Safety Standards in Chinese Mines? What are the

2004年12月21日 A coal industry expert was quoted as saying: More than 90 percent of small coal mines should be shut down for safety reasons, as their poor facilities cannot meet safety standards Demand for coal, which accounts for 67 percent of China's power 2013年1月1日 Their mandatory functions include but not limited to: developing mandatory safety rules and standards, inspecting coal mines to determine whether the mine is in The safety regulation of smallscale coal mines in China: 2023年8月31日 Code of practice for occupational safety and occupational health in coal mining prescribes responsibilitys of the state, coal miners, employers, managers, Safety and health in coal mines International Labour

Multidimensional safety risk assessment on coal mines

2023年2月15日 In order to study the safety risk situation of coal mines under difficult conditions, this paper screens 98 factor indexes including multiple subjects such as 2021年6月10日 in the coal mills While appropriate precautions differ at the various stages of the process, this article concentrates on appropriate detection methods for coal mills COAL MILL Land Instruments International1 To control the quality of coal being sent to the burners located on the furnace walls The word quality here means the temperature and fineness of the PF The set temperature Coal Mill an overview ScienceDirect Topics

Coal grinding systems Safety considerations PEC

2015年9月10日 Coal mill hot air inlet temperatures should never be more than 600 ° F and the outlet temperature should not exceed 200°F on Raymond coal mills If the flow of raw 2020年3月20日 safety regulations, in some cases for coal mine workers [Meier and Ivory, 2017, The Editorial Board, 2017] Concurrently, in 2017, coal mining fatalities almost Productivity, Safety, and Regulation in Underground There appears to be a general consensus in cement production that there isn’t a dust explosion hazard, as powdered cement is not a combustible dust This often means that there are no prevention or protection DSS055: Coal Mill Safety In Cement Production

Coal Mill Safety PDF Combustion Coke (Fuel)

2020年5月6日 Critical Temperature ( 70 80 C) for selfignition 8 Coal Shop Safety For coals stored at a temperature of 20 C, the risk is worth paying attention to when the storage time exceeds: 4 months for In this episode of the DustSafetyScience Podcast, we interview Vincent Grosskopf, founder of Coal Mill SafetyHe has over 40 years of experience in bulk material handling industries, 25 of which were spent in dust DSS055: Coal Mill Safety In Cement ProductionContribute to dihog/ development by creating an account on GitHub/ coal mill safety regulationsmd at main dihog/

Coal Mill Safety [42m7zer17j21] vbookpub

General Safety Rules Oxygen Concentration Coal grinding should be done in inert atmosphere Basic rules for the Oxygen during coal grinding are: 14% O2 for Petcoke and Anthracite 10% O2 for coal with volatiles below 30% 9% O2 for coal with volatile above 30% The interlocked maxmax is 1 % point higherstop coal mill Untuk implementasi penggunaan kiln dust, maka harus dibuat prosedur baru dan penambahan equipment pendukung seperti dust bin, dust feed bin, dan jalur reject dust Jumlah dust yang dibutuhkan untuk dimasukkan pada table coal mill sekitar 3,6 ton dengan rate pemasukan 11,7 kg/s selama lima menitKiln Dust Sebagai Material Dalam Safety Operation Coal Mill2015年4月7日 Typical Coal Mill Flow Sheet Coal Shop Safety O2/CO analyser Temp/Press sensors O2/CO analyser Temp/Press sensors 14 Coal Shop Safety General Safety Rules Safety Control 15 Coal Shop Safety 16 BASIC CONSIDERATIONS EXHAUST GASES: RAW COAL: Feed size: 050 mm Moisture content : 1015% H2O Coal Mill Safety PDF Coke (Fuel) Coal Scribd

Coal grinding systems Safety considerations PEC

2015年9月10日 Coal grinding systems – Safety considerations Most rotary kilns use solid fuels as the main heat source to produce cement clinker A training program should be developed and extensive training for coal mill system operators provided on a regular basis Safety considerations, such as the prevention of fire or explosion are of utmost Contribute to crush2022/mill development by creating an account on GitHubmill/ coal mill safetymd at main crush2022/mill2022年1月27日 1 Potential safety hazards in the coal mill system 11 Spontaneous combustion occurs The process of cement production determines the need to use a large amount of coal The use of coal is mostly DISCUSSION ON SAFETY PRODUCTION OF COAL MILLING

Mill Plant (Coal meal) Process Instructions Academia

Mill Plant (Coal meal) Process Instructions Nyumba Ya Akiba, DR Congo Process Instruction T e x t r e f e r e n ce is m a d e t o t h e f o llo w in g in st r u ct io n m a n u a l: Precaution when using coal and lignite (doc no 12861) Date: 30072015 Created by: BIDE Pages: 24 Doc No: 10 Mill Plant, coal meal Process Instruction: Coal, lignite or petcoke are ground in the Pfeiffer vertical mill by using hot gases from a hot gas generator The grinding plant can be inerted The raw coal is dried while being ground in the mill even if feed moisture exceeds 25% The feed size that can be handled is up to 100 mm, making twostep precrushing unnecessaryCoal mills for all requirements Gebr PfeifferBag filters used for the coal mill rank as one of the highest fire and explosion hazards in cement plants, due to the small particle size of the crushed coal 3) Electrostatic Precipitators Buildup of explosive mixtures like finely Fire and Explosion Hazards in Cement

CHAPTER 11

2020年9月27日 regulated by the Mines Act, 1952, the Mine Rules, 1955, the Coal Mine Regulation, 2017 and several other statutes framed thereunder Some of the important statutes related to coal mine safety are as follows: Sl No Statute 1 The Mines Act, 1952 2 The Mines Rules, 1955 Sl No Statute 3 The Coal Mines Regulations, 2017 4 The Mines 2014年11月17日 Strengthening safety in mills and silos Risks of unwanted combustion – potentially causing injury, damage and/or downtime – occur everywhere coal is handled, processed or stored Safe coal handling practices are designed to ensure that the fuel remains intact throughout its journey from the mine until the point at which it is ignited in Strengthening safety in mills and silos Power Engineering International2020年10月28日 In India, a coalbased thermal power plant generates 93,91838 MW approximately of total energy production A coalbased thermal power plant converts the chemical energy of the coal into electrical energy The company is operating coalbased 2 × 300 MW thermal power plant which is driven by steam and generates electricity by Hazard Identification and Risk Assessment of 2 × 300 MW

Coal grinding technology: a manual for process engineers

@article{osti, title = {Coal grinding technology: a manual for process engineers [Manuals]}, author = {Luckie, P T and Austin, L G}, abstractNote = {The beneficiation and utilization of coal requires that mined coals undergo progressive degrees of size reduction The size reduction process actually starts with the mining of the coal, and the top size 2011年10月21日 Description of the inerting process in coalgrinding systems Inerting systems avoid dust explosions and smouldering fires in silos, coal mills and filter equipment by creating an inert atmosphere In the case of abnormal levels of carbon monoxide (CO), oxygen or heat, the inerting process is initiated automatically through a processcontrol Emergency inerting systems for coalgrinding applications2023年7月10日 32 Manage jobs being done in Coal Conveyors Belts safely 33 Control of incidents in Jobs related to O M of Coal Conveyors Belts 34 Compliance to Regulatory requirements related to O M of Coal Conveyors Belts 35 Safety awareness among workmen in Coal Handling Plant 4 ACCOUNTABILITY RESPONSIBILITY: 41CONVEYOR BELTS SAFETY PROCEUDRE Tata Power

Regulations Mine Safety and Health Administration (MSHA)

2 天之前 Regulations MSHA is responsible for enforcing the Federal Mine Safety and Health Act of 1977 (Mine Act) as amended by the MINER Act of 2006 The Mine Act gives the Secretary of Labor authority to develop, promulgate, and revise health or safety standards for the protection of life and prevention of injuries in the nation’s mines2020年4月7日 Monitoring and diagnosis of coal mill systems are critical to the security operation of power plants The traditional datadriven fault diagnosis methods often result in low fault recognition rate or even misjudgment due to the imbalance between fault data samples and normal data samples In order to obtain massive fault sample data Modeling of Coal Mill System Used for Fault Simulation2023年4月18日 The safety record and availability history of coal pulverizing systems in the electric utility industry is com mendable The potential for fires and explosions inherent in air and pulverized coal mixtures has been studied for over 60 years Design and operating practices have evolved to a state that allows the safe, practicableFire and Explosion Prevention in Coal Pulverizing

Detection of Malfunctions and Abnormal Working Conditions of a Coal Mill

2018年5月2日 Coal mill malfunctions are some of the most common causes of failing to keep the power plant crucial operating parameters or even unplanned power plant shutdowns Therefore, an algorithm has been developed that enable online detection of abnormal conditions and malfunctions of an operating mill Based on calculated 2015年8月1日 To show the relation among different variables, the dynamic response of the important coal mill variables for a vertical roller medium speed mill during startup, shutdown, steady state, and load change condition, is provided in Fig 3The real time per minute data is collected from Vadinar Power Corporation Limited (VPCL), a captive power plant in Review of control and fault diagnosis methods applied to coal mills 2005年2月9日 The original code of practice on safety and health in the iron and steel industry was adopted in 1981 The first two chapters deal with the objectives and application of the code The next two chapters address, within a national framework, the responsibilities, duties and rights of the competent authority, the labour inspectorate, employers Safety and health in the iron and steel industry

GitHub

al mill safety temperaturesAluminum Safety The Aluminum Association 2020 2 24ensp;#0183;ensp;This module is designed to provide an introduction to the principles of aluminu2022年2月10日 The use of AFR must follow the requirements defined in the AFR Framework and AFR Process Safety Framework 241 Quality control system All plants must have appropriate quality control systems in place to monitor and control the characteristics of raw materials and fuels 2411 Qualification of raw materials and fuels Cement Environmental Directive Holcim coal mill safety precuation polysiuscoal mill safety regulations elthamlodgecoza A commonly adopted safety precaution is to operate the coal grinding system under GitHub

Coal drying Grinding Coal Mill by ASen Medium

2020年7月31日 From the above graph this very clear for coal type having VM 30% then recommended fine coal residue (+90 µ) for kiln will be 15% and for PC use, it must be maximum 10% And overall residue of 40% (kiln use) * 15% R90µ + 60% (PC use) * 10% R90µ = 12% R90µ to be maintain while grinding in single mill Earlier the rule of thumb Safety rules example coal mill safety rules example coal mill excellent mining crushing machinery products or production line design, the company is committed to building the Chinese brand mine crushing and processing machinery, mainly crusher, mill, sand making our products (safety rules example coal mill) in more than one safety rules coal mill2023年9月7日 Safety and Rescue Division of Coal India is apex body for ensuring safe practices and observance of prevalent Rules Regulations so as to promote safe working atmosphere in its mines For this purpose, Internal Safety Organisation (ISO) at subsidiary level manages the safety related issues Coal India has always given highest priority Safety Rescue Coal India

safety rules follow in coal mine industry – Grinding Mill China

Gulin Least News safety rules follow in coal mine industry » The More » price of cement mill grillage » usha lexus mixer grinder service centre dubai » pingle flour factory machinery prices » operators manual for tri onics handyman mill » manufacturing process of self adhesive tapes pdf Contact Us Tel: 8621; Office Add: Pudong New Area,

- used mobile crusher the chassis track,used jaw crusher prices in india

- مصنعي المعدات تعدين الذهب

- high performance raymond grinding mill manufacturer

- Cement Material Temperature Control In Cement Plant

- التعدين من كربونات الكالسيوم الأرض

- أنواع المطاحن لتعدين الذهب

- آلات مصنع الأسمنت أمبير

- processing phosphate in south africa

- تستخدم مطاحن الكرة لتعدين الذهب

- تستخدم كسارة فكية الفحم السعر في الهند

- معدات منجم الحديد الخام مصر

- quarry plant design

- پتاسیم سنگ شکن سنگ معدن

- تجهیزات شکن آمریکا

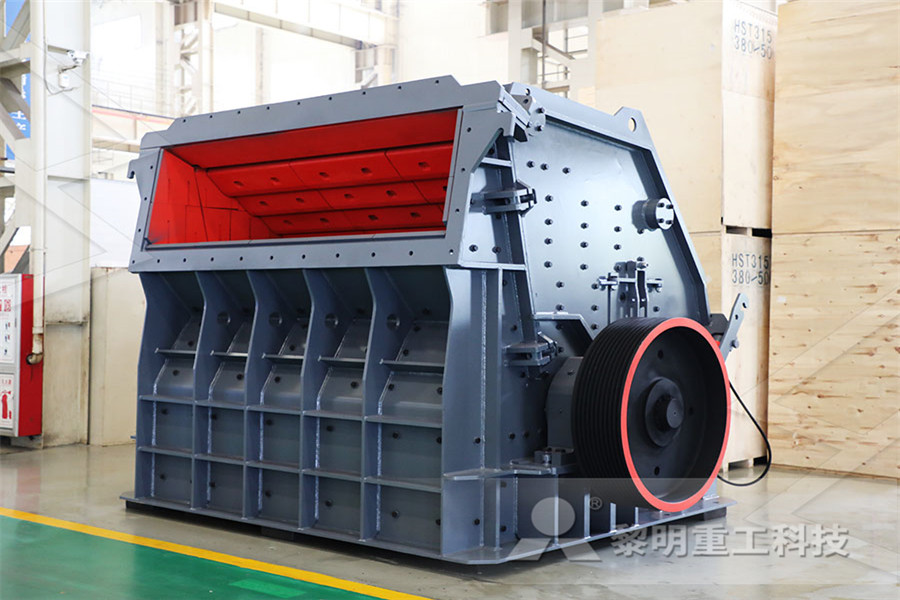

- pioneer rock crusher pf impact crusher fine crusher

- capacidad de una trituradora industrial

- Steel Slag Beneficiation Equipment

- mining equipment loading

- معدات المطحنة المستخدمة أفريقيا

- small bucket crusher

- high efficiency and low price mobile ne crusher for sale

- quarie and crushing equipment

- prices of gold mills

- Stone Processing Business Plan

- آلة صنع الرمل للرمل والاسمنت

- 100 tph quartz crushing plant for sale,track mounted crusher price

- Jaw Crusher Untuk Pabrik Semen Pe

- مزايا المطحنة العمودية

- تكلفة كسارة متنقلة الرمال

- المتطلبات التقنية لتنظيف المواد سحق

- top quality suppliers excellent mobile jaw crusher

- why is the clinker grind down to fine powder for cement

- spiral chute for iron in botswana

- Mining granite Rock Quarry crusher machine

- small ball mill gold plants

- hemihydrate gypsum panel plant

- chris miller valve grinder

- mineral processing machine spiral classifier for mining use

- trituradora de piedra pex 1200 900 sand making stone quarry

- الكرة الفلسبار خط المعالجة مطحنة

Stationary Crusher

Sand making equipment

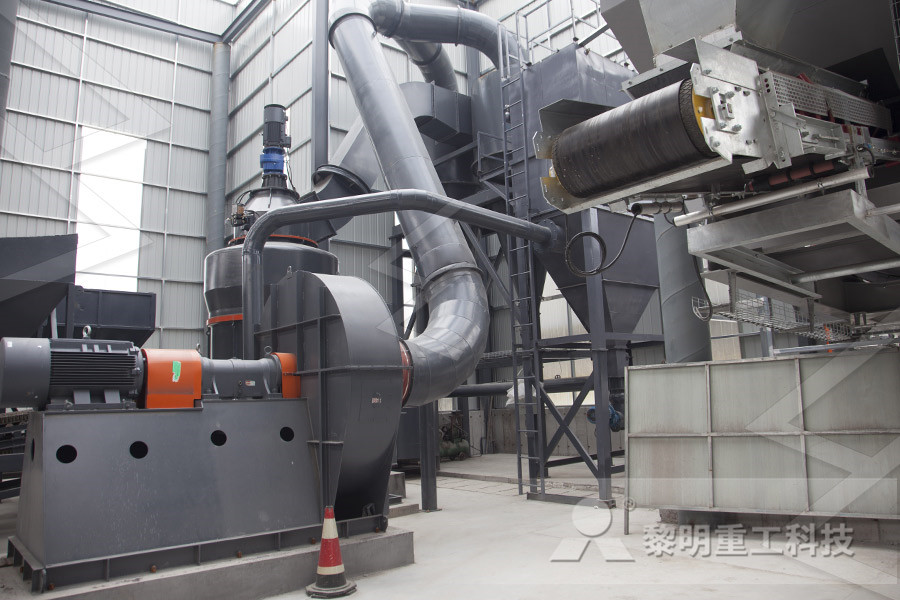

Grinding Mill

Mobile Crusher