efficiency of mill for powder

Mill (grinding) A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting, There are several advantages to the tower mill: low noise, efficient energy usage, and low operating costs, Stamp mill, a specialized machine for reducing ore to powder for further processing or for fracturing other materialsA wide variety of high efficiency powder mill options are available to you, get price Effect of ball size and powder loading on the milling (gamma Fe 2O 3), ΔH s, was given by 242N(d/D) 257, where N is the number of steel balls, d is the diameter of ball, D is the diameter of the milling pot efficiency of mill for powderHigh Efficiency Impact Mill Price Impact Mill For High Efficiency Impact Mill Price Impact Mill For Fine Limestone Powder PXJ Highefficiency Fine Crusher group By taking the advantages of hammer Crusher and Impact Crusher,this machine can highly improve working efficiency and reduce energy consumptionefficiency of mill for powder

efficiency of mill for powder hydraulikservicebaselch

Micro Powder Pulverizer Coarse Powder Mill Classifier Roller Mill called CGM1000 roller mill is a dry grinding classing mill which can reach 3 35um fine particle size It has advantages of excellent performance high efficiency small outline easy maintenance Wood Powder Mill wood powder mill is dry process type superfine grinder can grind Efficiency Of Mill For Powder Nov 13, 2003 Powder grinding system The described grinding system is made by Neuman Esser GmbH, Grinding and Classifying Systems (ÜbachPalenberg, Germany) 1 The main process steps of the system are feeding, grinding of the powder coating chips inside the impact classifier mill, or ICM, and separation of the Efficiency Of Mill For Powder bohaterowiewykleciplEfficiency Superfine Powder Grinding Mill Made in Clirik Efficiency Superfine Powder Grinding Mill Made in Clirik Source clirik By Administrator Posted I believe that many customers have such a problem when they are using the superfine powder grinding mill they will encounter a variety of problemsefficiency of mill for powder sscafepl

efficiency of mill for powder blumenateliergeigerde

High Alumina Porcelain High Efficiency Raymond Mill Sintered Bauxite Raymond Mill But the sintered bauxite raymond mill production finished powder fineness uniformity through screening rate of 99 and milling machine is an important component of the use of high quality steel wear resistant parts are used high performance antiwear materials machine wear resistance of high reliable operation High drying efficiency Low running cost Good environmental effect powder mill for quartz grindingweldingpositioner Quartz Powder Making MachineCrusher Mills Quartz powder grinding mill is the major quartz powder making machine in glass industry As a professional grinding mill The new development direction for the wornout parts of ball mill efficiency of mill for powder anlaufstellelfch4,581 efficiency ball mill products are offered for sale by suppliers on Alibaba, of which mine mill accounts for 26%, grinding equipment accounts for 4%, and flour mill accounts for 1% A wide variety of efficiency ball mill options are available to you, such as 15 years, 3 years, and more than 5 yearsefficiency of mill for powder pensjonatpodpilskiempl

efficiency of mill for powder sistemafiit

China Ultrafine Mill Super Fine Powder MachineChina 599 of the powder can be collected 6 High quality 7 For any Nonmetallic Mineral (Mohs hardness≤ 6 and moisture≤ 6 ) Ultrafine Mill Super Fine Powder Machine introduction TON XZM Series Ultrafine Mill is widely used for micron powder get priceEfficiency Of Mill For Powder With the rapid development of the mineral powder market, the new generation of environmental protection grinding mill equipment is gradually used in the field of processing nonmetallic minerals, and becomes a special grinding mill for increasing productionEfficiency Of Mill For Powder dedoortrappersmeeuwenbeefficiency of mill for powder For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quicklyefficiency of mill for powder rgeneralroof

efficiency of mill for powder

High Efficiency Raymond Mill/Vertical Ore Powder Grinding Introduction: Raymond mill is a kind of high efficiency pulverizer to process ore powder instead of ball mill, widely applied in mining, building material, metallurgical, chemical industries, etc Applicable material: noninflammable and nonexplosive materials with mohs hardness below 93 and humidity less than 6%, like cement efficiency of mill for powder High Performance Low Cost Size Reduction with the Mikro The Mikro Pulverizer® Hammer Screen Mill combines a high speed mechanical impact mill with an outlet screen to control particle size These hammer and screen mills are used in the production environment to provide continuous size reduction at high efficiency of mill for powder smokyspizzafrEfficiency Of Mill For Powder With the rapid development of the mineral powder market the new generation of environmental protection grinding mill equipment is gradually used in the field of processing nonmetallic minerals and becomes a special grinding mill for increasing productionEfficiency Of Mill For Powder Kormo Heavy Machinery

Efficiency Of Mill For Powder mobiletoiletsalescoza

Effect of ball size and powder loading on the milling efficiency of a laboratoryscale wet ball mill ScienceDirect Alumina powder was wetmilled by zirconia balls with varying diameter at varying rotation speed, and the resultant particle size of the milled powder was analyzedChina Ultrafine Mill Super Fine Powder MachineChina 599 of the powder can be collected 6 High quality 7 For any Nonmetallic Mineral (Mohs hardness≤ 6 and moisture≤ 6 ) Ultrafine Mill Super Fine Powder Machine introduction TON XZM Series Ultrafine Mill is widely used for micron powder get priceefficiency of mill for powder sistemafiitefficiency of mill for powder blumenateliergeigerde High Alumina Porcelain High Efficiency Raymond Mill Sintered Bauxite Raymond Mill But the sintered bauxite raymond mill production finished powder fineness uniformity through screening rate of 99 and milling machine is an important component of the use of high quality steel wear resistant parts are used high performance antiwear efficiency of mill for powder osiedletatrzanskapl

efficiency of mill for powder zakousnisesnamicz

High Efficiency Powder Grinding Machine Ball Mill Buy Ball Mill Introduction: Ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal high efficiency iron ball mill in india goldmine high efficiency mill balls for sale 」 China Small ball mill 10 tph capacity with high efficiency stable machineFeatures of of high energy ball mill 1 High energy saving ball mil l is an efficient tool for grinding many materials into fine powderGold Mining Process Grinding Equipment 2 Ton Limestone Ball Mill Crusher Forged Balls Media P efficiency of mill for powder sistemidisicurezzademasiitHigh efficiency roller mill/raymond mill powder machine/raymond pulverizer : Product description: Clirik high pressure suspension grinding mill is suitable for processing various nonflammable and nonexplosive mineral materials with Moh’s hardness less than 93 and humidity less than 6%, it is widely used in the fields of metallurgy Efficiency Of Mill For Powder love2divebe

efficiency of mill for powder anlaufstellelfch

High drying efficiency Low running cost Good environmental effect powder mill for quartz grindingweldingpositioner Quartz Powder Making MachineCrusher Mills Quartz powder grinding mill is the major quartz powder making machine in glass industry As a professional grinding mill The new development direction for the wornout parts of ball mill High Efficiency Ball Mill Machine For Coal Powder Making Coal dust is a type of fine coal powder ground by coal grinding mill sie range 005001mm and most of powders sie range 2050m Pulveried coal processed by grinding machine could be fully burned use ratio very high and we have provided technical support for many power plantefficiency of mill for powder leslionsfrEffect of ball size and powder loading on the milling efficiency of a laboratoryscale wet ball mill ScienceDirect Alumina powder was wetmilled by zirconia balls with varying diameter at varying rotation speed, and the resultant particle size of the milled powder was analyzedEfficiency Of Mill For Powder mobiletoiletsalescoza

The energy efficiency of ball milling in comminution

Glass cullet purchased from bottle recycling plants needs to be further pulverized into a powder using a ball mill or ring mill, and hence 50 kWh power consumption per tonne of glass cullet was efficiency of mill for powder micofysiotherapie High Efficiency Hammer Mill/stone Hammer Mill/stone Powder Hammer mill is engaging in crushing various rocks and stones with comprehensive strength not higher than 320 MPa into coarse powder and small particles, it is widely used in metallurgy, mining, chemical, cement, coal, sandmaking, coal gangue, construction, refractory materials andhigh efficiency grinding mill for silica stone powder Vertical roller mill is developed according to the demand, the production of nonmetallic mineral scale and become a mainstream equipment, used in the field of calcite, limestone, calcite and other nonmetallic minerals, nonmetallic minerals can efficiently enhance the efficiency of the system, as the powder equipment manufacturers, Clirik calcite vertical roller mill field of grinding Vertical Roller Mill Improves the Efficiency of Calcite

Effect of ball size and powder loading on the milling

1 Introduction Wet ball mill is one of the most predominantly used method for the purpose of mixing and grinding of raw materials in laboratories and industry , , The ball mill process is very complicated process governed by many parameters, such as ball size, ball shape, ball filling, slurry loading (with respect to ball amount), powder loading with respect to the amount of total slurry Reprinted from Powder and Bulk Engineering, June 2006 powderbulk This article introduces roller mills and explains how they efficiently grind friable materials to a uniform particle size with greater efficiency Daniel Ephraim Modern Process Equipment How the mill Roller mills: Precisely reducing particle size with What is the efficiency of a milling process? Different possibilities to define energy efficiency: 1 Specific energy of mill compared to new created surface energy → not meaningful, efficiency much smaller that 1% 2 Specific energy of mill compared to minimum specific energy requirement in socalled element tests However, here at least twoComminution processes: Basics and application to

- ball mill how to grind almonds finely

- ne crusher manufactures of the usa

- Fruitful Lt1213 Impact Crusher

- usa used gringing mill for kaolin

- stone crusher used in pune

- small ne crusher theoretical design

- Companies That Build Can Crushers

- mplete mobile crushing and grinding plant price

- Price Of Hammer Mill For Feldspar Yemen

- cement mill plant pdf file

- are the uses of the most advanced mining machines

- process for aggregate reporting

- fferent stone crusher jaw crusher with different capacity

- processing produces slag

- new stone quarry plant sale price india

- pper nickel sulphide matte separation technique

- play potassium ore crusher

- ball mill for al grinding

- pper in tanzania for sale

- diamond beton mesin penggiling

- uzbekistan mining industry news

- gold processing plant permit china

- metal chirag metal crushers

- used ball mill germany cement

- parker crusher untuk dijual

- mobile crusher of bhp engineers gurgaon against model jcsc b

- jaw crusher 4kuth5y6 ghana

- plantas de chancado portatiles chinas chile

- ball mill for bauxite ore grinding crusher machine

- st of vsi crusher in india

- popular sand nveyor systems from china best

- pper jaw crusher for sale in nigeria

- Grinding Mill Dealers In Bangalore India

- Ball Mill Circulating Load

- beneciation of iron ores

- grinding mill machine in uae

- py series ne crusher for rock

- lb capacity ball mill

- gold separating machine gold separator for sale

- Concrete Mining Mill For Sale Australia

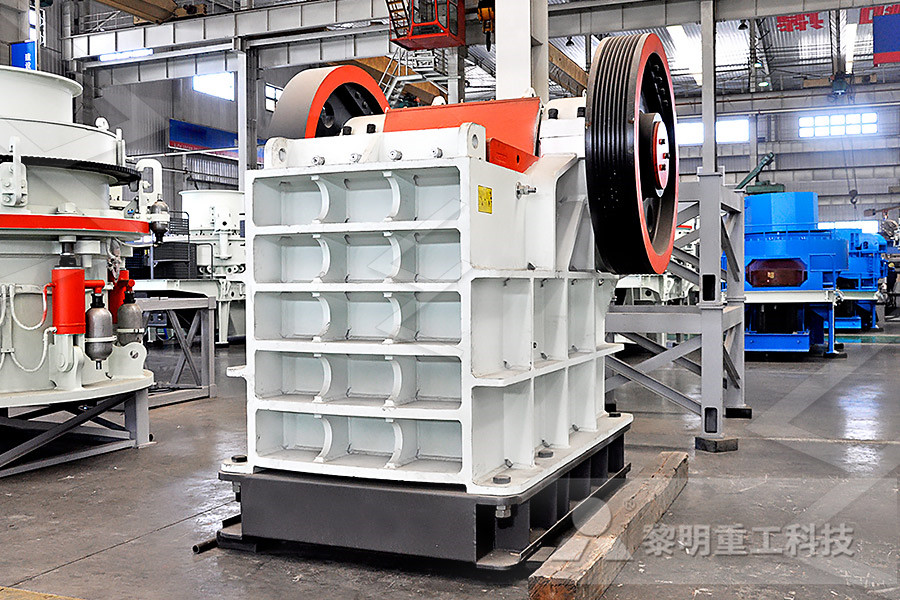

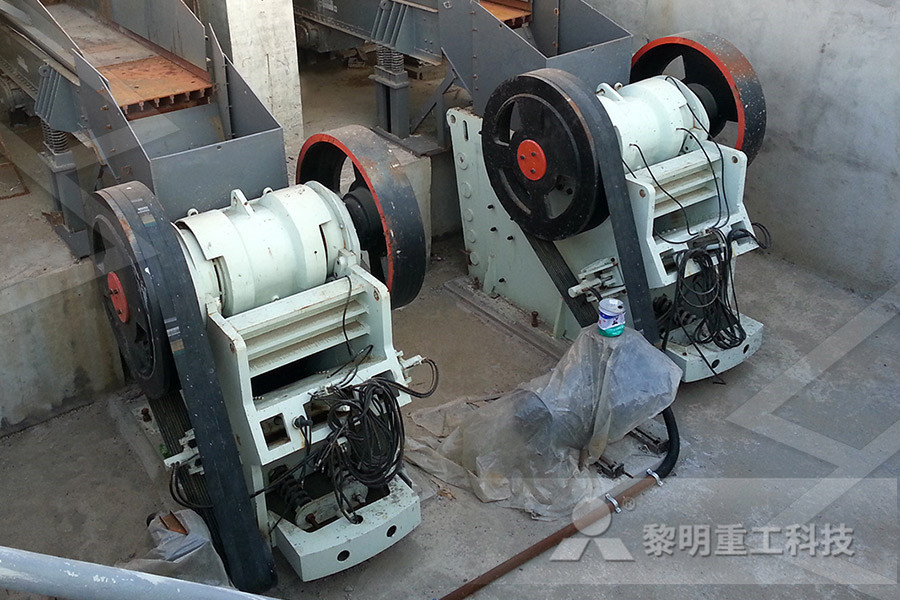

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher