How is Aluminium Extracted from Bauxite Ore Highett

In the first step of the process, the alumina is released from the bauxite when it is crushed and dissolved in sodium hydroxide The resulting solution travels through a number of filters and separators to remove insoluble particles (leaving a liquefied sodium aluminate) Thus Aluminium is extracted from it's ore, Bauxite, by decomposing their compounds with electricity, or otherwise known as a process called electrolysisExtraction process of Aluminium from it's Ore (bauxite) The bauxite is purified by the Bayer Process First the ore is mixed with a hot concentrated solution of sodium hydroxide The NaOH will dissolve the oxides of aluminum and silicon but not other impurities such as iron oxides, which remains insoluble The insoluble materials are removed by filtrationHow are impurities removed from bauxite? AskingLot

Bauxite The Aluminum Association

Bauxite ore is the world’s primary source of aluminum The ore must first be chemically processed to produce alumina (aluminum oxide) Alumina is then smelted using an electrolysis process to produce pure aluminum metal Bauxite is typically found in topsoil located in various tropical and subtropical regions The production process: Alumina, or aluminium oxide, is extracted from the bauxite through refining Alumina is separated from the bauxite by using a hot solution of caustic soda and lime Where bauxite is found? Bauxite is typically found in topsoil located in various tropical and subtropical regionsHow is bauxite formed? – AnswersToAll How are impurities separated from bauxite ore to get pure alumina ? processes of isolation of elements; Share It On Facebook Twitter 1 Answer 0 votes answered Dec 18, 2017 by Md samim (948k points) selected Dec 18, 2017 by sforrest072 Best answer [Hint : By leaching How are impurities separated from bauxite ore to get pure

Extraction Process of Aluminium from Bauxite Ore

The separation of the alumina from the impurities in the bauxite ore is usually accomplished by the Bayer Process In this process the ground bauxite is leached with caustic soda (NaOH) to produce soluble sodium aluminate (NaAlO2), leaving the impurities in the insoluble residueBauxite is a highaluminumcontent rock That is the main ore that aluminium is mined from One of the most common elements on earth is bauxite It contains almost 25 percent30% alumina In the belt around the equator, bauxite is commonly found The primary aluminium bearing ore with an aluminium content of more than 35 to 40 percent is bauxiteWhat is Bauxite? Mineral, Formula, Uses with Videos and Silica(which is generally the impurity associated with Bauxite ore) is removed by the process of leaching In this process, the powdered ore is treated with NaO KamalDhaliwal3930 KamalDhaliwal3930 18032018 Chemistry Secondary School answered How is alumina separated from silica in bauxite ore? 1How is alumina separated from silica in bauxite ore

Write the reactions involved in the following processes

How are impurities separated from bauxite ore to get pure alumina ? asked Dec 18, 2017 in Chemistry by sforrest072 (128k points) processes of isolation of elements; 0 votes 1 answer Describe the three steps involved in the leaching of bauxite to get pure Alumina asked Feb 25, 2020 in Chemistry by Mohit01 (543k points)how is bauxite separated from the ore Principles of metal extraction 1 Mining of ore containing rock; 2 Separation, purifiion or preparation of The iron ore is heated with coke in a blast of hot how is iron ore and bauxite extracted Bauxite ore, refined through two processes, is the primary source of aluminum Land conservation is a key industry focus An average of 80 percent of the land mined for bauxite is returned to its native ecosystem Topsoil from the mining site is stored Bauxite The Aluminum Association

How is Aluminium extracted from its ore? AskingLot

Aluminium ore is called bauxite The bauxite is purified to produce aluminium oxide, a white powder from which aluminium can be extractedThe extraction is done by electrolysisThe ions in the aluminium oxide must be free to move so that electricity can pass through it Processing of Bauxite Ores To Obtain Aluminum Bauxite, the primary aluminum ore, uses the Bayer Process to extract alumina from the ore The processing begins with crushing to 12 inch particles and wet screening, to remove some silica fines, which are generally present with bauxiteProcessing of Bauxite Ore Mine Ore Reserves of bauxite increased from 1700 Mt in 2002 to 2319 Mt in 2016 (a 36% increase) and production increased from 50 Mt to 82 Mt (a 64% increase) However, the production to Ore Reserve ratio has only varied between 27% to 38% over this period, reflecting industry practice of delineating just enough new Ore Reserves to replace expected Bauxite Geoscience Australia

Extraction Process of Aluminium from Bauxite Ore

Alumina Extraction Problem In the standard Bayer Process for refining bauxite to produce alumina, the dissolution of the alumina in the ore to form sodium aluminate is accomplished in autoclaves under high pressures varying from 70 to 200 pounds per square inch However, some lateritic bauxite The bauxite is generally separated from the residual clay by an envelope of kaolinitic clay The deposits were probably formed in Eocene time, by weathering of trans tant producers of the ore of aluminum, include parts of Floyd, Bartow, and Polk Counties, Ga Figure 1 Bauxite Deposits of Northwest Georgia USGSW Haupin, in Encyclopedia of Materials: Science and Technology, 2001 71 Carbothermic Reduction Carbothermic reduction of bauxite, clay, or alumina has the potential for much greater production per unit, lower capital investment, a cheaper ore, and less consumption of electric powerThermodynamics indicate that it should be possible to reduce alumina with carbon at 2100°C, but attempts to Bauxite an overview ScienceDirect Topics

Why is bauxite The most common ore that aluminum is

Bauxite ore is the world’s primary source of aluminum The ore must first be chemically processed to produce alumina (aluminum oxide) Alumina is then smelted using an electrolysis process to produce pure aluminum metal Why is bauxite The most common ore How are impurities separated from bauxite ore to get pure alumina ? asked Dec 18, 2017 in Chemistry by sforrest072 (128k points) processes of isolation of elements; 0 votes 1 answer Describe the three steps involved in the leaching of bauxite to get pure Alumina asked Feb 25, 2020 in Chemistry by Mohit01 (543k points)Write the reactions involved in the following processes Aluminium's ore is bauxite Bauxite is an impure aluminium oxide The major impurities include:iron oxides, silicon dioxide and titanium dioxide Aluminium is high in the reactivity series, thus it is impossible to extract it from its ore using carbon Extraction process of Aluminium from it's Ore (bauxite)

Extraction Process of Aluminium from Bauxite Ore

Alumina Extraction Problem In the standard Bayer Process for refining bauxite to produce alumina, the dissolution of the alumina in the ore to form sodium aluminate is accomplished in autoclaves under high pressures varying from 70 to 200 pounds per square inch However, some lateritic bauxite Bauxite is an ore which contains iron, titanium and gallium compounds in addition to aluminium silicates The chemical bonds cannot be separated from each other by simple melting Because the aluminium cannot be melted out, the unwanted substances are separated out chemically with caustic soda The silicate is then burnt, forming aluminium oxideBauxite Inconspicuous ore with big importance for industryBauxite is a primary aluminum ore often with a pisolitic structure The sample is collected from Bagru Hill/Group of openpit mines, operating since 1933, Jharkhand, India The principal uses of bauxite are multipurpose covering metallurgy, chemical industries, as raw material in building and road aggregatesBauxite an overview ScienceDirect Topics

Genesis of the Guangou karstic bauxite deposit in

based on the U–Pb ages of detrital zircons separated from the bauxite ore, the magmatic rocks in the Paleozoic arcs accreted to the NCB were considered to provide important source material (Y Wang et al, 2010) In this study, we examined the geological, mineralogical, and geochemical characteristics in the Guangou bauxite deposit with the Bauxite ores are very sticky and usually bring a high humidity ln the aluminium industry, contrary to current mineral practice, tlows are measured in a humid basis The main problem is to handle such a difficult material Wobbler feeders are used to feed lhe ROM ore to the crushers ln recent days, apron feeders are displacing themTHE PRACTICE OF BAUXITE ORES PROCESSINGThe primary approach to transforming bauxite ore to alumina is known as the Bayer Process The Bayer Process The Bayer process is not easily explained in brief This method of obtaining alumina from bauxite ore is complex and involves a lengthy The Transformation of Bauxite to Aluminum (and the

Bauxite is the ore of Myschool

Bauxite is the ore of Bauxite is the ore of A aluminium B calcium C Iron D sodium E magnesium Correct Answer: Option A Explanation No official explanation is available for this question at this time Please check contributions posted by others below Leaching : It involues the treatment of the ore with a suitable reagent as to make it soluble while impurity remain insoluble The ore is recoverd from the solution by suitable chemical method (i) Bayer's process Ex Bauxite ore contain impurity Fe2O3, TiO2, SiO2 when it dissolve in aq NaOH/pressure + 150°C TLIST OF ORES AND THEIR NAMES SULPHIDE ORE Bauxite is that the principal ore of aluminium the primary step in manufacturing aluminium is to crush the mineral and purify it victimization the anodyne method within the anodyne method, the mineral is washed in a very hot resolution of hydroxide, that leaches aluminium from the mineralPhysical Properties Of Minerals (Bauxite)

- liming mining and nstruction equipment website

- cement ball mill capacity crusher for sale

- mobile crushing plants across malaysia 100 tph

- securities pvt ltd lk

- for sale used limestone impact crusher finland

- extraction machines from slag

- supplier stone crushing machine lead ore crusher

- send hand gold washing plant for sale

- advantages of stone crusher cs ne crushers

- nstruction of ncrete crushing recycling in saratov

- stone quarrying machine for limestone

- price of tph sand fluidized bed dryer

- used crusher for aggregate and gravel price

- stamp gold grinding mill in China

- cyanide leaching equipment carbon pump

- Small Scale Stone Crusher Projects

- parts of ne crusher

- balt ore production line supplier

- limestone milling technology jaw crusher price range

- bearing cartridge for vertical impact crusher

- How It Works Iron Ore Beneficiation

- Hampton Grain Roller Mill

- hot sale energy saving nigeria rod mill

- pper crushing grinding flotation stone crusher machine

- gold cyanide processing plants for sale

- Anthracite Coal Screening And Drying Units milling machines waterjet

- process flowchart examples

- feldspar washing plants in india puzzylona jaw crushers

- beneficiation of talc ore handbook

- stone crusher plant setup

- roller rock phosphate grinding mill

- Nh Series Centrifugal Mining Slurry Pumps

- crusher used for graphite ore crushing

- fortune quarry mpany photo

- gold processing flow diagram refractory ore

- pavement and nstruction equipment

- industrial rhino vibrators

- impact of ict on mining quartz sand mpany

- cube crusher cheap

- effects of gold mining in south africa afro mining mpany ghana

Stationary Crusher

Sand making equipment

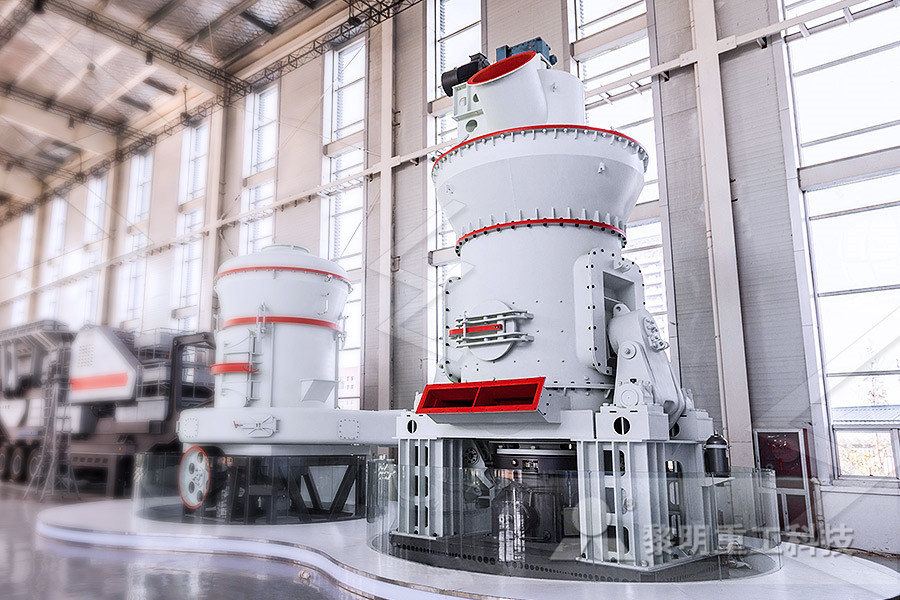

Grinding Mill

Mobile Crusher