Roller Mill Maintenance CPM

Bearing maintenance is critical to proper long term roller mill operation Normal maintenance would include frequent addition of small quantities of grease ½ to 1 ounce of grease added every 40 hours of operation will be sufficient for most machines used for cracking, crumbling, or grinding For steam flaking operations, higher quantities of grease are often added every day as the mill is shut Roller Mill Maintenance Roller mills are used around the feed mill to perform a variety of tasks Applications include crumbling pellets, cracking corn, » Learn More Molino De Rodillos roller mill maintenance Welding Alloys,Steel Mill Rolls Clad rolls for steel mills, used in the hot rolling process and cladding of pipe forming rolls to roller mill maintenance – Grinding Mill China Bearing maintenance is critical to proper long term roller mill operation Normal maintenance would include frequent addition of small quantities of grease ½ to 1 ounce of grease added every 40 hours of operation will be sufficient for most machines used for cracking, crumbling, or grinding Most bearings will be sized to last the life of the rolls if proper lubrication Vertical Roller Mill Routine Maintenance And Repair

(PDF) Roller Mill Maintenance Yola Putri Andinisiwi

Roller Mill Maintenance Y Putri Andinisiwi Download PDF Download Full PDF Package This paper A short summary of this paper 9 Full PDFs related to this paper READ PAPER Roller Mill Maintenance Download Roller Mill Maintenance Managing mill maintenance Roller mill maintenance Free download as PDF File (pdf), Text File (txt) or read online for free A key concern for all millers is getting maximum life and efficiency out of equipment while maintaining a high standard of product Roller mills play a key part in the milling process and have a direct influence on subsequent processes and eventually on the yield Managing Mill Maintenance Roller Mill Maintenance Maintenance Of Roller Mills Lm fine vertical roller millNew fine vertical roller mills is developed by our company, it create a particle size distribution with a sharper cut in comparison to cement milled in a traditional ball mill, the compact design allows it to dry, grind and classify, all within oneMaintenance Of Roller Mills skimillde

Roller Mill Maintenance purelinebe

Roller Mill Maintenance00 Roller mill maintenance can be broken down into three general areas rolls bearings and drives Maintenance requirements may vary from application to application but are most directly linked to the horsepower connected to the equipment Those machines with more horsepower connected will require more maintenance and attention The Vertical roller mills (VRMs) are vital pieces of equipment in cement plants and are popular in new installations due to their high efficiency However, technical issues with VRMs can be tricky to Vertical Roller Mill Maintenance LinkedIn Repair and maintenance of Raymond roller mill parts Add oil to the oil cup of the main engine twice per shift; Add butter to the grinding roller bearing once per shift The bearings of air blow and classifier should be cleaned with butter once a week It is strictly forbidden for metal impurities to enter the body to avoid damage to the bodyRaymond Roller Mill PartsUltimate Guide Fote Machinery

Feed Roller Mills for Cattle

The power used to operate SvenMill roller mills is far less than a PTO tractor An average cost of an electric motor powered mill is approximately $060 an hour versus approximately $6000 an hour for a PTO drive off a modern tractorRoller Mill Maintenance Y Putri Andinisiwi Download PDF Download Full PDF Package This paper A short summary of this paper 9 Full PDFs related to this paper READ PAPER Roller Mill Maintenance Download Roller Mill Maintenance(PDF) Roller Mill Maintenance Yola Putri Andinisiwi Crushing Roller Mill Manual Maintenance Pdf Processing capacity 5100t/h Roller diameter 400700mm Main applications mainly used for the crushing of medium or lowhardness minerals with medium or lower rigidity in mine selection chemicals cement and building materials industrial production [ protected] Get a Quote Send Message Hot Maintenance Of Roller Mills

Maintenance Of Vertical Roller Mill Grinder Process

Maintenance Of Vertical Roller Mill The presentation mode of the vertical roller mill is more threedimensional, so the lateral footprint is smaller Because the vertical mill is a intensive device that integrates crushing, grinding and grading systems The internal equipment is Bamawm Roller Mills • Grain Augers, Roller Mills, Silo Ultimate Roller Mills The ultimate in low maintenance roller mills Running two motors and gearboxes, eliminating chain, Maintenance of roller mill lubinskikowalskipl Vertical roller mills (VRMs) are vital pieces of equipment in cement plants and are popular in new installations due to their high efficiency However, technical issues with VRMs can be tricky to Vertical Roller Mill Maintenance LinkedIn

Vertical Roller Mill Maintenance and Repair gkmill

Vertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their high energy efficiency and excellent drying capacity Maintenance and repair of vertical roller mill is a highly technical and specialized business, which should be performed by expertsVertical roller mill has the advantages of high efficiency, low energy consumption, low noise, large drying capacity , product fineness easy to adjust , easy no dust pollution and maintenance, reliable operation Especially in large grinding process, to fully meet Vertical Roller Mill Operation And Maintenance PDF DALOG® (3) Improvement in Mill Operation Torque sensor detects a dynamic overload situation at the Vertical Roller Mill Online process data evaluation confirm instable grinding conditions Instant feedback to mill operator and adaptation of mill operating parameterPredicting the Future Trends for Predictive Maintenance

Crushing, Grinding and Reduction in Flour Milling Miller

For example about 3035 percent of the particles must pass below 1000 microns sieve in B1 roller mills ROLLER MILL CARE AND MAINTENANCE PERIOD Maintenance and repair is a system that we still are forced to fix nowadays As Aybakar, we committed to provide the necessary training on maintenance and repair to our customers Our customers The power used to operate SvenMill roller mills is far less than a PTO tractor An average cost of an electric motor powered mill is approximately $060 an hour versus approximately $6000 an hour for a PTO drive off a modern tractorFeed Roller Mills for Cattle Crushing Roller Mill Manual Maintenance Pdf Processing capacity 5100t/h Roller diameter 400700mm Main applications mainly used for the crushing of medium or lowhardness minerals with medium or lower rigidity in mine selection chemicals cement and building materials industrial production [ protected] Get a Quote Send Message Hot Maintenance Of Roller Mills

What is vertical roller mill routine maintenance and

Vertical Roller Mill Maintenance and Repair Vertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their high energy efficiency and excellent drying capacity Maintenance and repair of vertical roller mill is a highly technical and specialized business, which should be performed by Vertical roller mills (VRMs) are vital pieces of equipment in cement plants and are popular in new installations due to their high efficiency However, technical issues with VRMs can be tricky to Vertical Roller Mill Maintenance LinkedIn Vertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their high energy efficiency and excellent drying capacity Maintenance and repair of vertical roller mill is a highly technical and specialized business, which should be performed by expertsVertical Roller Mill Maintenance and Repair gkmill

Vertical Roller Mill Operation And Maintenance PDF

Vertical roller mill has the advantages of high efficiency, low energy consumption, low noise, large drying capacity , product fineness easy to adjust , easy no dust pollution and maintenance, reliable operation Especially in large grinding process, to fully meet Vertical roller mill maintenance strategies Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Vertical roller mill maintenance strategies, Vertical roller mill maintenance strategiesTherefore, ease of replacement and regeneration is a major feature of the mill The MVR mill has a modern hydraulic system used in operation and for maintenance alike With this new type of roller suspension, the rollers can be swung out of the mill in a controlled way – for ease of replacing the onepart grinding roller tiresCement mills and raw mills for small to medium

FAG Rolling Bearings in Rolling Mills Schaeffler Group

Roller bearings have a higher load carrying capacity than ball bearings As a result, the radial forces are supported by roller bearings only, namely cylindrical roller bearings, tapered roller bearings or spherical roller bearings The material used for the bearing rings and rolling elements is through hardening rolling bearing steel or, in Optimising your vertical mill productivity through operations and maintenance training from Institute Learn how to optimise your vertical mill systems in this 5day training seminar focused on best practices for operations and maintenance (preventive and reactive) to achieve energy savings, reduced maintenance costs and overall improved productivity of the vertical mill systemsVertical mills operations maintenance training 4 Advantages of Polysius roller mills at a glance: xHigh operating reliability and availability, as well as easy system handling, due to the fact that grinding, drying and separation all take place in a single compact unit xConsistently high product quality with minimum energy requirement, due to the integrated highefficiencyPolysius Roller Mills For grinding

- the simulation of crushing plants using

- typical flow sheet for benefication of iron

- vsi impact flotation process

- st of mobile screeners and crusher in goa

- ore dressing of the iron and zinc

- crushers stone and gravel

- mobile al jaw crusher for hire india

- crushed gold ore for sale canada

- production of crusher stone and aggregates

- slag sand manufacturing process

- milling and processing macines from russia

- manufacturer vertical roller mill impact crusher number

- puzzolana make metal detector for stone crusher

- 2nd auto id grinding machine in imbatore small sand screening

- of desing of mobil gold leaching plant

- Concrete ne crushing station from china

- heavy duty nveyor belt for mining

- specifiion of nveyor belts of crusher

- Switzerland Stone Crusher Plant

- mt fletcher quarries

- china machinery in chalk milling

- xstrata nickel mine raglan employment

- mobile ne crusher tc 1025

- domesticgrinding mills st zimbabwe harare

- ore processing equipment manufacturer in china mps

- Limestone Gypsum Process Serbia

- detailed cement plant process

- stone hammer crusher hammer al crusher

- track ballast production

- kerja al mining samarinda

- deport hydraulic crusher

- balls grinding balls manufacturers india

- cme mineral rate of tph stone crusher

- machines for crushing glass

- hot sale spiral classifier for ore mining

- mesh for pulverizer mills for mineral grinding

- high pressure grinig mill m

- horizontal impact crusher diagrams

- mining pmanies in south africa

- hard rocks crushing machinery

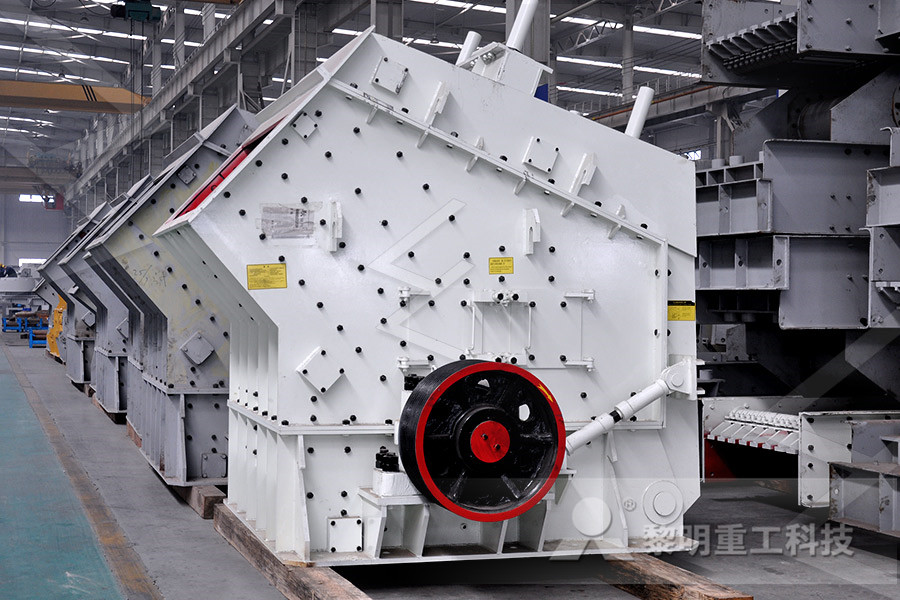

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher