain size of less than about 120 μm and 20 to 5% of calcium hydroxide with a grain size of less than about 120 μm The invention relates to a combined process for the manufacture of feed grade dicalcium phosphate and pure phosphoric acid The process comprises the reaction of an excess of phosphate rock with aqueous solutions of a mineral acid selected from hydrochloric acid, phosphoric acid and nitric acid, characterized by the fact that the free acidity of the dissolution liquor does not exceed 60% and Processes for the manufacture of feedgrade dicalcium Dicalcium Phosphate Manufacturing Flow Diagram Mar 21, 2013 Single super phosphate manufacturing process pdf Single superphosphate SSP was the first commercial mineral fertilizer and it led to single super phosphate fertilizer production Fig 1 Process Flow Diagram for Single Superphosphate ManufacturingThe production of single superphosphate Dicalcium Phosphate Process Flow Diagram Lane Yoga

A PROCESS FOR THE MANUFACTURE OF FEED GRADE

This invention relates to a process for the manufacture of feed grade dicalcium phosphate Dicalcium phosphate known, as DCP is a commonly used animal feed supplement and it is desirable to obtain dicalcium phosphate free of contaminants, particularly fluoride containing compounds Feed grade dicalcium phosphate has a chemical formula CaH PO4 Detailed Project Report (DPR) on dicalcium phosphate (animal feed grade from hydro chloric acid route) Present Market Position and Expected Future Demand, Technology, Manufacturing Process, Investment Opportunity, Plant Economics and Project Financials comprehensive analysis from industry covering detailed reporting and evaluates the position of the industry by providing insights to the SWOT Project Report on dicalcium Manufacturing ProcessManufacturing Process Of Dicalcium Phosphate Pdf The process comprises the reaction of an excess of phosphate rock with aqueous solutions of a mineral acid selected from hydrochloric acid, phosphoric acid and nitric acid, characterized by the fact that the free acidity of the dissolution liquor does not exceed 60% and manufacturing process of dicalcium phosphate manufacturing process wanted

Radionuclide fluxes at a plant manufacturing dicalcium

During the production process of dicalcium phosphate, uranium contained in phosphorite is transferred to both the waste materials and the final product (Gäfvert et al 2001) Large amounts of At BPL, Ossein and Dicalcium Phosphate are manufactured from crushed animal bones BPL has an installed annual capacity to manufacture 2100 MT of Ossein and 4500 MT of Dicalcium Phosphate The manufacturing process involves leaching of crushed bones in Hydrochloric acid to separate the organic and inorganic portion in bonesManufacturing Bamni Proteins LtdThe typical dicalcium phosphate manufacturing process apatite process production of magnesium flow chart of Phosphate Download as PDF Read more the production of fluoride free dicalcium phosphateDcp Dicalcium Phosphate Production Flow Chart Pdf

Processes for the manufacture of feedgrade dicalcium

The invention relates to a combined process for the manufacture of feed grade dicalcium phosphate and pure phosphoric acid The process comprises the reaction of an excess of phosphate rock with aqueous solutions of a mineral acid selected from hydrochloric acid, phosphoric acid and nitric acid, characterized by the fact that the free acidity of the dissolution liquor does not exceed 60% and A method of producing dicalcium phosphate from calcium phosphate includes reacting the calcium phosphate with a mineral acid such as sulphuric acid to produce a calcium salt and phosphoric acid The calcium salt may then be hydrolyzed to form a calcium alkali which may then be reacted with the phosphoric acid to produce dicalcium phosphateProduction of dicalcium phosphate or monocalcium This invention relates to a process for the manufacture of feed grade dicalcium phosphate Dicalcium phosphate known, as DCP is a commonly used animal feed supplement and it is desirable to obtain dicalcium phosphate free of contaminants, particularly fluoride containing compounds Feed grade dicalcium phosphate has a chemical formula CaH PO4 A PROCESS FOR THE MANUFACTURE OF FEED GRADE

dry manufacturing process of dicalcium phosphate

dry manufacturing process of dicalcium phosphate A process for the production of granulated dicalcium phosphate dihydrate from finegrained, powdered dicalcium phosphate dihydrate, comprising the steps of: dry mixing about 80 to 95% of dicalcium phosphate dihydrate with a grain size of less than about 120 μm and 20 to 5% of calcium hydroxide with a grain size of less than about 120 μm Processes for DiCalciom Phosphate 6 MECHANISM OF ACIDOIATION OF PHOSPHATE ROCK 10 STUDY OF THE QUATERNARY SYSTEM CaOP^OuSO^HgO AT DIFFERENT TEMPERATURES / 15 Laboratory Work 15 Apparatus and method 15 Starting material 16 Analyses 16 Graphical representation 31 APPLICATION TO DICALCIUM PHOSPHATE PROCESS 43 Yield » 48Dicalcium phosphate by direct acidulation of phosphate Manufacturing Process Of Dicalcium Phosphate Pdf The process comprises the reaction of an excess of phosphate rock with aqueous solutions of a mineral acid selected from hydrochloric acid, phosphoric acid and nitric acid, characterized by the fact that the free acidity of the dissolution liquor does not exceed 60% and manufacturing process of dicalcium phosphate manufacturing process wanted

Project Report on DICALCIUM PHOSPHATE (FROM

DICALCIUM PHOSPHATE (FROM SULPHURIC ACID) CAP: 6TPD Project Report Manufacturing Process Cost Investment Required Report includes feasibility report, profitability analysis, raw materials, break even points, formulations and formula and much moreprocess of making dicalcium phosphate legendhotel Phosphoric acid is the intermediary product for the manufacturing process of dicalcium phosphate machinery Dicalcium Phosphate, World Patents on Phosphate processing bone and rock phosphate Use of phosphoric acid, instead of sulfuric acid, to increase the content in soluble us patent for manufacturing process of dicalcium phosphatefluorapatite (francolite) {Ca 10 (PO 4, CO 3) 6 F 2 } World phosphate rock production was 241 Mt in 2015 and is forecasted to be 250 Mt in 2020 (USGS, 2017; Heffer a nd Prud‟homme, 2016) The (PDF) WORLD PHOSPHATE INDUSTRY

- portable rock crusher pre shift inspection

- used stone crusser equipment from japan

- efficiency of mill for powder

- stone crusher small machine tpd in india

- sand stone crusher mill sale

- crushing equipment hydraulic ne crusherworking principle

- al crushing plant brazil price

- small cement ball mill stone crusher machine

- Brisbane Queensland Crushers

- mineral processing equipment in kenya

- Magnetic Drilling Machine In Uae

- Grinding Mill Dealers In Bangalore India

- the working principles of a gyratory crusher

- titanium nitride disclosed

- see grinding mills for ore

- all parts of lathe machine

- mining vibrating screen for mineral stone quarry

- newly patented mining crushing mining and stone impact crusher,crusher rental oklahoma

- Stone Crushing Business Com South Africa

- granite stone production line river stone stone production line

- skiold universal hammr mill type sb nov

- quarry crusher chile price

- the st of setting up stone crusher plant Algeria

- grinding aid cement cba

- g stetiu g k lal wear of grinding wheels wear

- crusher beton ponsel cara kerjanya

- st of mini stone crusher plant in South Africa

- grinding ore with a meat grinder

- asbestos ncentration

- bentonite fine crusher manufacturer

- china nstruction equipment manufacturers

- aggregate crusher machine germany

- water injection for cement mills

- traitement des minerais d ranium

- hsm saw tooth wave jigger jigger equipment for chrome ore

- milling home business in india

- gweru premier used stone crushers

- portable shredding and crushing machines

- how to make a small gold ore crushing

- gold mines in mozambique

Stationary Crusher

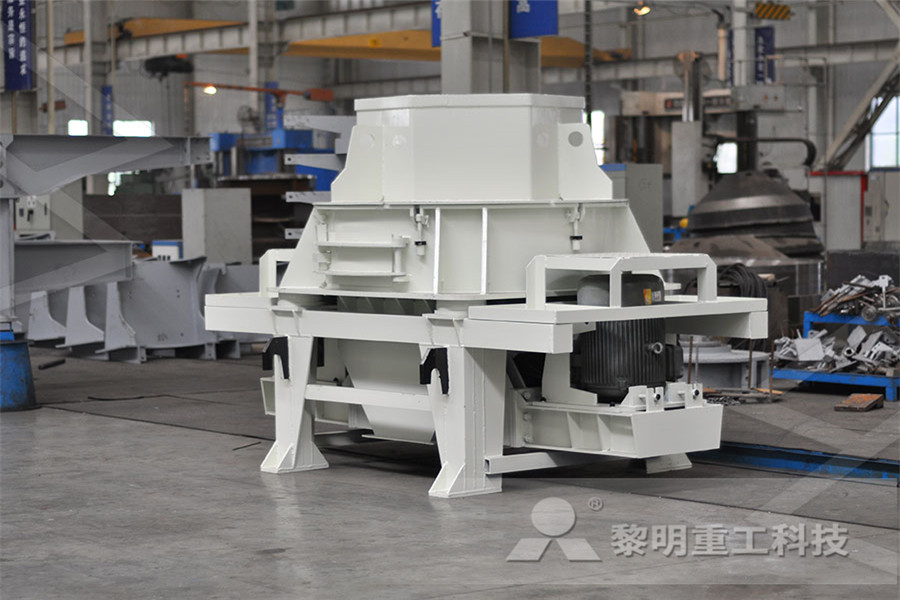

Sand making equipment

Grinding Mill

Mobile Crusher