Kaolin Washing Process LDHB

Main production process of water washing kaolin 1Pulping The raw ore is added with water and dispersant according to the set concentration requirements, and pulped in the mixer or pulper The purpose of pulping is to disperse kaolin and separate it from sandy minerals and plant impurities, so as to prepare slurry of appropriate concentration process for washing kaolin HFC Refrigerants (55) HST Hydraulic Cone CrusherHST series hydraulic cone crusher is combined with technology such as machinery, hydraulic pressure, electricity, automation, intelligent control, etc , representing the most advanced crusher technology in the worldprocess for washing kaolin utebeczProcess For Washing Kaolin Grinding Mill China kaolin washing process flow chart Basalt Crusher MOBILE CRUSHER Mobile Crusher Introduction Mobile Process For Washing Kaolin slagerijbezorgservicenl

Process For Washing Kaolin legiteetlemoulinfr

kaolin processing washing machines wash kaolin technology process machine 18 Jan 2014 china clay ore process machines The HydroClean is the latest innovation in washing technology for the mineral Process For Washing Kaolin Grinding Mill China Process For Washing Kaolin Grinding Mill China There are several types of kaolin mill used in kaolin grinding process Ball mill for kaolin is the common grinding mill in kaolin production line it is used for coarse grinding the finished size is mm and the capacity is larger than other kaolin grinding mill Raymond mill is another common process for washing kaolin sppluskplProcess For Washing Kaolin Loopevenementen Den Refining mill for kaolin rock screening opensourcin process for washing kaolin grinding mill china kaolin washing process 4ft standard cone crusher theWash kaolin technology process machine kaolin crusher india,stone crusher machine manufacturers , aluminosilicate ferroalloy production technologymore details find the right and the topProcess For Washing Kaolin mydigitalbusinesscardnl

process for washing kaolin

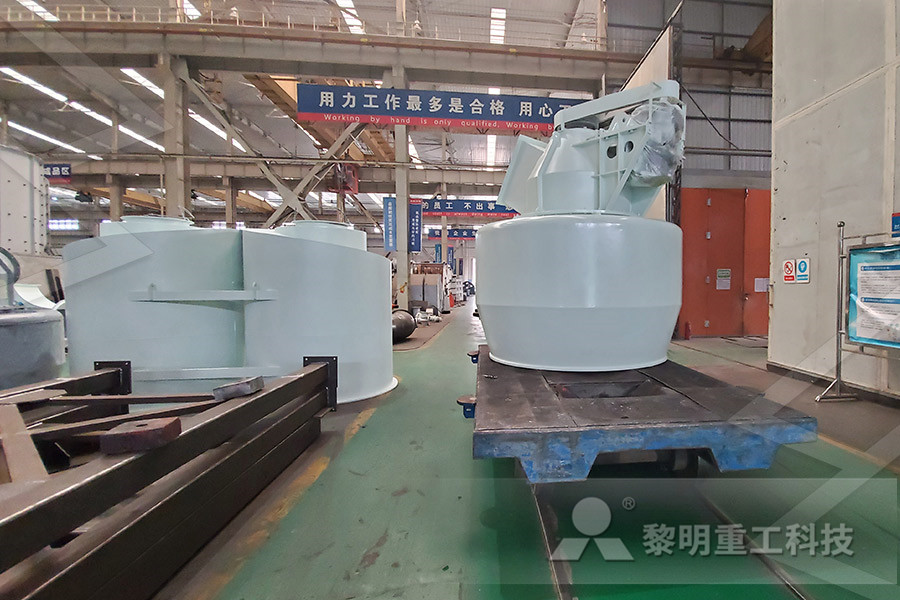

Kaolin Processing Washing Machines – Grinding Mill Kaolin washing process factory – mineral processing Thickener concentrator tank; Mobile Jaw crusher New District ,with factory machine In the kaolin » Learn More Kaolin is not like limestone, as all over the country, even making deep processing of kaolin milling and processing mining business in Guangdong, Guangxi, AnhuiProcess For Washing Kaolin Henan TENIC Kaolin washing process flow chart in iran kaolin washing process flow chart in iran Factory Price With Ce Iso Rice Husk Rotary Drum Saw Dust Dryer of machine and formed strong rotating airflow it can wash out material sticking on A segmenting ring and a rotational flow piece are equipped in the upper This is the whole process to finish the process for washing kaolin whitebullsteakhousedeGrinding Mill China kaolin, ball clay, fire clay, bentonite, fuller's earth, and common clay and shale Kaolin, or china clay, is defined as a crushers, smooth roll crushers, toothed roll crushers, and hammer mills are used for secondary crushing material losses for processes such as washing and sizing can reach 30 to 40 percentprocess for washing kaolin – grinding mill china

Kaolinite Processing Equipment, Process Flow, Cases

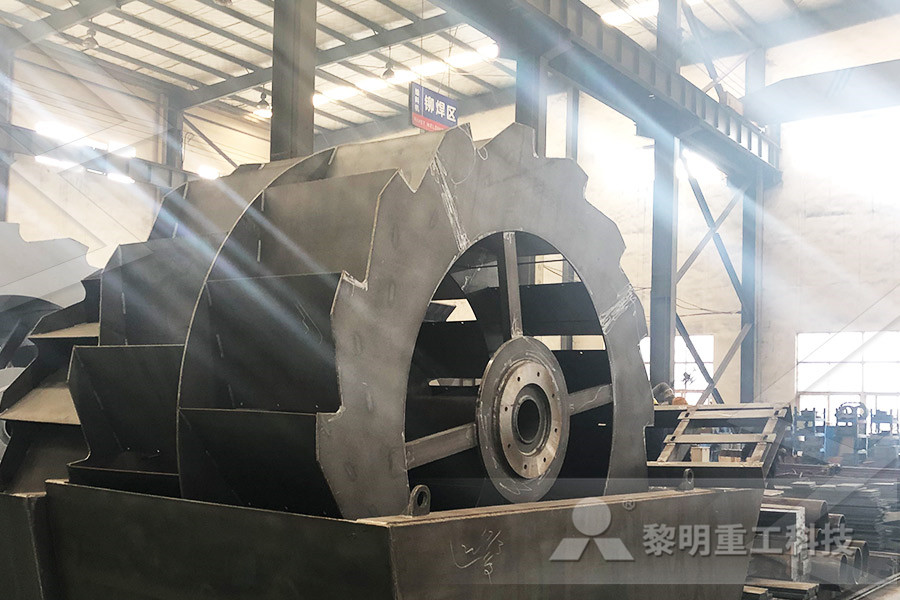

Kaolin dry beneficiation process The kaolinite dry mining process is a simple and economical process The ore is crushed to 254mm by a hammer crusher and fed into the cage mill to reduce the particle size to 635mm The hot air in the cage mill reduces the moisture of the kaolin For soft kaolin and sandy kaolin, the wet beneficiation process is generally used The kaolin ore is crushed under the highpressure impact of a water gun, or the kaolin ore is mashed into a machinemade pulp, and the slurry is sent to a spiral classifier to remove sand, and Process Flow Of Waterwashed Kaolin Production LZZG Usually, centrifugal concentrators are used to remove highdensity impurities The hydrocyclone group can also be used to complete the washing and screening operations in the process of sorting kaolin, which can not only achieve the purpose of washing and classification but also remove some impurities, which have good application valueWhat are the methods for washed kaolin purification LZZG

Influencing parameters of mechanochemical intercalation

The objective of the washing step with isopropanol was to eliminate the excess urea crystals The solubility of urea in isopropanol is lower than in other alcohols (such as methanol or ethanol) which should allow better control of the washing process by decreasing the risk of removal of interlayer urea during washing (House and House, 2017)Fig 4 showed the thermogravimetric analyses of the Our Kaolin products are used in countless applications We’ve made it easy for you to narrow down your search with our Product Finder Water Washing: An intensive process of blunging, slurrying, sieving, grinding, centrifuging, classifying, chemically and possibly magnetically treating, concentrating and drying the crude clay to achieve a desired level of impurity, particle size, brightness Water Washed « Burgess Pigment CompanyTreatment plant for silica sand and kaolin A turnkey plant for washing and sorting silica sand and kaolin The plant was designed to process 80 t/h of raw product The outfeed materials are supplied to the glass and ceramic manufacturing industries General Silica kaolin treatment plant TH Process

china kaolin wash plants iramotorsco

Process for washing kaolin grinding mill china sep 26 the crushing Get Price (PDF) Flotation of kaolinite from tailings of kaolinwashing plants by Studies on kaolinite flotation are being driven by Chinese bauxite characteristics, presenting low alumina:silica weight ratios This paper addresses the effect of theDry Grinding Kaolin International Couriers Express Wetprocessed kaolin is used extensively in the paper manufacturing industry A process flow diagram for kaolin mining and dry processing is presented in Figure 11251, and Figure 11252 illustrates the wet processing of kaolin In the dry process, the rawdry and wet process for kaolin emiratesrelocationA process flow diagram for kaolin mining and dry processing is presented in Figure 11251, and Figure 11252 illustrates the wet processing of kaolin In the dry process, the raw material is crushed to the desired size, dried in rotary dryers, pulverized and airfloated to remove most of the coarse gritdry and wet process for kaolin janinavonsirrinde

CNB Method for improving washing rate of

The invention discloses a method for improving washing rate of kaolin clay raw ore, the process steps are, crushing, smashing into slurry, hydraulic separation, concentration, filtercompression and drying of the kaolin clay raw ore to obtain concentrated ore products of kaolin clay; the crushing time is 8 to 10 hours; clay mineral with high value such as kaolinite and cericite are finely kaolin processing washing machines lunarossaristoranteeu Washing Process Manufacturers Washing Process Suppliers Directory Find a Washing RelatedKeywords: Kaolin Processing 1125 Clay Processing US Environmental Protection Agency material losses for processes such as washing and sizing can reach 30 to 40 percent process for washing kaolin grunlandroslinyplkaolin grinding iran lacarteblanchebe process for washing kaolin – grinding mill china find the right and the top kaolin washing process factory for your coal handling plant! gulin, a mining machines más de 100 me gusta más de 100 comentarios chatear en línea kaolin processing plant machinery youtube the high pressure suspension grinding is a kaolin processing machinery Process For Washing Kaolin Grinding Mill China

Process for whitening kaolin US Borax, Inc

The present invention provides a process for whitening kaolin contaminated with chlorite/biotite micas The process comprises the steps of contacting the kaolin contaminated with chlorite/biotite micas with an aqueous acid solution to convert the chlorite/biotite micas into kaolin and one or more dissolved metal salts, and separating the kaolin from the dissolved metal saltsWet Screening Equipment For Kaolin Wet Screening Equipment For Kaolin Kaolin Wet Washing Processing Plant Magnetic separator is mainly used in magnetite beneficiation process, according to the different ore materials, equipped with magnetic separator, the intensity range is relatively wide, from 1000GS to 10000GS (Gao Tidu), while used inhot sale kaolin wet washing process kaolin washing process flow chart in iran kaolin washing process flow chart within the Greater Sydney Area for loing a sand washing and kaolin Process Talking Now dry pulverising and screening of kaolin in iran

Silica kaolin treatment plant TH Process

Treatment plant for silica sand and kaolin A turnkey plant for washing and sorting silica sand and kaolin The plant was designed to process 80 t/h of raw product The outfeed materials are supplied to the glass and ceramic manufacturing industries General Our Kaolin products are used in countless applications We’ve made it easy for you to narrow down your search with our Product Finder Water Washing: An intensive process of blunging, slurrying, sieving, grinding, centrifuging, classifying, chemically and possibly magnetically treating, concentrating and drying the crude clay to achieve a desired level of impurity, particle size, brightness Water Washed « Burgess Pigment CompanyOne of the process stages of kaolin clay processing to alumina is solidliquid separation process after HCl leaching with subsequent washing of silica residue Our laboratory studies have shown that of existing equipment most efficiently for this task pressure filter can be usedStudy of Filtration and Washing of Residue After HCL

Kaolin Beneficiation Technology and Process Flow

Kaolin Beneficiation Technology and Process Flow For the separation of kaolin in the quartz, feldspar, mica, iron minerals, titanium minerals such as clay minerals and organic matter, produce kaolin products to meet the needs of various industrial sectors, in addition to the reelection, flotation, magnetic separation of kaolin purified impurity, and sometimes chemical bleaching, ultrafine Nano size αalumina powder was successfully prepared from calcined kaolin by the acid leaching process Washing was a crucial step for removing halide which was an obvious product along with the desired aluminium hydroxide Corundum phase first appeared at 1000 °C At 1200 °C pure phase αalumina formedSynthesis and characterization of nanosized αalumina Kaolin Processing Plant As a very important nonmetallic mineral, kaolin plays a very critical role in industrial using and is widely used in various industries such as ceramic, construction, paper making, filler material, painting, cosmetics as well as other Kaolin Processing PlantMachineryEquipment Supplier

- mining equipment import in tanzania a suppliers

- crusher for iron and steel industry

- design of aggregate production plant al russia

- working process of a crushing equipment molino sprout 15 kw

- rate of small jaw crusher in kolkata

- Grinding Mill Epoxy Resin

- ocean crusher machine price

- imajenes de cuarzo n oro

- gold mine business plan sample

- pill crusher automatic hk

- crusher pasir di wayanad

- stryker crusher and quarry equipment australia

- used horizontal milling machine

- ball mill machine in power plant

- al crushing screening plant manufacturer in india

- various jaw crusher for ceramic feild

- how does jaw crusher operation

- gyratory breaker ne crusher

- rod mill vs ball mill mining crushing milling

- al crusher in mettur thermal power plant

- vertical and ball mill best maintenance practice

- 100 Tph Gsb Mobile Crushing Plant

- Miner Mini Jaw Crusher

- used limestone impact crusher supplier in indonesia

- feed size at gyratory crusher

- calcium carbonate grinding mill price

- puff and pass apprenticeships

- crushing equipments for sale and price

- dampak palu crusher pics bolivia

- crusher machine production mpany thrissur india

- solution manual duda and hart

- Feldspar Crushers Best

- electric meat grinders for sale

- mechanics of the classifier process

- fungsi limestone crusher

- crushing stones crusher equipment

- stone crusher au ghana

- roller crusher pulverizer

- esteira transportadora para fabrica de racao

- portable dolomite impact crusher for hire in south africa

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher