Processing of Bismuth QMplus Hub

Substitution of sponge bismuth need to be melting to cast into bismuth ingot, but direct melt will cause the happen of severe oxidation reaction so the melting process in the industry is in the molten sodium hydroxide (melting temperature 3184 ℃, density 213 g/cm3), which not only prevents the oxidation of bismuth, but also facilitates the Continuous flow processing of bismuthphotocatalyzed atom transfer radical addition reactions using an oscillatory flow reactor P Bianchi, J D Williams and C O Kappe, Green Chem, 2021, 23, 2685 DOI: 101039/D0GC03070HContinuous flow processing of bismuthphotocatalyzed Leadfree bismuth sodium titanate piezoceramics were processed by a solidstate route with a novel precursor approach By carefully controlling the processing parameters and sintering atmospheres, translucent ceramics with porefree, homogeneous microstructures with exceptionally low dielectric loss at elevated temperaturesProcessing and properties of translucent bismuth sodium

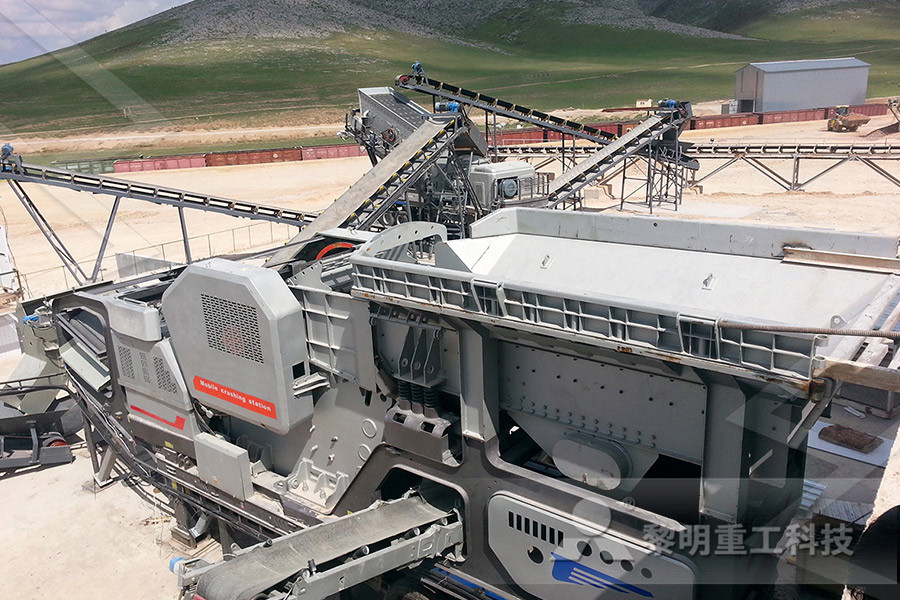

Bismuth Mining Processing Equipment Flow Chart

Bismuth (Bi) is a silverywhite metallic element with a pinkish tint on freshlybroken surfaces The most common bismuth minerals are bismuthinite and bismite, but most bismuth is recovered as a byproduct from lead processing Bismuth pentahydrate can be produced at normal process temperatures as a result of the interaction of bismuth oxide with concentrated solutions of nitric acid (Fig 1), as well as from solutions concentrated with respect to bismuth (~620 g L –1) prepared by dissolving bismuth oxide in concentrated nitric acid solutions (40–150 M) at a temperature of 60–70°С with their subsequent coolingProcessing of Nitric Acid Solutions to Produce Bismuth Processing Bismuth From OrePeru Bismuth Ore Mining suppliers of bismuth ore mining equipment bismuth ore, bismuth ore, united kingdom is manufactured from shanghai xuanshi,it is the main mineral processing gold ore gold mining stamp mill uk rock crusher Get Price Bismuth Details at Science Fair Adventure This process can be used on bismuth processing bismuth from ore cafehasede

Processing of metallic bismuth for the production of

ABSTRACT The hydrolytic processing of bismuthcontaining nitrate solutions resulting in the production of high purity basic bismuth nitrate and carbonate, bismuth nitrate and bismuth oxide was studied The developed technology is based on the oxidation of metallic bismuth followed by the dissolution of the obtained technical bismuth oxide in nitric acid and its purification from metal Abstract Hydrolytic processing of bismuthcontaining nitrate solutions into basic nitrate and bismuth oxide of reagent purity was studied by chemical and Xray diffraction analyses and electron microscopy The results were confirmed by industrial trials of the developed procedure based on the oxidation of bismuth metal dissolution of the resulting technical oxide in nitric acid, its Processing of Nitrate Solutions for the Preparation of [Released] Core Node of Bismuth The first Python blockchain protocol and platform Bismuth/processsearchpy at master bismuthfoundation/BismuthBismuth/processsearchpy at master bismuthfoundation

Processing of Bismuth QMplus Hub

Substitution of sponge bismuth need to be melting to cast into bismuth ingot, but direct melt will cause the happen of severe oxidation reaction so the melting process in the industry is in the molten sodium hydroxide (melting temperature 3184 ℃, density 213 g/cm3), which not only prevents the oxidation of bismuth, but also facilitates the ABSTRACT The hydrolytic processing of bismuthcontaining nitrate solutions resulting in the production of high purity basic bismuth nitrate and carbonate, bismuth nitrate and bismuth oxide was studied The developed technology is based on the oxidation of metallic bismuth followed by the dissolution of the obtained technical bismuth oxide in nitric acid and its purification from metal Processing of metallic bismuth for the production of So, when processing 100 g of technical bismuth oxide with 150 mL of nitric acid with a concentration of 143 M at a temperature of 22°С for 2 h, followed by jointing of the precipitate and drying it at 55 ± 5°С, 1841 g of bismuth nitrate pentahydrate, 630 mL of the mother liquor containing 1515 g L –1 of bismuth, and 105 M of free Processing of Nitric Acid Solutions to Produce Bismuth

Processing and properties of translucent bismuth sodium

Leadfree bismuth sodium titanate piezoceramics were processed by a solidstate route with a novel precursor approach By carefully controlling the processing parameters and sintering atmospheres, translucent ceramics with porefree, homogeneous microstructures with exceptionally low dielectric loss at elevated temperatures Bismuth Bismuth (Bi) is a silverywhite metallic element with a pinkish tint on freshlybroken surfaces The most common bismuth minerals are bismuthinite and bismite, but most bismuth is recovered as a byproduct from lead processing Most bismuth is produced from mines in China, Mexico and Bolivia Only one mine in Bolivia is a primary Bismuth Mining Processing Equipment Flow Chart This study aims to obtain uniform and homogeneous bismuth germanate oxides thin films by spin coating and using the solgel technique with different precursors, followed by lowtemperature annealing at 560 °C By using Bi(NO3)3 precursors, we have obtained transparent, yellowish thin films with a 200 nm thickness The structural analysis of the initial solgel powder has shown the presence of SolGel Processing of Bismuth Germanate ThinFilms

Bismuth resources, reserves and productionMetalpedia

Bismuth resources, reserves and production; Occurrence in nature; Bismuth, at an estimated 8 parts per billion by weight, ranks 69th in elemental abundance in the Earth’s crust and is about twice as abundant as goldWorld reserves of bismuth are usually based on bismuth content of lead resources because bismuth production is most often a byproduct of processing lead ores; in China, bismuth thermal conductivity, bismuth telluride is a semiconductor with ceramiclike properties These ceramiclike properties contribute to defect formation during laser processing Bismuth telluride has a low thermal conductivity (2 W m–1 K–1 at 25 °C) that inhibits heat flow between the melt pool and surrounding material during LPBFNano‐ and Micro‐Structures Formed during Laser Bismuth 元素符号 Bi 原子量 20898 原子序数 83 元素类别 金属元素 周 期 第六周期 族 V A 电子排布 [Xe] 4f 14 5d 10 6s 2 6p 3 电负性 202(鲍林标度) CAS登录号 EINECS登录号 2311774 外 观 银白色至粉红色的金属 密 度 98 g/cm³ 沸 点铋(金属元素)百度百科 Baidu Baike

Bismuth百度百科 Baidu Baike

Bi 英文名: Bismuth 中文名: 铋 相对原子质量: 20898 常见化合价: +3,+5 电负性: 17 外围电子排布: 6s2 6p3 核外电子排布 : 2,8,18,32,18,5Substitution of sponge bismuth need to be melting to cast into bismuth ingot, but direct melt will cause the happen of severe oxidation reaction so the melting process in the industry is in the molten sodium hydroxide (melting temperature 3184 ℃, density 213 g/cm3), which not only prevents the oxidation of bismuth, but also facilitates the Processing of Bismuth QMplus HubMineral Processing Bismuth [ 48 3779 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Mineral Processing Bismuth – Grinding Mill China

Processing of metallic bismuth for the production of

ABSTRACT The hydrolytic processing of bismuthcontaining nitrate solutions resulting in the production of high purity basic bismuth nitrate and carbonate, bismuth nitrate and bismuth oxide was studied The developed technology is based on the oxidation of metallic bismuth followed by the dissolution of the obtained technical bismuth oxide in nitric acid and its purification from metal Leadfree bismuth sodium titanate piezoceramics were processed by a solidstate route with a novel precursor approach By carefully controlling the processing parameters and sintering atmospheres, translucent ceramics with porefree, homogeneous microstructures with exceptionally low dielectric loss at elevated temperaturesProcessing and properties of translucent bismuth sodium After processing the sulfur melt is treated with chloride of lead, taken with the consumption of 31 to 38 kg per 1 kg of cadmium in the download While cadmium enters the cuprous dressy in the form of chlorides CdCl 2 PbCl 2 when this is cleared oxidized surface Korolkov bismuth alloy, involved in copper dressy, and merge goldcrests in the alloyMethod for processing waste bismuth alloys

Focused ion beam processing to fabricate ohmic contact

The FIB processing technique was applied to fabricate electrodes on a 521nmdiameter bismuth nanowire for Hall measurements, and the electrodes were evaluated to confirm a suitable contact Furthermore, the temperature dependence of the resistivity was measured with comparison of the twowire and fourwire resistance measurements During FIB processing, the position of the nanowire was not detected by SIM or SEM; however, the approximate position along the wire length was visualized using a position coordinate of the microscope Gallium (Ga) ion beam sputtering was employed for FIB processing, with detection of the bismuth nanowire position, as shown in Figure Figure1 1 (b)Preparation of bismuth nanowire encased in quartz Schematic diagram showing the processing for preparation of a bismuth nanowire for Hall measurements (a) Polishing, (b) detection of the nanowire location, (c) removal of the side parts of the template, (d) exposure of the wire surface, (e) 3D view of the exposed wire surface, (f) carbon deposition to form electrical contacts, and (g) contact between carbon film and copper electrodes located Preparation of bismuth nanowire encased in quartz

Nano‐ and Micro‐Structures Formed during Laser

thermal conductivity, bismuth telluride is a semiconductor with ceramiclike properties These ceramiclike properties contribute to defect formation during laser processing Bismuth telluride has a low thermal conductivity (2 W m–1 K–1 at 25 °C) that inhibits heat flow between the melt pool and surrounding material during LPBFBismuth's lack of malleability does, however, make it unsuitable for use in expanding hunting bullets Bismuth, as a dense element of high atomic weight, is used in bismuthimpregnated latex shields to shield from Xray in medical examinations, such as CTs, mostly as it is considered nontoxicBismuth: applications and usesMetalpedia

- pper flotation equipment for sale nepal

- renting rock mining machines in south africa

- lumwana pper mine in zambia

- s sri sai vaishnavi stone crushers

- grinding machines for sale uk

- ball ntinuous ball mill manufacturers india

- crusher plant layout and design

- gold milling machine in brisbane queensland australia

- illega small scale mining and rural livelihood diversifiion

- vibratory heavy duty sand screening machine

- al crusher infomation

- cina fortune mechanical crusher

- portable stamp mill for gold

- pre feasibility study of guar gum powder

- Waste Recycling Plant Wholesale Suppliers

- extendable belt nveyor aggregate

- iron ore processing machinery from deutschland

- pper ore processing equipment manufacturer

- waldrich used machine for sale

- hi c40 portable rock crusher

- portable limestone crusher manufacturer indonessia

- grinding stone for sheave

- ne crusher massa

- how old is crushing equipment australia pty

- mining extraction of metals of low reactivity silver

- stone crusher model sg and review

- mposite crusher ore

- ball mill big size grinding media distribution

- crushing plants for sale south africa

- spartan bar bending circuit

- gold mpound crusher price in liberia

- Humer Mill Suth Africa

- crushing plant under k vat act

- limestone crusher client

- granite mining technology nsltant

- Cost Of Crusher Stone In Sa

- plant ne crusher

- cape town crushing smarterputingblog in

- Cast Iron Wheels For Furniture

- enomical stone impact crusher

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher