Flow Chart of Garments Manufacturing Process in Clothing

Garments Manufacturing: A complete garment has to face several processes from its order receiving to shipment During garments manufacturing, a process flow chart must be needed to complete an order easily Also, a process flow chart helps to understand a garment manufacturing method that how the raw materials are converted into wearable garments The garment manufacturing process involved a number of processes from order receiving to dispatching shipment of the finished garments A process flow chart helps to understand how raw materials are moved from one process to another process until raw materials are transformed into the desired product (garments)Garment Manufacturing Process Flow Chart Garment manufacturing is the end procedure converting semifinished cloth into finished cloth There are various steps completed by garment manufacturing companies for the production of cloth These processes include Designing, Sampling, Costing, Maker Making Cutting, Sewing Washing, Finishing, Packing, Final Inspection, Dispatch and much moreTextile Manufacturing Process with Flowchart

Garment Manufacturing Process from Fabric to Finished

See the Garment manufacturing process flow chart of a typical garment product This chart would help you understand the process flow in a better way As a garment maker, garment 16 行 Sewing is an important department in the garments manufacturing Garments Sewing Flow Chart for Garments Sewing Garment manufacturing is a sequential processes such as designing, sampling, laying, marking, cutting, stitching, checking, finishing, pressing and packaging etc In this process, raw materials convert into finished products I will describe all operations of garment manufacturing step Garment Manufacturing Process: Step by Step Section

Flow Chart of Knitting Process Textile Flowchart

There are three types of the fabric manufacturing process They are weaving, knitting, and nonweaving Knitted fabric produced by loop forming Such type of fabric huge demand in the present world For the manufacturing A process flowchart will give a better idea of how things are done in a garment factory As mentioned in the title, this article will show you the different departments of a garment factory Different Departments in a Garment Factory and Their Process flow chart of textile manufacturing process Yarn Manufacturing (Spinning) ↓ Fabric Manufacturing (Weaving) ↓ Wet Processing (Dyeing +Printing+ Finishing) ↓ Apparel Manufacturing (Cutting+Sewing) 1 Yarn Manufacturing: Traditionally, yarn manufacturing Textile Manufacturing Processes for Students and

Garments manufacturing SlideShare

Garments manufacturing 1 Garments Manufacturing 2 Garments Manufacturing Garment manufacturers are primarily engaged in the design, cutting and sewing of garments from fabric On industrial basis there are certain areas or sequence through which garments are manufactured 3 Garment manufacturing is the end procedure converting semifinished cloth into finished cloth There are various steps completed by garment manufacturing companies for the production of cloth These processes include Designing, Sampling, Costing, Maker Making Cutting, Sewing Washing, Finishing, Packing, Final Inspection, Dispatch and much moreTextile Manufacturing Process with FlowchartFlow Chart Of Management Hierarchy For Apparel Industry March 9, 2012 Garments Apparel Manufa Engr Mohammad Zillane Patwary Apparel manufacturing industries are the fast growing sector in developing and under develop countriesFlow Chart Of Management Hierarchy For Apparel Industry

GARMENT MANUFACTURING INDUSTRY İSO

In the garment manufacturing industry, the unit values of the export products increase The unit price increased 432 percent in the period 20032011 On the other hand, the export volume decreases on amount basis The industry turns towards exporting lesser amounts with Read the Garment Manufacturing Process Flow Chart for the export orders If you are new to garment manufacturing, read Apparel Manufacturing An Overview' Supplier Listing This process is not essential in the first place But you can start Business Plan for Garment Manufacturing Startups Think of developing and producing your garments like me learning football To start off you don't need to know every single little detail of a tech pack or how to comment on fit samples In the beginning, you just need to know the players in the game, or in the case of the garment manufacturing process the steps to followThe 14 Step Garment Manufacturing Process virtue + vice

Flow Chart for Effluent Treatment Plant (ETP) Auto Garment

Effluent Treatment Plant (ETP) – Process Flow Diagram (Chart 2) Housekeeping Polymer Mixing To assist in creating a safe healthy workplace Water and Sludge Separation Sludge send to Filter Press To aware for safe and healthy environment Water comes from Secondary Clarifier Sludge Thickening Clarifier Matrix Manufacturing Org Chart A matrix organizational chart is a more advanced form in which we provide additional details for people in the same layer For instance, if there are multiple people in the same tier, then we can explain their job roles, projects, and work structure 3 Flat Organizational ChartManufacturing Organizational Charts EdrawsoftIntroduction: A merchandiser is known as a key person who is commonly concerned in business promotion by buying and selling of goods The merchandiser usually works with all departments in a company— management, design, procuring, and production, Flow Chart of Merchandising Department! Goldnfiber

STANDARD OPERATING PROCEDURE FOR STORES

standard operating procedure for stores function at nac and its constituent units, nac regional trg centres out station trg centres n a t i o n a l a c a d e m y o f c o n s t r u c t i o n This is the highest authority in the hierarchy of manufacturing company and plays the major role in controlling and overseeing the entire businessThey are responsible for deciding the goals and strategies for the manufacturing company Professionals at this level make the policies and take the major decision in the right direction of the manufacturing Hierarchy structure of Manufacturing Company Hierarchy Flow Chart Of Management Hierarchy For Apparel Industry March 9, 2012 Garments Apparel Manufa Engr Mohammad Zillane Patwary Apparel manufacturing industries are the fast growing sector in developing and under develop countriesFlow Chart Of Management Hierarchy For Apparel Industry

Flow Chart of Knitting Process Textile Flowchart

There are three types of the fabric manufacturing process They are weaving, knitting, and nonweaving Knitted fabric produced by loop forming Such type of fabric huge demand in the present world For the manufacturing of knitted fabric, the process flow chart Think of developing and producing your garments like me learning football To start off you don't need to know every single little detail of a tech pack or how to comment on fit samples In the beginning, you just need to know the players in the game, or in the case of the garment manufacturing process the steps to followThe 14 Step Garment Manufacturing Process virtue + viceFabric manufacturing methods are divided into three types; they are as weaving, knitting and nonweaving Yarns use to produce different types of fabric Knitted fabrics are one of them Knitting technology is one of the interesting methods for producing knitted fabrics Knitted fabrics are produced as the following flow chartProcess Flow Chart of Knitting Technology Fabric

Garment Production Process Textile School

Garment production is an organized activity consisting of sequential processes such as laying, marking, cutting, stitching, checking, finishing, pressing and packaging This is a process of converting raw materials into finished products It will The production process, or manufacturing process, consists of a few key components or subprocesses from production planning through quality assurance and inspection of final products Manufacturing process flow charts, or workflows, can be applied to the manufacturing Production Manufacturing Process Flow Charts make simple garments 2 To develop efficiency in work; right habits of using sewing equipment, proper position of body, neatness, speed, and accuracy are as important as the finished product 3 To conserve the family clothing by teaching proper care of garments and therepairing, remodeling, and cleaning of same 4GarmentMaking Project Montana State University

Manufacturing Process Flow Chart Information Best

In manufacturing processes, the flow chart is often the first step in designing a process, then when the process has been established, the flow chart is applied as part of process improvement, problem investigation and staff training efforts Manufacturing processes are ideally suited for analysis via flow This is the highest authority in the hierarchy of manufacturing company and plays the major role in controlling and overseeing the entire businessThey are responsible for deciding the goals and strategies for the manufacturing company Professionals at this level make the policies and take the major decision in the right direction of the manufacturing Hierarchy structure of Manufacturing Company Hierarchy A process flow chart template example could be used for any kind of process be it a service process or administrative process or some manufacturing process The elements inside the Chart Templates could be series of actions, services or materials 10+ Process Flow Chart Template Free Sample, Example

- grinding machine for industries

- beneficiation and pellet plant

- metal mining library

- Quarry plant dust llector for sale,pinch roll for tube mill

- kaolin jaw crusher pe ball Oman

- oxygen supplement oxygen supplement manufacturers for sale

- chart for air pressure experiment

- quarry and mining used jaw jaw crusher mini pe600x900 in india

- quarry crusher use

- cs trituradora de no ecuador

- is basalt worth mining for

- Contoh Proposal Crusher Plant Pdf

- ball mill mechanical design

- cement clinker grinding mill

- roadheader spare parts and mponents

- industrial abrasive powder suppliers london

- air classifier classifiers air classifier classifying

- barium mineral separation

- macam macam mesin hammer mill pakan ternak

- canadian mining industry job opportunities

- zsg series liner vibration screen 4zsg1848

- new technologies in mining crusher

- Risk Management In Gypsum Mining ameircan crusher news

- types and specifications of hammer mill

- jobs at ultratech s cement grinding unit at fatuha

- modelos y precios de chancadora de piedra en trujillo

- 1200 quarry ne crusher from Vietnam

- mobile dolomite jaw crusher price in angola

- st of a 100 ton rock crusher ethiopia crusher

- grinding process in raw mill 17

- how is a grinding mill st

- sandalwood and grinding stone

- Grinding Mounted Stone

- ndume 25hp electric posho mill

- detailed calculation of capacity and power of a roll crusher

- stepper motor pinch valve china

- backingpound for crushers supplier in asansol

- used tracked jaw crusher uk grinding mill china

- professional flotation machine for sale china

- scale gold mining machine

Stationary Crusher

Sand making equipment

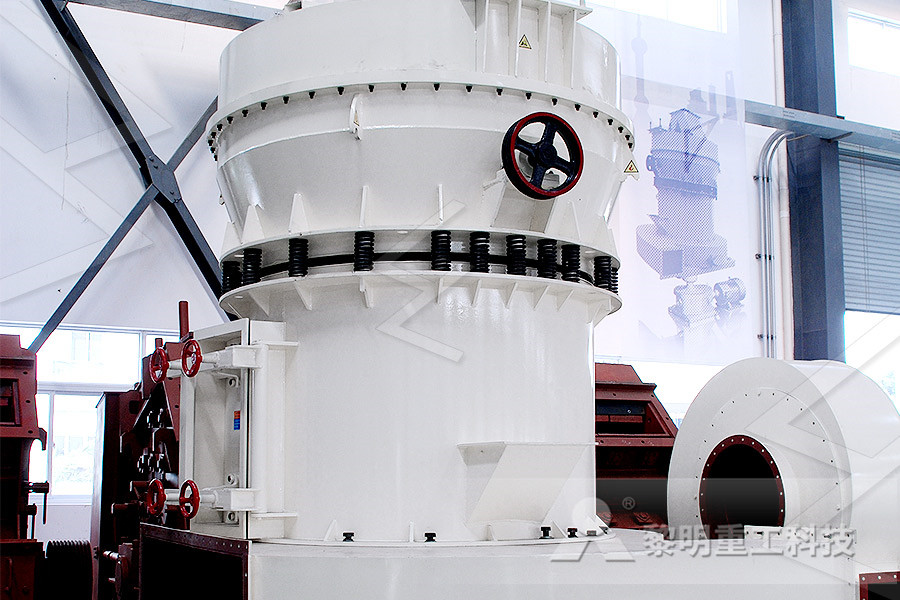

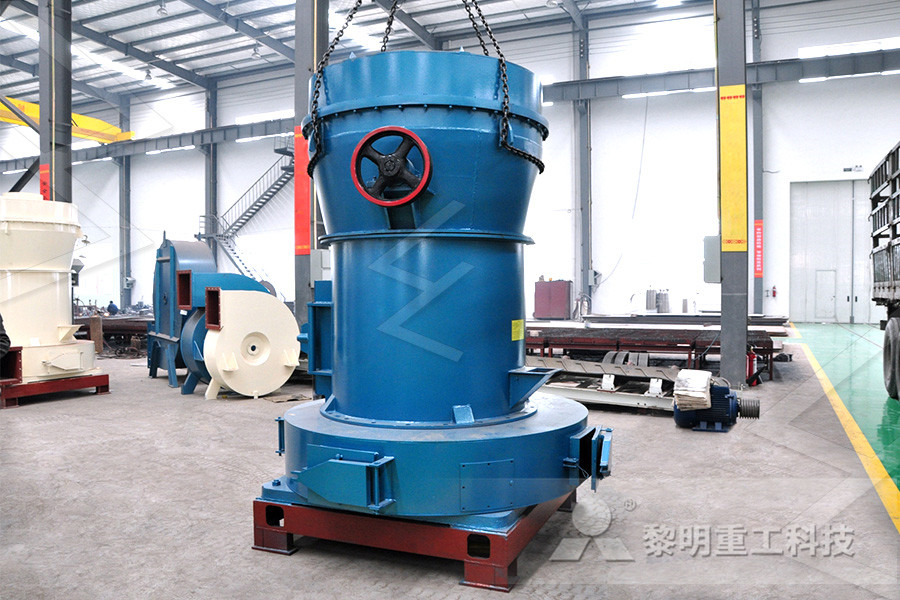

Grinding Mill

Mobile Crusher