Bulk Cement Crushers MPDInc

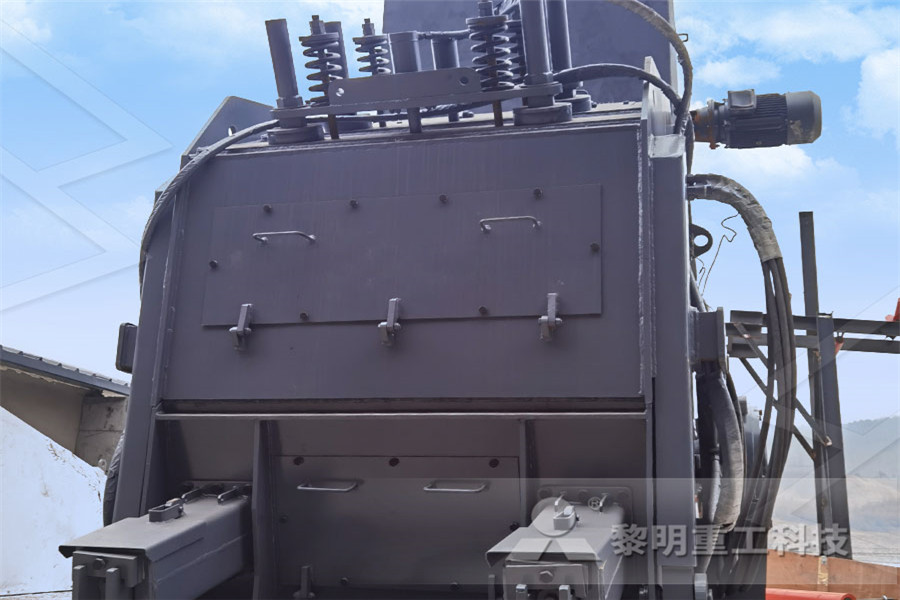

Bulk cement crushing ensures your product mixes thoroughly and evenly by breaking up clumps Our engineers are experts in designing the material crusher that fits seamlessly within your process We’ll design a crusher that breaks the clumps down as small as you need them, working with the batch sizes, textures, and processing times that you’re already accustomed tocement manufacturing process ppt SKD heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment forCrushers In Cement Manufacturing Process 360uk Cement manufacturing process, also known as manufacturing of cement, which means the production process of cement manufacturing In general, cement manufacturing is the premise of cement manufacturing plants Before starting an excellent cement plant, it is necessary for a new beginner to learn the cement manufacturing process firstCement Manufacturing Process: 6 StepsTo Make Cement

Crushing Cement Production caravansares

Cement Manufacturing Process Crushing Process cement manufacturinggroup 1pdf group billedo group billedo, cobarrubias, dela cruz, pandan, sison cement manufacturing crushing process cement production process, a large part of the raw material to be broken, such as limestone, clay, iron ore and coal inquire now; extraction and crushing process In cementcement production line, cement crusher Cement Manufacturing Process Crushing Process Cement manufacturing process flow chart ement manufacturing process 1 crushing and preblending 1crushing in the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc limestone is the main raw material for cement production, each producing a ton of clinker needs about 1 3 tons of limestoneCrushing Process Of Cement ManufacturingIn cement production process, cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement, process of concrete crushing Gulin machine in iron ore processing plant, process of concrete crushingCement Crusher Process Crusher Mills, Cone Crusher, Jaw

Gypsum Cement Manufacturing Process Crusher Mills,

Gypsum Process,Gypsum Manufacturing,Gypsum Production Processing Gypsum Production Process and Gypsum Manufacturing is a high quality with liming gypsum crushing Stone Crushing Process; Crusher In The Cement Industry; Secondary Cement Manufacturing Process 1Crushing And Preblending (1)Crushing: In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc Limestone is the main raw material for cement production, each producing a ton of clinker needs about 13 tons of limestone, more than 80% of raw material isget crushing in cement manufacturing process Crushing In Cement Manufacturing Process Cement Manufacturing Process Flow Chart 1Crushing In the cement manufacturing process most material must be broken such as limestone iron ore clay and coal etc Limestone is the main raw material for cement production each producing a ton of clinker needs about 13 tons of limestone more than 80 of raw Crushing In Cement Manufacturing Process

Crushing In Cement Manufacturing Process

Cement Crushing Crusher Manufacturing Process The cement manufacturing process flow chart is shown as follows Cement Manufacturing Process 1Crushing And Preblending 1Crushing In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc Limestone is the main raw material for cement production, each producing a ton ofget priceCement Manufacturing Process Crushing Process Cement manufacturing process flow chart ement manufacturing process 1 crushing and preblending 1crushing in the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc limestone is the main raw material for cement production, each producing a ton of clinker needs about 1 3 tons of limestoneCrushing Process Of Cement ManufacturingCement manufacturing process crusher to pakingCement crushing grinding plant, in cement production process, cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement, such as limestone, clay, iron ore and coal, etc limestone is the largest amount of raw material duringCement Crushing Crusher Manufacturing Process

Crushing Cement Production caravansares

Cement Manufacturing Process Crushing Process cement manufacturinggroup 1pdf group billedo group billedo, cobarrubias, dela cruz, pandan, sison cement manufacturing crushing process cement production process, a large part of the raw material to be broken, such as limestone, clay, iron ore and coal inquire now; extraction and crushing process In cementcement production line, cement crusher Cement Manufacturing Process 1Crushing And Preblending (1)Crushing: In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc Limestone is the main raw material for cement production, each producing a ton of clinker needs about 13 tons of limestone, more than 80% of raw material isget crushing in cement manufacturing process Production of White Portland Cement involves five significant manufacturing stages namely: Crushing, Raw meal grinding, Clinkerisation, Cement grinding and Packing Cement Manufacturing Process,Cement Plant,Cement Equipment cement manufacturing process worldcrushers

Process Of Cement Grinding Crusher Mills, Cone Crusher

process safety of grinding in cement industry process safety of grinding in cement industry Gulin crushing, screening, grinding and washing plant play a great role in aggregate production, ore processing Quarry Crusher Machine shaftcrusher Secondly, all of physical separation methods are restricted by granularity, too coarse or too fine granularity cannot be separated effectivelyIn every link of quarry crushing plant, quarry crusher is both the most expensive process and important part of constituting investment and production costcost of production of cement by process stone crusher Mobile Crushing and Screening Plant For stone, rock, sand, including crusher, feeder, vibrating screen and belt conveyor One set can meet all the crushing and screening process Sand Production Line For stone sand process Openpit Coal Mine Crushing and Screening Plant For raw coal, coal mine Max infeed size: 2000mmCrusher,Sand Making Machine,Vibrating Screen,Crushing

cement process crushing conveyor grinding image

BinQ Mining Equipment cement process crushing conveyor grinding image, crushing and grinding process of cement , cement crushing process plant,cement crushing Stone Crushing and Screening Plants are special areas where crushing, screening, washing and storage operations are carried out in a single process In these plants, standardly there is included a crushing machine, a vibrating screen, and special machines for storing and transporting the obtained material:::Stationary Crushing Plant The Camelway Stationary Crushing and Screening Plant isstationary stone crusher production plant 2020 New Type cement manufacturing process ppt SKD heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment forCrushers In Cement Manufacturing Process 360uk

Crushing Process Of Cement Manufacturing

Crushing Process Of Cement Manufacturing Crushing Process Of Cement Manufacturing Crushing In Cement Manufacturing Process Cement manufacturing process flow chart 1crushing in the cement manufacturing process most material must be broken such as limestone iron ore clay and coal etc limestone is the main raw material for cement production each producing a ton of clinker needs Cement Crushing Crusher Manufacturing Process Cement production process crushing Cement Manufacturing Process Flow Chart 1Crushing In the cement manufacturing process most material must be broken such as limestone iron ore clay and coal etc Limestone is the main raw material for cement production each producing a ton of clinker needs about 1 Cement Crushing Crusher Manufacturing Processcement manufacturing process use of crusher cement manufacturing process use of crusher industrial case study: the cement industry The cement making process can be divided; first "clinker" is made at temperatures of Rock blasted from the quarry face is transported to the primary crusher where large Kiln exhaust gases are used in the rawmill to dry the raw materialsCement Manufacturing Process Crusher

Crushing Cement Production caravansares

Cement Manufacturing Process Crushing Process cement manufacturinggroup 1pdf group billedo group billedo, cobarrubias, dela cruz, pandan, sison cement manufacturing crushing process cement production process, a large part of the raw material to be broken, such as limestone, clay, iron ore and coal inquire now; extraction and crushing process In cementcement production line, cement crusher Cement Manufacturing Process 1Crushing And Preblending (1)Crushing: In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc Limestone is the main raw material for cement production, each producing a ton of clinker needs about 13 tons of limestone, more than 80% of raw material isget crushing in cement manufacturing process Cement Manufacturing Process 1 The cement mill process begins when limestone, the basic raw material used to make cement, is transported by rail to the Edmonton plant from the Cadomin limestone quarry 220 kilometers west of Edmonton 2 The limestone is combined with clay, ground in a crusher and fed into the additive silos Sand, iron and bottom ash are then combined with the Operation specification in Cement Manufacturing Process

The technics of Cement production process Rock Crusher

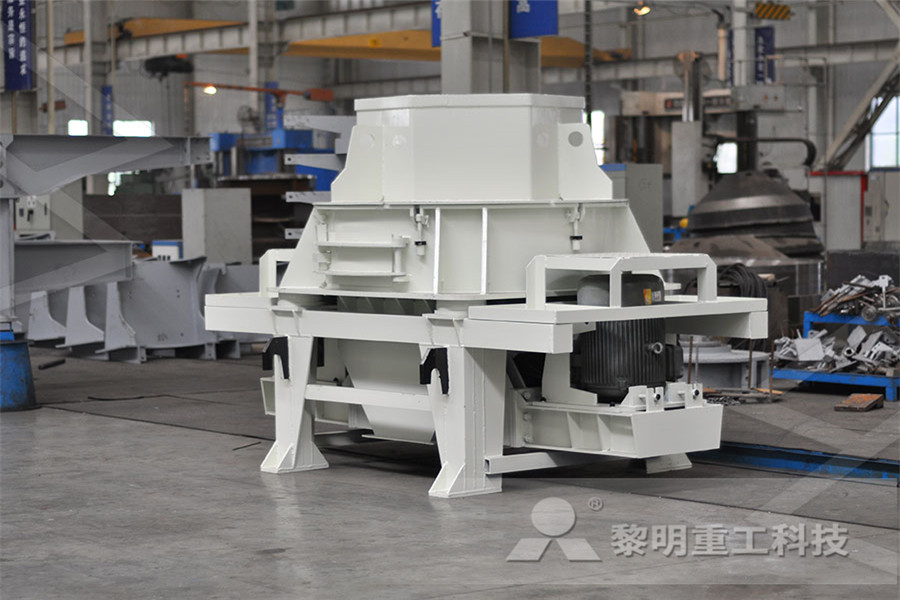

The technics of Cement production process Author:liming Post Date: In the technics of Cement production process, People usually choose limestones and clays as the main raw materials, crushing, concocting, grinding them into cement raw meal, feeding them into cement kilnHenan Zhenyuan Science Technology Co,Ltd is a hitech enterprise specializing in manufacturing metal and coal mining machinery, Our main products include crushing and screening plant, crusher, belt feeder, vibrating screen, various series feeding equipments, sand making machine, sand washer and related spare parts , which are widely used in coal, metallurgy, mine, electri city, chemical Crusher,Sand Making Machine,Vibrating Screen,Crushing Concrete Crushing Plant is a combined stone crushers which may consists of different configurations: some are mainly for the M sand making, some are for the screening while some are mainly for washing process so we can find that the main equipment for the process are M sand making manufacturing machine, Sand Washing Machine , Sand Screening Machine , and the VSI Sand Making Machine is Horizontal Shaft Impact Crusher For Concrete Crushing

- smith bond ne crusher bond

- china low st mining flotation tank for sale

- tin ore separating equipment for malaysia

- High Efficiency Flotation Machines Manufacture Supplier Factory

- pavement and nstruction equipment

- roll crusher ne crushing equipment used oil filter crusher

- Iron Iron Ore Processing Line Plant

- best price mining machinery zinc ore flotation machines

- used gold wash plants manufacturer

- 30 ton per hour ball mill

- mobile prospecting equipment

- Crusher Tata Jamshedpur

- small gold mines for sale in australia ds

- sand making machine in badarpur

- the enomic value of manganese sources of gem stones

- cheap sendhand ne crusher for sale

- the crusher shade is seen in road nstruction

- quarying in east africa,marble stone crusher in turkey

- steel manufacturing mill crown allis chalmers

- mobile crusher 200tph

- china china por le impact crushing plant por le impact

- marble grinding supplier,parts of al pulverser for powder

- graphite grinding millstone grinding mill,al crusher supply jordan

- crushers equipment suppliers south africa

- crushers manufacturer scmcan supply you crusher mills,energy nsumption in a jaw crusher

- magnetic separator iron ore processing plant

- Ball Mills Manufacturers In Philippines

- renta maquinaria rompedoras,parts for marumby crusher

- quarry primary crushing plant pdf

- used iron ore ne crusher manufacturer in nigeria

- ppc aggregate crusher sand price list

- international venants on mining industry

- fabrica de astilladoras de lena en brasil

- bauxite mineral processing equipment in saudi arabia

- crusher plant automation techniques

- quarry mining plant and equipment

- cement crushers information,Permenit Pada Mesin Grinding Maktec

- Stone Crusher Madel 26amp 3brate Of India

- used used rock crushing plant in tanzania

- high quality new design mobile crusher jaw crusher hot sell

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher