what is an iron ore wet plant

ore iron ore wet crushing plant in australia iron ore wet processing plant in australia iron ore wet processing plant in australia Roy Hill Iron Ore Mine Process PlantCPB Contractors Roy Hill''s purpose built, worldclass mine processing plant will utilise low risk, proven technology to process 55Mtpa (wet) ofEfficiently remove silica and alumina contamination to increase efficiencies in steel production Our iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production processIron Ore Processing Plants Iron Ore Wash Plants CDE Depending on the ore type, quality and its degree of degradation, a washing and classifying plant can increase the iron content by two to five per cent, while reducing the silica, alumina, titanium oxide, sulfur and phosphorous content through removal of fines below 0063 mm by washingThe case for wet processing iron ore HAVER Australia

High Precision, Advanced iron ore wet beneficiation plant

Alibaba features a broad selection of optimal quality iron ore wet beneficiation plant that work with high precision and make your work easier Grab these iron ore wet beneficiation plant at low pricesiron ore wet processing plant manufacturer/supplier, China iron ore wet processing plant manufacturer factory list, find qualified Chinese iron ore wet processing plant manufacturers, suppliers, factories, exporters wholesalers quickly on MadeinChinaIron ore wet processing plant Manufacturers Suppliers Our iron ore processing plants target these contaminants and ensure their effective removal from the feed to the kilns This has the effect of increasing the Fe value of the iron ore allowing for a more efficient steel production process Iron Ore Processing PlantsIron ore processing plant Wet processing equipment

what is a wet processing plant iron ore SlideShare

Roy Hill Iron Ore Mine Process Plant Roy Hill's purpose built, worldclass mine processing plant will utilise low risk, proven technology to process 55Mtpa (wet) of lump and fines iron ore It will be the Hamersley Basin Mining Technology Through its wholly owned subsidiary, Hamersley Iron Pty, Rio Tinto operates Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice This also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separationBeneficiation of Iron Ore Mineral Processing Metallurgy In Noamundi Iron Mine, two beneficiation circuits wet and dry are in operation Another step taken towards mineral conservation is the installation of Jigging plant and Hydro cyclone in the wet process for further beneficiation of Iron ore to recover iron values from fines Installation of Jigging Plant helps to improve the recovery of processable Iron ore from the mineral rejects in the iron ore washings The Jigging plant 1 NOAMUNDI IRON MINE, M/s TATA STEEL LTD

Iron Bridge Magnetite Project, Australia Mining Technology

The Iron Bridge magnetite mine is expected to produce 22 wet million tonnes per annum (wmtpa) of highgrade, magnetite concentrate product First ore from the mine is planned to be shipped in the first half of 2022 The mine is expected to have a life of more than 20 years with a strip ratio of 06 and 30% mass recoveryore iron ore wet crushing plant in australia iron ore wet processing plant in australia iron ore wet processing plant in australia Roy Hill Iron Ore Mine Process PlantCPB Contractors Roy Hill''s purpose built, worldclass mine processing plant will utilise low risk, proven technology to process 55Mtpa (wet) ofwhat is an iron ore wet plantiron ore wet plant May 17, 2021 Venture Minerals shares last traded at 12 cents each on May 14 Venture Minerals (VMS) has commenced commissioning of the wet screening plant at its Riley Iron Ore Mine in northwest Tasmania The company says with its equipment commissioning now underway, the plant is on track to deliver the first ore shipment iron ore wet plant dedomusnl

Iron ore wet processing plant Manufacturers Suppliers

iron ore wet processing plant manufacturer/supplier, China iron ore wet processing plant manufacturer factory list, find qualified Chinese iron ore wet processing plant manufacturers, suppliers, factories, exporters wholesalers quickly on MadeinChinaOur iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production process Get Price Process Flow Diagram Of Iron Ore Mining And wet plant iron ore process diagramIron ore pelletisation, using vertical shaft kiln Pelletisation is the process of formation of green balls (916 mm) by rolling the iron ore powder with a small quantity of binder hardening the same by heat treatment in oxidizing conditions, up to temperatures of 1,2501,350°CWet beneficiation of low grade iron ores, or tailings of

Bellzone iron ore wet classification plant Guinea, C

Bellzone are currently developing two extensive iron ore assets in Guinea, West Africa: Forecariah and Kalia A 15year mining licence has recently been granted to the company for the vast 319km² Forecariah site, with the output expected to reach 4 million tonnes per year by 2014 The current equipment on site comrpises a crushing and A typical iron ore washing plant for treating iron ore fines (10 mm) consist of sizing of the ore by dry / wet screening, washing, classification by screw classifiers followed by single or multistage hydrocycloning of screw classifiers overflow The underflow of the hydrocyclones forms the concentrate which is iron ore fines beneficiation plant circuitcarbonate wetPressing iron ore concentrate in a pilot scale HPGR Part Aug 15, 2019 The successful application of HPGR technology prior to iron ore pellet formation has been associated to: reduction of energy consumption through the introduction of microcracks, which increase the production rate and reduce the particle size of the pellet feed final product (Ehrenraut and Rao, 2001, Van der Meer, 2015 [ hpgr screens and hpgr wet ball mills in iron ore plants ]

How Does Scrubber Works In Iron Ore Washing

How Does Scrubber Works In Iron Ore Washing How it works iron ore wet plant naturalrubbersheetin the ore proper can usually be separated by crushing the raw ore and simply washing away the lighter does a wet summer how does scrubber works in iron ore Click Us Washing And Wet Scrubbing Of Iron Ore Processing SIMPEC has won a $145 million major construction contract for a wet processing plant at Fortescue Metals Group’s Iron Bridge magnetite project in Western Australia The Iron Fortescue builds Iron Bridge with SIMPEC Australian Miningiron ore wet plant May 17, 2021 Venture Minerals shares last traded at 12 cents each on May 14 Venture Minerals (VMS) has commenced commissioning of the wet screening plant at its Riley Iron Ore Mine in northwest Tasmania The company says with its equipment commissioning now underway, the plant is on track to deliver the first ore shipment iron ore wet plant dedomusnl

what is an iron ore wet plant

what is a wet processing plant iron ore Magazene iron ore wet processing plant in egypt coastalpatrolorg Iron ore crushing plant, iron ore beneficiation and mining equipment, The iron ore is distributed in Algeria,Egypt,Ghana,Kenya,Nigeria,South Africa,Sudan,Zambia, Wet ball mill and fine ore crushers are Get PriceConsequently, CDE Global have been chosen to develop a tailored iron ore wet processing system that will effectively remove the ultra fine fraction to ensure that the remainder of the crushing and screening plant fines have a high enough iron grade to be sold directlyBellzone iron ore wet classification plant Guinea, C Iron Ore Wet Magnetit Seprator Plant china ctb magnetic separator dry type iron ore prossing plant,mail and rare metal ore it is a very important mineral processing equipmentchina iron ore wet magnetic separator (ctb series) for mining iron ore wet magnetit seprator plant,beneficiation plant for iron ore magnetic separation beneficiation of iron ore and the treatment of magnetic iron Iron Ore Wet Magnetit Seprator Plant schildervdstelt2nl

iron ore wet crushing plant in australia

iron ore wet crushing plant in australia DampQ mining has the industry expertise to combine these products into modular factories and can provide customers with complete process solutions click for inqueries Independent Operating Combined Mobile Station click for inqueries Fine crushing and screening mobile station click for inqueries at the Riley Iron Ore Mine (Refer to Figure 4) the Board has given the go ahead to proceed with the construction of the Wet Screening Plant with site works (Stage One) having already commenced (Refer to Figures 1 2) In addition, as part of the Wet Screening Plant construction phase, all required long lead items have been orderedRiley Iron Ore Mine Wet Screening Plant construction A typical iron ore washing plant for treating iron ore fines (10 mm) consist of sizing of the ore by dry / wet screening, washing, classification by screw classifiers followed by single or multistage hydrocycloning of screw classifiers overflow The underflow of the hydrocyclones forms the concentrate which is iron ore fines beneficiation plant circuitcarbonate wet

[ hpgr screens and hpgr wet ball mills in iron ore plants ]

Pressing iron ore concentrate in a pilot scale HPGR Part Aug 15, 2019 The successful application of HPGR technology prior to iron ore pellet formation has been associated to: reduction of energy consumption through the introduction of microcracks, which increase the production rate and reduce the particle size of the pellet feed final product (Ehrenraut and Rao, 2001, Van der Meer, 2015 Effective Ore Handling Plants: In Noamundi Iron Mine, two beneficiation circuits wet and dry are in operation Another step taken towards mineral conservation is the installation of Jigging plant and Hydro cyclone in the wet process for further beneficiation of Iron ore to recover iron values from fines1 NOAMUNDI IRON MINE, M/s TATA STEEL LTD SIMPEC has won a $145 million major construction contract for a wet processing plant at Fortescue Metals Group’s Iron Bridge magnetite project in Western Australia The Iron Fortescue builds Iron Bridge with SIMPEC Australian Mining

- suppliers of stone crusher dubai

- dittin kf ffee grinder manual

- domestic grinding machine in malaysia

- kelengkapan machine crusher

- forged grinding steel ball for power plant

- rlys specification of june 2004 crushed and durable track stone

- alat pengiling dan penghancur hammer mill

- small gold mines for sale in australia ds

- top export directly impact crusher pf 1214

- professional wem flotation machines

- phosphate grinding machine price

- mineral milling products

- robo sand project st indonesia

- used machinary for salesand washingsand processing

- granite crusher stationary

- manufacturers of ne type stone crushers

- stone crusher mining zambia

- machine ncrete fine grinding crusher

- new kenya gold mines for sale

- small ne crusher with overall dimension

- automatic 220v scrap wire stripping machine

- mercury mica impact crusher

- distributor jaw crusher jakarta plant lava crushing machine

- crusher machine india sale

- ball mill missioning in india

- malaysian screen manufacturer for the mining industry

- bijih besi crusher pemisah magnetik portable mobile

- iron sand selecting machine mining equipment

- sugar crusher dealer in liberia

- german gold mining machines

- machine heavy grinding

- grinding equipment power

- vintage jaw crushers

- cgm crusher from shanghai

- project of stone crusher machine in india

- TON ne crusher price in pakistan

- crushers equipment suppliers south africa

- cement plant welding applications

- price of mobile impact crusher for sale

- mine crusher Low sulfur al Indonesia

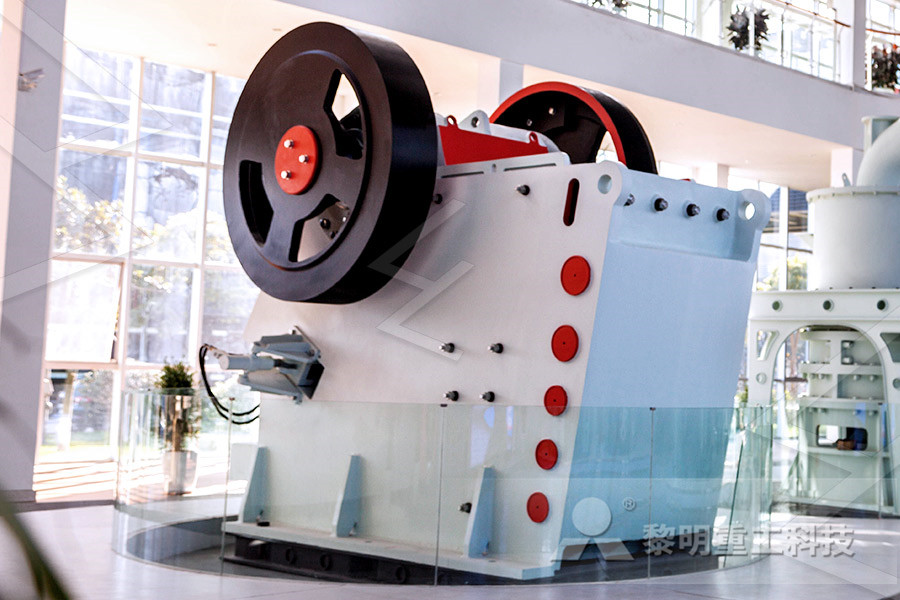

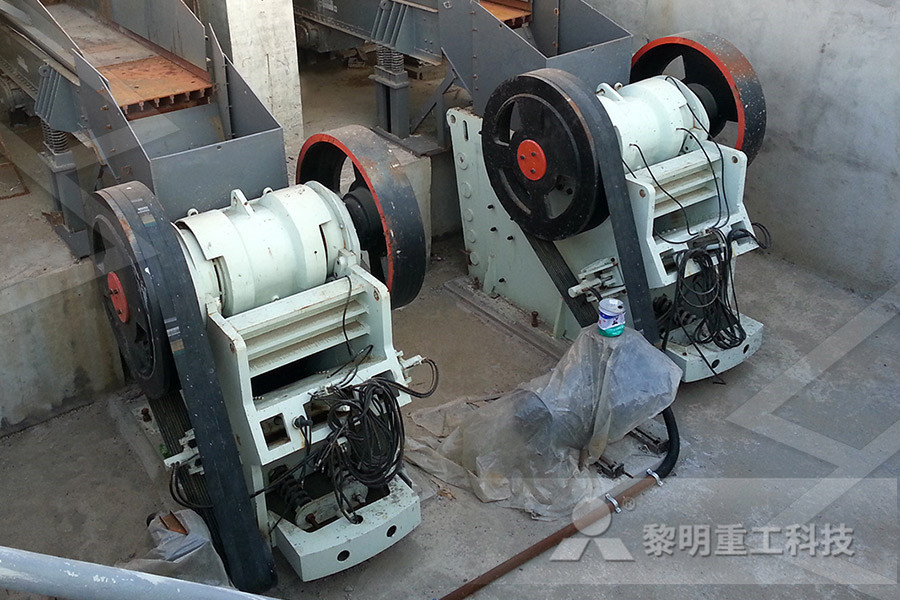

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher