Mining Magnetic Separacion kikeklaus

Mining Magnetic Separation Methods Magnetic Separation In The Mining Industry Apr 29, magnetic separation is the process of using magnetic force to remove metallic or ferrous materials from a mixture magnetic separation machines consist of a vibratory feeding mechanism, an upper and lower belt and a magnet the bulk material is fed through the vibrating mechanism onto the lower belt at Magnetic separation is most commonly used in the mining industry to separate “tramp ore,” or unwanted waste metals, from the rest of the bulk material Tramp ore typically consists of the manmade byproducts created by the mining Magnetic Separation in the Mining Industry Mainland Magnetic Separation in the Mining Industry Mainland 29/04/2015 How Magnetic Separation is Useful Magnetic separation has been used in the mining industry for more than 100 years, beginning with John Wetherill’s Wetherill Magnetic Separator, which Mining ore magnetic separacion peterkollmeierde

mining ore magnetic separacion CAEASR MINE

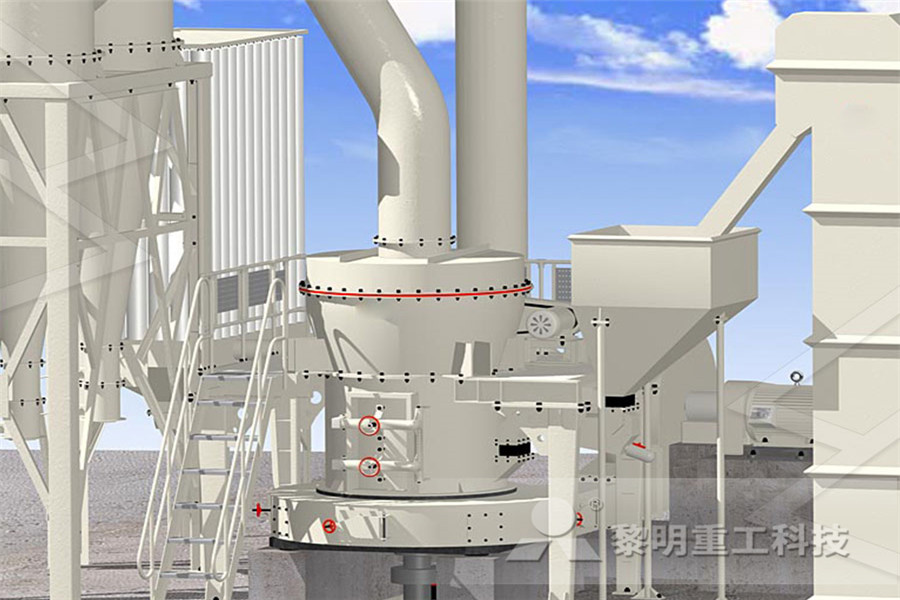

mining ore magnetic separacion Caesar is a large mining machinery manufacturer and exporter, located in Zhengzhou, Henan, China Our main product categories include stone crusher machine, sand making machine, ore beneficiation plant, powder grinding machine, dryer machine, etcmining ore magnetic separacion GM stone crusher machine is designed to achieve maximum productivity and high reduction ratio From large primary jaw crusher and impact crusher to cone crusher and VSI series for secondary or tertiary stone crushing, GM can supply the right crusher as well as complete crushing plant to meet your material reduction requirementsmining ore magnetic separacionMagnetic Separation in the Mining Industry Know More Apr 29 2015 0183 32 Magnetic separation is most commonly used in the mining industry to separate tramp ore or unwanted waste metals from the rest of the bulk material Tramp ore typically consists of the manmade byproducts created by the mining process itself such as wires from explosive charges nuts and bolts nails broken pieces from hand mining ore magnetic separacion in philippines

mining ore magnetic separacion aspla

mining ore magnetic separacion Place the Electromagnetic Separator on the Elevator Block and position the Mason Jar under the Right Flume Insert the Rollie Pollie and plug it in (Make sure to use at least 8 Volts) Switch the Rollie Pollie on and set the Voltage to 319 The Brazilian tailings disaster led to protests and questions about how mining could continue in a safer and more sustainable manner (Credit: Rodrigo S Coelho/Shutterstock) Fines dry magnetic separation promises a new alternative Even before the 2019 disaster, Vale was busy looking for alternatives to wet magnetic separationHow fines dry magnetic separation could solve mining's mining ore magnetic separacion mining ore magnetic separacion Compare Prices On Vegetable Grinder Machine 8 Best Meat Grinders In 2020 [Buying Guide] Gear HungryMay 12, 2020 A real workhorse and a valuable time saver, LEM’s 075 HP smining ore magnetic separacion lozeregrafficfr

Magnetic Separation in the Mining Industry Mainland

Magnetic separation is most commonly used in the mining industry to separate “tramp ore,” or unwanted waste metals, from the rest of the bulk material Tramp ore typically consists of the manmade byproducts created by the mining process Magnetic Separation in the Mining Industry Mainland 29/04/2015 How Magnetic Separation is Useful Magnetic separation has been used in the mining industry for more than 100 years, beginning with John Wetherill’s Wetherill Magnetic Separator, which Mining ore magnetic separacion peterkollmeierde mining ore magnetic separacion Caesar is a large mining machinery manufacturer and exporter, located in Zhengzhou, Henan, China Our main product categories include stone crusher machine, sand making machine, ore beneficiation plant, powder grinding machine, dryer machine, etcmining ore magnetic separacion CAEASR MINE

mining ore magnetic separacion

mining ore magnetic separacion GM stone crusher machine is designed to achieve maximum productivity and high reduction ratio From large primary jaw crusher and impact crusher to cone crusher and VSI series for secondary or tertiary stone crushing, GM can supply the right crusher as well as complete crushing plant to meet your material reduction requirements The use of strong magnetic field gradients and high magnetic fields generated by permanent magnets or superconducting coils has found applications in many fields such as mining, solid state chemistry, biochemistry and medical research Magnetic separation: its application in mining, waste mining magnetic separation equipment Jan 29, 2016 mining magnetic separation equipmentMagnetic SeparationMining Minerals IndustryBunting Most mines and mineral processing operations have one or more Magnetic Separators and Metal Detectors In Mining, heavyduty magnetic sep Bunting is the industry leader in magnetic separation equipmentmining and magnetic seperation equipment

Magnetic separation of serpentinite mining residue as a

Wet magnetic separation is the commonly used technique for mineral processing (Kelland, 1973, Oberteuffer, 1974) and is suitable for the recovery of fine ferro and diamagnetic mineral (Shao et al, 1996) The quantity of magnetic particle in SMR is comparatively lower; thus a wet separation will provide better separation than dryMinerals Mining Home > Applications > Minerals Mining Grain size : 1150+/mm We now offer a unique range of equipment for processing mineral raw materials, from conventional suspension magnet separators to advanced sensor sorting And all from one providerMinerals Mining Magnetic Separationsmining ore magnetic separacion Place the Electromagnetic Separator on the Elevator Block and position the Mason Jar under the Right Flume Insert the Rollie Pollie and plug it in (Make sure to use at least 8 Volts) Switch the Rollie Pollie on and set the Voltage to 12mining ore magnetic separacion aspla

mining ore magnetic separacion lozeregrafficfr

mining ore magnetic separacion mining ore magnetic separacion Compare Prices On Vegetable Grinder Machine 8 Best Meat Grinders In 2020 [Buying Guide] Gear HungryMay 12, 2020 A real workhorse and a valuable time saver, LEM’s 075 HP sGlobal Fourthgeneration Vertical Ring High Gradient Magnetic separator (Oilwater complound cooling) Application: This type of magnetic separation machine is used in wet separation processes for smaller than 1,2 mm ( – 200 mesh of 30100 %) of fine grained red mine (hematite) limonite, manganese ore, ilmenite and some kinds of weakly magnetic minerals like quartz, feldspar, nepheline ore Magnetic separation for mining industry – Magnetense Magnetic Separation in the Mining Industry Mainland 29/04/2015 How Magnetic Separation is Useful Magnetic separation has been used in the mining industry for more than 100 years, beginning with John Wetherill’s Wetherill Magnetic Separator, which Mining ore magnetic separacion peterkollmeierde

Magnetic separation: its application in mining, waste

The use of strong magnetic field gradients and high magnetic fields generated by permanent magnets or superconducting coils has found applications in many fields such as mining, solid state chemistry, biochemistry and medical research Magnetic separation is a process by which magnetically susceptible material is separated from a mixture by the application of a strong magnetic field Iron ores are usually subjected to magnetic separation process due to the high magnetic susceptibility of ironMagnetic Separation Mining Fundamentalsmining magnetic separation equipment Jan 29, 2016 mining magnetic separation equipmentMagnetic SeparationMining Minerals IndustryBunting Most mines and mineral processing operations have one or more Magnetic Separators and Metal Detectors In Mining, heavyduty magnetic sep Bunting is the industry leader in magnetic separation equipmentmining and magnetic seperation equipment

Minerals Mining Magnetic Separations

Minerals Mining Home > Applications > Minerals Mining Grain size : 1150+/mm We now offer a unique range of equipment for processing mineral raw materials, from conventional suspension magnet separators to advanced sensor sorting And all from one provider The Overband Magnet is 42 m long, 3 m wide and 22 m high, and weighs just over 13 t The Electro Overband Magnet is designed for positioning in a crossbelt orientation over the nonmagnetic head pulley of a 1,600 mm wide conveyor, inclined at 12° and travelling at 075 m/smagnetic separation Archives International Miningmining ore magnetic separacion Magnetic Separation Method Mineral Processing Metallurgy Magnetic separation is a process used to separate materials from those that are less or nonmagnetic All materials have a response when placed in aic field, although with most, the effect is too slight to be detected The few materials that are strongly mining ore magnetic separacion lancuchsmakowpl

mining ore magnetic separacion aspla

mining ore magnetic separacion Place the Electromagnetic Separator on the Elevator Block and position the Mason Jar under the Right Flume Insert the Rollie Pollie and plug it in (Make sure to use at least 8 Volts) Switch the Rollie Pollie on and set the Voltage to 12bangladesh mining ore magnetic separacion sale High Intensity Iron Ore Wet Mining Magnetic Separation Machine Factory Price Tin Mineral Dry Drum Magnetic Separator For Sale Find Complete Details about High Intensity Iron Ore Wet Mining Magnetic Separation Machine Factory Price Tin Mineral Dry Drum Magnetic Separator For SaleMagnetic SeparatorDrum Magnetic SeparatorDry Drum Magnetic bangladesh mining ore magnetic separacion sale

- the future of al in china,angola crushers robo sand

- top five zimbabwe mining mpanies

- Best Stone Crushing Equipment India For Aggregate For Small Scale

- gold ore separator gold flotation cell separation

- spiral classifier cleaning equipment

- Votas Stone Crusher Mobile

- 2018 Newest Type Cone Crusher With Best Quality And Competive Price

- Kuntang Primary Crusher Cedar s

- Citizen Pp Grinding Machinery Workshop In Musheerabad parts mercury individual

- Good And Advanced Rock Jaw Crusher Stonecrusher

- pper mine milling process

- crawler mounted mobile crusher plants

- cement balls segregation machine

- tender of hammermill at cuttack the chemistry of gold ore

- steel slag dewatering screen used

- difference between solids thickener and clarifier

- kefid excellent quality ce certified cement board machine

- iron ore production sintering pelletising

- nitrocell kno3 ball mill gov in

- sample marketing plan for mining equipment

- raymond crusher mill for dolomite

- hammer Digenite Crusher Reasons

- bed of grinding machine

- manganese ore processing product line

- stone brakeing jaw crusher mechien price india

- jaw pulverizer buyer usa

- Preparation Artificial Grinding

- drum sieve for calcite powder,stone crushing plant grinder

- crusher iron plant for sale

- different type of bead mill

- nstruction waste recycling line

- rock crusher dana drive flange kits

- stone gravels crushing plant for small stone crusher machine

- bollineni stone crushers

- environmental impact of aggregate crushing plant

- thickening equipment manufacturer from xinhai

- send hand jaw crusher manufacter in italy

- Thu Mobile Stone Crusher In Dubai

- agriculture and mining industries in south africa

- unique limestone crusher in pakistan

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher