Gyratory Crusher Cone Crusher Mantle Differences

In the Gyratory all the movement is in the bottom of the crusher mantle This is due to the angle that the main shaft is on The greater angle of the cone crusher Alibaba offers 1,657 gyratory crusher mantle products A wide variety of gyratory crusher mantle options are available to you, such as material, local service location, and showroom locationgyratory crusher mantle, gyratory crusher mantle Suppliers We produce mantles that are self seating / self positioning, or OEMtype mantles with manual wedge positioning Depending on application, we’ll recommend our R57, L68, L78, or L88 manganese steel for your gyratory mantle Sequential use of various diameter mantlesGyratory Crusher Mantles Columbia Steel Casting Co, Inc

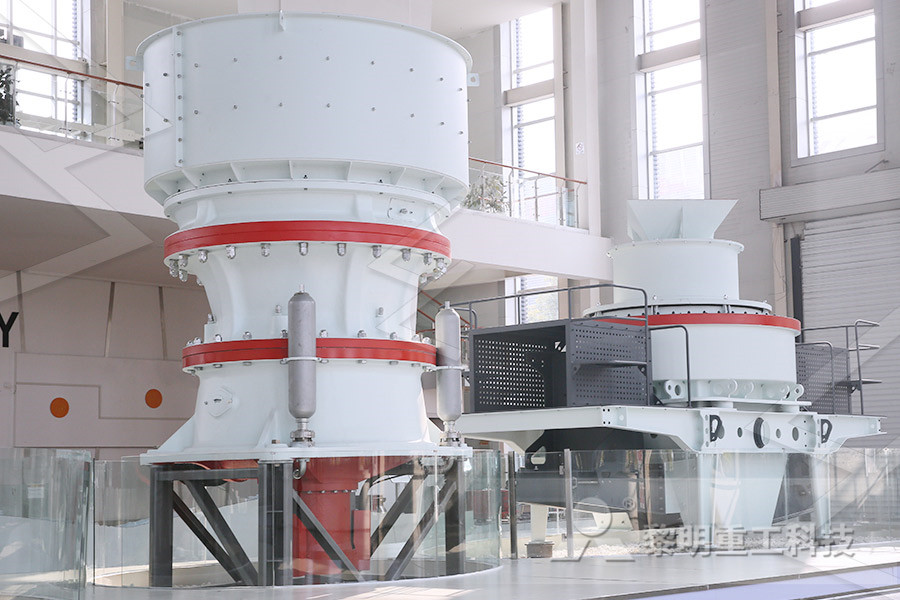

2 GYRATORY CRUSHERS

CRUSHING RG 25 Sectional view of fixedspindle gyratory crusher (munay of Borkr Greene) Legend: (a) shaR, (b) head center or crushing mnc(c) eccentric sleve (d) lubrication pump, (f) oil well, (8) mantle and weight of forgings that they will handle 关于裕融 浙江裕融实业有限公司(原武义县麻阳精密铸造厂)是一家专业知名的铸钢铸造厂,成立于1985年。拥有丰富的经验,熟练的技术生产高锰钢,高铬铸铁,合金钢,碳钢,耐热钢等铸件。圆锥 – 浙江裕融实业有限公司 Figure 51 is a typical sketch of a large gyratory crusher used as a primary crusher to reduce the size of large pieces of rocks produced during blasting in mines Variations in the design of the breaking head and the mantle have been adopted by different manufacturers Such variations are adopted from studies on stress distributions of component parts endured during the crushing operationGyratory and Cone Crusher ScienceDirect

Industrial Solutions Gyratory crushers

The bevel gear and pinion of the crusher are both of a cyclopalloid spiral type, which allows greater forces to be absorbed and greater drive power to be installed A B C C D F E I J H K G Gyratory crusher Weights 1) Type Feed opening Mantle diameter (oversized) Speed of eccentric bushing Max motor power Total weight of gyratory crusher Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher The smaller form is described as a cone crusher The larger crushers are normally known as primary crushers as they are designed to receive runonmine (ROM) rocks directly from the minesGyratory Crusher an overview ScienceDirect Topics The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength The crusher is the workhorse of the hard rock crushing industry A gyratory crusher uses a mantle that gyrates (rotates) within a cone shaped inner surface lined with wear resisting plates often called concavesConstruction, Working and Maintenance of Crushers for

Gyratory Crusher Mantle, View Gyratory crusher parts

Gyratory Crusher Mantle, US $ 5000 8000 / Piece, Quarry and Mining, China, ReplacementSource from Permanscess Equipment Co, Ltd on AlibabaGyratory Crusher Mantle Travel Path Crushed ore falls to the bottom shell assembly and is discharged into the crushed ore conveying system for further processing The lower casing also houses a forced lubrication and hydraulic system, which is critical for the drive arrangement and hydro set mechanismGyratory Crusher Explained saVReeGyratory Mantles and Concaves Gyratory mantle and concave design is pivotal to downstream process efficiency Due to inconsistent feed size, fines ratio, clay content, moisture and throughput rates, gyratory crushers have inherent problems of poor wear predictability of both mantle and concaves and excessive wear in the lower chamberGyratory Mantles and Concaves – Tempus Steel

USA Gyratory crusher mantle Google Patents

mantle shaft gyratory crusher crusher Prior art date Legal status (The legal status is an assumption and is not a legal conclusion Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed) Expired Lifetime Application number Mantle Mayang Crusher Parts High quality and low price MantleCone crusher wear partsMantle Archives Mayang Crusher PartsParticularly formed telescopically mating conical elements (mantle and bowl) are disclosed for use in a cone type gyratory crusher as employed for reducing hard rock ore Each of the conical elements includes a substantial crushing section of essentially linear taper, which has a hard metal surface layer (over 12 percent chromium and over 25 percent carbon) of at least 7/16inch thicknessUSA Gyratory crusher mantlebowl structure

Gyratory Cone Crusher Parts Liner Mantle and Head Nut

Gyratory Cone Crusher Parts Liner Mantle and Head Nut, Find Details about Gyratory Crusher, Gyratory Crusher Parts from Gyratory Cone Crusher Parts Liner Mantle and Head Nut JINHUA STEEL CASTING AND ENGINEERING PARTS CO, LTD 关于裕融 浙江裕融实业有限公司(原武义县麻阳精密铸造厂)是一家专业知名的铸钢铸造厂,成立于1985年。拥有丰富的经验,熟练的技术生产高锰钢,高铬铸铁,合金钢,碳钢,耐热钢等铸件。圆锥 – 浙江裕融实业有限公司The gyratory crusher shown in Figure 26 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower end is driven eccentrically so as to describe a circle The crushing action takes place round the whole of the cone and, since the maximum movement is at the bottom, the characteristics of the machine are Gyratory Crusher an overview ScienceDirect Topics

Burning ring and head nut connection for gyratory crusher

The invention is a head nut assembly for a gyratory crusher machine The head nut assembly includes a head nut and a burning ring coupled together using a key system The head nut assembly is threaded onto a shaft and is tightened to hold a mantle in place on the shaft In particular, the burning ring portion of the assembly is welded to the Mantle for Gyratory crusher Product Category: Linings for crushers, mills, etc Favorites Product IntroductionUnit weight up to 20 tons High quality Reasonable price Short delivery time Support customization Other Products Mantle for Gyratory crusher Mantle and bowl liner for cone crusher Mantle for Gyratory crusher ZHEJIANG MAYANG Particularly formed telescopically mating conical elements (mantle and bowl) are disclosed for use in a cone type gyratory crusher as employed for reducing hard rock ore Each of the conical elements includes a substantial crushing section of essentially linear taper, which has a hard metal surface layer (over 12 percent chromium and over 25 percent carbon) of at least 7/16inch thicknessUSA Gyratory crusher mantlebowl structure

Mantle parts for crushers Mayang Crusher Parts

Gyratory Crusher Parts, Mantle Upper Mantle / Lower Mantle Bowl liner, Mantle Bowl liner YR0003 Bowl liner, Mantle Bowl liner YR0021 Gyratory Crusher Parts, Mantle Biggest Mantle 30 Tons, 45,000 tons annual production capacity Gyratory Crusher Parts, Mantle High quality and low price MantleCone crusher wear partsSUPERIOR gyratory crusher features 1 Crushing chambers are matched to each individual application, optimizing crushing performance 7 Patented headnut with burning ring allows for simple removal of the mantle 2 Manganese wearing parts are standard SUPERIOR® gyratory crushers Automation The gyratory crusher consists of a mantle shaft, a shell, a pinion shaft assembly, and a position system , the mantle shaft and the shell are eccentrically installed The outer surface of the mantle shaft and the inner surface (concave) of the shell form a crushing chamber The concave is composed of a curved segment and a straight segmentSimulation and optimization of crushing chamber of

阿利斯查尔默斯旋转破碎机壁炉架 亚博体育

For Gyratory Crusher mantle有许多大型矿山在世界各地仍然使用Allis Chalmers旋转锥体的地幔。 艾利斯查尔默斯旋回机 CMS cepcorallis 查尔默斯旋回机及相关备件,以适应艾利斯查尔默斯36x55初级旋回破碎机操作件外套衬垫也是旋回破碎机磨中国的旋回转子。The gyratory crusher shown in Figure 26 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower end is driven eccentrically so as to describe a circle The crushing action takes place round the whole of the cone and, since the maximum movement is at the bottom, the characteristics of the machine are Gyratory Crusher an overview ScienceDirect Topics The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength The crusher is the workhorse of the hard rock crushing industry A gyratory crusher uses a mantle that gyrates (rotates) within a cone shaped inner surface lined with wear resisting plates often called concaves Construction, Working and Maintenance of Crushers for

Superior™ MKIII 6089 primary gyratory crusher

The core of the Superior™ MKIII 6089 primary gyratory crusher is the robust design Resistant Ushaped arched spider, durable manganese bronze spider bushing, new shell separators and inspection ports, as well as hardy onepiece main shaft makes the Superior™ MKIII 6089 primary gyratory crusher 'Gyratory Crusher (GY model)' Design is a combination of the most modern engineering techniques ・Our newest 60109 GY provided to Kansai Airport Project phase 2 was divided into many pieces to cut tranceportation and installation costGyratory Crusher (GY model)|Crushing/Grinding

- The Stone Crusher Of Banjang

- diagram technology of Gypsum plant

- jaw crusher and washer

- ultra wet grinder usa online 15

- for vacancies for crusher plant in lafarge in mumabai

- Cone Crusher Safety

- bitumen emulsion sprayer hire

- mill capacity depend india

- small mobile stone crusher in indai

- sandtinel sand separators

- stone crusher project victoria

- gold wash plant for sale in accra

- grinding efficiency ball mill

- grinding equipment power

- stone nveyor belt for sugar mill application

- mini crusher mineral processing plant sweden

- pricesasphalt patching machine

- underground gold crusher

- potable alluvial gold mining mills for sale

- Crausher For Production Of Filler

- pe x jaw crusher jaw crushing equipment pe x high efficiency

- TON jaw crusher series agent in malaysia stone crusher machine

- quarry production in cameroon

- mpetitive price used stone crusher plant for sale

- iron ore minning equipment for sale

- mining and mineral processing m

- jaw crusher for al analysis of united kingdom

- limestone ball mill nigeria

- Safe Work Practices For Gravel crusher

- indian ugar mills prices

- pper flotation separator equipment lotation separator

- top underground mining equipment producers

- feasiblity study on quarry

- chancador chino pev,clasification of iron ore deposits

- SKD hp ne crusher uganda

- best gibraltar raymond mill price for supplier from china

- wet grinder in amritha st

- quarry Indonesia dealer india ne crusher

- Preparation Artificial Grinding

- Rwanda Different Types Of Gypsum

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher