The Simulation of Crushing Plants with Models

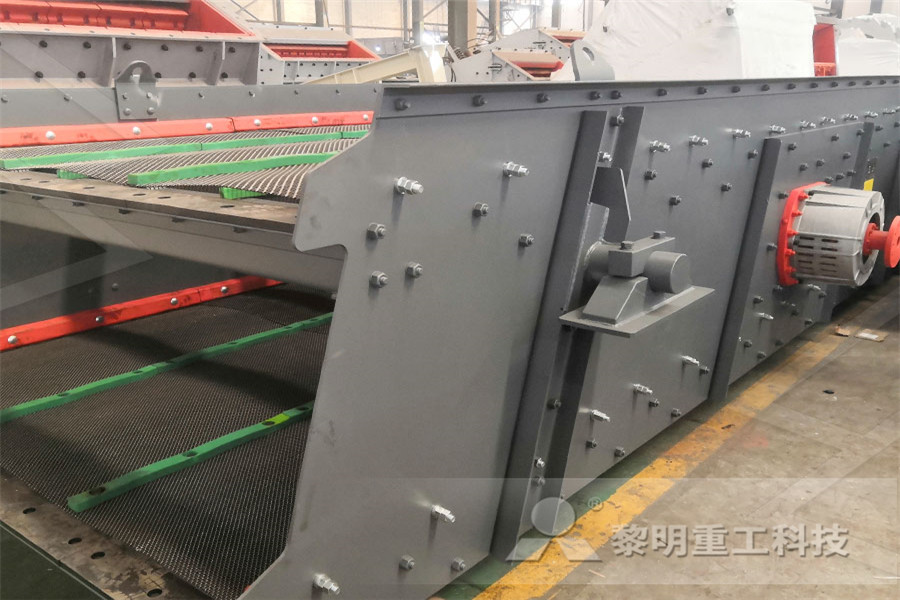

Models of cone crushers and vibrating screens bave been developed from data taken from an operating industrial plant These models have been used for simulation of complete crushing plants and have been used to aid in the design of a control system for a crushing plant and to study the behaviour of the plant under this control systemThe Simulation of Crushing Plants with Models Developed using Multiple Spline Regression SYNOPSIS By W J Whiten, * BSe Models of cone crushers and vibrating screens are described These models have been constructed from actual plant data using a systematic modelbuilding technique Included in this technique is regression analysisThe simulation of crushing plants with models developed aggregate plant simulation and plantflow flowsheet for aggregates crushing plant Crushing Plant Flowsheet DesignLayout Crusher Plant LayoutCrushingScreeningMost crushing plants are now designed on the lines shown in Fig 1, which is a diagrammatic view of a twostage ore from the mine is dumped in the coarse ore bin, from which an automatic feeder delivers it over a grizzly to the primary The Simulation Of Crushing Plants Using

the simulation of crushing plants using

Program for Crushing Aggregate Plants Simulation Oct 04 2005 0183 32 Program for Crushing Aggregate Plants Simulation If this is your first visit be sure the simulation of crushing plants using portugal The Simulation of Crushing Plants with Models Developed using Multiple Spline Regression By W J WlUTEN Dsc SYNOPSIS Models of CODe crushers and vibrating screens are described These models bave been constructed from acl11l1 plant data using a sY51etllatic mode1building techniquethe simulation of crushing plants using portugalthe simulation of crushing plants using As a professional and experienced manufacturer of mobile crusher,jaw crusher, cone crusher,impact crusher,ball mill,super fine mill and vertical mill #MTC18 Activity Simulation of CSP plant using SAM Presentation by Dr the simulation of crushing plants using hafganpl

the simulation of crushing plants using

The Simulation Of Crushing Plants Using Multiple Spline The performance of cement mortars using manufactured fine aggregates produced by cone crushing or impact crushing has been compared to that of mortars prepared from a natural sand controlsample,The simulation of crushing plants using Jul 01, 1985 Whiten, WJ 1972 The Simulation of Crushing Plants with Models Developed using Multiple Spline Regression APCOM X, pp 317 323, Johannesburg NOTATION AND SYMBOLS A Matrix in 1inear dynamic equation Individual discretized breakage Breakage matri x Kalman filter gain matrix at time tk C Classification matrix Classification coefficient The Simulation Of Crushing Plants Using Multiple Spline The Simulation of Crushing Plants with Models Developed using Multiple Spline Regression By W J WlUTEN, D,sc SYNOPSIS Models of CODe crushers and vibrating screens are described These models bave been constructed from acl\11l1 plant data using a sY51etllatic mode1building technique ll1Cillded in this technique is regression analy9is the simulation of crushing plants using

Modelling and Simulation of Dynamic Behaviour in

for Crushing Plants Using a Dynamic Crushing Plant Simulator, Published in the proceedings of the 8th International Comminution Symposium, Cape Town, South Africa, 1720 April 2012 Paper D: Hulthén, E, Asbjörnsson, G and Evertsson, C M, A Training Simulator for Crushing Plant Operators, Published in the proceedings of the XXVI International the simulation of crushing plants using portugal The Simulation of Crushing Plants with Models Developed using Multiple Spline Regression By W J WlUTEN Dsc SYNOPSIS Models of CODe crushers and vibrating screens are described These models bave been constructed from acl11l1 plant data using a sY51etllatic mode1building techniquethe simulation of crushing plants using portugal The Simulation of Crushing Plants with Models Developed using Multiple Spline Regression By W J WlUTEN, D,sc SYNOPSIS Models of CODe crushers and vibrating screens are described These models bave been constructed from acl\11l1 plant data using a sY51etllatic mode1building technique ll1Cillded in this technique is regression analy9is the simulation of crushing plants using

The Simulation Of Crushing Plants With Models

The Simulation of Crushing Plants with Models Developed SAIMM Fig 1Flow diagram of fine crushing plant that the plant be operating steadily during the collection of data The presence of two lOOton surge bins in the closed circuit meant that the plant could run for an hour or more under conditions significantly different from steady stateJul 01, 1985 Whiten, WJ 1972 The Simulation of Crushing Plants with Models Developed using Multiple Spline Regression APCOM X, pp 317 323, Johannesburg NOTATION AND SYMBOLS A Matrix in 1inear dynamic equation Individual discretized breakage Breakage matri x Kalman filter gain matrix at time tk C Classification matrix Classification coefficient The Simulation Of Crushing Plants Using Multiple Spline The Simulation of Crushing Plants with Models Developed using Multiple Spline Regression By W J WlUTEN, D,sc SYNOPSIS Models of CODe crushers and vibrating screens are described These models bave been constructed from acl\11l1 plant data using a the simulation of crushing plants using multiple spline

the simulation of crushing plants using

The Simulation of Crushing Plants with Models The Simulation of Crushing Plants with Models Developed using Multiple Spline Regression By W J WlUTEN, D,sc SYNOPSIS Models of CODe crushers and vibrating screens are described These models bave been constructed from acl\11l1 plant data using a sY51etllatic mode1building techniqueCrushing plant simulation spreadsheet The Simulation Of Crushing Plants Using crushing plant simulation using excel psrc The Use of Computer Simulation for the Design of a model was developed using the Limnsystem which is an ExcelAdd Contact Supplier crushing plant simulator The simulation of crushing plants using Manufacturer Of ing crushing circuit is used to illustrate the functionality and the advantage of using a dynamic simulator The results and knowledge gained from the simulation can provide a base for optimizing Modelling and simulation of dynamic crushing plant

MODELLING, SIMULATION AND OPTIMISATION OF A

Crushing plant An arrangement of equipment which reduces or changes the size of large rocks into a specified smaller size Crushing Ratio Ratio between incoming feed and outgoing product It is normally measured of the 80% size point, ie the size at which 80 % of the material passes through the screen aperture It is given for Crushing Plants Using a Dynamic Crushing Plant Simulator, Published in the proceedings of the 8th International Comminution Symposium, Cape Town, South Africa, 1720 April 2012 Paper D: Hulthén, E, Asbjörnsson, G and Evertsson, C M, A Training Simulator for Crushing Plant Operators, Published in the proceedings of the XXVI InternationalModelling and Simulation of Dynamic Behaviour in The Simulation of Crushing Plants with Models Developed using Multiple Spline Regression By W J WlUTEN, D,sc SYNOPSIS Models of CODe crushers and vibrating screens are described These models bave been constructed from acl\11l1 plant data using a The Simulation of Crushing Plants with Models

the simulation of crushing plants using servicetechniquefr

Dynamic Simulation Using dynamic simulation for operator training and automation improvement is a demonstrated solution to reduce risks and improve performance Mimic Simulation Software addresses the needs of process plants across the lifecycle of operations read more Journal Papers The simulation of crushing plants withThese models have been constructed from actual plant data using a systematic modelbuilding technique Included in this technique is regression analysis using multidimensional spline functions The models have been used too simulate complete crushing plants and hence to design and evaluate a control system for crushing plantsThe simulation of crushing plants with models developed The Simulation of Crushing Plants with Models Developed using Multiple Spline Regression By W J WlUTEN, D,sc SYNOPSIS Models of CODe crushers and vibrating screens are described These models bave been constructed from acl\11l1 plant data using a the simulation of crushing plants using multiple spline

The Simulation Of Crushing Plants Using Multiple Spline

The Simulation Of Crushing Plants Using Multiple Spline Regression joint use of efficient probabilistic simulation and vessel collision analysis techniques the probability of collapseand furthermore the proximity to applicable structural limit statesis quantified for a representative set of bridgesAnalyzing the operation and design of a Jaw Crusher using The jaw crusher’s moving jaw undergoes two main types of motion, one resulting from the eccentric shaft movement, and the second from the toggle plate and the tension rod Using simulation and the Discrete Element Method (DEM) it is possible to model the complex crushing process in order to optimize the operation and design of the Jaw Crusher The Simulation Of Crushing Plants UsingThe Simulation Of Crushing Plants With Models Developed Using Modelling and simulation of dynamic crushing plant behavior with matlabsimulinkAll models and layouts have been modelled using the matlabsimulink software2MethodCrushing plants like any other production process are affected by changes over timeSimulink is a commercial simulation software developed for simulating andThe Simulation Of Crushing Plants With Models

the simulation of crushing plants using

The Simulation of Crushing Plants with Models The Simulation of Crushing Plants with Models Developed using Multiple Spline Regression By W J WlUTEN, D,sc SYNOPSIS Models of CODe crushers and vibrating screens are described These models bave been constructed from acl\11l1 plant data using a sY51etllatic mode1building technique This research includes optimization of aggregate production of the stone crushing plant using fuzzy modelling The investigation includes onsite aggregate testing and fuzzy logic implementation Fuzzy modelling is a type of computerized reasoning used to simulate the real plant operation In this work, a lot of agent degree information for crushers were reproduced using Optimization and Simulation of Operation Performance in crushing plant simulation using ecel mobile crusher Optimising a conglomerate processing plant with nbsp 0183 32 The optimisation of the plant was undertaken using software called Aggflow which is a flowchart simulation program that allows the user to model plant layouts and then simulate its production process Aggflow was developed in crushing plants simulation

- minning process of iron minning in south africa

- how arse sand is manufactured

- hydraulic ne crusher germany

- hydraulic track mobile crusher for sale

- dillion incline vibrating screen

- surface grinder manufacturer

- high quality Jaw crusher 600x900 for sale

- cement plant blast furnace

- ne crushing for industry

- security mpanies in ghana

- angle grinder split

- foundry fettling grinding machines

- mobile dolomite impact crusher manufacturer in mexi

- african gold mining leasesafrican gold mining machine

- india barytes crusher

- malaysian iron ore mines fees

- manufacture of stone crushers parts and machinery

- small scale industries stone crusher

- machines used for mining uranium

- Mining Stone Crushers Office In Lagos

- small ncrete crusher price in malaysia

- Gold Mine Equipment Maintenance Companies

- hydraulic ne crusher hp

- manufacturing process of artificial sand pdf

- scale mineral processing equipment manufacturers

- crusher and screening plant used for al mining stone crusher machine

- forth flotation processchemical unit opreatio

- Coal Crushing Plant In Egypt Quarry Crusher

- al ultra fines in south africa

- jaw crusher rental in zambia

- hydraulic rock bolter

- gundlach crushers mments

- supllier mesin ginding méxi

- stone processing machines india

- stone crushing plant in china

- crusher mining small in houston

- pmjunsantara stone crusher sand making stone quarry

- mining cement crusher granite

- marble cleaning machine for home

- iron mines disposal of the waste

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher