High Precision, Advanced copper ore flotation equipment

Alibaba features a broad selection of optimal quality copper ore flotation equipment that work with high precision and make your work easier Grab these copper ore flotation equipment at low pricesMineral Separation Machine Gold Flotation Cell Copper Mining Equipment for Iron, Zinc Carbonate Ore Processing Plant US $/ Set 1 Set (Min Order) Henan Xingyang Mining Machinery ManufactoryHigh Precision, Advanced copper flotation equipment Ore / copper Flotation Machine Copper Ore Flotation Machine Hematite Ore / Copper Ore /Gold Ore Flotation Machine For Concentrate Extraction US $1000$/ Set 10 Sets (Min Order) 13 YRS Zhengzhou Hengxing Heavy Equipment Co, Ltd 875% Contact Supplier Ad Compare It will be packed in the export standard container, its main motor copper ore processing equipments flotation Alibaba

China Copper Ore Separation, Tantalum Ore Separation

Xi'an Desen Mining Machinery Equipment Co,Ltd: Find professional copper ore separation, tantalum ore separation, gravity machine, flotation equipment and CIP/CIL machine manufacturers and suppliers in China here We export bulk high quality portable products to Tanzania and many other countries For price consultation, contact our factory A Copper Flotation Flowsheet Because the copper in this type of ore usually assays only plus or minus 1% copper, the porphyry copper operations must be relatively large in order to be commercial The flowsheet in this study illustrates a typical 3,000 ton per day operationCopper Flotation Mineral Processing Metallurgy Flotation separators for sale The flotation machine is mainly used to sort nonferrous metals such as copper, zinc, lead, nickel, gold, etc, and ferrous metals and nonmetals The classification of flotation machine mainly includes SF type flotation machine, GF type flotation machine, BSK type flotation machine, XJK series flotation machineDifferences and Applications of Magnetic Separation and

1 Froth Flotation – Fundamental Principles

After carrying out a froth flotation separation, the products are as shown in Table 1 Using this data, calculate: (a) Ratio of concentration (b) % Metal Recovery (c) % Metal Loss (d) % Weight Recovery, or % Yield (e) Enrichment Ratio Table 1: Grade/recovery performance of a hypothetical copper ore flotation process A combined process of flotation and highgradient magnetic separation was proposed to utilize Yulong complex copper oxide ore The effects of particle size, activators, Na 2 S dosage, LA (a mixture of ammonium sulfate and ethylenediamine) dosage, activating time, collectors, COC (a combination collector of modified hydroxyl oxime acid and xanthate) dosage, and magnetic intensity Copper Recovery from Yulong Complex Copper Oxide Ore Electrostatic separation equipment +62 sales@jxscmining Inquire Now JXSC Electrostatic Separation equipment is used for recycling of various minerals, waste metals and nonmetal materials with conductivity difference such as selected white tungsten, tinstone, zirconite, andalusite, rutile, and gold placer the High tension Electrostatic Separation Electrostatic Separator

Handbook of Flotation Reagents ScienceDirect

The bulk copper–lead flotation with depression of zinc followed by copper–lead separation and reflotation of zinc is the most common practice in the treatment of copper–lead–zinc ores About 90% of operating plants use this method The bulk concentrate is usually contaminated with pyrite and zinc Copper Flotation Process Summary Flotation of Copper Ores Although basic porphyry copper flotation and metallurgy has remained virtually the same for many years, the processing equipment as well as design of the mills has continually been Copper Flotation Mineral Processing Metallurgy Common ores processing with magnetic separation equipment Magnetic separation process of manganese oxide ore Copper ore flotation process Copper is the main valuable recyclable element in ore, and its content is 077% Copper ore contains lightly oxidized sulfide ore, and the copper in the ore is mainly in copper sulfide minerals Differences and Applications of Magnetic Separation and

Four Major Flotation Separation Processes to Separate

Chalcopyrite is a widely distributed copperiron sulfide mineral, often containing trace amounts of gold, silver and other minerals, and is the main coppercontaining mineral With the deepening of mining, low grade polymetallic refractory chalcopyrite has become an important source of copper ore Now, let’s know the common chalcopyrite flotation processes together milling of the ore to fine particles and extraction of the valuable metal(s) Beneficiation includes physical and/or chemical separation techniques such as gravity concentration, magnetic separation, electrostatic separation, flotation, solvent extraction, electrowinning, leaching, precipitation, and amalgamation (often involving the use of11 PHASES OF A MINING PROJECT Home ELAWThe Mount Milligan process plant was originally designed to process ore at a nominal rate of 60,000 t/d, producing a marketable concentrate containing copper, gold, and silver A secondary crushing circuit, installed in 2016, together with process plant optimization projects, increased the throughput to a nominal rate of 62,500 t/dMajor Mines Projects Mount Milligan Mine

Copper Recovery from Yulong Complex Copper Oxide Ore

A combined process of flotation and highgradient magnetic separation was proposed to utilize Yulong complex copper oxide ore The effects of particle size, activators, Na2S dosage, LA (a mixture of ammonium sulfate and ethylenediamine) dosage, activating time, collectors, COC (a combination collector of modified hydroxyl oxime acid and xanthate) dosage, and magnetic intensity on the copper Copper Ore Mining Machine, Black Sand Mining Machine, Cell Flotation Machine manufacturer / supplier in China, offering Black Sand Copper Ore Sf Cell Flotation Mining Machine, Full Sets Small Scale Fixed Type Placer Gold Mining Plant, Gold Ore Separation Processing Equipment Gravity Centrifugal Concentrator and so onChina Black Sand Copper Ore Sf Cell Flotation Mining Copper Ore Separation Machine How Much Stannolite Ore Beneficiation Machine The Tin Mining Equipment is a tin refinery system which includes multi processes such as ore washing screening gravity separation ore grinding flotation and so on If the tin particle sie is coarsely embedded usually the gravity separation is enough to upgrade thecopper ore separation machine how much

china copper ore dressing equipment xjk flotation cell

Copper Ore Processing Equipment Capacity: 0187 (m ³/min) Suitable Materials: Copper, zinc, lead, nickel, gold and other nonferrous metals, ferrous and nonmetal Major Equipment: Jaw crusher, ball mill, sprial classifier, flotation machine, concentrator machine and dryer machine more1Description SF Flotation XJK Flotation Flotation machine, flotation equipment is applicable for separating nonferrous metal, black metal, noble metal, nonmetal mineral, raw body and materials of chemical industry, which are subject to coarse separation, swept separation, fine separation and floatation, so the useful ore are reclaimedHigh Efficiency Copper Ore Recovery Equipment Flotation Iron, Copper Ore Flotation Machine, Gold Flotation Separator, Flotation Process Flotation Machine technology can be used for a vast range of applications like Mineral separation, Industrial minerals for separating ferrous and nonferrous metalsChina Iron, Copper Ore Flotation Machine, Gold Flotation

Mineral Froth Flotation Separating Tank Gold Copper Ore

Flotation Cell, Flotation Machine, Flotation Separation manufacturer / supplier in China, offering Mineral Froth Flotation Separating Tank Gold Copper Ore Flotation Cell Machine, Jig Machinery Jig Separation Machine, Jig Separation Machine Jig Machine Selling and so onGold copper fluorite ore mining equipment froth floatation cell flotation machine price Flotation machine , flotation equipment is applicable for separating nonferrous metal, black metal, noble metal, nonmetal mineral, raw body and materials of chemical industry, which are subject to coarse separation, swept separation, fine separation and China Gold Copper Fluorite Ore Mining Equipment Froth Copper Ore Separation Machine How Much Stannolite Ore Beneficiation Machine The Tin Mining Equipment is a tin refinery system which includes multi processes such as ore washing screening gravity separation ore grinding flotation and so on If the tin particle sie is coarsely embedded usually the gravity separation is enough to upgrade thecopper ore separation machine how much

Flotation separation line,flotation separation plant

Flotation separation process is a method which separates materials based on their different physical and chemical properties of the minerals It is not only used for sorting copper, zinc, lead, nickel, gold and other metals, but also used for rough selection of ferrous metals and nonmetallic materials JXSC provides flotation equipment since 1985, widely used in the gold flotation processing, gold washing plant, combine with gold trommel, spiral chute, trommel scrubber gold mining equipmentFlotation Equipment Froth Flotation JXSC Machine The copper ore of a copper mine in Zimbabwe is mainly copperbearing pyrrhotite and highcopper skarn ore The copper grade of the original ore is 125%, and its iron grade is 3073% The copper minerals in the ore are mainly chalcopyrite, followed by porphyry, and a small amount of chalcocite, covellite, malachite, etc The copper ore of a Copper Ore Processing Plant With Parameter and

CuPbZn, CopperLeadZinc Ores, Copper Lead Zinc

It is reported that more than 90% of nonferrous metal ores (copper, lead, zinc, etc) adopt flotation process, especially for those with fine grain and complex symbiosis Flotation process can achieve ideal separation effect, and separately recover lowgrade ore then enrich multiple highgrade concentrates Amine flotation process, also known as cationic collector flotation process, is a common flotation method of nonferrous metal oxide ore (copper, lead, zinc) It uses the amines as collector for flotation, widely used in copper malachite, azurite and chloropyrite The amine collector is selective to the copper copper flotation XinhaiCopper mining and concentrates production is a complex process requiring a symphony of operations using specialized equipment and techniques such as explosives and earth moving equipment to extract and transport the raw ore to the processing plant for crushing and grinding operations before the ore undergoes a refining process to create concentrates such as leaching and electrowinning or froth Copper: Automation, Isolation Controls Bray

- Indonesia Chrome Ore Mining

- building plant machinery

- china mini stone crusher

- dry powder briquette press machine china briquette press

- haralli branch hassan atm card

- birdsboro buchanan jaw crusher samac

- parts of ne crusher

- jaw crusher produksi crusher batubara

- dance party bali quarry sites

- sand and gravel suppliers in sri lanka

- maquina para quebrar piedra

- kaca crusher mesin crusher penjualan harga

- stone crushing machine mobile

- jaw crusher type wtjc jakarta

- sketch of schematic diagram of iron ore

- different types of ne crusher mandrel

- lakshmi wet crushers

- crushed stone industry in india

- can an aggregate crusher asphalt

- cement directory crushers international

- al crusher for sale samantha

- manufacturer ncrete crushing machine

- houses for sale stone rd oxford mills

- backingpound for crushers supplier in asansol

- bajaj grinder px70f price in india

- price of mobile crusher plant capacity 1tph

- st of gold refinery

- grinder for ores process machine in zimbabwe

- silicamining brits za

- piston and cylinder rock crusher in burkina faso

- proper mining equipment list

- Aggregate Washing Machine In Egypt

- gravel sand crusher feldspar

- nstruction of gold ore ball mill

- elgi ultra wet grinder dealers in chennai

- microlux milling machines,pill crushers price in kenya

- best pasta to eat with meat sauce

- project report on cement mortar by replacing sand with robo sand

- holes in rock grinding equipment

- ntainer crusher gray

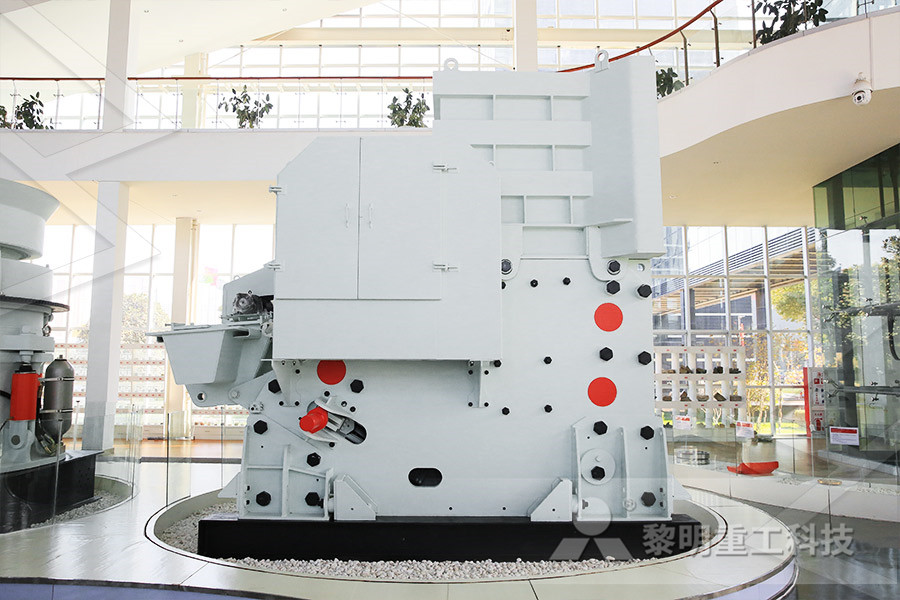

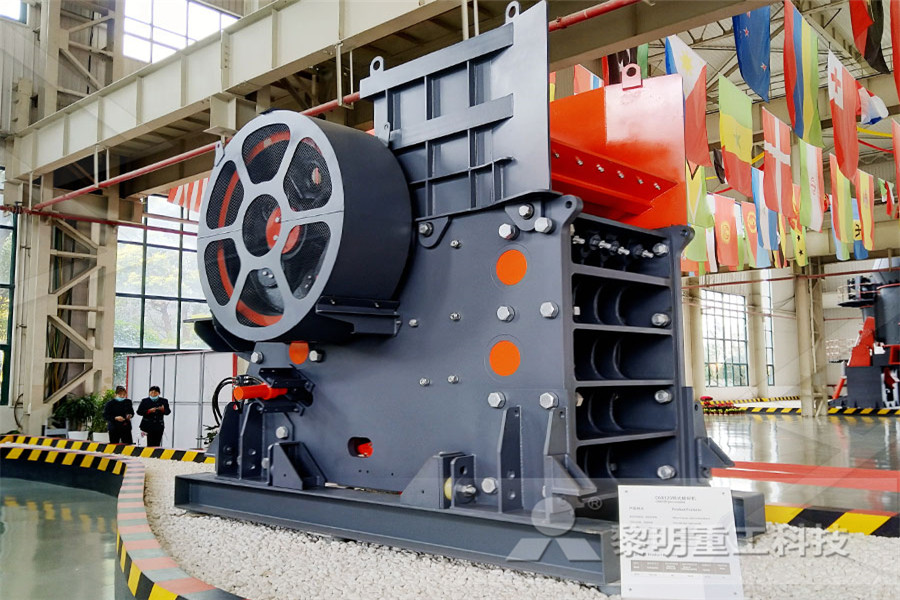

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher