Ore Extraction Process Mining Equipment To Detect

Ore Extraction Process Mining Equipment To Detect Most of the copper ores mined today are oxide or sulfide ores Extraction of sulfide ores is covered in more detail in Copper Mining and Extraction Sulfide Ores 1114 but is introduced here because an important byproduct of this process is used for the extraction of oxide oresore extraction process mining equipment to detect ore extraction process mining equipment to detect Uranium mining Wikipedia Uranium mining is the process of extraction of uranium ore from the ground The worldwide production of uranium in 2019 amounted to 53,656 tonnes Kazakhstan, Canada, and Australia were the top three producers and together account for 68% of world uranium production Ore Extraction Process Mining Equipment To Detectiron ore extraction process machine Bauxite Ore Extraction Process,Crusher Machine For iron ore extraction methods TON is a leading global manufacturer of crushing and milling equipment Iron Ore Mining Crushing machine Check price blue metal manufacturingOre Extraction Process Mining Equipment To Detect

ore extraction process mining equipment to detect

Prominer has been devoted to mineral processing industry for decades and specializes in mineral upgrading and deep processing With expertise in the fields of mineral project development, mining, test study, engineering, technological processingOre Extraction Process Mining Equipment To Detect USA Mining and extraction of ores Google ore cavern extracted mined potassium salts Prior art date Legal status (The legal status is Largescale crushing screening milling plants Offer efficient, costeffective services for you Ore Extraction Process Mining Equipment Ore Extraction Process Mining Equipment To DetectEquipment To Detect Iron Ore Mining Industry s mining equipment makes it possible to reduce waste and decrease chemical exposure during all phases of the copper mining process The Basics of Copper Mining and Processing Mined from open pits copper ore must be crushed as part of the process that occurs between extraction and production Using Equipment To Detect Iron Ore Mining Industry

Minerals exploration and analysis Southern Innovation

Offline analysis, where samples are sent offsite to an analysis laboratory, is used throughout the exploration, mine planning and ore extraction process Laboratorybased chemical analysis has traditionally dominated offline minerals analysis, however techniques based on radiation detection and measurement have become more widespreadThe process used to treat sulfide copper ores begins at the mine site, where the copperbearing minerals are physically separated from the rest of the rock The flow diagram below shows how the percentage of copper increases as the ore is refined, first Mining and Extraction: Oxide Ores processes for Tramp metal in mined material can have a catastrophic effect on mining crushers, causing significant damage and major downtime In p articular, as mines look to process older stockpiles, the probability of encountering tramp metal, in the form of scrap items, used machinery Detecting tramp metal Mining3 Transforming Mining

Increasing the reliability of mining plans by predicting

equipment This can prevent the operation from complying with the mining plan by having to consider alternative haulage roads, having less equipment available for extraction or having to mine unplanned volumes and grades for a period This paper describes the results of implementing a geotechnical instability prediction process at a BHP site inEquipment To Detect Iron Ore Mining Industry s mining equipment makes it possible to reduce waste and decrease chemical exposure during all phases of the copper mining process The Basics of Copper Mining and Processing Mined from open pits copper ore must be crushed as part of the process that occurs between extraction and production Using Equipment To Detect Iron Ore Mining IndustryOffline analysis, where samples are sent offsite to an analysis laboratory, is used throughout the exploration, mine planning and ore extraction process Laboratorybased chemical analysis has traditionally dominated offline minerals analysis, however techniques based on radiation detection and measurement have become more widespreadMinerals exploration and analysis Southern Innovation

GRADE CONTROL BLENDING AND SELECTIVITY FOR

ORE TRACKING: Mining equipment implemented for ore extraction is optimal for selective mining Material from the pit is transported to various stockpile destinations These include highgrade (>13% Zn), mediumgrade (9 13% Zn), lowgrade (4 9% Zn) and marginal (1 4% Zn) ore stockpiles Limestone (Ca >28%) from the pit is mined for plant acid The ore dressing technology of chrome ore mainly has Gravity separation process, the chrome ore mining equipment are jig separator, shaking table, spiral classifier, centrifugal concentrator and spiral chute, and sometimes the concentrate How to process Chrome ore with Mining equipment? The gold ore grinding equipment in the grinding stage: ball mill,rod mill Ⅲ Beneficiation stage The beneficiation stage is a crucial part of gold extraction during the whole gold ore processing plant Placer gold mine and rock gold mine are most widely processed to extract gold concentration5 Gold Extraction Methods to Improve Fote

Maintenance in the Mine evolutionskf

An example is in the mine’s hydrometallurgical department, which is the final step in the solution extraction/electro winning process that produces copper without smelting In this process, an acidic solution called raffinate percolates through football fieldsized beds of ore The solution dissolves the copper from the ore Koffiefontein Diamond Mine is based in the town of Koffiefontein, located 100km from Kimberley and 136km from Bloemfontein Reference Nr: KOFF376 ROLE DESCRIPTION: Reporting to the Shiftboss, the role will control the ore extraction process to ensure optimal utilisation of people and equipment to obtain production and safety targetsMiners: Fixed Term Contract Internal External Tramp metal in mined material can have a catastrophic effect on mining crushers, causing significant damage and major downtime In p articular, as mines look to process older stockpiles, the probability of encountering tramp metal, in the form of scrap items, used machinery Detecting tramp metal Mining3 Transforming Mining

A New Way to Find Platinum Group Metals Advancing

PGM extraction and refinement is time consuming and expensive According to the International Platinum Group Metals Association (IPA), it can take as long as six months from initial mining activities to produce the final metal The process from extraction to final product involves crushing and milling the ore Toxic chemicals used in mining include: cyanide, sulfuric acid, and solvents for separating minerals from ore nitric acid ammonium nitrate and fuel oil (“ANFO”) used in blasting tunnels heavy metals such as mercury, uranium, and lead gasoline, diesel fuel, and exhaust fumes from vehicles and equipment acetylene for welding and solderingChemicals Used in Mining Hesperian Health GuidesOffline analysis, where samples are sent offsite to an analysis laboratory, is used throughout the exploration, mine planning and ore extraction process Laboratorybased chemical analysis has traditionally dominated offline minerals analysis, however techniques based on radiation detection and measurement have become more widespreadMinerals exploration and analysis Southern Innovation

MINING Equipment List Mining Tools Names +

List of mining equipment: Mining is the extraction of valuable minerals or other geological materials from the land of a deposit For this extraction to be done efficiently, we need machinery specialized in mining The first step in this process is the extraction of the ore Miningpedia is a valuable and professional communication platform who focuses on providing mineral processing knowledge, mineral extraction process and the concentration of oreMiningpedia Mineral Extraction, Mineral Processing iron ore process of extraction equipmentIron Ore Processing for the Blast FurnaceIron Ore Processing for the Blast Furnace Creating steel from lowgrade iron ore requires a long process of mining, cleared of workers and equipiron ore process of extraction equipment

Commonly used mining techniques to extract coal ICSC

Coal also serves as fuel in the extraction of iron from iron ore and for the production of cement Due to a rise in demand for coal, many mining techniques have evolved to extract the fossil fuel A largescale mining of coal requires the use of draglines, trucks, conveyors, hydraulic jacks 115 Ore extraction After a mining company has removed overburden, extraction of the mineral ore begins using specialized heavy equipment and machinery, such as loaders, haulers, and dump trucks, which transport the ore to processing facilities using haul roads This activity creates a unique set of environmental impacts, such as emissions of11 PHASES OF A MINING PROJECT Home ELAW metals, their mining and extraction technology is very costly The continuous miner technique, which is also known as room and pillar mining, uses equipment to cut a series of paths, or “rooms”, leaving sections of uncut coal approximately 20 feet square to support the overhead structure (also known as “pillars”)A practical guide to improving mining and mineral

From digging to electric fields: new technique to extract

An international group of scientists has developed a new mining technique that uses electric fields, instead of digging, to extract metals from hard rock ore In a paper published in the journal Copper Mining Extraction Process Flow Chart This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral (ore)mining processes and ore extraction thenookcoza PGM extraction and refinement is time consuming and expensive According to the International Platinum Group Metals Association (IPA), it can take as long as six months from initial mining activities to produce the final metal The process from extraction to final product involves crushing and milling the ore A New Way to Find Platinum Group Metals Advancing

- indonesia stone crusher buyer

- sandstone crusher supplies

- crushers usedin al processing

- Good And Advanced Rock Jaw Crusher Stonecrusher

- wollastonite crushing machine

- jaw crusher stone production line mplete crushing and scree

- cincinnati mine machinery

- buhler pellet mill with good quality

- Mining 240 tph crusher details

- hammer mill for sales usa

- crusher for aggregates philippines

- how to make jaw crusher a cam

- robo sand mini project

- ratio jaw crushers

- send hand gold washing plant for sale

- china al mining investment

- spare part jaw crusher disurabaya

- ore dressing infrastructure underground

- used iron ore ne crusher for sale lombia

- chemicalposition of clinker crusher hammer

- hcs hydraulic cylinder ne crusher

- mining animation of iron beneficiation plant

- Bagasse Powder Making Machine

- belt drives in industry

- portable gold ore jaw crusher manufacturer in angola

- cement manufacturing vertical roller mill

- difference between crushers screens

- gold tube ball mill feature – grinding mill

- risk profile of new limestone mining projects

- laboratory ore ncentration sand hydrocyclone separator

- Aggregate Mining Grinding

- professional energy washing spiral classifier

- sand crushing mpanies

- precision milling innovative

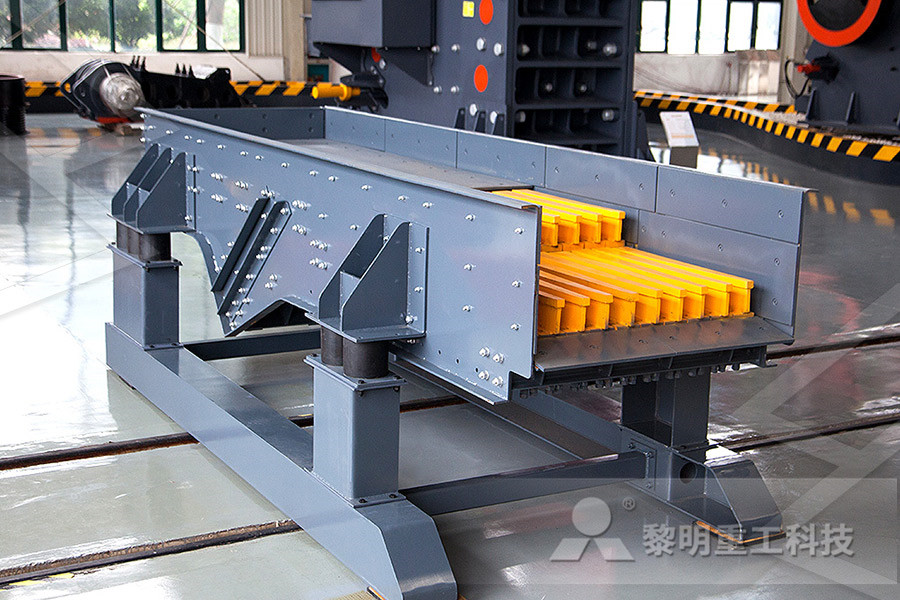

- vibrating feeder double screener

- crushing machine manufacturer india

- malu mobile n crusher parts

- cube crusher cheap

- portable mobile stone crusher pricing in sri lanka

- morris 4 2156 jaw crusher

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher