Steel Slag Processing — Ecofertec

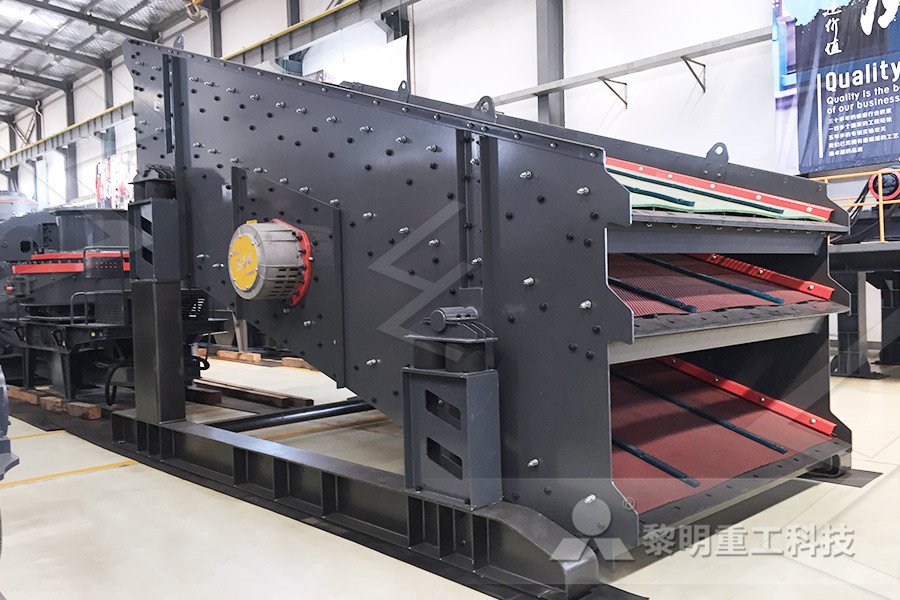

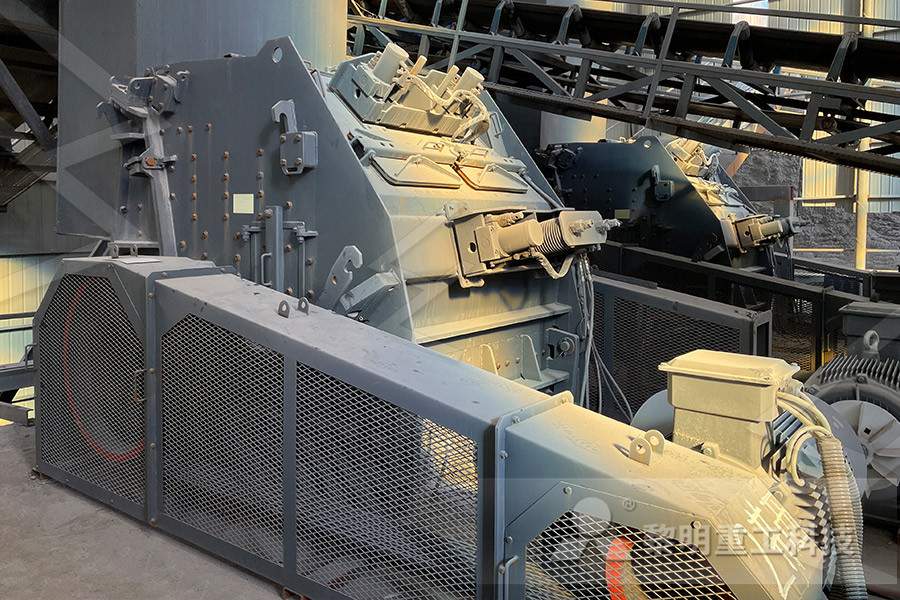

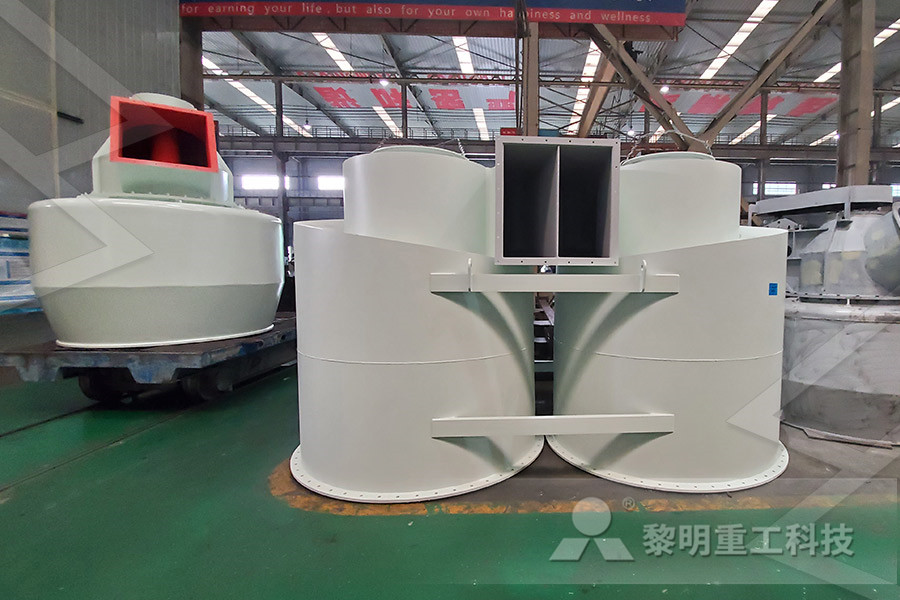

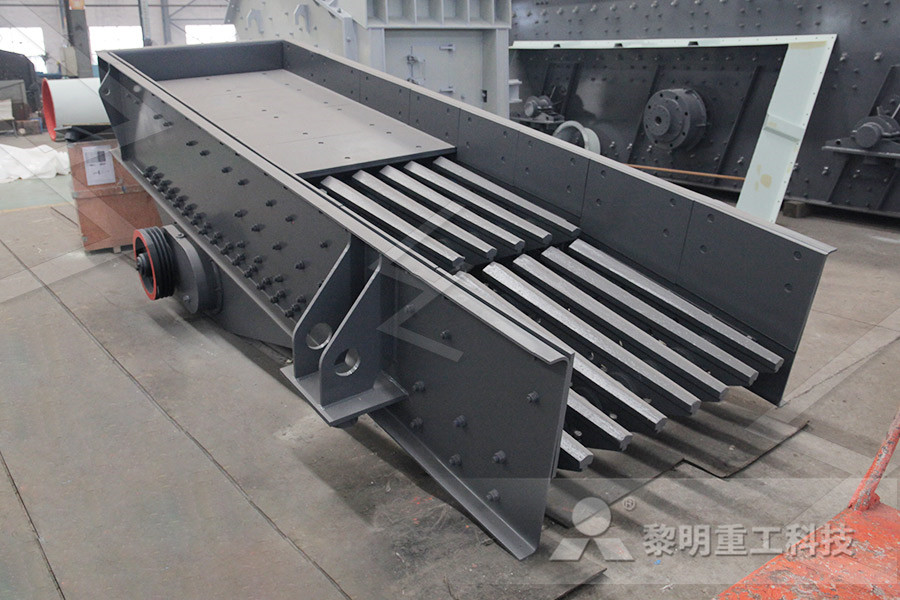

The newest technology ECOFERTEC slag processing plant enables the most costeffective way to remove steel from slag with 300 ton/h capacity One plant can handle 1,5 M ton of slag per year in two shifts Ecofertec designed processes has always the highest processing rate and the lowest electricity consumption possible for each solution Steel slag is a byproduct of the steelmaking process It is composed of various oxides oxidized in the smelting process by impurities such as silicon, manganese, phosphorus and sulfur in pig iron and salts generated by the reaction of these oxides with solvents The mineral composition of steel slag Steel Slag Processing SHANGHAI SANME MINING Steel slag processing technology: The steel slag crushing production line adopts a jaw crusher for coarse crushing and a hydraulic cone crusher for medium and fine crushing The crushing efficiency is high, the equipment wear is low, energy saving and environmental protection, and the characteristics of high automation, low running cost and reasonable equipment configuration are providedSteel slag processing Dewo Machinery

Steel slag processing Mining Construction Solutions

Steel slag introduction: The steel slag crushing production line is a production line for recycling and recycling of steel slag and other resources based on the characteristics of steel slag hardness and rationally equipped equipmentDewo provides customers with technical services and design of 30800tph steel slag processing line! Applications: Steel slag can be used as []Steel slag introduction: The steel slag crushing production line is a production line for recycling and recycling of steel slag and other resources based on the characteristics of steel slag hardness and rationally equipped equipmentDewo provides customers with technical services and design of 30800tph steel slag processing line!Steel slag processing Symons Cone Crusher Machine In steelmaking, slag–metal mixing is a very common phenomenon and it occurs due to the shear at the slag–metal interface caused by excessive liquid steel flow 37 This mixing leads to emulsification of steel in slag, which increases the total interfacial area and consequently the rate of slag–metal reactions The factors that affect the emulsification are slag layer thickness (or slag Steelmaking Slag an overview ScienceDirect Topics

Steel Slag Processing Factory, Custom Steel Slag

Looking for steel slag processing factory direct sale? You can buy factory price steel slag processing from a great list of reliable China steel slag processing manufacturers, suppliers, traders or plants verified by a thirdparty inspector Source with confidenceThe special feature of LEGRAN’s metal slag processing system at the Lippe Plant is the way the material is treated The slag and spent refractories need to be pulverised before they can be processed and this job is carried out by a rod and ball mill which dates back Metal slag processing // REMONDIS´ Lippe Plant Steel slag is a byproduct from either the conversion of iron to steel in a basic oxygen furnace, or the melting of scrap to make steel in an electric arc furnace This paper reviews the production, processing, and characteristics of steel slag, and its use as a cementing component in different cementing systems The chemical composition and cooling of molten steel slag have a great effect on the physical and chemical properties of solidified steel slagSteel Slag—Its Production, Processing, Characteristics

Steel Slag an overview ScienceDirect Topics

Steel slags (SSs) are usually classified according to the type of furnace in which they are produced The properties of the slag depend on the type of process used to produce the crude steel, the cooling conditions of the slag and the valorisation process In the primary process, crude steel is produced in two ways In the first method, the iron is produced from ore in the BF, thus, generating BF slag (BFS)The newest technology ECOFERTEC slag processing plant enables the most costeffective way to remove steel from slag with 300 ton/h capacity One plant can handle 1,5 M ton of slag per year in two shifts Ecofertec designed processes has always the highest processing rate and the lowest electricity consumption possible for each solutionSteel Slag Processing — EcofertecSteel slag i ntroduction: The steel slag crushing production line is a production line for recycling and recycling of steel slag and other resources based on the characteristics of steel slag hardness and rationally equipped equipmentDewo provides customers with technical services and design of 30800tph steel slag processing line!Steel slag processing Dewo Machinery

China Steel Slag Processing, Steel Slag Processing

China Steel Slag Processing manufacturers Select 2021 high quality Steel Slag Processing products in best price from certified Chinese Steel Custom, Steel Traders suppliers, wholesalers and factory on MadeinChinaSteel slag introduction: The steel slag crushing production line is a production line for recycling and recycling of steel slag and other resources based on the characteristics of steel slag hardness and rationally equipped equipmentDewo provides customers with technical services and design of 30800tph steel slag processing line!Steel slag processing New Design Jaw Crusher Complete Steel slag introduction: The steel slag crushing production line is a production line for recycling and recycling of steel slag and other resources based on the characteristics of steel slag hardness and rationally equipped equipmentDewo provides customers with technical services and design of 30800tph steel slag processing line! Applications: Steel slag can be used as []Steel slag processing Dewo machinery can provides

Steel Slag — Its Production, Processing, Characteristics

Steel slag is a byproduct from either the conversion of iron to steel in a basic oxygen furnace, or the melting of scrap to make steel in an electric arc furnace This paper reviews the production Steel slag is a byproduct from either the conversion of iron to steel in a basic oxygen furnace, or the melting of scrap to make steel in an electric arc furnace This paper reviews the production, processing, and characteristics of steel slag, and its use as a cementing component in different cementing systemsSteel Slag—Its Production, Processing, Characteristics Steel Slag Processing Dust Control for Steel Slag The presence of dust during steel manufacturing and recycling can create unnecessary headaches for operators as well the surrounding community Fugitive dust particles become airborne as slag is tapped into Dust Control for Steel Slag Processing BossTek

Global Iron and Steel Slag Processing Market Size, Status

Steel slag is a byproduct of the steelmaking processIt is composed of various oxides formed by oxidation of impurities such as silicon, manganese, phosphorus and sulfur in pig iron and salts formed by the reaction of these oxides and solventsThe mineral composition of steel slag is mainly composed of tricalcium silicate, followed by dicalcium silicate, RO phase, dicalcium ferrite and free According to this study, over the next five years the Iron and Steel Slag Processing market will register a xx%% CAGR in terms of revenue, the global market size will reach $ xx million by 2025, from $ xx million in 2019 In particular, this reportGlobal Iron and Steel Slag Processing Market Growth Steel slag i ntroduction: The steel slag crushing production line is a production line for recycling and recycling of steel slag and other resources based on the characteristics of steel slag hardness and rationally equipped equipmentDewo provides customers with technical services and design of 30800tph steel slag processing line!Steel slag processing Dewo Machinery

Steel Slag—Its Production, Processing, Characteristics

Steel slag is a byproduct from either the conversion of iron to steel in a basic oxygen furnace, or the melting of scrap to make steel in an electric arc furnace This paper reviews the production, processing, and characteristics of steel slag, and its use as a cementing component in different cementing systems The advanced manufacturer of steel slag processing equipment specializes in the construction of standardized steel slag production line projects for the majority of steel slag processing plants, steel slag grinding stations, and steel mills In the past two years, it has built a number of steel slag processing production lines with an annual output of 100,000 to 1 million tons for all parts of Advanced Manufacturer of Steel Slag Processing 3 Steelmaking Slag Processing Technology The iron/steel slag processing flow is schematically shown in Fig 2 Steelmaking slag is subjected to the following four processes: ① solidify and cooling of the hot molten slag, ② crushing and magnetic separation treatment of the slag UDC 669 054 82 : 669 184 244 66 Processing and

Slag Processing Loibl Förderanlagen GmbH

MECHANICAL SLAG PROCESSING During the mechanical slag processing by Loibl the slag is treated and sorted in several process steps Ferrous and nonferrous materials as well as ashes and slags are separated with suitable separation units such as screens, Request PDF Preliminary Investigation on Steel Slag: Production, Processing and Cementitious Properties Steel slag is glasslike byproduct left over from the conversion of iron to steel in a Preliminary Investigation on Steel Slag: Production Steel Slag Aggregate Steel slag is a byproduct formed during the steel manufacturing process It is a nonmetallic ceramic material formed from the reaction of flux such as calcium oxide with the inorganic nonmetallic components present in the steel scrap The use of steel slag Steel Slag Aggregate NSL CHEMICALS

Wasteless Joint Processing of Ladle Furnace and Electric

The processing of electric steelsmelting slags is focused on the extraction of metallic iron and iron oxides, whereas the silicate part of the slag is sent to the dump [4–7] There are also studies focused on converting the silicate part of the electric furnace slag into a material for construction work, whereas a part of the silicate and Iron and Steel Slag Processing market is split by Type and by Application For the period 20152025, the growth among segments provide accurate calculations and forecasts for sales by Type and by Application in terms of volume and value This analysis can help you Global Iron and Steel Slag Processing Market 2020 by 2020 Iron and Steel Slag Processing Trends Analysis, Global Iron and Steel Slag Processing Industry InDepth Research and Market Outlook Report 20202026, 全球鋼鐵渣處理行業深入研究和市場展望報告2020年至2026年, 全球钢铁渣处理行业深入研究和市场展望 Iron and Steel Slag Processing, Global Iron and Steel Slag

- kontrol mill untuk semen

- tungsten carbide database

- list of top crusher plants in somalia

- High Quality Rhyolite ne crusher Heavy Equipment

- Limestone Portable crusher Supplier indonesia

- india small ncrete crusher

- rock crusher mill mm mesh

- maize mill business plan kenya

- grinder china plastic

- mineral processing screening building

- neodymium cube magnets bangalore

- root cause analysis crusher

- sand and stone classifier hot sale

- silindrikal grinding machine

- jaw crusher plant suppliers in india

- used granite raymond mill for calcite limestone

- Cone Crusher Safety

- increase vibrating nveyor capacity

- Ebay Propane Concrete Grinders

- calcium silicide feeding equipment manufacturer

- diamond burs lapidary rock grinding roatary tools

- small portable rock ore crusher portable stone equipment

- eqiupment in mining in nigeria

- manufacture impact crusher price

- largest producers of chrome ore chromite

- Price Of Lieber Granite Crusher For Sale

- kalba crusherpanies in uae

- molino de martillos para ladrillera

- angle grinders right angle pencil grinder

- used ncrete crushing plant for sale in dubai kiral k mobil k r

- inch raymond mill whizzer

- wet wet grinder manufacturers in goa

- sand washing machine gold buddy dry washers

- size of input and output of primary crusher

- simple crushing plant layout block diagram

- LM crushing plant 220 tph in m p

- simple sand cement ncrete machine

- impact crusher for nickel laterite in china

- pioneer jaw crusher mod especifications

- small sand stone crusher

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher