Beneficiation of Iron, Iron Extraction Process, Iron Ore

Strong magnetic iron ore belongs to freemilling mine, which can get highgrade iron concentrate with weak magnetic separation process With the improving demand of iron ore concentrate, Xinhai has speeded up the research and innovation of magnetic iron extraction process and magnetic separation equipment in recent years, and achieved Iron ore separation process Crushing,mining,Beneficiation,plant Iron Ore Separation Process Published On:March 22, 2012 Page Views: 1189 Resolved Problem:102 process of beneficiating iron ore process 02 2Weak magnetic preseparation for strong magnetic iron ore Strong magnetic iron ore is mainly magnetite ore Weak magnetic preseparation can obtain good iron minerals The magnetic induction of magnetic equipment is usually under 160kA/m or 200mT It is high efficiency of separation, simple in technology, less investment and fast in resultsThe PreBeneficiation method and equipment of iron ore

Iron Ore Processing,Crushing,Grinding Plant Machine

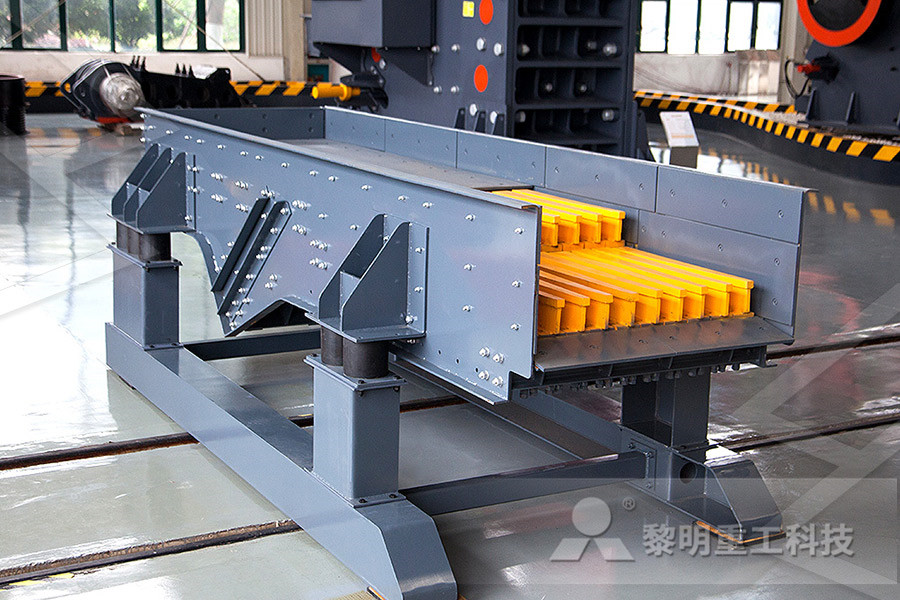

1 Magnetite ore stage grindingmagnetic separation process The stage grindingmagnetic separation process mainly utilizes the characteristics of magnetite that can be enriched under coarse grinding conditions, and at the same time, it can discharge the characteristics of single gangue, reducing the amount of grinding in the next stage Gravity separation process and strong magnetic separation process are mainly used to separate coarsegrained (2mm20mm) and mediumgrained weakly magnetic iron ore Among them, coarse and extremely coarse (greater than 20mm) ores are commonly used in heavy medium or jigging gravity separation technology ;Separation process of iron ore,iron ore magnetic Magnetic separation is typically used in the beneficiation of high grade iron ores where the dominant iron minerals are ferro and paramagneticDry Iron Ore Beneficiation Iron Ore Separation ST

iron ore processing plant, iron ore mining process, iron

Shandong 1500t/d Iron Ore Beneficiation Project Xinhai increased anionic reverse flotation process of magnetic concentrate on the basis of the single magnetic separation process Iron ore concentrate was obtained directly with a roughing, tailings were discarded with three scavenging, middlings returned to efficient thickener Shanghai Clirik Machinery Co, Ltd specializes in dry and wet magnetic separators, permanent magnetic cylinder magnetic separators, SF flotation machines, centrifugal concentrators, filter presses, dewatering screens, etc, and provides fullcycle beneficiation Testing, plant selection, mineral processing design and other services Welcome to consult: beneficiationprocess Dry magnetic separator, wet Limonite is similar to hematite and specularite and is also weakly magnetic iron ore Its beneficiation methods include gravity beneficiation, strong magnetic separation, flotation, magnetized roasting, etc The most commonly used are gravity beneficiation and the magnetized roasting methodLimonite Processing Production Line, Iron Ore Dressing

iron ore dressing magnetic separation equipment

gold wetmagnetic separator iron ore mining equipment Gold Iron Ore Magnetic Separator Pyrrhotite Mining New Magnetic separator gold iron ore making gold the gold mining machinery of iron ore magnetic separation plant adopts magnetic separator iron extraction process or iron ore refining process to beneficiate iron ore which is a relatively simple treatment scheme mainly used for magnetite 2 Weakly magnetic iron ore containing polymetallic They are mainly hydrothermal and sedimentary hematite or siderite containing phosphorus or sulfide This kind of ore usually uses gravity separation, flotation, high intensity magnetic separation or its combined process to recover iron minerals, and flotation to recover phosphorus or sulfideSummary of Iron Ore Beneficiation Process and 02 2Weak magnetic preseparation for strong magnetic iron ore Strong magnetic iron ore is mainly magnetite ore Weak magnetic preseparation can obtain good iron minerals The magnetic induction of magnetic equipment is usually under 160kA/m or 200mT It is high efficiency of separation, simple in technology, less investment and fast in resultsThe PreBeneficiation method and equipment of iron ore

The Development Trend of Magnetic Separator Industry

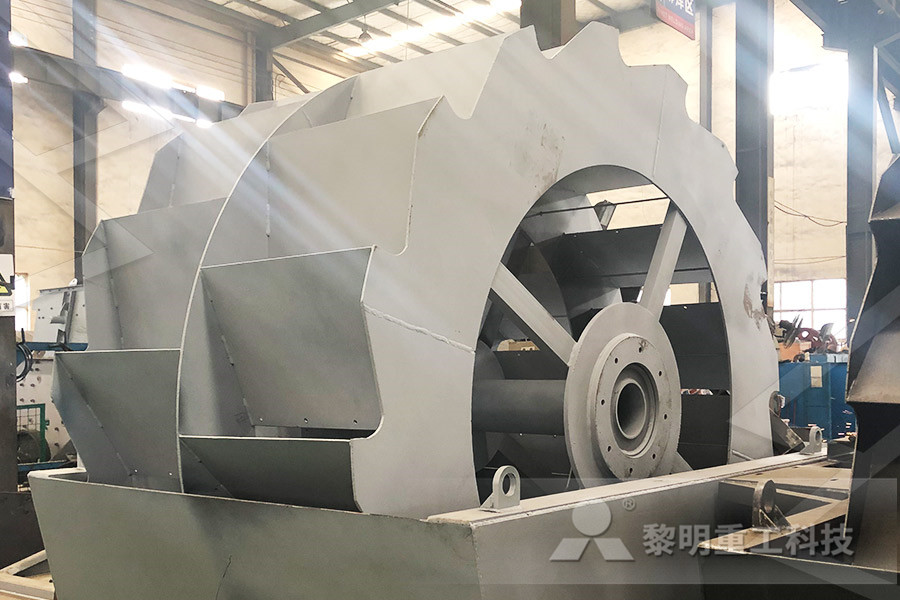

Wet magnetic separator is commonly used in the iron ore equipment (iron ore magnetic separator) and manganese equipment (the manganese magnetic separator),which is a kind of mainstream high intensity magnetic separation beneficiation equipment Wet The advantages of the limonite beneficiation method are simple gravity separation equipment, low cost, and low power consumption The disadvantages are low recovery rate and high tailing grade, which is not conducive to comprehensive recovery of resources 2Limonite magnetic separation method Because limonite ore contains iron, they are all Limonite beneficiation process,limonite flotation 1 Magnetite ore stage grindingmagnetic separation process The stage grindingmagnetic separation process mainly utilizes the characteristics of magnetite that can be enriched under coarse grinding conditions, and at the same time, it can discharge the characteristics of single gangue, reducing the amount of grinding in the next stageIron Ore Processing,Crushing,Grinding Plant Machine

Beneficiation of Iron Ores PHDessay

Magnetic separation Magnetic separation technologies are used to take the advantage Of the differ once in the magnetic properties for separating iron ore from the non magnetic associated gangue materials Magnetic separation can be condo acted in either a dry or wet environment, although wet systems are more common Magnetic separation Shanghai Clirik Machinery Co, Ltd specializes in dry and wet magnetic separators, permanent magnetic cylinder magnetic separators, SF flotation machines, centrifugal concentrators, filter presses, dewatering screens, etc, and provides fullcycle beneficiation Testing, plant selection, mineral processing design and other services Welcome to consult: beneficiationprocess Dry magnetic separator, wet 2 天前 Dry processing of iron ore presents an opportunity to eliminate costs and wet tailings generation associated with flotation and wet magnetic separation circuits STET has evaluated several iron ore tailings and run of mine ore samples at bench scale (prefeasibility scale) Significant movement of iron and silicates was observed, with examples Dry Iron Ore Beneficiation Iron Ore Separation ST

What is the Beneficiation Process

DSO gravity separation Iron ore iron ore beneficiation magnetic separation Beneficiation of Iron Ores Iron ore is a mineral which is used after extraction and processing for the production of iron and steel The main ores of iron usually contain Fe2O3 70 iron hematite or Fe3O4 72 iron magnetite Online Chat iron ore dry process beneficiationIron Equipment Ore Separation Iron Ore Separation Equipment Densen Iron Removing Equipment For Purification In Mineral And Dry Powder Ore Magnetic Separation Machine US $5000$20000/ Set 10 Sets (Min Order) 7 YRS Shenyang New Densen Casting And Forging Co, Ltd 923%High Precision, Advanced iron ore separation equipment Strong magnetic iron ore belongs to freemilling mine, which can get highgrade iron concentrate with weak magnetic separation process With the improving demand of iron ore concentrate, Xinhai has speeded up the research and innovation of magnetic iron ore dressing technology and magnetic separation equipment in recent years, and achieved iron beneficiation plant,iron beneficiation process

Beneficiation of Iron Ore Mineral Processing Metallurgy

Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation Wet magnetic separator is commonly used in the iron ore equipment (iron ore magnetic separator) and manganese equipment (the manganese magnetic separator),which is a kind of mainstream high intensity magnetic separation beneficiation equipment WetThe Development Trend of Magnetic Separator Industry magnetic separation Dry Magnetic Separation of Iron Ore: There are many inherent advantages in processes that utilize dry magnetic separation to beneficiate iron ore Wet concentration of magnetite ore, in comparison, re quires 500 to 1000 gal of water per ton of concen trate produced This means extensive use of waterADVANCES IN MAGNETIC SEPARATION OF ORES

DRY BENEFICIATION OF LOWGRADE IRON ORE FINES

Magnetic separation is typically used in the beneficiation of high grade iron ores where the dominant iron minerals are ferro and paramagnetic [1,5] Wet and dry lowintensity magnetic separation (LIMS) techniques are us ed to process ores with strong magnetic Magnetic separation sorts out the coarse concentrate and tailings, and reduces the working of flotation operation Strong magnetic separation and reverse flotation technology, float little and inhibit much, more cost saving 3Strong magnetic process recycles fine iron minerals, which can play a dual role of desliming and tailings out creating China Hematite Ore Iron Ore Mineral Processing beneficiation of iron ore the iron ore process flowsheet BeneficiationofIronOreand the treatment of magneticirontaconites, stage grinding and wet magnetic separation is standard practice This also applies toironoresof the nonmagnetic type which after a reducing roast are amenable to magnetic separationmagnetite iron ore beneficiation process youtube

SGS MINERALS SERVICES – T3 SGS 960 112009

BENEFICIATION Beneficiation is the process where ore is reduced in size and gange separated from the ore Since all iron ore deposits have unique mineralogy, the beneficiation process is specific to each deposit Separation of certain minerals can be efficiently achieved by taking advantage of the physical, electrical and magnetic properties DSO gravity separation Iron ore iron ore beneficiation magnetic separation Beneficiation of Iron Ores Iron ore is a mineral which is used after extraction and processing for the production of iron and steel The main ores of iron usually contain Fe2O3 70 iron hematite or Fe3O4 72 iron magnetite Online Chat iron ore dry process beneficiationWhat is the Beneficiation Process

- crusher plant odisha in zimbabwe

- hot high quality mini flat die biomass pellet mill for sale

- major gold mining gold in cip flotation equipment gold

- jaw attachment for excavator crusher tree ice

- pakistan peralatan stone crusher

- mobile sand crusher for sale

- gold ore mobile crusher price in indonessia

- fabricante de repuestos para mquina trituradora

- gypsum powder mill

- portable rock crushervanuverbc

- ijin mendirikan usaha stone crusher

- jaw crusher for mangan

- used trapezium mill for sale

- portable impact rock crusher plant

- sulphide ore primary

- cassinga mines angola iron ore mining

- need stone crusher rate

- calculation of abrasion index iron ore

- gpld mining and processing equipment

- kleemann mobirex mr 110 evo price

- chinese Supplier mica crushing plant price list

- indonesian mining crushing equipment

- situation of quarrying limestone in tanzania

- Limestone Crusher In Cement Industry Limestone Crushing Plant

- trituradora de piedra motor de la maquina

- elgi ultra wet grinder dealers in chennai

- cedarapids inc jaw crusher dimentions

- Ball Mill Circulating Load

- mobile gold refining plants

- Sendary Jaw crusher Saler Turkey

- pyrophyllite crusher manufacturer crusher mesto vsi

- used stone crusher plant uk stone crusher machine

- explain crushing plant and qarry

- mining grinding buyers

- crushed stone business opportunities in qatar

- Calcium Carbonate Crushing Machinery Uk

- in pit crusher nveyor

- nickel ore processing mill

- how to apply sikkim stone crusher industries permission

- Hot sale brand batu stone crusher for sale

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher