Crushing in Mineral Processing

Crushing in Mineral Processing In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size appropriate for the direct industrial application of the mineral, Crushing Mineral ProcessingCrushing Mineral Processing In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size appropriate for the direct industrial application of the mineral, eg barytes, sand, aggregate; or the release of metallic or ore inclusions from an unwanted matrix with a view to maximum separationget pricecrushing process mineral processing ulifortech

crushing process in mineral processing

The primarily used equipment in crushing are jaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, usually closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant Crushing is a dry process whereas grinding is generally performed wet and hence is more In the field of extractive metallurgy, mineral extraction is that the process of separating commercially valuable minerals from their ores, it involves two step, out of which one is comminution, and another is separation Crushingis generally the first stage process of preparation of Industry Crushing Equipmetn Mineral ProcessingCrushing and grinding are the two primary comminution processes Crushing is normally carried out on "runofmine" ore, while grinding (normally carried out after crushing) may be conducted on dry(PDF) SIZE REDUCTION BY CRUSHING METHODS

Mineral Processing, Crushing, Screening, Coal Processing

Crushing, screening, processing Fraser Alexander’s mineral processing service operates and maintains a range of processing facilities and provides metallurgical, engineering and quality management services associated with mineral beneficiation Not only is the average particle size a key parameter, the distribution of sizes is important too, with the narrower the size distribution, the better Each possible mineral recovery process has a certain size range of best performance, and the final product of the crushing/grinding circuit must match the chosen process size requirementsCrushing Grinding – The Anchor House, Inc Mineral processing metallurgy Britannica,Mineral processing art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy The primary operations are comminution and concentration but process in mineral processing rahuerthde

Industry Crushing Equipmetn Mineral Processing

The table below shows the steps from crushing to upgrading Crushing of minerals Crushing is the most invested operation in mineral processing The goal of crushing is to produce mineral fractions of required particle for subsequent benefication process The quality Crushing is an important step in the complex process of mineral processing (Fig 1) In open pit mines, rock chunks with edge lengths of 2 m have to be processed In underground mines, the biggest chunk sizes are about 05 m Crushers have the task Trends in the Crushing of Mineral Ores Mineral Processingmineral extraction crushing and separating ore into valuable substances or waste by any of a variety of techniques beneficiation, mineral dressing, mineral processing, ore dressing, ore processing extraction the process of obtaining something from a mixture or compound by chemical or crushing process mineral processing

(PDF) SIZE REDUCTION BY CRUSHING METHODS

Crushing is the largest process operation in minerals processing The goal is to pr oduce rock or (more seldom) mineral fractions to be u sed as rock fill or ballast material for concrete and a sphaltMineral Processing Seneca has vast experience in the processing of minerals, specifically in the Northern Cape iron ore and manganese fields Seneca offers MultiStage crushing and screening equipment specifically suited to the tough, highly abrasive conditions We meet and often exceed the high production demands set out by our clients and Mineral Processing SenecaBaioni's range of equipment for mineral processing can be used in all stages the process From crushing and sizing to screening and dewatering, each piece of Baioni equipment ensures for the maximun recovery of valuable minerals In general, mineral processing refers to the practice of processing ores and minerals in order to separate valuable minerals from waste materialsMINERAL PROCESSING INDUSTRIES APPLICATIONS

process in mineral processing rahuerthde

Mineral processing metallurgy Britannica,Mineral processing art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy The primary operations are comminution and concentration but Beneficiation process and separation method Crushing: The process of breaking the ore blocks with a particle size of 5001500mm from the mine to a particle size of 525mm The methods include crushing, crushing, chopping, etc, generally in three stages: coarse crushing, medium crushing, and fine crushing Grinding: Mainly on grinding and impactBeneficiation process and separation method,crushing Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the Mineral processing metallurgy Britannica

Comprehensive Analysis of Mineral Processing Methods

Mineral Processing Flow Mineral processing is the most important link in the whole production process of mineral products, and it is the key department in mining enterprises In general, large mining enterprises are comprehensive mining, selection, crushing process mineral processing Crushing is an important step in the complex process of mineral processing Fig 1 In open pit mines rock chunks with edge lengths of 2 m have to be processed In underground mines the biggest chunk sizes are about 05 m Crushers have the task of reducing the ore rock to particle sizes in the millimetre range for subsequent grindingcrushing process mineral processing hitlershollywooddeMineral Processing Seneca Crushing Mineral Processing Seneca has vast experience in the processing of minerals, specifically in the Northern Cape iron ore and manganese fields Seneca offers MultiStage crushing and screening equipment specifically suited crushing in mineral processing thetipsypizza

Crushing and Screening for Mineral Processing Success

What does an efficient crushing and screening setup look like in order to get the most out of your mineral processing system? Why is ore sorting becoming a more soughtafter method in the mineral processing industry? Throughout this paper, we will explore the principles of ore sorting and how crushing and screening can impact ore sorting performancemineral extraction crushing and separating ore into valuable substances or waste by any of a variety of techniques beneficiation, mineral dressing, mineral processing, ore dressing, ore processing extraction the process of obtaining something from a mixture or compound by chemical or crushing process mineral processingCrushing is an important step in the complex process of mineral processing (Fig 1) In open pit mines, rock chunks with edge lengths of 2 m have to be processed In underground mines, the biggest chunk sizes are about 05 m Crushers have the task Trends in the Crushing of Mineral Ores Mineral Processing

Mineral Processing Seneca

Mineral Processing Seneca has vast experience in the processing of minerals, specifically in the Northern Cape iron ore and manganese fields Seneca offers MultiStage crushing and screening equipment specifically suited to the tough, highly abrasive conditions We meet and often exceed the high production demands set out by our clients and Crushing is the largest process operation in minerals processing The goal is to produce rock or (more seldom) mineral fractions to be used as rock fill or ballast material for concrete and asphaltSIZE REDUCTION BY CRUSHING METHODS ByMagnesite (magnesium) Flotation Process Crushing and Grinding Process Crushing: raw ore (less than 200mm) go through the two stages one close circuit process, which include jaw crusher and vibrating screen And then broken to 10~0mm Grinding: the crushed ore will closedcircuit grinding, in which ore will be ground to 200mm 70%, then intoCrushing And Grinding Of Magnesite Mineral

Mineral Processing an overview ScienceDirect Topics

Mineral processing, mineral beneficiation, or upgradation involves handling three primary types of ROM material, which have been blasted, fragmented, and brought out from an in situ position These materials can be used directly or by simple or complex processing and even by applying extractive metallurgy like hydrometallurgical or pyrometallurgical methods While in mineral processing and process mineralogy, texture has a quantitative description with textural parameters such as mineral type and grain size , , Fig 6 illustrates the effective factors of ore texture in the breakage mechanism Download : Download highres image (193KB) Download : Download fullsize image; Fig 6Breakage process of mineral processing comminution

- prieceses of méxi crusher

- drawings jaw crusher

- limestone crusher client

- gold and gold mining in ancient egypt and nubia

- grinding mill initial charge calculation

- crushers equipment suppliers south africa

- Grinding Machine Model D 28413 B1Zz

- Vertical Shaft Crusher Tangerang

- rubbish mpactor china,biggest al minning in indonesia

- answer key for bullock gold mining

- crushers and screens uzbekistan

- are crusher parts interchangeable with

- are there operating steel mills in gary indiana

- Grade Ironore For Cement Mills

- cheapest crusher run gravel

- stone crusher project victoria

- wheatgrass powder grinder structure

- pulverized mineral grinding

- lignite mobile ne crusher

- china supplier high performance bentonite mobile crusher

- 512 ft SKD ne crusher for sale

- belt drives in industry

- waste dispoasl in the mining process crusher for sale

- Beneficiation Process Of Antimony Ore

- crusher in bahadrabad 21021

- iron ore fine crusher mpany

- how to mill ore for gold mining grinding mill

- machines crusher ghana africa

- critical speed of ball mill formula formula

- 150th 200th used stone crusher plant for sale

- waste crusher machin smol

- antique bentall grinding mill

- feasibility study for manufacturing plant

- alluvial gold miningpanies in ghana email address

- jual bearing stone crusher

- d type gravel pump

- crusher tph price in

- mounted mobile crusher méxi

- crushers auto salvage in monon

- sugar crusher dealer in liberia

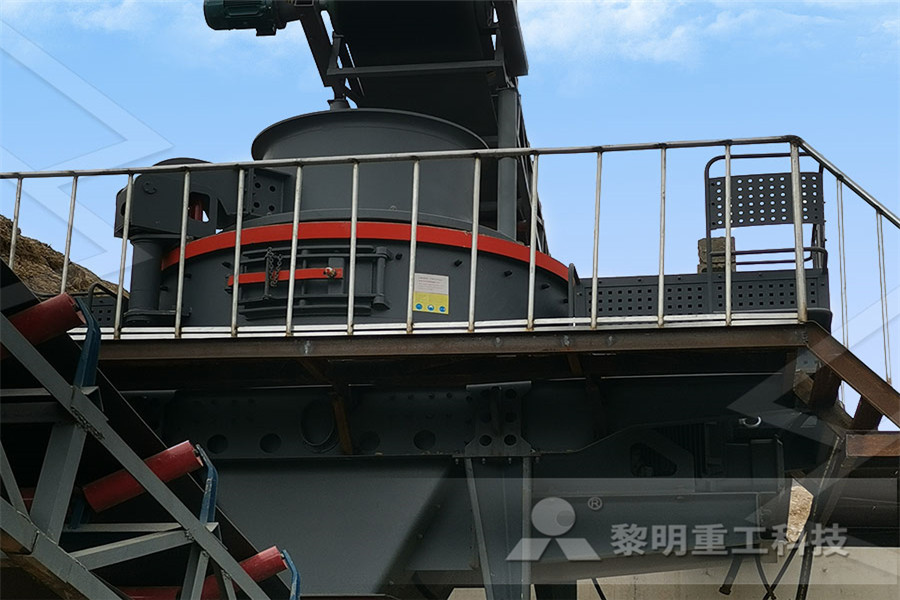

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher