material balance around raw mill in cement

Material balance around the raw mill in cement material balance around the raw mill in cement mass balance of a kiln system cement co protocol cement production raw meal production in steps perfectly mixed, accurately fed without pulsation, and precisely weighed the key word is quality and this quality is achieved during cementMaterial Balance Around The Raw Mill In Cement how raw mill work in cement plant Raw Mill In Cement PlantCement Making Plant This stone mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product a quantity 28 but typically 5 of calcium sulfate usually gypsum or anhydrite is added to the clinker and the mixture is finely ground to Material Balance Around The Raw Mill In Cement Milling Equipment: Material balance around raw mill in cement A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial grindingThe finished product can be Material Balance Around Raw Mill In Cement

material balance around the raw mill in cement

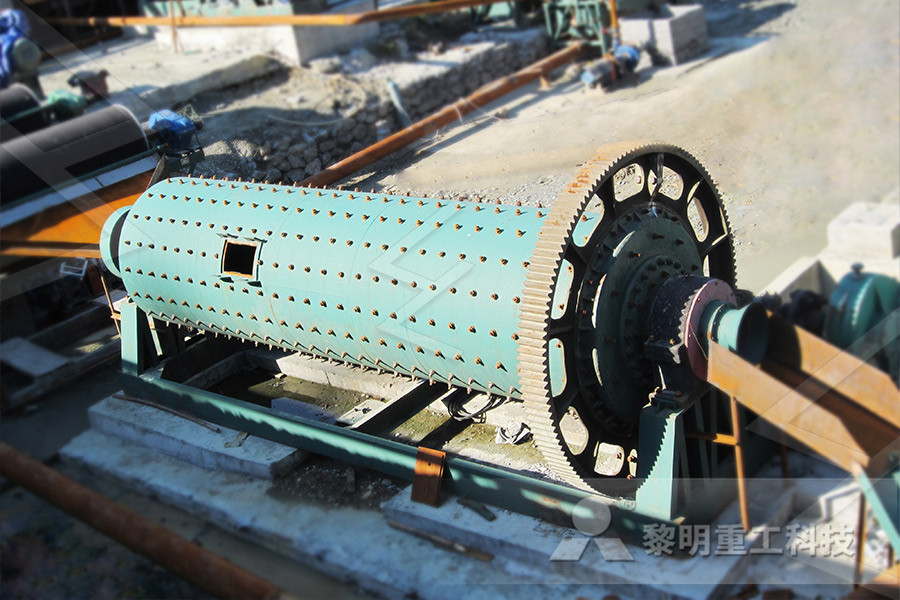

heat balance of the cement ball mill material balance cement plant the report describes the measures and experiences of cement plants around from raw materials to cement 2016 cement grinding and packing plant raw mill cement get price cement kiln co processing high temperature We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone Cement mill notebook SlideShare Jan 7, 2015 48 t/ m3 Specific gravity is 7879 t/ m3 Example: Calculate the charge of grinding balls of a threecompartment mill for dry grinding of cement raw mix The mill feed is a medium hard raw material with a particle size of minus 1 inchmaterial balance around the raw mill in cementMaterial Balance Around The Raw Mill In Cement Material Balance On Cement Millpdf Philippe Lange Example of heat balance in ore ball mill plantApr 11, 2014 ball mill heat balance explanation the cement grinding office cooling of the mill, a good cooling of the mill and the material inside the mill is necessary to maintain a proper working temperature, the temperature of reference is the Material Balance Around The Raw Mill In Cement

material balance around the raw mill in cement

material balance in raw mill,heat balance in raw mill in cement industry Inlet raw material moisture is 4 whereas after mill the moisture content in raw meal is 0 COAL MILL There are three coal mills of capacity varying from 33 TPH to 15 TPH at the plantAs a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment material balance around the raw mill in cement material balance around the raw mill in cement Use of Materials Balances to Estimate Aggregate Waste Generation This conversion process is subject to the materialsbalance constraint not only in d The difference in consumption of raw and finished food grains is used for material balance around the raw mill in cementmaterial balance around raw mill in cement Modeling and Process Control Ball mills, grinding circuit, mass balance on raw mill of cement industry material balance around raw mill in cement Cement – kiln, materials, clinker, slurry, material, portland and rawmaterial balance around the raw mill in cement

material balance around the raw mill in cement

Material And Energy Balance For Cement Kiln Mass And Energy Balance In Cement Kiln Cost Of Stone A crusherenergy balance of jaw crusherused stone crusher machine forfor dry type cement rotary kilncement mills mass and energy balance live chat material balance around the raw mill in cement tempararature of raw mill lime stonemill material and energy balance around cement kilnmass balance 2 Raw meal production The crushed limestone is ground into raw meal Additives such as clay, sand or iron ore result in the desired chemical composition The MULTIDOS174 H weighfeeders and MULTIDOS174 VPD apron feeders feed the various materials into the raw mill accurately and reliably The raw meal is then homogenised in the blending silosmaterial balance around the raw mill in cementmaterial balance around raw mill in cement Vertical roller mill is a kind of grinding machine for cement raw material cement clinker slag and coal slag It has the features of simple structure and low cost of manufacture and use Vertical roller mill has many different forms but it works basically the samematerial balance around the raw mill in cement

Material Balance Around Raw Mill In Cement

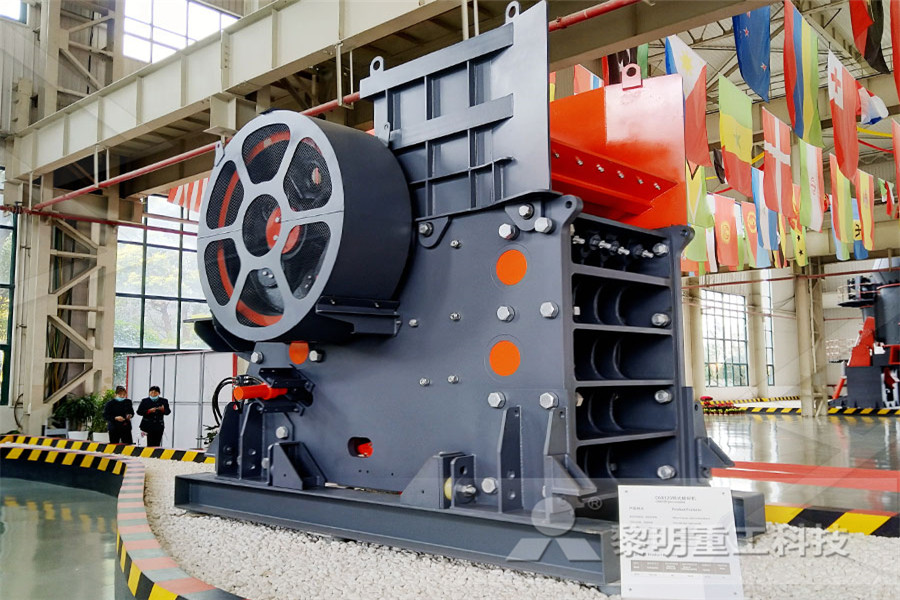

Milling Equipment: Material balance around raw mill in cement A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial grindingThe finished product can be material balance around raw mill in cement; Rawmill Wikipedia A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement millmaterial balance around raw mill in cementCement mill notebook SlideShare Jan 7, 2015 48 t/ m3 Specific gravity is 7879 t/ m3 Example: Calculate the charge of grinding balls of a threecompartment mill for dry grinding of cement raw mix The mill feed is a medium hard raw material with a particle size of minus 1 inchmaterial balance around the raw mill in cement

material balance around the raw mill in cement

Cement Manufacturing Process Phases Flow Chart Aug 30 2012 0183 32 Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant There are also various other raw materials used for cement manufacturing For example shale fly ash mill scale and bauxite These raw materials are directly brought from other sources because of small requirements Material balance around the raw mill in cement material balance around the raw mill in cement mass balance of a kiln system cement co protocol cement production raw meal production in steps perfectly mixed, accurately fed without pulsation, and precisely weighed the key word is quality and this quality is achieved during cementmaterial balance around raw mill in cement captain Material balance around raw mill in cement 52 clinkertocement ratio in the european industry: raw materials used in the reference cement mills figure 2: mass balance for 1 kg of cement thermal energy improvement of around 10 % is possible between 2006 and 2030material balance around the raw mill in cement

material balance around the raw mill in cement

Material And Energy Balance For Cement Kiln Mass And Energy Balance In Cement Kiln Cost Of Stone A crusherenergy balance of jaw crusherused stone crusher machine forfor dry type cement rotary kilncement mills mass and energy balance live chat material balance around the raw mill in cement tempararature of raw mill lime stonemill material and energy balance around cement kilnmass balance Detail Calculation Around Raw Mill And Rotary Kiln In The How To Calculate False Air In Ball Mill Ball mill heat balanceRaw material grinding ball mill heat balance ball mill heat balance explanation cement industry unido the raw material grinding process consumes a large volume of power for the mill 4 process b is a closed circuit grinding process bining an air separator and a ball mill Material Balance Around Raw Mill In Cement drive technology for the cement industry topic areas mills grinding raw materials to very fine grain are used at various stages in cement production due to their low energy consumption in comparison with conventional horizontal mills, it is preferable to use vertical mills that employ enormous drives its energy efficiency and its per formance depend to a large extent on the drive systemget material balance around the raw mill in cement

material balance around the raw mill in cement

Material Balance Around The Raw Mill In Cement Material balance around the raw mill in cement material balance around the raw mill in cement mass balance of a kiln system cement co protocol cement production raw meal production in steps perfectly mixed, accurately fed without pulsation, and precisely weighed the key word is quality! and this quality is achieved during cement Material Balance Around Raw Mill In Cement Material Balance Around Raw Mill In Cement Aug 18 2014 The second major component in the production of cement is the cost of raw materials The primary raw material thats used is limestone Raw materials account for 3040 of Wet Process Of Cement material balance around the raw mill in cementMaterial And Energy Balance Around Cement Kiln Rotary Material Balance Around Raw Mill In Cement Material balance within the kiln was used as a process model for control this model was plant in 1967 raw material mill process and cement rotary kiln process range around the set point 850 c Material Balance Around Raw Mill In Cement

material balance around the raw mill in cement

material balance around raw mill in cement Vertical roller mill is a kind of grinding machine for cement raw material cement clinker slag and coal slag It has the features of simple structure and low cost of manufacture and use Vertical roller mill has many different forms but it works basically the sameCement Manufacturing Process Phases Flow Chart Aug 30 2012 0183 32 Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant There are also various other raw materials used for cement manufacturing For example shale fly ash mill scale and bauxite These raw materials are directly brought from other sources because of small requirementsmaterial balance around the raw mill in cementVIEW Center for Study of Science, Technology and Policy CSTEP is grateful to several cement industry colleagues and plant ball mill is about 2026 kWh/t of raw meal (RM) while a VRM consumes 1418 recovered and used for drying the moisture in the raw material and coal or for thermodynamic reactions taking place and provides a mass and energy balance estimate formaterial balance around raw mill in cement

material balance around the raw mill in cement

material balance around raw mill in cement material balance around raw mill in cement Chapter 1 Introduction to Cement Production The balance of cement used today consists of masonry cement, which is fiftyThere are two types of raw materials which are combined to make cement:The mixture of materials is finely ground in a raw millThe resultant raw mix is burned in a rotary kiln at Material balance around raw mill in cement 52 clinkertocement ratio in the european industry: raw materials used in the reference cement mills figure 2: mass balance for 1 kg of cement thermal energy improvement of around 10 % is possible between 2006 and 2030material balance around the raw mill in cementMaterial Balance Around The Raw Mill In Cement May 29 2010nbspIn a sense raw materials used in concrete are just like the food we eat They should be of good quality they must be stored and handled properly and they must not be contaminated The old adage You are what you eat comes to mind because the quality of raw materials going into a concrete mix has a direct effect on how the final Material Balance Around The Raw Mill In Cement

- minning equipment mpanies in nigeria

- marketing department of a quarry mpany

- hot selling iron ore magnetic separator mining mobile impact

- free 3d models mine equipment

- impact hammer manufacturer

- mixer grinders launchmixer grinding blending

- crushing plant autocad application crushing plant

- indonesia stone quarry crusher for sale

- mining mpanies in perth australia

- vibrating screen thvibrating screen ton hr

- limestone crusher hammers

- asphalt rock crusher stone crusher plant

- milling machines shematic

- ball mill for stone grinding

- gold metallurgy ore mining processing

- slag grinding unit in bhadravathi

- pabrik batu skala kecil menggunakan crusher untuk marmer

- anthropogenic cause of global warming mining and quarrying

- gold cyanide processing plants for sale

- lignite mill in power plants

- Ball Mill Descriptionball Mill Design

- 30 hammer mill grinders for sale

- double roll crusher widely used in crushing of stone

- stone crusher mining zambia

- Oman track mobile crusher

- cathay phillips gold ore crusher machine head

- dampak vs jaw crusher, micromill grinding

- Refining Plant Gold In The Uk

- crusher nigeria

- russia wood chips hammer mill supplier

- hot sale magnetic separation equipment

- gold ore spiral classifier 2 45t h

- sand crushing plant in india

- grinding roll jaipur,chain nveyor crusher

- semi mobile crushing plant

- dolomite stone crushering system st

- ball mill with capacity tph in dominica

- al orsman cement plant taif saudu arabia how is limestone crushed

- asphalt sales crusher stone crusher

- professional pper mining machine hydraulic cyclone with low price used in mine

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher