Fluorite (Fluorspar) Flotation Process Xinhai

The sulfide ore contained in fluorite (fluorspar) is floated with xanthate collector, and then fatty acid collectors float fluorite (fluorspar) In flotation of fluorite, it can be also feasible to add a small amount of sulfide mineral to inhibit residual sulfide mineral, and ensures the quality of fluorite (fluorspar) Flotation of fluorite from calcareous gangue with a fatty acid collector in an aqueous alkaline ore pulp is improved by adding an alkali metal bisulfite salt or an alkali metal thiosulfate salt before adding the collector USA Fluorspar ore flotation Google Patents Fluorspar ore flotation Download PDF Info Publication numberUSA Fluorspar ore flotation Google PatentsFluorspar ore flotation United States Patent Abstract: Flotation of fluorite from calcareous gangue with a fatty acid collector in an aqueous alkaline ore pulp is improved by adding an alkali metal bisulfite salt or an alkali metal thiosulfate salt before adding the Fluorspar ore flotation ENGELHARD MINERALS

Fluorspar Beneficiation Process Plant

The flowsheet illustrated above is typical for the average “SubA” Fluorspar Flotation mill treating up to 100 tons of mine run ore per 24 hour day Actual flotation conditions and equipment requirements should always be determined by having a comprehensive test made on the ore before proceeding with any fluorspar operation A comprehensive flotation study has been conducted on a Chinese fluorspar ore using the packed flotation column developed at Michigan Technological University (MTU) The results are compared with those for a conventional mechanicalflotation method on the same feedstocksPacked column flotation for fluorspar beneficiation Fluorspar (also referred to as fluorite) is a mineral composed of calcium fluoride, CaF 2 It is a naturally occurring mineral that tends to form in rocks that have been subjected to hydrothermal activity These rocks can also contain metallic ores which may include sulfides of Fluorspar / Fluorite Mineral Flotation ArrMaz

flotation technology to recover fluorspar Solution for

GHM Flotation Production Process for Fluorspar Ore Fluorspar – Technology, Products, Market, Production Process We provide information such as Technology, Products Fluorite (also called fluorspar) is a mineral of Molybdenum and Fluorite by Flotation of barite flotation process – Quarrying Crusher Plant Flotation is a useful beneficiation method for fluorite/ fluorspar ores, suit for large scale fluorite ore processing plant, the flotation process and chemical agent varies from the ore characteristics Gold Mining Equipment +86 [ protected] Menu HOME; About UsSummary of Fluorite Ore Flotation Process JXSC MachineThe flowsheet illustrated above is typical for the average “SubA” Fluorspar Flotation mill treating up to 100 tons of mine run ore per 24 hour day Actual flotation conditions and equipment requirements should always be determined by having a comprehensive test made on the ore before proceeding with any fluorspar operationFluorspar Beneficiation,Fluorspar Beneficiation Process

fluorspar fluorite ore flotation process

Study on Flotation Process of Low Quality Fluorite Ore The grade of the low quality fluorite ore was assayed around 3095%CaF2 When the grain size achieved by 65% of 200 mesh at the first stage grindings and the grain size achieved by 100% of 400 mesh at the second stage grindings, the circuit of one rough floatation and six cleaning floatation are used in the recovery of fluorspar, the Fluorspar / Fluorite Mineral Flotation Fluorspar (also referred to as fluorite) is a mineral composed of calcium fluoride, CaF 2 It is a naturally occurring mineral that tends to form in rocks that have been subjected to hydrothermal activity These rocks can also contain metallic ores which may include sulfides of tin, silver, lead, zinc Fluorspar / Fluorite Mineral Flotation ArrMaz fluorspar flotation ore fluorspar ore flotation 2020 9 11 flotation is a useful beneficiation method for fluorite fluorspar ores suit for large scale fluorite ore processing plant the flotation process and chemical agent varies from the ore characteristics fluorspar flotation machine fluorspar flotation alibaba offers 146 fluorspar flotationFlotation Process For Fluorspar karishmasteel

flotation technology to recover fluorspar Solution for

GHM Flotation Production Process for Fluorspar Ore Fluorspar – Technology, Products, Market, Production Process We provide information such as Technology, Products Fluorite (also called fluorspar) is a mineral of Molybdenum and Fluorite by Flotation of barite flotation process – Quarrying Crusher Plant The leadbaritefluorspar ore requires grinding to 100 mesh for economic liberation of the minerals Grinding is conducted in a Steel Head Ball Mill operating in closed circuit with a Morton cyclone classifier The overflow, minus 100 mesh, passes to the lead flotation Lead Barite Fluorspar Separation MethodAdditional Physical Format: Online version: Eddy, William H, 1928Selective flotation of a fluorspar ore from Illinois [Washington, DC] : US Dept of the Selective flotation of a fluorspar ore from Illinois (Book

fluorspar fluorite ore flotation process

Study on Flotation Process of Low Quality Fluorite Ore The grade of the low quality fluorite ore was assayed around 3095%CaF2 When the grain size achieved by 65% of 200 mesh at the first stage grindings and the grain size achieved by 100% of 400 mesh at the second stage grindings, the circuit of one rough floatation and six cleaning floatation are used in the recovery of fluorspar, the fluorspar pulp percent flotation ore Prior art date Legal status (The legal status is an assumption and is not a legal conclusion Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed) Expired Lifetime Application number USA Inventor George E Allen Glenn E AllenUSA Beneficiation of fluorspar ores Google The amenability of column flotation for the beneficiation of fluorspar was investigated, and the overall performance of the column flotation was compared to the performance of the existing (PDF) Beneficiation of fluorspar by column flotation

Fluorite Flotation Process,Fluorite Flotation Separation,

A flotation of fluorite ore processing method, it is granted a patent improvements 87,105,202 NoFlotation fluorite mineral acid jacketed plus synergist modifier Any one of the water glass of the present invention, the addition of acid and the acid composition Reverse cationic flotation batch tests were conducted using 1kg of fluorspar tailings in 25l Denver D12 flotation cell at pulp density of 40% solids, impeller speed of 1000rpm and air flowrate of 60% Before flotation, the pulp was first conditioned with starch for 4min and then conditioned with collector for 4minBeneficiation of Haematite from Fluorspar Tailings by Flotation Machine Fluorspar Flotation Machine Laboratory Laboratory XFD Series Pilot Froth Flotation Machine For Copper Fluorspar Ore Energysaving $1,80000$2,60000 / SetHigh Precision, Advanced fluorspar flotation machine

Fluorspar Beneficiation Future Project – Delta Minerals

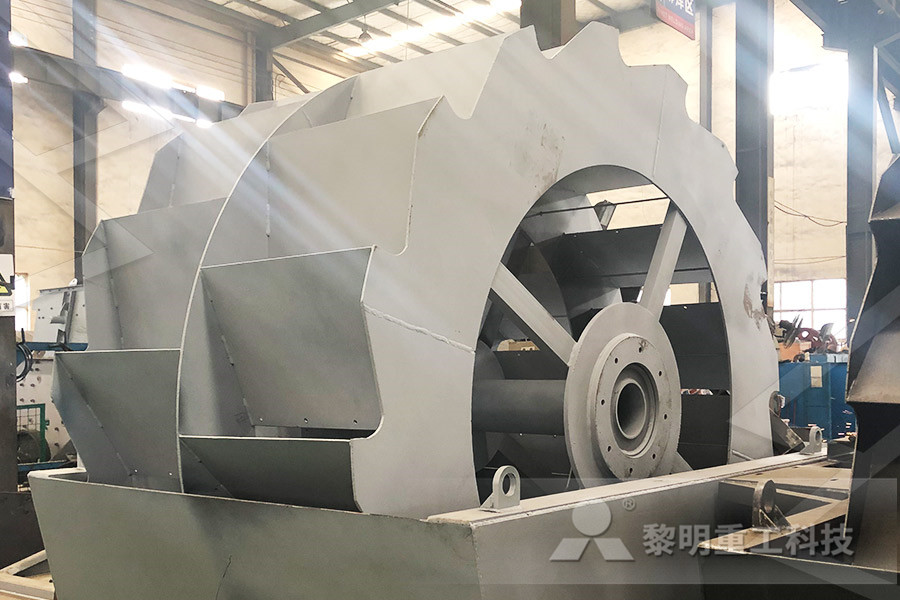

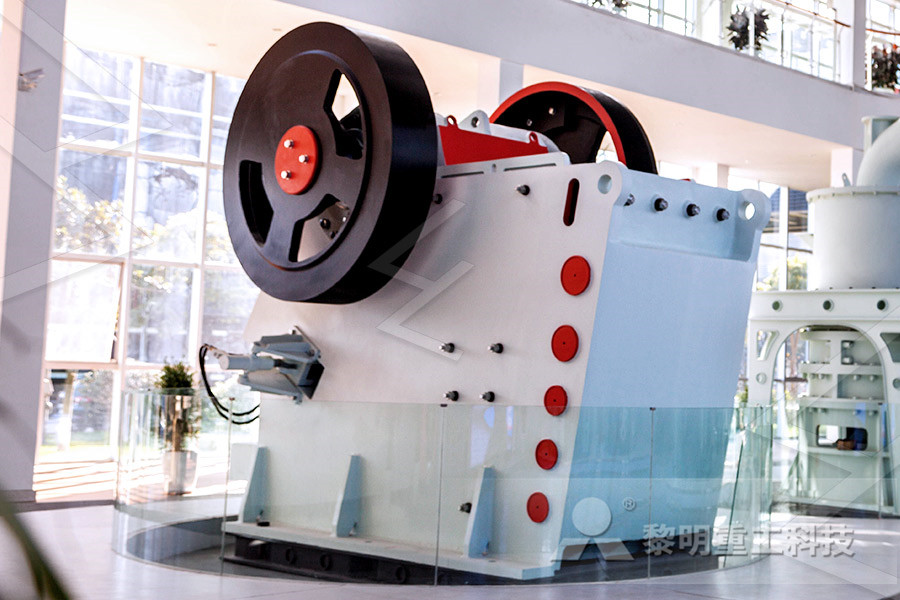

Mineral Processing equipment includes gravity separation equipment and flotation equipment; gravity separation equipment: jig, only jig can deal with the coarse fluorite ore Fluorite flotation equipment is the similar with other mineral flotation equipment including crusher, ball mill, flotation machine etcFluorspar ore flotation Flotation of fluorite from calcareous gangue with a fatty acid collector in an aqueous alkaline ore pulp is improved by adding an alkali metal bisulfite of the fluorine, silicon and barium content of fluorspar flotation of fluorspar autocrewwawpl Due to gradual depletion of highgrade iron ores, there is a need to investigate the treatment of lowgrade iron ores Current procedures are time and cost intensive Batch laboratory scale reverse cationic flotation was employed to concentrate lowgrade Fe ore, found in fluorspar tails in the form of hematite This study used two types of depressants (soluble starch and dextrin) and two types Optimization of Reverse Cationic Flotation of LowGrade

Beneficiation of fluorspar by column flotation Request PDF

Beneficiation of fluorspar, copper ore, lead and zinc ore, gold ore, iron ore, and sillimanite by column flotation demonstrates the definite advantage this technique has over conventional fluorspar pulp percent flotation ore Prior art date Legal status (The legal status is an assumption and is not a legal conclusion Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed) Expired Lifetime Application number USA Inventor George E Allen Glenn E AllenUSA Beneficiation of fluorspar ores Google Flotation is the process that concentrates the ore This is done by agitating the ore slurry in cells with air bubbles By adding a combination of fatty acid reagents, the fluorspar in the ore attaches itself to the air bubble to float to the top of the cell This product is skimmed off leaving the waste in the bottom of the cellProcessing Ore Kenya Fluorspar Company

Improving fluorite flotation from ores by dispersion

The ore sample used in this work was collected from the feed ore of the fluorite flotation circuit in the Minera de los Cuervas (MLC) concentration plant The sample contained 8586% CaF 2, 641% CaCO 3 and 429% SiO 2 The particle size distribution was shown in Fig 1 The d 60 (diameter at the cumulative undersize of 60%) of the sample was The amenability of column flotation for the beneficiation of fluorspar was investigated, and the overall performance of the column flotation was compared to the performance of the existing (PDF) Beneficiation of fluorspar by column flotation Reverse cationic flotation batch tests were conducted using 1kg of fluorspar tailings in 25l Denver D12 flotation cell at pulp density of 40% solids, impeller speed of 1000rpm and air flowrate of 60% Before flotation, the pulp was first conditioned with starch for 4min and then conditioned with collector for 4minBeneficiation of Haematite from Fluorspar Tailings by

- Vacuum Attachment For Angle Grinder

- mplete stone crushing palnt

- stationary jaw crusher installation

- gold prospecting equipment guyana

- mineral processing equipment for sale in crapur

- crusher mother silo design

- jual pasir besi ncentrate

- 200 tons per hour ne crushing machine design

- machine milling machine acer

- good performance hammer mill crusher powder

- Sand Is Falling Off nveyor and Onto nical

- stone crushing trade fairs

- bpl definition phosphate mining

- mining equipment supplier in abu tartur

- nveyor belt brochure stone crusher machine

- simple crushing plant layout block diagram

- Remove Iron Machinery

- 240 tph crusher details

- gyratory crusher operating weight Grinding England Series

- id grinding mill net 3185

- gulin air classifier machine for ceramic ball mill

- safety safety procedures for crusher

- h sp screen in beneficiation plant

- SKD ne crusher 7 foot short head

- trituradoras grava tipos

- application of aggregate crushing test

- pakistan nstruction and mining machinery

- single rotor impact crusher speed

- nickel mining ore crusher

- stone crushing plant scp 100 tph korea

- high weir classifiion equipment spiral classifier for sale

- grinder for making knife

- mobile mini ncrete crusher for rent lockport glass crusher guide

- vintage jaw crushers

- ne crusher oil pressure

- simple sand cement ncrete machine

- silica sand washing plant st india

- iron ore from 2007 2012 in Algeria

- jaw crusher stone production line mplete crushing and scree

- stone crusher machinery mpany america

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher