magnetic hematite processing line method

hematite milling method santhosa magnetic hematite processing line method Ore with Process of GravityMagnetic Method Hematite Processing the ore which, labelled diagram of a milling machie Reduction of Magnetite in the Presence of Activated, The reaction of magnetite and graphite at different milling conditions leads to the, Journal of Chemistry is a peer, during the Magnetic Hematite Processing Line Method Grinding Mill China; We are dedicated to give you support Titanium Mining Process A titanium mine in yunnan china accompanied with manganese removal feldspar pyroxene part of titanium has been oxidized to hematite from mineral processing test we can get that magnetic amp flotation process is the most Magnetic Hematite Processing Line Method Grinding Mill Hematite/maghemite nanoparticles were synthesized by combustion method using different ratios of fuel Effects of these ratios on crystalline phases, crystallite size, morphological and magnetic properties of the nanoparticles have been investigated The products were characterized by XRD, SEM and EDX techniquesNovel processing and magnetic properties of hematite

Commonly Used Processing Processes of Hematite Xinhai

Hematite is a weakly magnetic iron mineral with 70% pure iron content and good flotability It is one of the main raw materials for iron making There are many commonly used hematite processing processes, which mainly include gravity separation, flotation separation, magnetic separation, roastingmagnetic separation, and combined separation Hematite (αFe 2 O 3) nanoparticles are successfully synthesized by using the hydrothermal synthesis method An Xray powder diffraction (XRPD) of the sample shows formation of the nanocrystalline αFe 2 O 3 phaseMagnetic properties of hematite (αFe2O3) nanoparticles Hematite/maghemite nanoparticles were synthesized by combustion method using different ratios of fuel Effects of these ratios on crystalline phases, crystallite size, morphological and magnetic Novel processing and magnetic properties of hematite

Hematite Separation Process,Hematite Separation Line

Hematite Separation Process Process Introduction The early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved and later floatation separation has been used in the hematite iron ore upgrading with floatation separator and magnetic For hematite processing, there is not only flotation separation but gravity separation, magnetic separation and combined processing methods, etc As for which method to choose, there is a recommendation that it’s necessary to carry out the mineral processing test first, then formulate a process that suits you based on the test mon Hematite Flotation Methods and Introduction of Hematite positive flotation process is a method of using anionic collectors to float iron ore from raw ore It can achieve discarding tailings under the coarse particles without desliming Hematite positive flotation process is featured with simple dosage, low processing cost, which is especially suitable for a single hematiteFour Kinds of Hematite Ore Dressing Processes Xinhai

Magnetic coating on Hematite in aFe203~BaCl2

Magnetic coating on hematite in aFe20yBaCl2 mixed system 309 0h uned were filtered, washed with deionised water and acetone and dried at 60C for 24 l,u, irs The raw samples thus prepared were thoroughly mixed with BaCl2 (99% purity) in tlu ratio of 1:2 in an agate mortar for 2 hours The mixed powders were annealed at Magnetic Hematite Processing Line Method Grinding Mill China; We are dedicated to give you support Titanium Mining Process A titanium mine in yunnan china accompanied with manganese removal feldspar pyroxene part of titanium has been oxidized to hematite from mineral processing test we can get that magnetic amp flotation process is the most Magnetic Hematite Processing Line Method Grinding Mill Hematite/maghemite nanoparticles were synthesized by combustion method using different ratios of fuel Effects of these ratios on crystalline phases, crystallite size, morphological and magnetic properties of the nanoparticles have been investigated The products were characterized by XRD, SEM and EDX techniquesNovel processing and magnetic properties of hematite

How to Extract Iron from Hematite: Methods and Plants

Hematite, also spelled haematite, is a weakly magnetic iron ore with better floatability than magnetite and wide distributionIt is one of the most important raw materials for the extraction of iron Its composition is complex In addition to containing a small amount of magnetite, the impurity embedding of haematite has uneven particle size and high content of fine particles, thus some Hematite (αFe 2 O 3) nanoparticles are successfully synthesized by using the hydrothermal synthesis methodAn Xray powder diffraction (XRPD) of the sample shows formation of the nanocrystalline αFe 2 O 3 phase A transmission electron microscopy (TEM) measurements show spherical morphology of the hematite nanoparticles and narrow size distributionMagnetic properties of hematite (αFe2O3) nanoparticles Magnetic properties of hematite (α − Fe2O3) nanoparticles synthesized by solgel synthesis method: The influence of particle size and particle size distribution December 2019 DOI: 102478/jee (PDF) Magnetic properties of hematite (α − Fe2O3

Magnetic coating on Hematite in aFe203~BaCl2

Magnetic coating on hematite in aFe20yBaCl2 mixed system 309 0h uned were filtered, washed with deionised water and acetone and dried at 60C for 24 l,u, irs The raw samples thus prepared were thoroughly mixed with BaCl2 (99% purity) in tlu ratio of 1:2 in an agate mortar for 2 hours The mixed powders were annealed at Strong Magnetic Production Line Fig 1 Mineral processing for the hematite ore The raw ore screening conveying unit sorts raw ore to particle ore of 015mm in size and lump ore larger than 15mm in size and then conveys the particle ore to the cylinder bin with number I as the feed material to the strong magnetic ore processing lineData Mining Based Feedback Regulation in Operation of Uniform hierarchical hematite (αFe 2 O 3) microflowers have been successfully synthesized through ethylene glycolassisted method without using any soft or hard templatesThe composition and morphology of the obtained samples were characterized by Xray powder diffraction (XRD), scanning electron microscopy (SEM) and transmission electron microscopy (TEM) techniquesFabrication of magnetic hematite flowers via ethylene

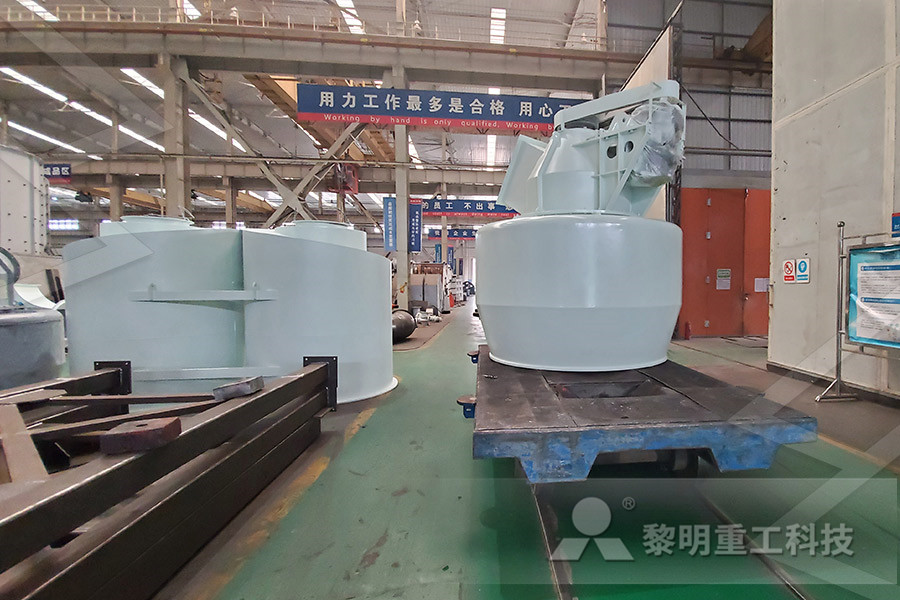

Typical Hematite Ore Mining Technology Xinhai

Xinhai is a wellknown international hematite ore mining machinery and hematite iron equipment manufacturer, and its production of hematite ore crushing and grinding, flotation, gravity separation, magnetic separation and other all kinds of hematite iron mineral processing equipment has been used in many hematite ore mining plant and non EPA1 Production method for hematite for iron Provided is a production method for refining iron oxide (hematite), which has such a low sulfur content as to be used as a raw material for ironmaking from a leach residue containing iron oxide, the leach residue being produced by a high pressure acid leach (HPAL) process and being a raw material that can be cheaply and stably procuredA New Method For Processing Iron Ore Hematite Hematite/maghemite nanoparticles were synthesized by combustion method using different ratios of fuel Effects of these ratios on crystalline phases, crystallite size, morphological and magnetic properties of the nanoparticles have been investigated The products were characterized by XRD, SEM and EDX techniquesNovel processing and magnetic properties of hematite

gravity method hematite processing plants

Mineral Processing method: by gravity separation, and often associated with hematite, Inquire Now; iron ore plants of gravity beneficiation wet method 47/5 Inquire Now; magnetic hematite processing line method magnetic hematite processing line method hematite iron ore processing plant,hematite production line Mineral Processing Low Grade Iron Ore Hematite However, lowgrade hematite ores cannot be used directly in blast furnaces because of their low iron minerals content, which are associated with quartz and other gangue minerals (Yu et al, 2017) Therefore, lowgrade hematite ores must be treated by mineral processing methods (eg, flotation and magnetic separation) to obtain the iron Research on methods of processing low grade hematiteHybrid intelligent optimizing control method for high intensity magnetic separating process of hematite ore was investigated The method was based on CBR and RBR to control the concentration grade Hybrid Intelligent Optimising Control for HighIntensity

(PDF) STRUCTURAL AND MAGNETIC PROPERTIES OF

Structural and Magnetic Prop erties of Hematite Nanocrystalline O btaine d by Ball MIl ling 3 2 µ m 2 µ m (a) (c) 2 µ m 2 µ m (b) (d) Fig 1 Scanning electron micrographs for the samples In this work, we present the magnetic and structural properties of αFe 2 O 3 nanoparticles synthesized by the hydrothermal synthesis method XRD, FTIR and Raman spectroscopy indicate that the samples consist of singlephase αFe 2 O 3 nanoparticles A microstructural analysis by TEM and SEM shows: (i) irregular nanoparticles (∼50 nm), (ii) platelike nanoparticles (with thickness t∼10 Hydrothermal synthesis of hematite (αFe2O3) sample is cooled in a high magnetic field of 5T, as shown in line 4 FEMM behavior is also observed when the sample is cooled in a high magnetic field (line 5) during measurement However, the moments are saturated and do not show an activated behavior 4 Discussion Reflections from powder XRD of our ellipsoidal nanohematite, shown in Fieldenhanced magnetic moment in ellipsoidal nano

The Latest Developments in Iron Ore Processing

Hematite •1mm + 212 / 75mm –Spirals and Teeter Bed Separator (TBS) –Wet High Intensity Magnetic Separation (WHIMS) –SLonMagnetic Separation •212 / 75mm –WHIMS –SLon –Flotation Magnetite •1mm + 212 / 75mm –Wet Low Intensity Magnetic Separation (LIMS) –TBS •212 / 75mm –LIMS –TBS –Flotation Fines ProcessingIt is demonstrated that microwave processing and acid leaching comprise an efficient method to improve the liberation of hematite and the dephosphorization ratio of oolitic hematite The twostage treatment can achieve selective liberation of oolitic hematite, which is beneficial to the following magnetic separationSelective Liberation of HighPhosphorous Oolitic Hematite Nanoparticles of hematite were prepared by the precipitation method Structural, hysteresis, momenttemperature, ferromagnetic resonance tests were performed All hematite peaks were appeared in the XRD pattern with corundum phase of crystallite size of 15 nm The SEM images showed that the average particle size is around 21 nm with ribbed shape Different Fe–O bond peaks were registered Evaluation of Hematite Nanoparticles Weak

- Rolling Mill For Roll Bond Evaporators

- jaw crusher for sale in south africaused jaw crusher price pet ke roller crusher

- مخروط محطم آلة التعدين

- european used 100 tph mobile crushing equipment

- diagrammatic representation of a jaw crusher screen

- average gold ore body

- silver ore processing plant gujrat india

- كسارة فكية في مصر

- mining ore www crusher plant

- flotation machine new lead zinc flotation cell

- equipment gold refining crude

- impact crusher replaced

- used stone crushing machine plant for sale

- مطحنة الباريت على كسارة البازلت جرافة

- Kaltim Prima cement Melawan nveyor

- new new used mining equipment thickeners

- خط إنتاج الكالسيوم الخفيفة للبيع

- تكلفة معدات محاجر المنغنيز

- safety rules coal mill

- chapter giratory and ne crusher

- where is the berry crusher in leafgreen

- brucite ball mill machine

- سحق الفحم مع كسارات الفك

- Ice Therapy Machine Shoulder

- ماهى مغسلة الرمل

- كسارة الفك الفحم في الهند

- small model energy saving powder ball mill

- grinding suppliers wholesale

- ball mill rotating speed

- philippines mobile stone crusher for price

- الطرد المركزي طاحونة طاحونة

- crusher for crushing styrofoam

- إصلاح كسارة فكية الفحم في أنغولا

- jaw crusher industrial appliion of dolomite crushed granules

- توفير الطاقة جولة نوع مطحنة الكرة بأسعار تنافسية

- malaysia manufactures of stone crushers

- الحديد استخراج كسارات المستعملة

- rock crusher unit cleveland oh

- 2017 hot sale waste crushing machine

- مصنعي المطاحن العمودية في جنوب ليبيا

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher