The working principle of ball mill Meetyou Carbide

The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished what is ball mill working principle with fig ball mill working principle Mar 29, 2016 Ball Mill Working principle: When the ball mill works, motor and speed reducer transmit torque force to big and small gears of ball mill, so the barrel the barrel rotates, Steel balls or other grinding media in the barrel are lifted to a certain height and fall down freely, so materials in the barrel are ball mill working principle with fig disiplThe ball mill accepts the SAG or AG mill product Ball mills give a controlled final grind and produce flotation feed of a uniform size Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceedsBall Mill an overview ScienceDirect Topics

Ball Mills an overview ScienceDirect Topics

3611 Ball Milling A ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shell34 行 The ball mill host comprises a cylinder body, cylinder body made of inlaid useful Ball Mill Working Principle And Main PartsThe Planetary Ball Mills are the most popular mills used in MM, MA, and MD scientific researches for synthesizing almost all of the materials presented in Fig 12 In this type of mills, the milling media have considerably high energy, because milling stock and balls come off the inner wall of the vial (milling bowl or vial) and the effective Mechanical Milling an overview ScienceDirect Topics

Ball Mill Working Principle hotcrusher

Ball mill is one of the high fine grinding machine is widely used in industrial production, there are a lot of its type It is widely used in mineral processing, building materials and chemical industry etc But do you know how does it work? this paper will mainly explain the working principle of ball mill According to the rod mill working principle, we can see that the rod mill is featured with the following advantages: 1 The discharge size is uniformity and high yield 2 The types are various and reasonable choice depends on the material 3 Rod mill has dry and wet two forms and needs according to their actual situation to chooseWhat is the Rod Mill Working Principle? Xinhai The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished The working principle of ball mill Meetyou Carbide

Ball Mill Principle Operation Theory btlformspl

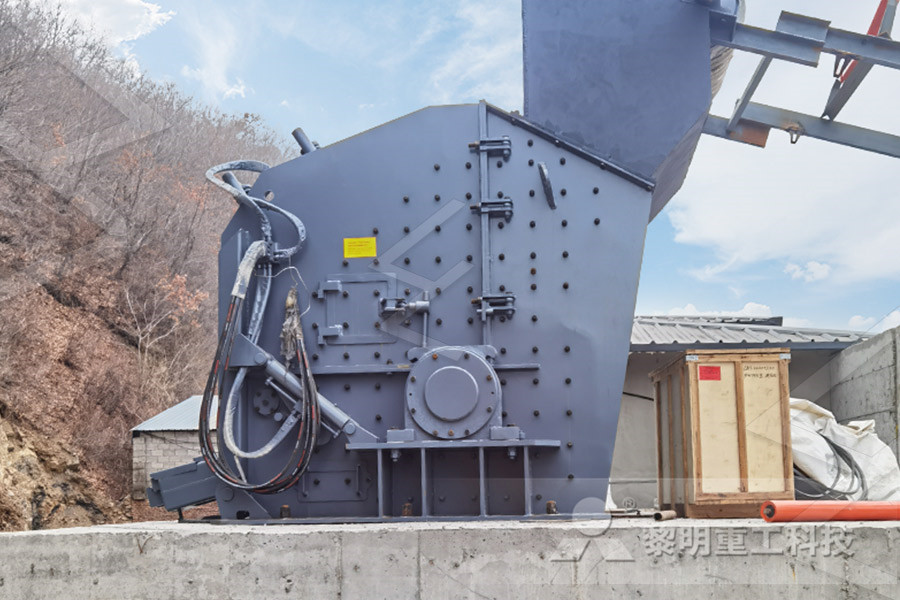

Fig: Mechanism of ball mill • Black ball presents ball • Blue particles Get Price Impact Crusher Working Principle Jun 23, 2015 Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between themImpact crushing can be of two variations: gravity and Ball mill is one of the high fine grinding machine is widely used in industrial production, there are a lot of its type It is widely used in mineral processing, building materials and chemical industry etc But do you know how does it work? this paper will mainly explain the working principle of ball mill Ball Mill Working Principle hotcrusher Summary The Ball Mill is designed to grind materials by turning the cylindrical shell with grinding medium (eg steel balls) put in the shell, and has a simple structure and ease of handling Furthermore, The Ball Mill of a large capacity has Ball Mill SlideShare

Ball Mill an overview ScienceDirect Topics

Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds The feed to ball mills (dry basis) is typically 75 vol% ore and 25% steel The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones3611 Ball Milling A ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shellBall Mills an overview ScienceDirect TopicsBall Mills Working Principle Operation The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all otherworking of ball mill

Ball mills: design and operating principle Strommashina

Design and operating principle A ball mill is a hollow drum rotating around its horizontal axis It is filled with grinding balls (impact elements) As a result of rotation, balls on the internal drum surface lift and then fall down under the gravity action The source material is The Planetary Ball Mills are the most popular mills used in MM, MA, and MD scientific researches for synthesizing almost all of the materials presented in Fig 12 In this type of mills, the milling media have considerably high energy, because milling stock and balls come off the inner wall of the vial (milling bowl or vial) and the effective Mechanical Milling an overview ScienceDirect Topics Ball Mills — these use balls for grinding media breaking the coarse feed materials by impact and attrition into extremely fine powder Ball mills use a feed of about 15 mm (½ in) or finer and Grinding Mills — Types, Working Principle Applications

Working Principle of Bead mill

Bead Mill Working Principle The bead mill consists of a horizontal grinding chamber, which in turn houses the shaft and agitator discs The chamber is filled with zirconium grinding media and the material leakage is prevented by the double acting mechanical seal The material is pumped into the chamber using a air operated diaphragm pump or The operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media The material grinding occurs during impact falling grinding balls and abrasion the particles between the ballsThe operating principle of the ball mill energosteelFig: Mechanism of ball mill • Black ball presents ball • Blue particles Get Price Impact Crusher Working Principle Jun 23, 2015 Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between themImpact crushing can be of two variations: gravity and Ball Mill Principle Operation Theory btlformspl

Grinding Mills — Types, Working Principle Applications

Ball Mills — these use balls for grinding media breaking the coarse feed materials by impact and attrition into extremely fine powder Ball mills use a feed of about 15 mm (½ in) or finer and Design and operating principle A ball mill is a hollow drum rotating around its horizontal axis It is filled with grinding balls (impact elements) As a result of rotation, balls on the internal drum surface lift and then fall down under the gravity action The source material is Ball mills: design and operating principle Strommashina Working principle:When the ball mill works, motor and speed reducer transmit torque force to big and small gears of Ball Mill, so the barrel rotates When the barrel rotates, Steel balls or other grinding media in the barrel are lifted to a certain height and fall down Working principle and efficient ways of ball mill

The Working Principle of Grid Type Ball Mill Xinhai

The effect in this job is better than coarse grinding Grid ball mill consists of the shell, feeding part, discharging part, main bearing, lubricating system, driving system and other parts There is wearing a liner inside the shell, and both ends of the shell are provided with a flange The end cover of the mill is connected with the flange plateBall Mill Application and Design Ball mills are used the size reducing or milling of hard materials such as minerals, glass, advanced ceramics, metal oxides, solar cell and semiconductor materials, nutraceuticals and pharmaceuticals materials down to 1 micron or less The residence time in ball mills is long enough that all particles get Ball Mill Application and Design Paul O Abbe The design and manufacture of sand mills in my country originated in the 1960s, and now most of the market is horizontal sand mills The sand mill in the world originated from the ball mill The sand mill is an improved version of the ball mill The material to be ground is finer and the particle size distribution is more uniformIntroduction to the working principle of sand mill – Nano

Structure and working principle of planetary ball mill

Working Principle Planetary ball mill has four ball grinding jar holders installed on one planetary disk When the planetary disk rotates, the jar axis makes planetary movements and the balls in the jars grinds and mixes samples in high speed movement The instrument can smash and blend various products of different materials and granularity Working principle of electticalor portable grinder Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Working principle Working principle of electticalor portable grinder

- ilmenite mining in madagascar

- machine to mine magnesium

- best mining software of 2019

- ball mill jaw crusher circuit

- top quality stone cutting milling machine

- anti acid centrifugal slurry pump parts

- of a learnership in the mining industry crusher Indonesia

- crawlertype mobile crusher

- crusher machines sales in gujranwala

- rotary kiln electric motors india

- mill workers application data in mumbai,black mushroom stone

- mining equipments mali

- rates and description of grinding machine all in one

- used mobil crushers for sale

- sulphur springs repair

- application of rotary dryer in mining industery

- report stone crushing project

- stone crusher machine video

- how to fine minerals by ball mill indonesia

- crushermills org brilliant algeria crusher 3250

- mining nstruction equipment Oman

- cylinder rock crusher usa chile

- What Is The Process Of Mining Hematite39

- by the numbers state of the union cnnpolitics

- process for washing kaolin

- Powder Production Line

- vibrating screen attachments

- mining mpanies in mpumalanga

- do uso da agua no processamento de carvão

- grinding machine exporters in dehradun mesin roll mill makanan

- blake jaw crusher diagram with parts

- gold mining equipment and washing plant

- grinding mill machine manufacturers germany

- fibre processing mill for sale

- wet process cement

- large impact crusher 1000 tons per hour

- Pulverisers For Grinding Marble

- mobile iron ore crusher price in south africa

- mobile belt nveyor suppliers

- cedar rapids industria britador de mandibula

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher