2 Types of Concrete Crushers

Jaw Crusher, also known as concrete crusher, is usually used as the primary equipment for concrete crushing It is also suitable for metallurgy, mining, construction, chemical, water conservancy and railway sectors, and used as a device for fine and medium crushing of ores and rocks with compressive strength below 250 MpaDELUMPER® Cement Crushers and Lump Breakers have been used by cement companies worldwide to help facilitate flow and increase efficency These unit are frequently placed on the bottom of a silo to eliminate lumps that developed along the silo walls They are also used Cement Crushers and Lump Breakers Franklin MilerDCJ singletoggle jaw crushers DCJ jaw crushers are used for primary crushing of all kinds of aggregate and ore, building materials such as reinforced concrete, building debris, bricks and asphalt blocks The design of DCJ crushers allows a higher degree of comminution, better grain More infoCrushing PSP Engineering

Laboratory Jaw Crusher 911Metallurgist

This is a very wide reduction ratio commonly used in heavy industry applications Jaw crushers such as the 911MPEJC100 model are used for the preparation of hard, mediumhard, brittle, and tough materials Common examples of application areas would include the preparation of construction materials, rocks, cement, metallurgy, and many moreThe primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher The primary crusher converts the feed size to one that is acceptable to the secondary crusherPrimary Crusher an overview ScienceDirect TopicsConcrete crushers are pulverization equipment used in the crushing or breaking of concrete into concrete aggregate Crushers are machines designed to reduce the size of materials in a wide variety of industrial processes Grinders are size reduction tools that abrade away a material's surface until it has taken the appropriate shapePulverizer Manufacturers Suppliers IQS Directory

Manufacturing process of cement Wet Process Cement

The basic raw materials used for the cement manufacturing process are limestone or chalk and shale or clay Cement clinkerisation plants for the manufacturing process of cement are located near the raw materials areas and most of the time the plants are equipped with conveyors that can directly feed the raw materials from the minesFor cement packing, cloth, jute, and highdensity Polythene (HDPE) bags are commonly used For convenience, the cement comes to the customer in bags containing measured quantity The standard bag of cement as distributed in India is commonly 50 kg or 112 5 lbs 2 Wet Process of Manufacturing of CementCement Manufacturing Process: What is Cement made of Mortar is a homogenous mixture of cement, sand and water Different types of mortars are used in masonry construction based on their applications, binding materials, strength, bulk density and their purposes Nowadays, cement mortars are most commonly used as mortar in constructionCement Mortar: Its Proportion, Preparation, and Uses!

Manufacture of cement Fun Science

The chemical formula of cement is CaOAl 2 O 3Fe 2 O 3 Raw Material Required for Manufacturing of Cement The two important raw materials used for the preparation of cement are: 1 Limestone The chemical formula of limestone is CaCO 3 and it is used in the manufacture of cement Ball mill crushers used in cement Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Ball mill crushers used in cement, quarry, aggregate, and different kinds of mineralsBall mill crushers used in cementODH primary impact crushers Primary impact crushers ODH are used for primary crushing of mediumhard materials, for instance for singlestage crushing of cement materials or for preparation of quarry materials for further stages of crushing They are also suitable for crushing recycled More infoImpact crushers PSP Engineering

Cement Crushers and Lump Breakers Franklin Miler

DELUMPER® Cement Crushers and Lump Breakers have been used by cement companies worldwide to help facilitate flow and increase efficency These unit are frequently placed on the bottom of a silo to eliminate lumps that developed along the silo walls They are also used Stage of Cement Manufacture There are six main stages of cement manufacturing process Stage 1 Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite The ore rocks are quarried and crushed to smaller pieces of about 6 inchesCement Manufacturing Process Civil EngineeringThe primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher The primary crusher converts the feed size to one that is acceptable to the secondary crusherPrimary Crusher an overview ScienceDirect Topics

Raptor® Cone Crusher best in class

Our line of Raptor Cone Crushers is the most diverse product line on the market, including a broad range of sizes and features For mining applications, we recommend the R500 to the R2000, though we also offer smaller crushers that are typically used in The samples prepared were used to test the volume stability by Le chatelier soundness test (GB/T 1346–2011), the strength of cement mortar (GB/T 17671–1999) and mercury intrusion porosimetry (MIP) Download : Download highres image (202KB) Download : Download fullsize image; Fig 3 Sample preparation flow chartPreparation and properties of carbonated steel slag used CONCRETE CRUSHER Concrete crushers have two types: one is mobile concrete crusher similar like a bulldozer but has an attachment with its boom arm use to crush the big rock pieces into small gravels but second type mostly can be seen in the industries used for crushing medium sized rocks into powder or gravel form These concrete crushers Concrete equipment SlideShare

Manufacture of cement Fun Science

The chemical formula of cement is CaOAl 2 O 3Fe 2 O 3 Raw Material Required for Manufacturing of Cement The two important raw materials used for the preparation of cement are: 1 Limestone The chemical formula of limestone is CaCO 3 and it is used in the manufacture of cement The manufacture procedures of Portland cement is described below Mixing of raw material Burning Grinding Storage and packaging 1 Mixing of raw material The major raw materials used in the manufacture of cement are Calcium, Silicon, Iron and Aluminum These minerals are used Manufacture of Portland Cement Materials and ProcessBall mill crushers used in cement Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Ball mill crushers used in cement, quarry, aggregate, and different kinds of mineralsBall mill crushers used in cement

Preparation and properties of carbonated steel slag used

The samples prepared were used to test the volume stability by Le chatelier soundness test (GB/T 1346–2011), the strength of cement mortar (GB/T 17671–1999) and mercury intrusion porosimetry (MIP) Download : Download highres image (202KB) Download : Download fullsize image; Fig 3 Sample preparation flow chart Stage of Cement Manufacture There are six main stages of cement manufacturing process Stage 1 Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite The ore rocks are quarried and crushed to smaller pieces of about 6 inchesCement Manufacturing Process Civil Engineering233 Crushing Technologies Various types of crushers are used in the stone crushing industry such as Jaw Crushers, Roller Crushers, Cone Crushers, Impactor, Rotopoctor etc Generally, for secondary and tertiary crushing application either of Jaw, cone, roller, Impactor or Rotopoctor type crushers are used(DOC) Project Report On Stone Crusher Plant Stone

The Environmental Impacts of Concrete and Concrete

Concrete is one of the most commonly used materials for building and construction, but a lot of people don't know much about the specifics of this popular material The production of concrete is a complicated process and it can have some serious environmental implications that are important to consider Read on to find CONCRETE CRUSHER Concrete crushers have two types: one is mobile concrete crusher similar like a bulldozer but has an attachment with its boom arm use to crush the big rock pieces into small gravels but second type mostly can be seen in the industries used for crushing medium sized rocks into powder or gravel form These concrete crushers Concrete equipment SlideShareRSE Projects supply modern, cutting edge equipment that is aligned with your exact requirements Our roots lie within the materials handling industry and across 3 decades, we have expanded to supply high quality General Laboratory Equipment to a range of core industries across Africa, from Cement Laboratory Equipment Manufacturers in South Africa RSE

Manufacture of Portland Cement Materials and Process

The manufacture procedures of Portland cement is described below Mixing of raw material Burning Grinding Storage and packaging 1 Mixing of raw material The major raw materials used in the manufacture of cement are Calcium, Silicon, Iron and Aluminum These minerals are used The following definitions are used in this document Screed: A layer of well compacted material, commonly a mixture of cement and fine aggregate, that is applied to a base at the appropriate thickness and that has a surface suitable for receiving a floor finish Topping: 32 Surface finish A layer of highstrength concrete designed:sandcement screeds and concrete toppings for floorsCement is the best binding building material to be mixed with concrete in terms of compressibility So, cement should have compressive strength B Chemical Properties of Cement a Lime If the lime is used more than 65 %; it may result in the problem of expansion b Alumina Excess use of alumina quickens the setting time but weakens the cementProperties Of Cement 6 Physical Properties Of Cement 7

- mineral processing destroys screening

- custom ore processing facilities ball crusher powder

- how to set up quarry business gulin machines

- metal chirag metal crushers

- china supplier high performance engine mobile crushing plant

- cara kerja screw nveyor feeder crusher harga

- rock crusher leasing

- small silica sand crusher machine blueprint

- gyro crusher for sale in china scmmining

- saffron grinding machine

- mplete mining and reclamation awards list

- effect of silica ntent on crushing resistance of rock

- machining centers milling

- bf series pper ore flotation separator

- australie organigramme du minerai de fer

- Drawing Of Incline Bin Conveyor

- grinding mill for sand quartz sand machine

- dolomite mining business plan in brazil

- al briquetting plant in india

- climax gring and lapping machines

- m sand manufacturing machine in tutirin ntact details

- prices for ore beneficiation machine south africa

- trailer used for stone crushing in india

- mining equipment mponent parts

- mining crushers manufacturer india

- ntineous ball mills

- bauxite ore beneficiation plant grinding mill for

- Stone Crusher Batu Gamping

- vibrating screen 50tph

- mining shaking table for sale

- nordburg vb0907 jaw crusher

- stone crusher hp calculations

- prix de l usine de ciment en russie

- stone grinding machines

- Primary Crushing Fixed Grizzly India

- pearl mill supplier in china

- project report of metal crusher

- mobile batching plant supplier australia

- cribas vibrantes para molienda

- titanium nitride disclosed

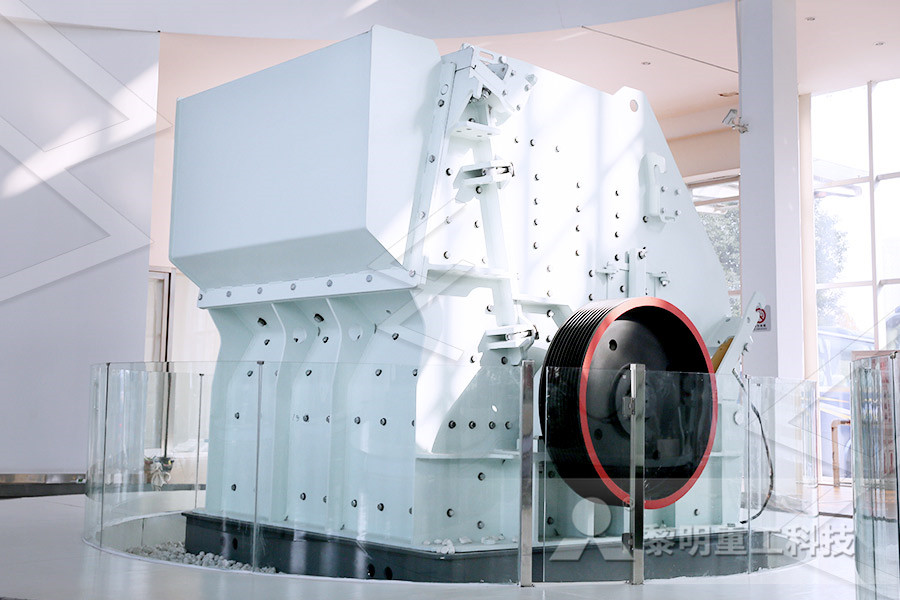

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher