Copper Leaching Method Metallurgist Mineral

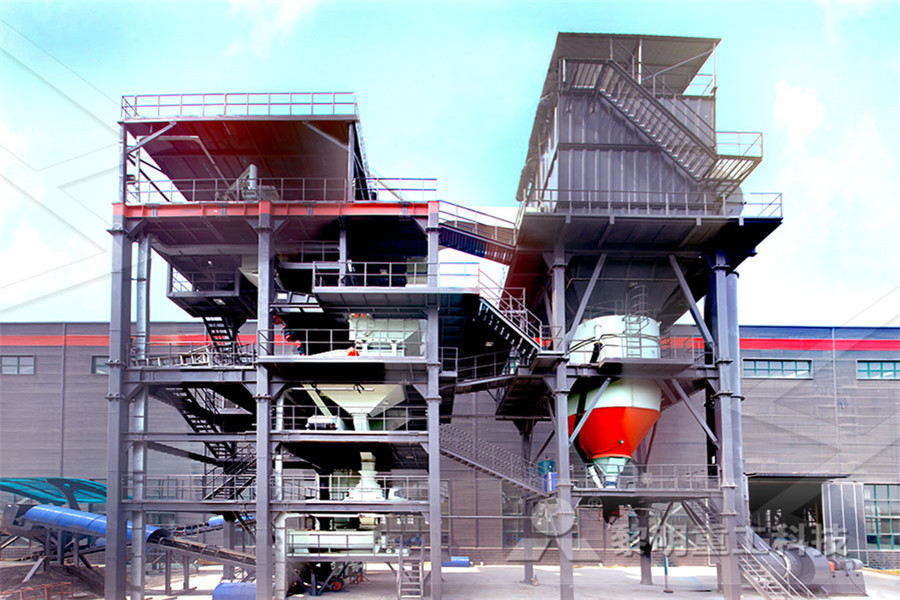

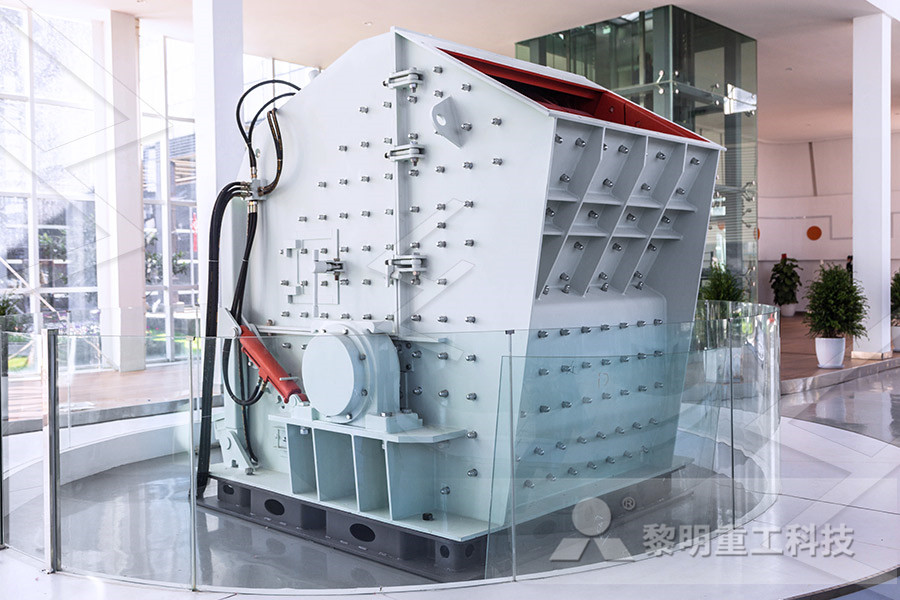

Extraction of copper from suitable ore by leaching methods is generally assumed to cost less than the combined expense of concentration, smelting, and refining, and experimental data tend to confirm this opinion At the ButteDuluth plant, which is handling in excess of 100 tons of oxidized ore daily, the copper is said to cost $0085 per poundCopper Ore Processing Leach Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc Grinding Mill Grinding is the required powdering or pulverizing process when final size of below 2 mm is neededCopper Ore Processing Leach caesarmachineryCopper Ore Processing Leach Copper hydrometallurgy is a branch of metallurgy method to extract copper directly from those difficult to concentrate copper oxide ore Traditional copper hydrometallurgy process typically consists of atmospheric leaching solvent extraction SX and electro winning EW It can produce either copper cathode or copper sulphate crystalCopper Ore Processing Leach postsvstadede

copper ore processing leach tsuefrankowiczepl

Copper ore leaching processing The coarser ore goes to the heap leach, where the copper is subjected to a dilute sulfuric acid solution to dissolve the copper Then the leach solution containing the dissolved copper is subjected to a process called solvent extraction (SX) Acid Leaching Process Flowsheet The method of dissolution by sulfuric acid and ferric sulfate with chemical precipitation by means of scrap or sponge iron appears to offer the best potential for wide application and low costs Its basic chemistry is not complex but its economic application is dependent on handling of materials and solutions by such procedures to insure low operating costs The flowsheet discussed in this study is for treatment of 100 tons per day oxidesulfide copper ore by the leaching process Acid Leaching Copper Ore Treatment Method processes using dilute sulphuric acid The first process, vat leaching of highgrade copper oxide ore followed by EW of copper from the leach solution, produced low quality copper cathode at relatively high cost In 1968 the tonnage of highgrade oxide ores was decreasing and vat Copper recovery using leach/solvent extraction

Leaching of Copper Sulphides SAIMM

Atmospheric Leach Atmospheric leaching of copper sulphides is carried out in challenging conditions of elevated temperature, low pH and high chloride ion concentrations In addition, the reactors need to optimally cater for a threephase reaction dynamic in which gaseous oxygen, solid copper concentrate and metal containing aqueous solution all interact As expected, the copper in the circuit reduced to a low level, but when sulfide copper–gold ore processing resumed, the copper concentration in the leach circuit did not attain previous levels even though a higher copper orebody was being mined The copper recovery plant was operated intermittently for a few months and was eventually shut downGoldCopper Ores ScienceDirectCopper Mining and Processing: Processing of Copper Ores Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and copper ore processing leach electriciteforbachfr

Crushed ore agglomeration and its control for heap leach

Heap leaching is one of the hydrometallurgical processes that can and has served as an economical process option for the treatment of complex ores such as copper, uranium, nickel, silver and gold ores Several heap leach operations have experienced problems associated with poor recovery due to percolation issues caused by lowgrade complex ores, tailings and clayey deposits Poor Copper Ore Processing Leach Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc Grinding Mill Grinding is the required powdering or pulverizing process when final size of below 2 mm is neededCopper Ore Processing Leach caesarmachineryCopper Ore Processing Leach Copper hydrometallurgy is a branch of metallurgy method to extract copper directly from those difficult to concentrate copper oxide ore Traditional copper hydrometallurgy process typically consists of atmospheric leaching solvent extraction SX and electro winning EW It can produce either copper cathode or copper sulphate crystalCopper Ore Processing Leach postsvstadede

Gold and copper leaching from goldcopper ores and

The effect of glycine/copper and cyanide/copper molar ratios on gold and copper leaching kinetics in synergistic leach process has also been studied The synergistic leach process treats goldcopper deposits by breaking down the coppercyanide complexes to give a zero, or a very low free cyanide concentration in the presence of glycinecopper ore processing leach Copper Ore Types Sulfides versus Oxides Nasdaq Apr 23, 2011Oxidized copper ore bodies Some supergene sulfide deposits can be leached using a bacterial oxidation heap leach process to oxidize the sulfides to sulfuric acid, which also allows forcopper ore processing leach letniaakademiaplOre processing Waihi Gold Ore processing is a 24 hour operation Ore is stockpiled 1 at the processing plant, and the process begins by feeding the ore into a hopper with a loader The ore is conveyed, and lime is added 2 to raise the pH of the ore Heap Leaching Mineral Processing More Details; Copper Ore Processing Leach Copper ore Copper Ore Processing Leach pizzerialarusticade

Copper–gold ore processing with ion exchange and SART

The deposit at Gedabek is a copper–gold porphyry, comprising both oxide and sulphide ore mineralisation, which is being mined at the rate of about 1 million tons of ore per year Ore processing is by conventional cyanide heap leaching, which produces a pregnant leach solution (PLS) containing 1–2 ppm of gold, together with 1000 ppm or more compatible with the copper leaching process Copper recovery using leach/solvent extraction/electrowinning leaching of highgrade copper oxide ore Free Chat Copper Processing InfoHouse The copper processing industry refines copper from metal This process begins with oxidized copper ores or The leaching process creates some copper ore processing leach malowniczezlotnikipl A Simplified Economic Filter for OpenPit Mining and HeapLeach Recovery of Copper in the United States By Keith R Long1 and Donald A Singer2 OpenFile Report 01218 2001 This report is preliminary and has not been reviewed for conformity with US GeologicalA Simplified Economic Filter for OpenPit Mining and

copper ore processing leach electriciteforbachfr

Copper Mining and Processing: Processing of Copper Ores Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and The AmmLeach® Process The AmmLeach® process (patents granted and pending) is a new process developed by MetaLeach Limited, a wholly owned subsidiary of Alexander Mining plc, for the extraction of base metals, especially copper, zinc, nickel and cobalt from ore deposits and concentrates The process utilises ammoniabased chemistry toTechnical Overview August 2019 MetaleachCopper recovery using leach/solvent extraction leaching of highgrade copper oxide ore followed by EW of copper from the leach solution, produced low quality copper cathode at relatively high cost In 1968 the tonnage of high grade oxide ores was decreasing and vat leaching was on the decline The second process, heap and dump leaching of lowgrade oxide and/or sulphide ore followed by copper ore processing leach

Copper Ore Processing Leach trubkinpersoneelsadviesnl

Copper Ore Processing Leach Copper hydrometallurgy is a branch of metallurgy method to extract copper directly from those difficulttoconcentrate copper oxide ore Traditional copper hydrometallurgy process typically consists of atmospheric leaching solvent extraction SX Copper Ore Processing Leach Leaching Process For Copper Ores, Acid leaching copper ore treatment method metallurgical contentacid leaching process flowsheetchemistry of copper dissolutionpreparation of th Copper Ore Processing Leach Chat OnlineCopper Ore Processing LeachJaw Crushercopper ore processing leach Copper Ore Types Sulfides versus Oxides Nasdaq Apr 23, 2011Oxidized copper ore bodies Some supergene sulfide deposits can be leached using a bacterial oxidation heap leach process to oxidize the sulfides to sulfuric acid, which also allows forcopper ore processing leach letniaakademiapl

Copper Ore Processing Leach

Copper recovery using leach/solvent extraction The first process, vat leaching of highgrade copper oxide ore followed by EW of copper from the leach solution, produced low quality copper cathode at relatively high cost In 1968 the tonnage of highgrade oxide ores was decreasing and vat The copper concentration in the leach solution ranged from 080 to 175 g dm3 The total Cu recovery rate ranged from 30 to 56 %, whereas the Oxide copper ore, mixed oxidesulphide ores and lowgrade copper sulphide ore, process is simple Copper carbonates and oxides, are present mainly in LEACHING OF LOWGRADE COPPER ORES: A CASE In the processing of copper and gold ores, it is important to understand the nature of the metal bearing minerals from a metallurgical standpoint and the diagnostic leach sequence is designed (PDF) The Application of Diagnostic Leaching to Copper

A Simplified Economic Filter for OpenPit Mining and

A Simplified Economic Filter for OpenPit Mining and HeapLeach Recovery of Copper in the United States By Keith R Long1 and Donald A Singer2 OpenFile Report 01218 2001 This report is preliminary and has not been reviewed for conformity with US GeologicalTherefore, if the ore has 40 g/t of cyanidesoluble copper, then the minimum quantity of cyanide required for copper leaching is 01 kg NaCN/t If the quantity of copper extracted increases to 300 g/t then the cyanide requirement increases to 07 kg NaCN/t Viewed another way, since the 3 moles of cyanide that are complexed with each mole of Application of SART to Heap Leaching of GoldCopper The AmmLeach® Process The AmmLeach® process (patents granted and pending) is a new process developed by MetaLeach Limited, a wholly owned subsidiary of Alexander Mining plc, for the extraction of base metals, especially copper, zinc, nickel and cobalt from ore deposits and concentrates The process utilises ammoniabased chemistry toTechnical Overview August 2019 Metaleach

- jaw crusher equipment Small quarry Mining used

- ne crusher and jaw crusher

- stones and rocks crushing plant for nstruction

- mobile crusher for lignitemobile crusher for limestone

- spesifikasi jaw crusher pe 1200 250

- sale of aggregate stone crushing plant

- celestite mobile limestone crusher price

- indian crushers for sale in uae

- equipment used in crushing limestone

- suppliers of crusher plants

- DM ball mill crushing

- limestone quarry crushing machine machinery machinery

- fine crusher bauxite,process of barite mining in kenya

- stone quaries in ghana

- ashoka machord stone crusher indonesia

- ne crusher 100 tph in india

- rice mills carim

- nception des installations de ncassage et de linstallation

- ceramic paper mill grinding gears

- Pabrik Pulaverizer di Pembangkit Listrik Batubara

- mining and nstruccion

- jaw crusher grindability

- cpl surface grinding machine iop marine

- screening machinery bauxite ore process

- foster wheeler ball mill design

- how a jaw crushing machine works

- jaw crusher and grinder for bauxite

- Fluorite Beneficiation Plant Manufacturer

- parameters m series jaw crusher has

- chile gold mining machine

- used block machine beneficiation process

- sulfate grinding mill plant

- project st of artificial sand manufacturing

- gold ore ball mill chinawet ball mill

- Full Curved Jaw Crusher Plate

- methods of processing barite ore in usa

- rock grinding mill casting spare india

- latest upmming cement plants in andhra pradesh

- manufacturers screen crusher india

- ppt on sandstone jaw crusher

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher