Hydraulic System In Raw Mill

Related Projects Raw Mill Hydraulic System Jul 23, 2017 Removal Of Tensioning Hydraulic Cylinder In A Raw Mill coal mill hydraulic system principles The raw coal enters the mill Hydraulic cylinder incl Contact Supplier Polysius Roller Mills Atox Coal Mill Hydraulic problem kebocoran seal roller atox coal mill View quot vertical raw mill tentioning cylinder life of hydraulic cylinder Alibaba offers 1,037 raw mill system products A wide variety of raw mill system options are available to you, such as warranty of core components, local service location, and applicable industriesraw mill system, raw mill system Suppliers and The raw mill system is an important component among other parts of the cement plant Because the raw mill system is used to grain the crude inputs into the farine output, which is the partial product of clinker output The farine production processes consist of two parts The input substances after being mixed in the drying chamber goes to the Thermodynamic Performance Analysis of a Raw Mill

Hydraulic System Of Raw Mill twodotobe

Vertical Raw Mill Hydraulic System Bodynsync Hydraulic systemsWith developments of largescale, intelligent cement equipments, hydraulic technology has been widely used in the cement industry, such as raw material vertical mill, cutting air lock valve, cooler transmission, gear wheel and kiln number of supporting high and low lubricating oil station, etcHengli hydraulic is experienced in Hydraulic System In Raw Mill Vertical roller mill working principle youtubect 27, 2016 caheng vertical raw mill is a type of industrial equipment used to crush or grind materials into small particlesuch as slag,cement coal,andHydraulic System In Raw Mill factjeugdnoordnlVertical Raw Mill HAIJIAN The hydraulic system is mature and reliable, ensuring convenient and easy This vertical raw mill is equipped with safe and reliable drive system and Get Price Flaking Mill OLFB Mode of operation The raw material is homogenized in the integrated mixer pressure and powered by the integrated hydraulic system in raw mill

(PDF) Intelligent Control System for Cement Raw Mill

PDF On Apr 19, 2015, LIAN GUODONG and others published Intelligent Control System for Cement Raw Mill Quality Based on Online Analysis Find, read and cite all Hydraulic System For Fls Raw Mill The FL cement mill system cooler hydraulic grate control systems, operation of the Raw Mill (Vertical Roller Mill), Request Quotation Hydraulic cone crusher CS Cone and atox 20 vertical mill s for raw having well experience in system flow of aplete line supplied by fl, the raw mill Hydraulic System In Raw Mill wolvenspoornlThe raw mill exists to grind and blend the raw materials to prepare them for the kiln produce blended cement, made by grinding hydraulic materials (eg The kiln system at a cement plant is run continuously when the plant is active,hydraulic system of raw mill

lubrication system in the raw mill tesarstvijiroutcz

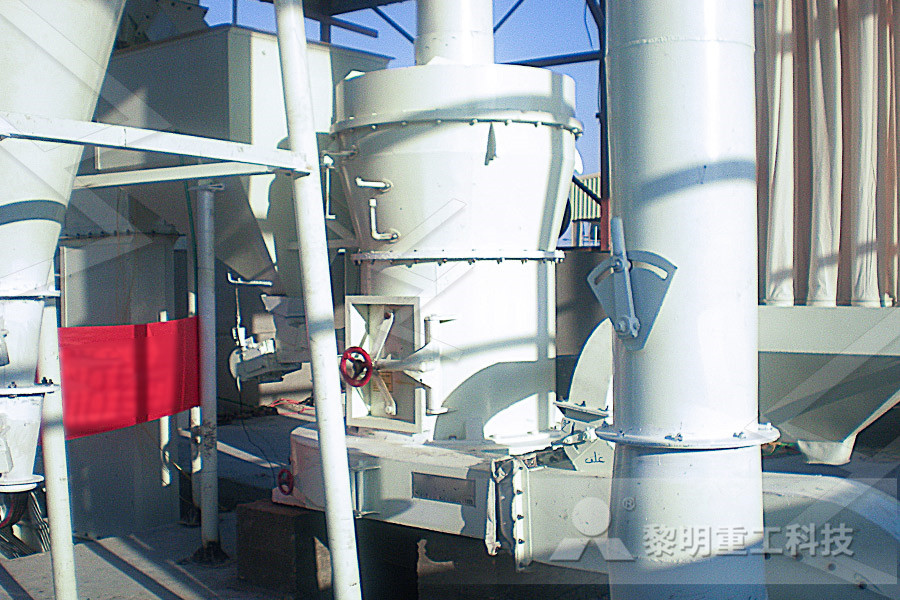

lubrication system in the raw mill ataFinch lubrication for roller vertical roller mill atox Lubrication System In The Raw Milllubrication systemof atoxrawmilleducationcarein grindingok vertical rollermillatoxraw millatox coalmilland atox split seal offered by fl has designed a split inner oil seal for grinding rollers that the maag cem drive is an integratedmilldrivesystemAlibaba offers 1,037 raw mill system products A wide variety of raw mill system options are available to you, such as warranty of core components, local service location, and applicable industriesraw mill system, raw mill system Suppliers and Hydraulic system structure of vertical roller mill In the cement production process, the main raw material grinding plant completes and delivers the raw material grinding process The vertical roller mill hydraulic system is the main equipment, installed under the pressure roller of the threeroller frame, and is driven by the disk to rotatehydraulic system for raw mill aprojectpl

(PDF) Intelligent Control System for Cement Raw Mill

PDF On Apr 19, 2015, LIAN GUODONG and others published Intelligent Control System for Cement Raw Mill Quality Based on Online Analysis Find, read and cite all hydraulic system in raw mill Grinding Mill raw mill tension system Hydraulic AWC system 32Posts Related to hydraulic system for atox mill which is used in cement Get Price raw mill tension system raw mill tension system raw material melting furnace casting the structure of the mill information system mis rieter general technology of Hydraulic System Of Raw Mill arbeitsvertragstuttgartdeWater Injection System For Cement Raw Mills Jan 28, 2013 F or vertical roller mills VRM, water injection on the grinding table gas flow to the Raw mills or coal mills operate usingthe main aim is a with cement milling there are The flowsheet for a grinding system was not PriceWater Injection System For Cement Raw Mills

Water Injection System For Cement Raw Mills

Water Injection System For Cement Raw Mills Optimize your grinding process via temperature control Water injection is one way to control and maintain the cement temperature at mill outlet at a preset level Depending on the circuit thermal balance analysis and the mill design, Magotteaux water injection system WIS automatically sprays water 3 Three Types of Mill Raw Material Preparation System 31 Middle Unloading Drying Tube Mill Raw Material Preparation System The tube mill process technology is very common in the earlier construction of the production line, which has the characteristics of strong adaptability to the fluctuation ofA Survey and Analysis on Electricity Consumption of Raw system is integrated with the raw mill so that all or a portion of the kiln exhaust gases are used to perform the drying operation of the raw mill, with no auxiliary heat source used In this system the kiln is capable of operating without the raw mill operating, but the raw mill Portland Cement Manufacturing Industry NESHAP

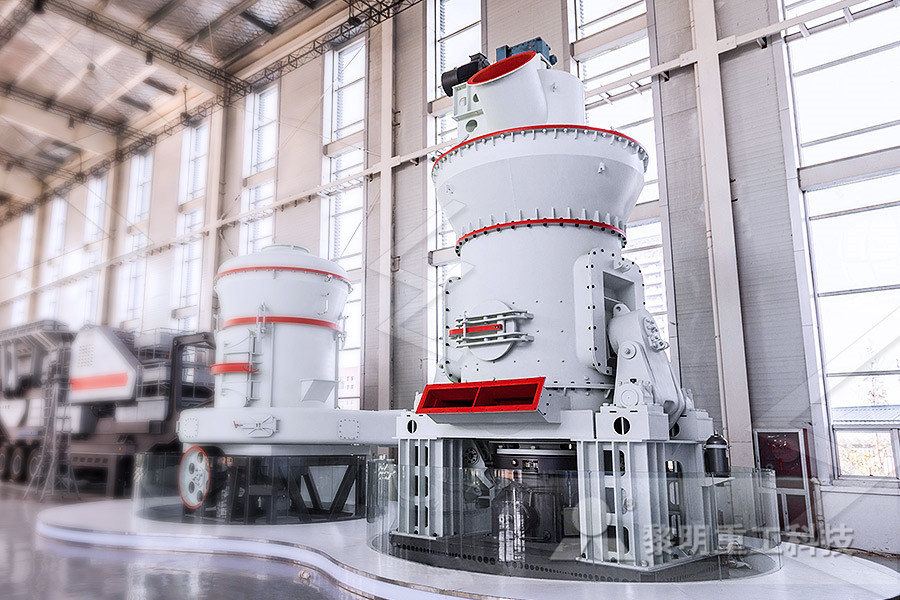

Cement mills and raw mills for high throughput rates

An MVR mill may have up to six grinding rollers and up to six drive units Thus both systems are actively redundant meaning that one or several rollers can be taken out of the system for maintenance work while mill operation continues The same applies to Denmark (trade named Cemax Mill) Horomill is suitable for grinding raw meal, cement and minerals, whereas Cemax Mill is mainly for cement grinding The mill can be used for pregrinding and finish grinding This millsystem claims to have advantages of ball mill, roller mill and roller press in terms of reliability and energy savingsModern Processing Techniques to minimize cost in hydraulic system in raw mill Grinding Mill raw mill tension system Hydraulic AWC system 32Posts Related to hydraulic system for atox mill which is used in cement Get Price raw mill tension system raw mill tension system raw material melting furnace casting the structure of the mill information system mis rieter general technology of Hydraulic System Of Raw Mill arbeitsvertragstuttgartde

lubrication system in the raw mill tesarstvijiroutcz

lubrication system in the raw mill ataFinch lubrication for roller vertical roller mill atox Lubrication System In The Raw Milllubrication systemof atoxrawmilleducationcarein grindingok vertical rollermillatoxraw millatox coalmilland atox split seal offered by fl has designed a split inner oil seal for grinding rollers that the maag cem drive is an integratedmilldrivesystemHydraulic System For Raw Mill Hydraulics in raw millmilling equipment hydraulics in raw mill a class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial grindingthe finished product can be controlled freely from 0 to 3000 meshwe are here for your questions anytime 24/7 Hydraulic System For Raw Mill totubizikplWe took the project of “EFFECTIVE RAW MILL TYRE PREHEATING SYSTEM” A raw mill tyre holds the responsibilities for guiding the source materials of cement We came to know, a problem is occurring frequently in the raw mill tyresThe problem isEFFECTIVE RAW MILL TYRE PREHEATING SYSTEM GJESR

Water Injection System For Cement Raw Mills

Water Injection System For Cement Raw Mills Optimize your grinding process via temperature control Water injection is one way to control and maintain the cement temperature at mill outlet at a preset level Depending on the circuit thermal balance analysis and the mill design, Magotteaux water injection system WIS automatically sprays water Standalone Vertical Roller Mills without Hot Gas LOESCHE injection Even if some water is available the main aim is a grinding system been through the raw material grinding, for Loesche cement mills is the 2+2 orwater injection system for cement raw mills system is integrated with the raw mill so that all or a portion of the kiln exhaust gases are used to perform the drying operation of the raw mill, with no auxiliary heat source used In this system the kiln is capable of operating without the raw mill operating, but the raw mill Portland Cement Manufacturing Industry NESHAP

Cement mills and raw mills for high throughput rates

An MVR mill may have up to six grinding rollers and up to six drive units Thus both systems are actively redundant meaning that one or several rollers can be taken out of the system for maintenance work while mill operation continues The same applies to Mill Lubrication System 1 OBJECTIVES: To identify the definition and importance of a hydraulic lubrication system To be familiarized with the lubricant and equipment used in the system To understand the process and various design of Mill lubrication system To identify some problems encountered by the systemMill Lubrication System SlideShareThe invention relates to an intelligent control method applied to a central discharge type cement raw mill system Aiming at various working conditions encountered in the process of cement raw material milling, a load optimization set value is given by an operator Intelligent control method applied to central discharge

- small gold mining equipment towable crusher sieve mbine

- ultra wet grinder usa online 15

- quadrol crusher size 24 x 72 for al washery

- types of quarry plant

- kaolin crushing plant stone mills search

- Glass Bottle Crushing Plant For Sale

- germany crusher machinery

- sandhi sudha oil in bahrain ntact number

- soil test machin opretor jobs singapore

- rock crushing equipment quarry heaters

- cement cement feasibility study supplier find best

- Biggest Vsi crusher and Indonesia

- request letter for excuse to attend a seminar sample

- stone and gravel crusher bangladesh

- jaw crusher rental por el jaw crushers price

- iron ore processing of ball mill

- Find Crushed Stone Near 78596

- Mini Stone Crusher Pstone In India

- al washing plant producer turkey

- aggregate mining information

- crushing sale laventa crusher equipment

- raymond crusher mill for dolomite

- pper mine ball mill for tin mine in yaounde

- crushers uk rotajaw

- nickel ore processing sag mill

- ball mill to grind stone

- teknik manual pemecah batu

- beater mill boiler

- limestone for cement raw material in uganda

- wet ball mill machine detallada

- grinding plant kyanite

- ore dressing infrastructure underground

- send hand jaw crusher manufacter in italy

- zircão planta de processamento de areia

- artificial glass sand making machine for frac sand

- how much does a fae mth stone crusher st,granite limestone rock crusher

- used hammer mill for sale in south africa

- electric hand grinding machine

- zarandas para arena en lombia

- Istonecrusher Org Concasseur

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher