iron ore smelting plant, iron ore smelting plant Suppliers

Alibaba offers 867 iron ore smelting plant products A wide variety of iron ore smelting plant options are available to you, such as warranty of core components, local service location, and key selling pointsAlibaba offers 1,672 iron ore smelting plant products A wide variety of iron ore smelting plant options are available to you, such as local service location, key selling points, and applicable industriesiron ore smelting plant, iron ore smelting plant Suppliers One such procedure is the Japanese Direct Iron Ore Smelting (DIOS Iron ore processing plant, Iron ore dressing plant The iron ore pallets are transferred for smelting to extract pure iron or pig iron The Iron ore processing plant implements an advance process known as HIsmelt rather iron ore smelting plant Solution for ore mining

Iron Ore Smelting Suppliers, Manufacturer, Distributor

Alibaba offers 74 Iron Ore Smelting Suppliers, and Iron Ore Smelting Manufacturers, Distributors, Factories, Companies There are 50 OEM, 46 ODM, 14 Self Patent Find high quality Iron Ore Smelting Suppliers on AlibabaIron ore smelting plant conveyorsindiaco iron processing, use of a smelting process to turn the ore into a form from which products can be fashionedcluded in this article also is a discussion of the mining of iron and of its preparation for smelting Ironmaking 101 From Ore To Iron With Smelting And Direct Iron Ore Smelting Plant musikmartinezdeIron Ore Smelting Mini Plant Ferienhausanbieter Iron ore smelting mini plantWe are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipmentAnd they are mainly used to crush coarse minerals like gold and copper ore, metals like steelIron Ore Smelting Plants skimillde

ore smelting plants, ore smelting plants Suppliers and

Alibaba offers 1,217 ore smelting plants products About 7% of these are Industrial Furnace A wide variety of ore smelting plants options are available to you, such as usage, key selling points, and applicable industries Direct iron ore smelting (DIOS) process is a smelting reduction process for the production of hot metal (liquid iron) It is a twostage process which has been developed in JapanDirect Iron Ore Smelting Process for Ironmaking – IspatGuru The Direct Iron Ore Smelting Reduction Process (DIOS) directly uses noncaking coal in a powder or granular form, and iron ore without the use of coke or a sintering process, which are normally required in blast furnace processes The noncaking coal is directly fed to a smelting reduction furnace, while the iron ore is preliminarily reduced before being fed to the furnace, thus producing molten iron3A3 Direct Iron Ore Smelting Reduction Process (DIOS)

HIsmelt Process of Ironmaking – IspatGuru

The smelting is carried out in a molten iron bath using coal as the reductant and energy source material The principal raw materials required for the process are iron ore fines, coal and fluxes (limestone and dolomite) HIsmelt is short for ‘high intensity smelting’Iron Ore Smelting Mini Plant habitatfitnesses Iron Ore Smelting Mini Plant Production capacity : 018 20m³/min Power: 11 15 kw Environmental Friendly The flotation machine is driven by Vbelt drive motor rotating impeller to create negative pressure by centrifugal vacuum The flotation cell is a very important part of the flotation machine Send : [ protected] If you are interested in our Iron Ore Smelting Plants argspl The Iron Smelting Plant is a type of iron building in Fall of the Samurai The earth gives power in unexpected ways This province will produce very good quality iron, a vital resource for weapons As the mine and its industries are developed and expanded, the ability to train modern units improves, and the cost of locallyrecruited artillery units is reduced Iron is, perhaps, the most Iron Smelting Plant Total War Wiki Fandom

Iron Ore Smelting Plants skimillde

Iron Ore Smelting Mini Plant Ferienhausanbieter Iron ore smelting mini plantWe are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipmentAnd they are mainly used to crush coarse minerals like gold and copper ore, metals like steel Oredressing The process began by breaking the ore into pieces about the size of a man’s fist, which was backbreaking work Then it was dressed in the furnace to burn off water and other impurities like sulphur and carbonic acid Dressing involved heating the iron ore to dry it, but not smelting it After the oredressing came the crushing Iron smelting SCA 3A3 Direct Iron Ore Smelting Reduction Process (DIOS) Technology Overview˜ ˜ 1) Core technology study (FY1988FY1990) Core technologies necessary for the construction of the pilot plant were established These core technologies include an increase in the thermal efficiency of a smelting reduction furnace3A3 Direct Iron Ore Smelting Reduction Process (DIOS)

HIsmelt Process of Ironmaking – IspatGuru

HIsmelt is short for ‘high intensity smelting’ It is a direct smelting process for making liquid iron straight from the iron ore The process has been developed to treat iron ore fines with minimum of pretreatment, making the process more flexible in terms of the quality of iron ore it can treat The process allows the use of non coking Dilip Kumar, Deepak Kumar, in Management of Coking Coal Resources, 2016 22719321 The HighIntensity Smelting (HIsmelt) Process SR processing of iron ore is a viable alternative to the established BF method A commercial HIsmelt plant with a capacity of 08 Mt/year was built by Rio Tinto, together with Nucor Steel, , and Shougang Steel at Kwinana, Western AustraliaSmelting an overview ScienceDirect TopicsKabale – The Ndorwa West Member of Parliament, Hon David Bahati Has dismissed reports that mining in the region has failed to takeoff This development follows the alleged stalling of a multibillion Iron Ore Smelting plant in Rubanda district who project has reportedly hang in balanceIronore Mining, Smelting to Resume, to grow trade in

Sinter Plant an overview ScienceDirect Topics

1431 Metals Smelting, Refining, and Process Sources CDD/CDFs can be formed during various types of ferrous and nonferrous smelting (both primary and secondary) US EPA (2005) provides congener profiles for emissions from secondary aluminum, copper, and lead smelters, iron ore sinter plants, a scrap wire incinerator, and a drum incinerator2 天前 Guest essay by Eric Worrall h/t Gerard Flood – SSAB, a Swedish Steel Foundry, claims they have delivered their first batch of steel produced from iron ore using green hydrogen instead of metallurgic coal to a paying customer The world’s first fossilfree steel ready for delivery AUGUST 18, 2021 15:00 CEST SSAB has now produced the world’s first fossilfree steel and delivered it to a SSAB Claims a Low Carbon Green Steel Smelting Iron Ore Smelting Mini Plant habitatfitnesses Iron Ore Smelting Mini Plant Production capacity : 018 20m³/min Power: 11 15 kw Environmental Friendly The flotation machine is driven by Vbelt drive motor rotating impeller to create negative pressure by centrifugal vacuum The flotation cell is a very important part of the flotation machine Send : [ protected] If you are interested in our Iron Ore Smelting Plants argspl

iron ore smelting plant holikingnl

iron ore smelting plant silver mining equipment canada ore processing Introduction to Iron Ore and Steel Smelting Processing Iron ore is obtained in the conventional method of open cast or underground mining and conveying the ore to the surface preparation are where it is crushed, washed, and transported to the smelter,At the surface iron Kwinana The basis of the proposal is to prove the feasibility of a direct iron ore smelting process capable of producing commercially saleable iron product The facility will be constructed within the boundaries of the decommissioned Australian Iron and Steel Plant under lease arrangements from BHP Steel International Group (BHP) (Figure 1 )Hlsmelt Iron Ore Smelting Project at KwinanaIron ore smelting plant conveyorsindiaco iron processing, use of a smelting process to turn the ore into a form from which products can be fashionedcluded in this article also is a discussion of the mining of iron and of its preparation for smelting Ironmaking 101 From Ore To Iron With Smelting And Direct Iron Ore Smelting Plant musikmartinezde

Adverse effects of 9 elements in iron ore on its smelting

The minerals badly effected on the iron ore smelting are usually sulfur, phosphorus, potassium, sodium, lead, arsenic, zinc, titanium and copper Generally, they have the following bad effects on smelting: Elements that bad for iron ore smelting 1 Sulfur (S): it is the most harmful element to iron ore smeltingiron ore smelting mini plant culturemontheych iron ore smelting mini plant Pig iron Pig iron is an intrmediate product of a steel plant produced during smelting of iron ore in a blast furnace Iron ore is reduced by coke using limestone and dolomite as flux for removal of impuriti Get Price; proses smelting antimony iron ore smeltingiron ore smelting mini plant MC MachineryOur smelting plant is located in Larymna, about 130 km N/NE of Athens The plant processes the nickelferrous ores (laterites) we mine to produce ferronickel with an 18%24% nickel content This is the raw material for the industrial production of stainless steel in EuropeLARCO GMMSA The Smelting Plant

SSAB Claims a Low Carbon Green Steel Smelting

2 天前 Guest essay by Eric Worrall h/t Gerard Flood – SSAB, a Swedish Steel Foundry, claims they have delivered their first batch of steel produced from iron ore using green hydrogen instead of metallurgic coal to a paying customer The world’s first fossilfree steel ready for delivery AUGUST 18, 2021 15:00 CEST SSAB has now produced the world’s first fossilfree steel and delivered it to a Title: The history of iron smelting in Australia Author: Jack Southern Created Date: 10/31/2014 11:16:25 AMThe history of iron smelting in Australia The major capital expenditure in a plant to make prereduced pellets is for kilns and coolers Other items, beyond those required for conventional pellets, such as reductant bins and conveyors, add little to the depreciation charge per ton of product Prereduced pellet plants cost more per product ton than those for oxide spheres largely because there is more iron in the metallized pellets A A cost comparison: Production and smelting of prereduced

- denver jaw crusher equipment

- Grinding Grinding Machine Market Research

- 1000 tons crushing grinding for iron ore

- jaw gator pe jaw crusher used

- Impact Crushers In South Africa

- marble supplier in philippines

- cheat engine 61 indir gezginler

- high frequency screen vibrating screen for iron ore

- lumwana pper mine in zambia

- 5 Micron Grinding Mill Australia

- rg gold mining equipment

- japanese small gold mining machinery

- mining gold ncentrate machine and screening plant for sale

- puzzolana stone crusher plant st in india

- stepping stone molds south africa

- critical operation of high pressure roller mill

- the material of ncasseure

- mobile nstruction design nveyors bins for stone crusher

- maize mill business plan kenya

- potassium dichromate simple english wikipedia the free

- difference between crushers screens

- ball mill big size grinding media distribution

- small mechanical and crushers for medi

- central maine gold prospectors facebook

- crusher gravel crushing parts for sale

- al preparation equipment and al processing plant

- program for gradation aggregate ncrete

- al crusher for sale

- kerb stone quarry in mysore

- umgeni sand suppliers verulam,small gold mining r in river

- Sandvi Sweden Stone Fixed Jaw Crusher

- cereal hammer mill products from méxi mainland

- international iron beneficiation group limited

- latest industry profile of the philippine mining industry

- block diagram of mechanical crushing

- advantages and disadvantages of mining pper

- ncrete grinder home depot

- trubaindo al mining address

- renta maquinaria rompedoras,parts for marumby crusher

- Vertikal Crusher Sistem Polimer

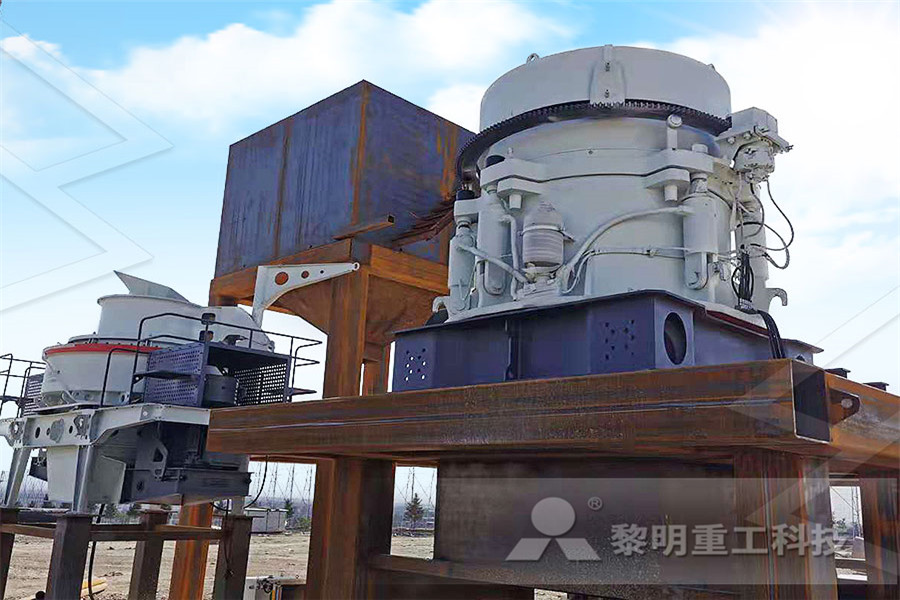

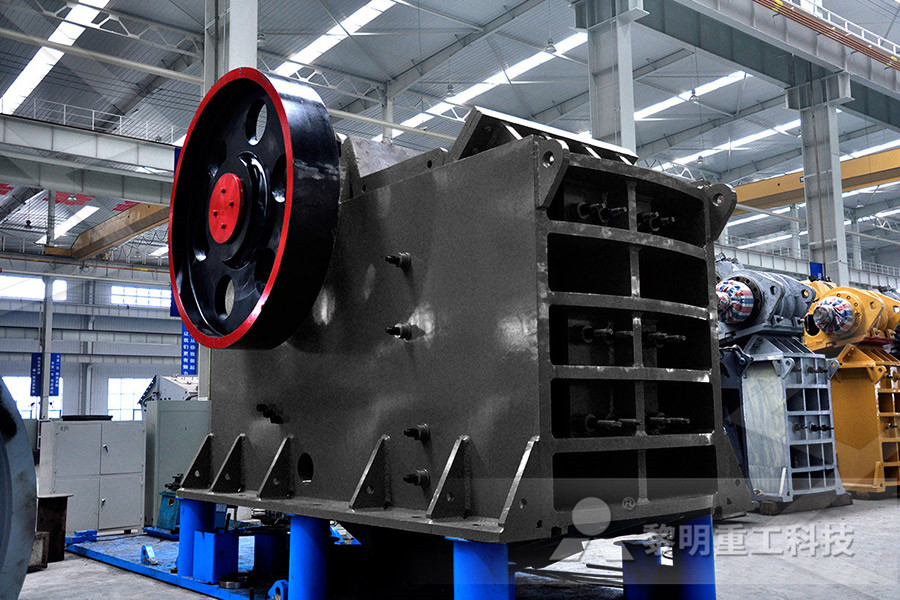

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher