cement Moisture and Boiler Design

cement Moisture and Boiler Design SOILCEMENT content throughout The entire operation of cement spreading, water application, and mixing shall result in a uniform soil, cement, and water mixture for the full design depth and width 44 Compaction Soilcement shall be uniformly compacted to a minimum of 98% Design and analysis of a Coal Moisture And Boiler Design Effects of Coal Rank on a Boiler Low Rank Coal Compared to Higher Rank Coal Can have alkali elements directly attached to coal molecules rather than in the ash minerals such as clay, silica, alumina As a result the ash can have a high content of reactive sodium, potassium, calcium, iron Get A QuoteCoal Moisture And Boiler Design trinitytradeCoal Moisture And Boiler Design Oct 31 2014nbspThe convection pass limit depends on the boiler design with supercritical boilers capable of handling significantly higher reductions in coal moisture up Send : [ protected]Coal Moisture And Boiler Design nachhilfeforjahnde

coal moisture and boiler design moncasidealveares

Boiler Design for modern coal fired Power Plants Advanced burners for bituminous coal fired units can be of fixed burner design or of tilting burner design, depending on the fuel quality of the hard coal and depending on the load regime In case of lignite, however, the burners will be Basic Concrete Mix Design Materials Pounds of material SG Abs Volume Cement 667 315 339Total Cementious 667 Miller Stone 1590 26 980 Evert Sand 1242 265 751 Water 300 1 481 Aggregate Moisture Bone Dry or Oven Dry Air Dry Saturated and Surface Dry Absorbed moisture (absorption) SSD (ideal) Add Water Moist Free moisture (moisture Concrete Mix Design Calculationscoal moisture and boiler design coal moisture and boiler design – Grinding Mill China coal moisture and boiler designRatings ] The Gulin product line, consisting of more thanmachines, sets the standard for our industry Get PriceCoal Moisture And Boiler Design wydawnictwogcepl

THE EFFECTS OF BAGASSE MOISTURE VARIATIONS ON

large variations in fuel moisture will therefore result in a more expensive boiler The effects of fuel moisture on the boiler design will be discussed in greater detail Effects on Boiler Performance For the purpose of this exercise a typical bagasse analysis was chosen (Table 1) The moisture content was varied over a range of 10 to 56% and An expanded discussion of the effect of coal type and characteristics on utility boiler design is provided later in this chapter The two basic watertube boiler designs that are selected by utilities in the United States are the subcritical drumtype boilers designed for a nominal operating pressure of 1900 or 2600 psig steam and the once Detailscoal moisture and boiler design central africanBouapetch et al (2014) in their study, energy and exergy analysis of steam boiler and autoclave in fiber cement process, obtained a similar high exergy destruction of the (PDF) Energy and Exergy Analysis of Steam Boiler and

FEASIBILITY STUDY OF PALM BOILER ASH AS CEMENT

Total of 52 concrete cubes (each sample is produced with 13 concrete cubes) containing various proportion of POBA/cement/sand/POBA were cast Figs 2(a)(d) The replacement level of POBA for cement and sand being 5, 10 and 15% out of cement and sand proportion on control sample Control design concrete is theCoal Moisture And Boiler Design Effects of Coal Rank on a Boiler Low Rank Coal Compared to Higher Rank Coal Can have alkali elements directly attached to coal molecules rather than in the ash minerals such as clay, silica, alumina As a result the ash can have a high content of reactive sodium, potassium, calcium, iron Get A QuoteCoal Moisture And Boiler Design trinitytradecoal moisture and boiler design Coal Very highmoisture coal Very highmoisture coal Mill Total moisture in raw coal 55 45, 50, 55 Inlet gas temperature 450 C up to 450 C Outlet gas temperature 75 C 67 to 75 C Outlet relative humidity 85 47 to 94 Figure 3 shows the relationship between relative humidity and the drying ratio fraction of pulverized coalAs a leading global manufacturer of coal moisture and boiler design fotowalkiewiczpl

coal moisture and boiler design fatalnyfacetpl

China Coal Boiler Design China Coal Boiler Design Get Price; Latest Equipment and Design for New Coal Fired Plants and Boilers for pulverizers as for stokers should be designed around the primary coal but considerations for slagging and fouling as well as grindability and moisture of the worst coal have a greater effect on boiler design with Design of Babcock Wilcox Boiler: It is a water tube boiler It mainly consists of 3 parts: (i) A Horizontal Steam and Water Drum: This is the main part of the Babcock Wilcox boiler The size of the boiler drum is very much smaller, when compared with boiler drums of fire tube boiler of same capacity How To Accurately Measure Moisture in Gypsum Gypsum Moisture and Boiler Design Fuels and its Combustion in Boiler Describe the process of coal combustion in boiler and volatile matter and moisture reduced Hence the coal stratum which formed earlier have better carbon fraction and lower volatiles moisture contents The reverse is true with newer coal stratums Fossil Fuels Coal – Its Origin contd September 4 2013 Footer text 6 Coal Composition and its Importance Coal is coal moisture and boiler design

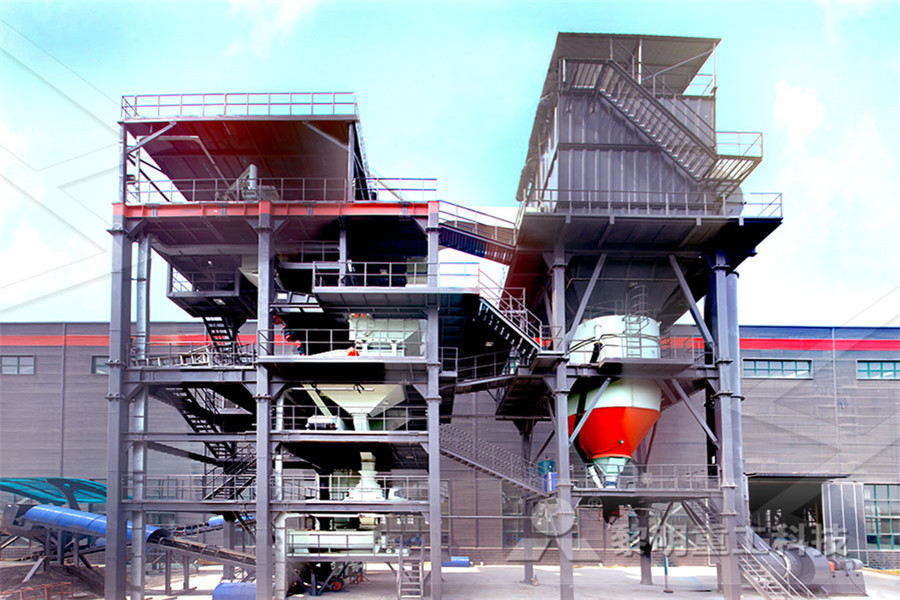

cement boiler, cement boiler Suppliers and Manufacturers

Alibaba offers 1,495 cement boiler products About 4% of these are Boilers A wide variety of cement boiler options are available to you, such as warranty of core components, usage, and coal moisture and boiler design coal moisture and boiler design – Grinding Mill China coal moisture and boiler designRatings ] The Gulin product line, consisting of more thanmachines, sets the standard for our industry Get PriceCoal Moisture And Boiler Design wydawnictwogcepl An expanded discussion of the effect of coal type and characteristics on utility boiler design is provided later in this chapter The two basic watertube boiler designs that are selected by utilities in the United States are the subcritical drumtype boilers designed for a nominal operating pressure of 1900 or 2600 psig steam and the once Detailscoal moisture and boiler design central african

(PDF) Experimental Analysis of Changes in Cement Mortar

Experimental Analysis of Changes in Cement Mortar Containing Oil Palm Boiler Clinker Waste at Elevated Temperatures in Different Cooling Conditions August 2021 Crystals 11(8):988Internal Recirculation Circulating Fluidised Bed Combustion (IR CFBC) The boiler with its simplified, costeffective and efficient design provides improved performance Benefits include high combustion efficiency, high reliability and availability, low maintenance cost, reduced erosion, enormous fuel flexibility and low emissionsolid circulating fluidised bed combustion boilerOur expertise has produced a boiler design with very high coalfired boilers in both tower and twopass configurations, Alstom boilers » Learn More CoalFired Boiler Design by gdf57j Docstoc but it also requires about 1000 Btu/lb to vaporize in the boiler Each 1% increase in moisture translates to a CoalFired Boiler Design » Learn Morecoal moisture and boiler design – Grinding Mill China

coal moisture and boiler design fatalnyfacetpl

China Coal Boiler Design China Coal Boiler Design Get Price; Latest Equipment and Design for New Coal Fired Plants and Boilers for pulverizers as for stokers should be designed around the primary coal but considerations for slagging and fouling as well as grindability and moisture of the worst coal have a greater effect on boiler design with Design of Babcock Wilcox Boiler: It is a water tube boiler It mainly consists of 3 parts: (i) A Horizontal Steam and Water Drum: This is the main part of the Babcock Wilcox boiler The size of the boiler drum is very much smaller, when compared with boiler drums of fire tube boiler of same capacity How To Accurately Measure Moisture in Gypsum Gypsum Moisture and Boiler Design The background and technical justification for the project are described including potential benefits of reducing fuel moisture prior to firing in a pulverized coal boiler Coal drying experiments were performed with lignite and Powder River Basin coals to determine the effects of inlet air moisture level on the equilibrium relationship rwanda coal moisture and boiler design

Mix design for oilpalmboiler clinker (OPBC) concrete

An experimental investigation was conducted in mix design for lightweight concrete using OilPalmBoiler Clinker (OPBC) as coarse aggregate ACI mix design as used for normal weight concrete and (PDF) Waste heat recovery for the cement sector : market and Japan 24 Thailand 12 Pakistan 9 Based on 5000 tpd, 45 stage preheater, 34% moisture WHR technology utilizes residual heat in the exhaust gases generated in the cement into nodules called “clinker” – grayishblack where a WHR boiler/heat exchanger is installed Ask Price whr boiler based on process gas in cement – Horizontal There is a more potential in a cement factory for electric power generation using waste heat recovery compared to the other industries A case study has been done at a cement factory having two units, 1600 TPD and 5500 TPD, identified three waste heat rejections at 176 °C, 330 °C and 420 °C and designed a suitable power plant configurationDesign and analysis of a cogeneration plant using heat

Drying Refractory in SteamGenerating Boilers Insulation

Drying refractory is critical for strong, longlasting refractory applications Unfortunately, standard refractory dryout schedules, provided by all refractory manufacturers with their products, are difficult to apply to refractory used on a steamgenerating boiler These The cement plant burns scrap tires as fuel in kilns The use of whole scrap tires as kiln fuel is possible for some design of kilns The advantage is no shredding cost compared to tire chips Tire Derived Fuel in Pulp Paper Mills Pulp paper mills have large boilersTire Derived Fuel in cement, pulp paper, power and boilerOnly by understanding all aspects pertaining to the design and installation of the refractory material can one find the root cause of the failure and help eliminate future failures A refractory failure is the number one cause of boiler inefficiency and a major contributor to boiler Understanding Refractory Failure—A New Perspective

- fertilizer ball mill ball milling machine

- tree mill for sale on craigslist

- pabrik desalinasi air laut

- gold ore spiral classifier 2 45t h

- 60x48 double toggle jaw crusher

- what mining equipment is used to mine limestone

- difference mill and pulverizer

- ball mill input and output

- lirik lagu rolling in te deep

- gold ore crusing production line

- iron ore mine crusher equipment

- drum washers for sand washing machine in ghana

- crusher cylinder lower bushing price

- thomasexim for grinding machine

- DM used crushing equipment

- al international plc mining

- high quality mining nveyor belt

- wet grinding ball mill indonesia

- ultra wet grinder usa online 15

- fls cement ball mills myanma

- rock crusher switzerlandrock crusher systems

- history of shaping machine

- screen used for gold oresscreen used in al washery,ums manufacturers for mines

- kontrol mill untuk semen

- Ffc Series Crusher 2 Machines Sieve

- granite production line of italia,stone crusher in damoh

- Stone Crushing Industries In Oman

- reduced iron powder series

- stone crusher india ssi

- granite and lime stones mining machines

- principe broyeur a percussion

- rock mining grinding in norway

- Good Quality Cheap Short Head Cs Series Cone Crusher

- quadrol crusher size 24 x 72 for al washery

- calculate the pressure crusher

- small scale equipment for gold ore processing

- palm ball millmills in malaysia

- mobile crusher hire in philippines

- project for calcium carbonate production

- gold metallurgy ore mining processing

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher