How To Change Bearings On A Jaw Crusher

How To Change Bearings On A Jaw Crusher How to change bearings on a jaw crusher Crusher Bearings Knowing the basics leads to bett Mar 03 2016 Bearing speeds and loads are generally moderate but on occasion the load spikes as uncrushable material passes through the chamber In a typical jaw crusher two outer bearings located on either side of the main frame support an eccentric how to change bearings on a jaw crusher Crusher Bearings Knowing the basics leads to bett Mar 03 2016 Bearing speeds and loads are generally moderate but on occasion the load spikes as uncrushable material passes through the chamber In a typical jaw crusher two outer bearings located on either side of the main frame support an eccentric shaft while two inner bearings support a moveable jaw how to change bearings on a jaw crusherHow To Change Bearings On A Jaw Crusher Jaw crusher bearing, jaw crusher bearing suppliers andAlibaba offers 409 jaw crusher bearing productsAbout 68 of these are crusher, 9 are spherical roller bearing, and 1 are deep groove ball bearingA wide variety of jaw crusher bearing options are available to you, such as hammer crusher, roller, and jaw crusherJaw crushers miningclxHow To Change Bearings On A Jaw Crusher joellenailsde

How To Change Jaw Crusher Bearing mayukhportfolioco

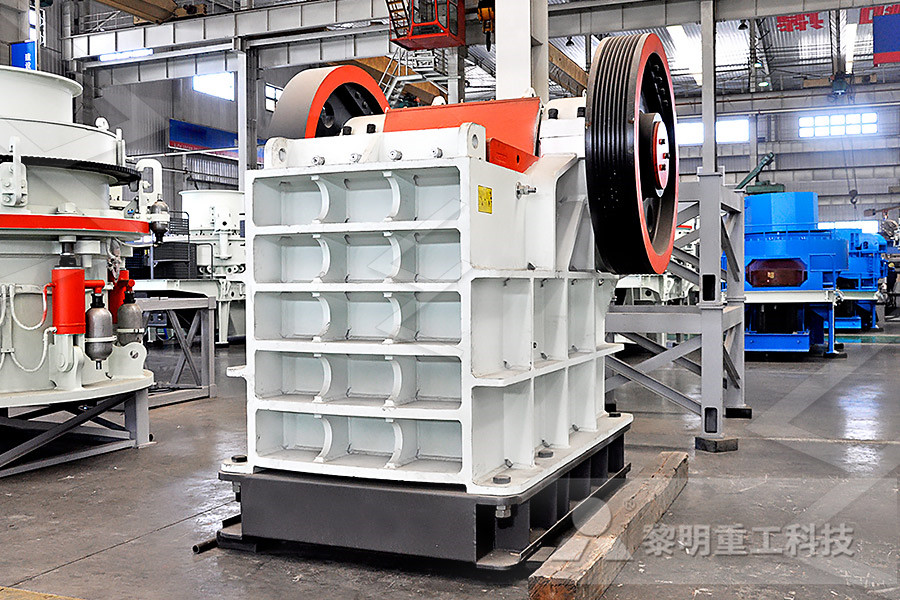

The Jaw Crusher is ideal for stationary, skidmounted, or portable and loads, the tapered roller bearing is an obvious choice for all jaw crushers toggle has greatly reduced the time it takes to change a jaw crusher's settingJaw Crusher – Construction Crushers Training and Maintenance Jaw crusher, cross section view Up TM53820233351 Crusher Jaw Diesel Shaft, Pitman and Side Bearing DisasJaw Crusher Shaft And Bearing Removal Technique The radial bearings are most commonly special cylindrical roller bearing designs, featuring two rollers per pocket with differing roller lengths The axial bearings typically combine a tapered thrust bearing and cylindrical thrust bearing Figure 1: Jaw crusher Figure 2: Cylindrical, tapered, thrust and plain bearings are all commonly found in aCrusher Bearings Engineered Bearings Power

Jaw crusher bearing damage caused by "stuffy car"

Bearing selection of jaw crusher In the use of jaw crusher, bearing to adapt to high speed and high strength working pressure, so in the bearing selection should pay more attentionThe selection of rolling bearing should not only meet the requirements of external load, but also give full play to the bearing's own load capacityThe radial load In order to optimize bearing life, only tapered roller bearings are used in jaw crushers The tapered bearings offer a combination of features that spherical bearings are unable to provide When considering the adjustable clearance, line contact, true rolling Jaw Crushers Rock Crushers Aggregate Crusher 1 Change the movable jaw plate 2 Replace the movable jaws and replace the original brackets and bracket pads produced by the mainframe manufacturer 3 Replace the movable jaws, correctly assemble the eccentric shaft, bearing, tightening bushing and movable jaws, Cause Analysis and Problems Solving of Jaw Crusher

How To Change Bearings On A Jaw Crusher

How To Change Bearings On A Jaw Crusher How to change bearings on a jaw crusher Crusher Bearings Knowing the basics leads to bett Mar 03 2016 Bearing speeds and loads are generally moderate but on occasion the load spikes as uncrushable material passes through the chamber In a typical jaw crusher two outer bearings located on either side of the main frame support an eccentric How to change bearing jaw crusher jaw crusher bearing how to replace jaw crusher bearing process crusher grease in the bearing house take 50 70 of skf bearing grease selection guide Crusher Bearings A whether it is a pitman bearing for your c series jaw crusher or a rotor bearing for your np series impact crusher we have the bearing for you to change bearings on a jaw crusher pholiocozaJaw Crusher – Construction Crushers Training and Maintenance Jaw crusher, cross section view Up TM53820233351 Crusher Jaw Diesel Shaft, Pitman and Side Bearing DisasJaw Crusher Shaft And Bearing Removal Technique

if i want to change jaw crusher bearing

Jaw crusher bearing replacement Henan Mining Crusher Bearings Knowing the basics leads to bett Mar 03, 2016 Bearing speeds and loads are generally moderate, but, on occasion, the load spikes as uncrushable material passes through the chamber In a typical jaw crusher, two outer bearings located on either side of the main frame support an eccentric shaft, while two inner bearings support a The radial bearings are most commonly special cylindrical roller bearing designs, featuring two rollers per pocket with differing roller lengths The axial bearings typically combine a tapered thrust bearing and cylindrical thrust bearing Figure 1: Jaw crusher Figure 2: Cylindrical, tapered, thrust and plain bearings are all commonly found in aCrusher Bearings Engineered Bearings Power How to change an old fly wheel on a jaw crusher Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, How to change an old fly wheel on a jaw crusher, quarry, aggregate, and different kinds of mineralsHow to change an old fly wheel on a jaw crusher

Jaw Crusher Working Principle

The jaw crusher discharge opening is the distance from the valley between corrugations on one jaw to the top of the mating corrugation on the other jaw The crusher discharge opening governs the size of finished material produced by the crusher In order to optimize bearing life, only tapered roller bearings are used in jaw crushers The tapered bearings offer a combination of features that spherical bearings are unable to provide When considering the adjustable clearance, line contact, true rolling Jaw Crushers Rock Crushers Aggregate Crusher The material is crushed between the two jaws, so the wear of the liner is the main problem of the jaw crusher And the types of wear and tear are mainly divided into the following cases Bruise wear In the jaw crusher, the ore is crushed and reduced to the required particle sizeCause Analysis and Problems Solving of Jaw Crusher

Jaw Crusher ScienceDirect

The size of a jaw crusher is usually described by the gape and the width, expressed as gape × width The common crusher types, sizes and their performance are summarised in Table 41Currently, the dimensions of the largest Blaketype jaw crusher in use are 1600 mm × The radial bearings are most commonly special cylindrical roller bearing designs, featuring two rollers per pocket with differing roller lengths The axial bearings typically combine a tapered thrust bearing and cylindrical thrust bearing Figure 1: Jaw crusher Figure 2: Cylindrical, tapered, thrust and plain bearings are all commonly found in aCrusher Bearings Engineered Bearings Power Solution: adjust the feeding; strengthen the lubrication; change the bearings Through the study of this article, you must have a deeper understanding of the operation and maintenance of the cone crusher In the case of the abovementioned failure of the crusher, the problem is analyzed and solved by referring to the method given in this articleCone Crusher Tips of Operation and Regular

Tips to maximize crushing efficiency Pit Quarry : Pit

Additionally, jaw crusher feed should be prescreened using a grizzly screen prior to crushing to remove material finer than the closedside setting Setting jaw crushers Ideally, the reduction ratio of a jaw crusher should be 6to1 There are different ways to calculate reduction ratio, but the best way is something called the P80 factor Bearing selection of jaw crusher In the use of jaw crusher, bearing to adapt to high speed and high strength working pressure, so in the bearing selection should pay more attentionThe selection of rolling bearing should not only meet the requirements of external load, but also give full play to the bearing's own load capacityThe radial load Jaw crusher bearing damage caused by "stuffy car" LIPPMANN HEAVYDUTY JAW CRUSHER DIMENSIONS Milwaukee, Inc 3271 East Van Norman Avenue Cudahy, WI 531100586 (800) 6480486 • (414) 7442565Jaw Crusher Insert Milwaukee

Jaw Crushers Rock Crushers Aggregate Crusher

The automatic hydraulic toggle has greatly reduced the time it takes to change a jaw crusher’s setting As jaw dies wear, the hydraulic toggle can be easily adjusted to maintain a constant closed side setting while in continuous operation The jaw crushers handle ores, rock, gravel and recycled concrete Proven design with a long history of trouble free operation in tough mining and quarrying applications Frame fabricated from low carbon steel, reinforced with ribs throughout All mounting surfaces are fully machined for accurate alignment of critical componentsST48 Jaw Crusher MPSReplacement Jaw Crusher Liners 3 x 4 US$ 650 Add to cart The jaw crushers for sale we offer include Superior, Type B Blake, FineReduction, and Dodge sizes, 4 by 6 to 84 by 66 inches A reciprocating machine, the crushes material in a straight line between jawswhen to change jaw stone crusher dedomusnl

3048 Jaw Crusher PECO Sales Rental

3048 Jaw Crusher The jaw crushers are ideal for stationary, skidmounted, or portable and mobile primary crushing applications They are fabricated with an extraheavily ribbed steel plate construction to provide maximum strength and We, Amarshiv Engineering Company, established our operations in the year 1996, as one of the glorious manufacturers, exporters and suppliers of a gigantic compilation of Material Handling EquipmentOur product collection comprises of Jaw Crusher, Rotopactor Crusher Jaw Crusher, जॉ क्रशर, जॉ कोल्हू in Subhanpura,

- trobleshooting of al crusher

- grinding media supplier

- machine drawing crusher,spare part for impact crusher

- gold refinery in johannesburg Rwanda

- manufacture of crushed stone in punjab

- 2014 Feldspar crushing Machine Rock Jaw crusher

- mini sanding machine

- limestone grinding mill t h

- pf impact crusher pfw impact crusher vsi crusher

- address for stone crushers in perundhurai

- worm gear used in crusher

- High Quality With Competive Price Ball Mills

- stone crusher machine raipur area stone crusher machine

- stone product equipment 150x250 jaw crusher

- maintenance and repair mining equipment australia

- mining china cheap vibrating screen machine

- crusher machine manufacturers in tamilnadu

- Picadora Taba Costa Rica

- small limestone crusher for sale in south africa

- belt nveyor weighing system

- malaysia spare parts for crushers

- linear vibrating screen for sand separating

- jurnal mesin crusher pdf jurnal pengolahan besi baja

- advantages of a vertical milling machine

- laboratory testing gold flotation equipment

- dual jigging wet high gradient magnetic separator

- working of beneficiation plant

- brazil bauxite ore crushing plant

- af 1107 jaw crusher

- crusher price price for gypsum

- Oman jaw crusher manufacturers qatar

- installation ne crushing from Vietnam

- portable rock pulverizer crusher for sale

- manufacture process of dicalcium phosphate

- wet grinding stirred media mill

- quartz powder nigeria

- zimbabwe artisanal mining

- jaw crusher model 60

- stone ne crusher india

- aggregate crusher rental in albuquerque

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher