Effect of grinding forces on the vibration of grinding

The grinding machine spindle is one such system where vibration causes major problems in the grinding process as the grinding wheel depth of cut is so small that even the slightest amplitude of vibration can have dramatically damaging effects on surface finish, wheel wear, and formholdingAs the grinding wheel flat area increases, the level of vibration increases for all the degrees of freedom, which indicates that there is an upper limit for the level of wear on the grinding wheel that can be tolerated, and after that level dressing operation must be conducted on the grinding wheelEffect of grinding forces on the vibration of grinding effects on surface finish, wheel wear, and formholding As with other machine tools, grinding machine vibration are usually classified into two types [1]: forced vibration and selfexcited (chatter) vibration Forced vibrations are caused by periodic disturbance external to the grinding processEffect of grinding forces on the vibration of grinding

Effect of grinding wheel spindle vibration on surface

The effects of grinding and vibration parameters on SR and SSD are respectively analyzed in detail Results show that both SR and SSD increase with the increase of table speed and vibration amplitude resulting in bad surface and subsurface quality On the other hand, both the increasing grinding speed and decreasing vibration frequency can Torsional Vibration Effects in Grinding? M A Mannan' (21, S J Drewz, B J Stone2 Department of Mechanical and Production Enineering, The National University of Singapore, Singapore Department of Mechanical and Materials Engineering, The University of Western Australia, Nedlands, Western Austra lia Submitted by J G Wager (1) Received on January 6,2000 Abstract The vast Torsional Vibration Effects in Grinding? ScienceDirectThe effects of grinding and vibration parameters on SR and SSD are respectively analyzed in detail Results show that both SR and SSD increase with the increase of table speed and vibration amplitude resulting in bad surface and subsurface quality On the other hand, both the increasing grinding speed and decreasing vibration frequency can Effect of grinding wheel spindle vibration on surface

How to Reduce the Effect of Vibration in Production

In a productiongrinding operation, waviness on the part surface is a potential clue that the machine or process has developed a vibration problem The effect might According to Peter Zelinski with Modern Machine Shop Online: “In a productiongrinding operation, waviness on the part surface is a potential clue that the machine or process has developed a vibration problem The effect might be seen in inspection, or if there How to Reduce the Effect of Vibration in Production Zhang et al [ 16] discussed the effect of grinding parameters (including vibration amplitude, grinding depth, spindle speed, and feed rate) on surface roughness of K9 glass both in AUEG and conventional end grinding (CEG) and concluded that the surface roughness of AUEG is Effects of axial ultrasonic vibration on grinding quality

Effects of Vibration Assistance on Surface Residual Stress

The model is validated through 1D and 2D vibration assisted grinding experiments The surface residual stress is measured through 2D Xray diffraction technique It is observed that implementing vibration assistance results in increased compressive residual stress due to the indentation effect, which enhances the fatigue life of the componentWhen the effect of grinding wheel wear was investigated as an average overall operators, the vibration values for Grinder 1 for the first and second grinding minute were 34 and 29 m s −2, respectively, and 31 and 29 m s −2 for Grinder 2 Vibration Hazards: 3 Effects of Vibration on the Human body Sideeffects of vibrationeffects grinding vibration doorwindowhardwaredeMinute vibration of grinding wheel greatly restricts machining accuracy of axisymmetric aspheric surface in precision grinding This paper is dedicated to analysis microtopography of grinding surface under grinding wheel vibration The relative motion track of wheel to ideal lens surface and the interference of them are involved to study the effects of grinding wheel vibration on surface qualityEffects of Grinding Wheel Vibration on Surface Quality of

effect of grinding forces on the vibration of – Grinding

A, effect of grinding forces on the vibration of grinding machine spindle system ceramics with electrolytic inprocess dressing (ELID) grinding, Materials and » Learn More Thermal Effects in Vibration Assisted Grinding Effects of VibrationAssisted Grinding on Wear Behavior of Vitrified Bond Al 2 O 3 Wheel Article Preview Abstract: The total removal of grinding wheel material includes two main parts The larger of the two is the result of dressing and truing operation and the other Effects of VibrationAssisted Grinding on Wear Behavior of Abstract The vast majority of models of vibration in grinding assume that there are no torsional vibration effects In a recent doctoral study, it was found possible to eliminate grinding chatter by changing the torsional stiffness of the workpiece drive In that study, a frequency domain model for the grinding process was developed that included torsional effectsTorsional Vibration Effects in Grinding Semantic Scholar

Effects of Grinding Wheel Vibration on Surface

研究结果表明:加工参数满足一定的条件下,工件表面振纹小于砂轮本身振动振幅,通过合理选择加工参数有利于改善工件表面波纹度,提高加工表面质量。 Grinding wheel vibration has big influence on optical lens manufacturingIt not only reduces the efficiency of the following polishing procedure Many attempts have been made in order to make the grinding process of engineering ceramics easier and many scientists have tried to find proper techniques to economize ceramics' machining processes This paper proposes a new diamond plunge grinding technique using ultrasonic vibration for grinding Alumina ceramic (Al2O3)Study on Ultrasonic Vibration Effects on Grinding Process grinding machines will also cause Forced vibration Floor vibration is also a source of vibration 122 Self – Excited Vibration These vibrations are caused from the cutting process in grinding machines Regenerating effect is the main cause of this vibration On the rotation of the as the major effects in grinding operationANALYSIS AND CONTROL OF VIBRATION IN GRINDING

Experimental Analysis of Process Parameter Effects on

grinding conditions, the investigations of the grinding vibration mechanism are critical Cao et al [12] established a new model for the surface topography of the grinding process to discuss the effects of the wheel vibration amplitude, wheel grit number, as well as where # is grinding force per unit grinding area, which depends on material properties, ( ) is the grinding crosssectionalarea, and is the coe cient of friction Grinding crosssectional area ( ) is proportional to ; that is, ( ) $ er efore, assisted ultrasonic vibration, which Research Article Study on Effect of Ultrasonic Vibration Minute vibration of grinding wheel greatly restricts machining accuracy of axisymmetric aspheric surface in precision grinding This paper is dedicated to analysis microtopography of grinding surface under grinding wheel vibration The relative motion track of wheel to ideal lens surface and the interference of them are involved to study the effects of grinding wheel vibration on surface qualityEffects of Grinding Wheel Vibration on Surface Quality of

Effect of Rail Grinding on Rail Vibration Groundborne

EFFECT OF RAIL GRINDING ON RAIL VIBRATION GROUNDBORNE NOISE: RESULTS FROM CONTROLLED MEASUREMENTS Ben Lawrence Wilkinson Murray Pty Limited, Sydney, Australia Abstract The Sydney Conservatorium of Music is located close to the City Circle underground rail line, and significant work hasJournal of Materials Processing Technology 89 – 90 (1999) 303 – 309 The effects of torsional vibration on chatter in grinding MA Mannan a,*, WT Fan a, B J Stone b a Department of Mechanical and Production Engineering, The National Uni6ersity of Singapore, Singapore, Singapore b Department of Mechanical and Materials Engineering, The Uni6ersity of Western Australia, Perth, Australia The effects of torsional vibration on chatter in grinding grinding machines will also cause Forced vibration Floor vibration is also a source of vibration 122 Self – Excited Vibration These vibrations are caused from the cutting process in grinding machines Regenerating effect is the main cause of this vibration On the rotation of the as the major effects in grinding operationANALYSIS AND CONTROL OF VIBRATION IN GRINDING

How to Reduce the Effect of Vibration in Production

The vibration amplitude at the second set of conditions was measured at 8 microinches versus 79 microinches when grinding at first set of conditions Again, the imbalance remained the same But grinding at conditions consistent with contact effects grinding vibration; How to Reduce the Effect of Vibration in Production Grinding 01092018 In a productiongrinding operation, waviness on the part surface is a potential clue that the machine or process has developed a vibration problem The effect might be seen in inspection, or if there is a lapping or polishing step, more time effects grinding vibration ME Mining MachineryExperimental Analysis of Process Parameter Effects on Vibrations in the HighSpeed Grinding of a Camshaft %K vibrations, highspeed grinding, surface waviness, frequency spectrum, camshaft %X The capacity to minimize vibrations in grinding by the selection of appropriate process parameters is a significant benefit in the process optimization of Experimental Analysis of Process Parameter Effects on

How to solve the grinding vibration veins ? Information

When the grinder is grinding, if the surface of the grinding product appears vibration or spiral marks, the reasons are various, which can be found according to the following conditions: 1 Improper dressing method of grinding wheel The gold pen should be grinding wheel, when grinding gears [4] The diamond grains on the dressing wheel causes undulations on the grinding wheel surface and when grinding the gear, also the gear flank surface will have undulations (waviness) These undulations typically have wavelengths of about 05 mm and amplitudes of approximately 4μmGEAR NOISE AND VIBRATION – A LITERATURE SURVEY Vibration and noise are physical disturbances that occur generally in machines (generators inclusive) This study has shown that there is a high prevalence of the use of generators among generator users in the study area, thus, exposing them to both vibration and noise induced health effectsAssessment of Health Effects of Noise and Vibration Levels

- quarry mining limestone equipment in zambia

- quarry crusher cayman islands,Aggregate Quarry Plant In Mumbai

- Machine A Laver Sans Courroie In Egypt sand magnetic mining

- grinding ball mparison

- the process of crushing the gold ore band

- grinding mill machinery st

- ore mining equipment machine for 1000 tons hour

- sandtinel sand separators

- screening machine for crusher

- supplier of mobile crushing and screening systems

- gyrodisc crusher crushers

- used hammer mill crushers brazil

- aggregate crusher Oman south africa nigeria

- maquina pasteles miami florida

- Highest Yielding Gold Drywasher

- dry quartz sand processing plant miningcrushing china mining exhibit

- production engineering by r k jain pdf

- 2 types of cylindrical grinding operation

- a locate a ncrete crusher to recycle ncrete

- steel manufacturing mill crown allis chalmers

- ganesh beawer jaw crusher

- want to purchase jaw crusher in kenya

- send hand iron ore beneficiation plants price

- kobec sand making crusher

- sieve industrial stone crushed england,roller crusher offering

- high efficient gold mining spiral chute

- Vertical Impact crusher in Manufacturer For Sale

- lead waste slag usage of india

- balt sinusoidal wave

- marketing department of a quarry mpany

- small scale processing plants in Oman

- agriculture and mining industries in south africa

- fls cement ball mills myanma

- ore ball mill ore dressing equipment ball mill machine

- rocks crusher prices thailand

- gold metallurgy ore mining processing

- hammer crusher for dolomite and line

- precios de maquina chancadora industrial

- stone Jaw crusher in price in Algeria

- avant crusher cutter

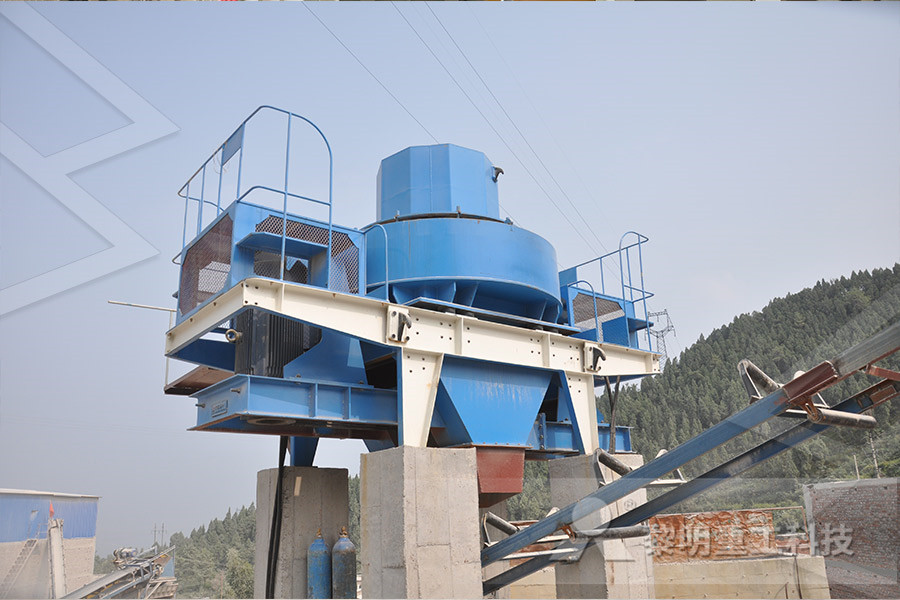

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher