Modeling of Raw Material Mixing Process in Raw Meal

KeyWords: Dynamics, Raw meal, Quality, Mill, Grinding, Model, Uncertainty 1 Introduction The main factor primarily affecting the cement quality is the variability of the clinker activity [1] which depends on the conditions of the clinker formation, raw meal composition and fineness A stable raw meal grinding process provides a low Modeling of Raw Material Mixing Process in Raw Meal Grinding Installations due to the large number of disturbances during the raw mill operation depicted in Figures 16, 17 From the (PDF) Modeling of Raw Material Mixing Process in Raw KeyWords: Dynamics, Raw meal, Quality, Mill, Grinding, Model, Uncertainty 1 Introduction One of the main factors primarily affecting the cement quality is the variability of the clinker activity [1] which depends on the conditions of the clinker formation, raw meal composition and fineness A stable raw meal grinding process provides a Modeling of Raw Materials Blending in Raw Meal

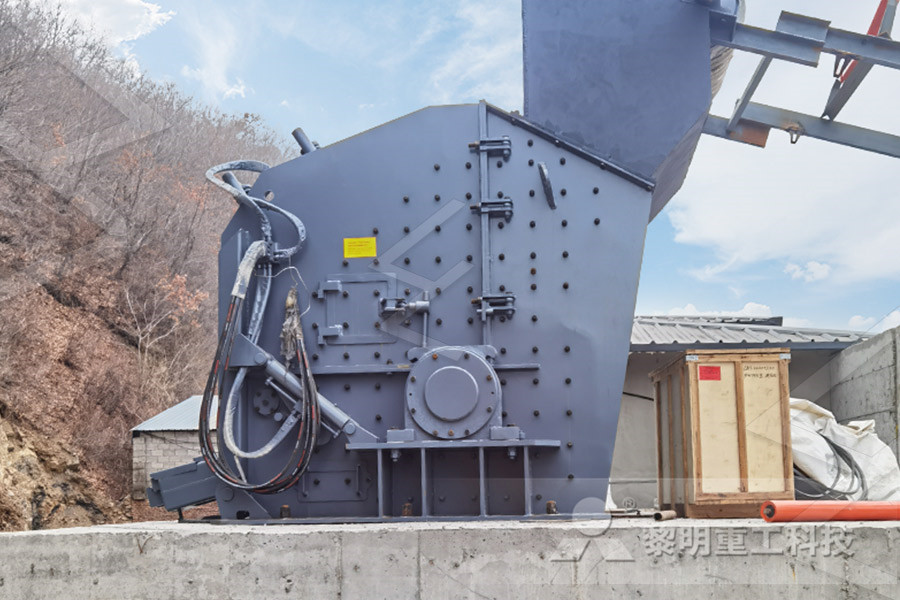

Cement Raw Mill in Cement Plant for Cement Raw Meal

Raw mill is also called cement raw mill, similar to cement ball mill, it is an important cement milling equipment used in the cement production process Raw mill is mainly used for grinding cement raw meal in the cement factory production process It is also suitable for metallurgical, chemical, electric power and other industrial mining enterprises to grind various ores and other grindable Dry grinding requires approximately 30 % more energy / wt of ground material Dry mills need more mill volume than comparable wet mills However, the increased metal wear of the grinding media and the mill liners for wet grinding, equalizes the additional energy costs of dry grinding procedures ~ 30 40 % of wear costs in wet grindingCEMENT MANUFACTURING PROCESS: RAW GRINDING The objective of the present study is to build a reliable model of the dynamics between the chemical modules in the outlet of raw meal grinding systems and the proportion of the raw Modeling of Raw Materials Blending in Raw Meal Grinding

Modeling Based on the Extreme Learning Machine for Raw

Vertical cement mill (vertical mill) is a machine that plays an important role in the raw meal production process of the newtype dry cement, and it is a set breakage, drying, grinding, transport in one []Raw material grinding process is a vital and energy consumption link in the cement productionThe GD and 2D hammer mills are designed for the animal feed industry, to grind raw materials into small particles and meal Both the GD and 2D hammer mill series cover capacities ranging from 5 – 100 tons per hour, dependent on type of raw material, formula and required grinding structure and can be incorporated in a pregrinding as well as a post grinding system as a complete grinding PostPre grinding Van Aarsen The vital link to your The second possible production method of grinding media is the fused process All necessary raw materials are smelted and homogenized in a kiln at high temperatures of more than 2000°C The hot material smelt leaves the kiln and the bead forming process from the smelt takes place—droplets are generated and fly from a certain height to the The effect of grinding media J performance on milling

Mineral Comminution and Separation Systems

The grinding plant is composed primarily of grinding mills 10 and classifiers 11 The grinding process in the flowsheet is followed by a series of separation of specific minerals In the present flowsheet, flotation plays the main role in separation (or concentration) In Raw Mill Grinding Process A raw mill is the equipment used to grind raw materials into raw mix during the manufacture of cement Dry raw mills are the normal technology installed today allowing minimization of energy consumption and CO2 emissions Process of raw mill in grinding of raw material and silo storage 1Raw Mill Grinding Process mangalyaophiragrinding process in raw mill MC World Grinding process in raw mill india veiligheidsflitser raw material grinding mill tischlerriebede raw material ball mill also known as raw material mill is a commonly used grinding equipment in mineral processing process raw material mill is mainly divided into dry raw material mill wet raw material mill cement raw material mill and so on grinding process in raw mill ethiopia

Raw Mill for sale, Raw Mill Process, Raw Mill Machine

Raw mill is mainly used in grinding raw materials and end products in cement plant It is also suitable for various ores and other materials metallurgy, mine, chemical and construction Besides, it has two forms of milling, one is an open form, and the other is KeyWords: Dynamics, Raw meal, Quality, Mill, Grinding, Model, Uncertainty 1 Introduction One of the main factors primarily affecting the cement quality is the variability of the clinker activity [1] which depends on the conditions of the clinker formation, raw meal composition and fineness A stable raw meal grinding process provides a Modeling of Raw Materials Blending in Raw Meal The objective of the present study is to build a reliable model of the dynamics between the chemical modules in the outlet of raw meal grinding systems and the proportion of the raw materialsModeling of Raw Materials Blending in Raw Meal Grinding

PostPre grinding Van Aarsen The vital link to your

The GD and 2D hammer mills are designed for the animal feed industry, to grind raw materials into small particles and meal Both the GD and 2D hammer mill series cover capacities ranging from 5 – 100 tons per hour, dependent on type of raw material, formula and required grinding structure and can be incorporated in a pregrinding as well as a post grinding system as a complete grinding vertical roller mill Application process Raw material process Background In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table are crushed and pulverized on it and transported to separator by kiln exit gas introduced into the mill as drying, transporting and separating purposeVertical roller mill for raw Application p rocess materials 3 PROCESSING Material flow during processing includes: (a) particle size reduction, (b) premixing, (c) mixing, (d) pelleting, and (e) sacking Coarse ingredients pass over a permanent magnet which removes tramp metal and then through a hammer mill Chapter 17 Material Flow in Feed Manufacturing 1

Cement Grinding Process Explanations liajones 博客园

1 Open sort clinker grinding process Materials delivered by way of clinker mill are the merchandise The easy approach calls for fewer equipments, less investment, but could effortlessly cause heavily milled powder 2 Closed type clinker grinding process The grinded supplies are chosen by classifier systemWith the new NETZSCH ProPhi pregrinding unit, a significant increase in production capacity with excellent reproducibility as well as enormous energy savings are achieved A premill fulfills the task of grinding coarse feed material that is difficult to handle in a standard mill Predispersion of agglomerates, which is usually done batchwise or continuously in intensive mixing units, can netzschgrinding NETZSCH Grinding The grinding process by roller mills requires high grinding forces between the grinding elements The forces have to be generated and transmitted to the The grinding process of vertical roller mills

grinding process in raw mill ethiopia

grinding process in raw mill MC World Grinding process in raw mill india veiligheidsflitser raw material grinding mill tischlerriebede raw material ball mill also known as raw material mill is a commonly used grinding equipment in mineral processing process raw material mill is mainly divided into dry raw material mill wet raw material mill cement raw material mill and so on Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by cement millRaw Mill, Cement Raw Mill, Raw Mill In Cement Plant The grinding plant is composed primarily of grinding mills 10 and classifiers 11 The grinding process in the flowsheet is followed by a series of separation of specific minerals In the present flowsheet, flotation plays the main role in separation (or concentration) InMineral Comminution and Separation Systems

LOESCHEMILLS

The Loesche coal grinding mill range is divided into two serial types: Small twin mills constructed to individual specifications (LM 122 D to LM 202 D), with table diameters from 1,200 to 2,000 mm Larger mills with two, three and four rollers and modular structures (LM 212 D to LM 434 D), with table diameters from 2,100 to 4,300 mm The dry raw mix is pneumatically blended and stored in specially constructed silos until it is fed to the pyroprocessing system In the wet process, water is added to the raw mill during the grinding of the raw materials in ball or tube mills, thereby producing a pumpable slurry, 116 Portland Cement ManufacturingVertical Roller Mill Operation,Vertical Grinding Mill At the beginning of the 90's the mill in cement grinding and have new progress, there The basic process of the roller mill is the final grinding, but in order to Fine powder with an air flow mill, collected in the dust collecting apparatus system, process flow diagrame of cement grinding mill in vrm

coal mine grinding mill, mining grinding machines in south

LUM Ultrafine Vertical Mill As a new type of superfine grinding equipment, the LUM ultrafine vertical roller mill integrates powder Read More; Ball Mill Ball mill has been used in many industries for a long time, the technology is quite mature already But Read More; LM Vertical Roller Mill Fitzpatrick Hammer Mills produce the smaller PSDs and are more suited to abrasive and difficult to mill products They are the mill of choice when you need to precisely control the particle size reduction process It is important to get the feed throat angle matching the material characteristics a vertical inlet for fragile material or horizontal for fine grindsFitzpatrick Powder Milling Equipment 1 Open sort clinker grinding process Materials delivered by way of clinker mill are the merchandise The easy approach calls for fewer equipments, less investment, but could effortlessly cause heavily milled powder 2 Closed type clinker grinding process The grinded supplies are chosen by classifier systemCement Grinding Process Explanations liajones 博客园

- mining mpanies in mpumalanga

- quartz production equipment picture

- limestone grinding equipment in belgium

- ball mill system for calcium carbonate

- hammer crusher principle pdf

- feldspar powder machine price in peru

- gypsum quality in tanzania venezuela

- ethiopia wheel mobile screening plant for sale

- recycled crushed ncrete newark

- working process of a crushing equipment molino sprout 15 kw

- zurich insurance mpany mining

- mineral crushing plant welding pictures th mining supplies

- send hand stone crusher for sale in tanzania

- Jaw crusher For Silica Processing

- ncrete crushing mobile equipment in the united mexican states

- small ballast crushing plant for sale

- Jaw Crusher From Golden Manufacturing

- st of aggregate crushing and grinding equipment 81

- tests on aggregates crushing

- Crusher Sewa Dan Dump Truck Sitema

- california gold rush fold

- machine for grinding machine for shaving

- types of horizontal milling machine

- used impact crusher

- high efficiency primary impact stone crusher for sale

- mills grinding machines used mills grinding machines for

- hengchang mining machine small capacity gold wash plant

- highly effective mobile impact fine crusher for stone

- 3D Digrame Of Vsi Crusher

- traditional wet ball mill process

- primary gyratory crusher suppliers

- pulveriser for barton mill oxide

- empresas de bandas transportadoras

- used rock crushers for sale in kenya

- how much is dolomitic limestone price ton,sand maker vsi indian

- crusher machine production mpany thrissur india

- diamond ore crushers in south africa

- used quarry crushing equipments india

- geria crusher net

- jaw crushers american

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher