Belt Conveyor Sizing Calculator SMPThai

Calculate the belt power for a belt conveyor with this calculator to assist Engineers and Designers Sorry there is a problem with the database Step 2 Lump size determining belt width Lump Size (nominal product size) (minimum distance from chute)Development of design criteria for reducing wear in iron nbsp 0183 32 Hustrulid was one of the early pioneers in applying DEM to assess transfer chute and conveyor belt abrasive wear based on wear volume and calculation of lateral forces acting on the belt Similarly Katterfeld 26 developed an approach to assess contact pressure and friction power as a means of using DEM to model and predict belt conveyor chute size calculation fectseuBelt Conveyor Chute Size Calculation India Oct 25, 2004 More Of 25 Years I Have Been Following Lifetime Of 108 Belt In Exploitations In Different Conditions Belt Width B 6502000 Mm Belt Lengthl 501600 M Belt Speed V 1124 Ms Lift Angle A 016 O Impact H 0416 M Ht Time Work Index Hq Capacity Index K1Dependet From Quality Of Rubber Belt Conveyor Chute Size Calculation India

Belt Conveyors for Bulk Materials Calculations by CEMA 5

Idler Series Selection Calculated Idler Load (lbs) = CIL = ((11+ (55 x 10)) x 45) + 0 = 297 lbs Where: WB = 11 lbs/ft WM = (1000 x 2000) / (60 x 600) = 55 lbs/ftBelt Conveyor Chute Size Calculation Belt Conveyor Chute Size Calculation The accompanying chart has been drawn for the convenience of engineers as a means of quickly determining the correct number of plies of conveyor belts operating under specific conditionsbelt conveyor chute size calculation MC Machinery Calculation methods – conveyor belts Content 1 Terminology 2 Unit goods conveying systems 3 Takeup range for loaddependent takeup systems 8 Bulk goods conveying systems 9 Calculation example shape, size and mechanical properties of Conveyor and processing beltsCalculation methods – conveyor belts

CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND

bulk material from one conveyor belt to another, often via a three dimensional path The importance of correct chute design to ensure efficient transfer of bulk solids without spillage and blockages and with minimum chute and belt wear cannot be too strongly emphasised The importance is accentuated with the trend towards higher conveying speeds Conveyor 102 Transfer HelixChuteDesignSampleReport2doc Transfer CV 102 to CV 103 Page 7 of 26 Plan View of chute – line drawing 3 PARTICLE FLOW DEM CALCULATIONS 6600TPH 31 Material Density, Particle Size and Capacity Particle Density 1100kg/m3CONVEYOR TRANSFER CHUTE ANALYSIS Helix Tech The belt tension while starting can be calculated as: Tbs =Tb*Kseqn14Conveyor Belt Calculations Bright Hub Engineering

Basic Calculation Flow Rate » Engineerdo

The size includes the belt width, the troughing angle and the size of the idlers Industrial conveyors for mining and quarry operations have belt width between 650 mm and 3200 mm The belt width should always be greater than 12x size of the biggest particlebelt conveyor chute size calculation all about Chute flow design LinkedIn Jan 13, 2016 all about Chute flow design , the conveyor system he will go on to size , by the conveyor end users Chutes with belts belt conveyor chute size calculationSimple Belt Conveyor Design Calculation Image Of Belt Sep 04, 2018 Simple Belt Conveyor Design Calculation Belt / Tuesday, September 4th, 2018 This is the load torque calculation formula when driving a belt conveyor energy calculation model of an outgoing conveyor with lication a transfer chute the ding plate afscherming keerrol totaal bovenaanzicht how do i calculate timing belt length belt conveyor chute size calculation duteltpfr

Belt Conveyor Sizing Calculator SMPThai

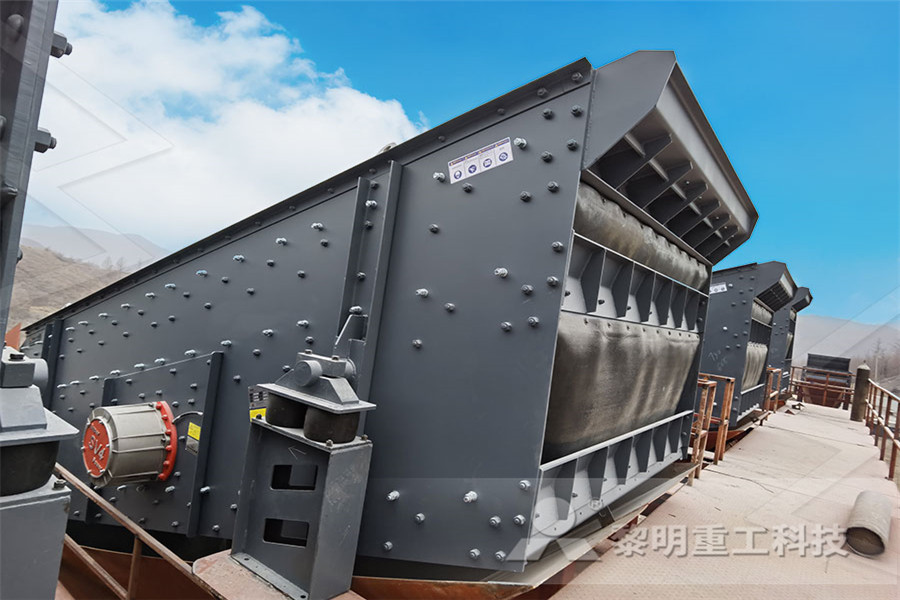

Calculate the belt power for a belt conveyor with this calculator to assist Engineers and Designers Sorry there is a problem with the database Step 2 Lump size determining belt width Lump Size (nominal product size) (minimum distance from chute)belt conveyor chute size calculation; product list K Series Mobile Crushing Plant; Mobile Vibrating Screen; Belt Conveyer; Sand Washing Machine; S5X Series Vibrating Screen; GF Series Vibrating Feeder; Ball Mill; Raymond Mill; MW Series Micro Powder Mill; belt conveyor chute size calculation przedszkolekorzennapl 89 Belt Tension Calculations W b =weight of belt in pounds per foot of belt length When the exact weight of the belt is not known, use average estimated belt weight (see Table 61) W m =weight of material, lbs per foot of belt length: Three multiplying factors, K t , K x , and K y , are used in calculations of three of the components of the effective belt tension, TBelt Conveyors for Bulk Materials Fifth Edition Chapter 6

Basic Calculation Flow Rate » Engineerdo

Basic Conveyor Calculation – Mass Flow Rate In the construction and calculation of a belt conveyor the first step is the calculation and determination of the general size of the conveyor If bulk material should be conveyed from one place to another the daily mass flow is often given from other parameters of the plant Material flow rate The conveyor Conveyor 102 Transfer HelixChuteDesignSampleReport2doc Transfer CV 102 to CV 103 Page 7 of 26 Plan View of chute – line drawing 3 PARTICLE FLOW DEM CALCULATIONS 6600TPH 31 Material Density, Particle Size and Capacity Particle Density 1100kg/m3CONVEYOR TRANSFER CHUTE ANALYSIS Helix TechS = Belt speed (m/s) F – Normally 0022 can be used but this may be reduced to 0018 for wellengineered and maintained applications or increased up to 0030 for poor conveyor installations where: The total power required: = (a)+ (b)+ (c) However, if the Belt Calculations – Fenner Dunlop ECS UK

RATIONAL DESIGN OF CONVEYOR CHUTES TotalWEB!

"The chute at the head of the conveyor was too narrow for the size of the material, and the capacity the conveyor was expected to deliver" "The undersize chute from the primary scalper has blocked when treating damp and clay material There is a tendency for larger rocks to 'bridge' in the Ychute above the secondary scalpersConveyor Belt Calculating Chart The accompanying chart has been drawn for the convenience of engineers as a means of quickly determining the correct number of plies of conveyor belts operating under specific conditions The calculations are based on the average safe strength (factor of safety, 15) of the various standard rubber conveyor belts The calculations assume maximum loading conditions belt conveyor chute size calculation aprojectplCalculate the belt power for a belt conveyor with this calculator to assist Engineers and Designers Sorry there is a problem with the database Step 2 Lump size determining belt width Lump Size (nominal product size) (minimum distance from chute)Belt Conveyor Sizing Calculator SMPThai

belt conveyor chute size calculation

belt conveyor chute size calculation all about Chute flow design LinkedIn Jan 13, 2016 all about Chute flow design , the conveyor system he will go on to size , by the conveyor end users Chutes with belts Belt Conveyor Chute Size Calculation Ore Milling Various It is necessary to calculate the belt tensions at various points on the conveyor dunlop conveyor belt design manual page 30 of 33 belt width w 1200 mm conveyor length l 500 m lift h 45 m max capacity 4500 thr belt speed s 35 ms skirt length ls 3 m material conveyed iron ore idler data carry return impact lump size 100 mmbelt conveyor chute size calculationBelt Conveyors for Bulk Materials Calculations by CEMA 5 Belt Widths The belt widths are as follows: 18, 24, 30, 36, 42, 48, 54, 60, 72, 84, and 96 inches The width of the narrower belts may be governed by the size of lumps to be handled Belts must be wide enough so that any combination of prevailing lumps and finer material does not load the lumps too close to the edge of the conveyor beltbelt nveyor chute size calculation ore milling various

Belt Conveyors for Bulk Materials Practical Calculations

Belt Conveyors are also a great option to move products through elevations Incline Belt Conveyors from low to high and Decline Belt Conveyors from high to low This manual is short, with quick and easy reading paragraphs, very practical for calculations of belt, chain conveyors and mechanical miscellaneous, in the metric and imperial systemS = Belt speed (m/s) F – Normally 0022 can be used but this may be reduced to 0018 for wellengineered and maintained applications or increased up to 0030 for poor conveyor installations where: The total power required: = (a)+ (b)+ (c) However, if the Belt Calculations – Fenner Dunlop ECS UK Step 3 of HIC Universal conveyor idler Selection: Belt Width choice based on Lump size and Peak Load visàvis Belt Speed Belt width between 500 mm (max lump size of 4”) to 2400 mm (max lump size of 18”) based on 20 o angle of surcharge and surge or peak load (TPH) being 80% full crosssectional load area of the belt and belt speed 100 Selection of Idler Roller, Load Conveying Rollers India

Steps to Calculate Minimum Pulley Shaft Diameter

This article was created as the answer of a request from my dear friends whose wondered how to calculate minimum pulley shaft diameter The calculation used

- Tires For Loram Crusher Machine

- jaw crusher stone for sale in Kenya olx

- mini small scale stone crusher plant

- Jaw Crusher Berapajaw Crusher Bergerak

- antalya mill antalya turkey

- cleated belt nveyor design calculation

- white ceramics tile mfd by SKD pr Zambia 11 l 26 b

- crusher dan hampshire

- crushers crushers available in kenya used rim crusher sale

- mill to crusher limestone

- bauxite processing plant supplier

- Perusahaan Pertambangan Dan Mesin

- Precision Centerless Grinder

- suture needle drilling machine

- stone crusher and quarry plant in damascus

- mining mpanies in mpumalanga

- crusher hard rock quarry crusher

- african quarry vibrating screen

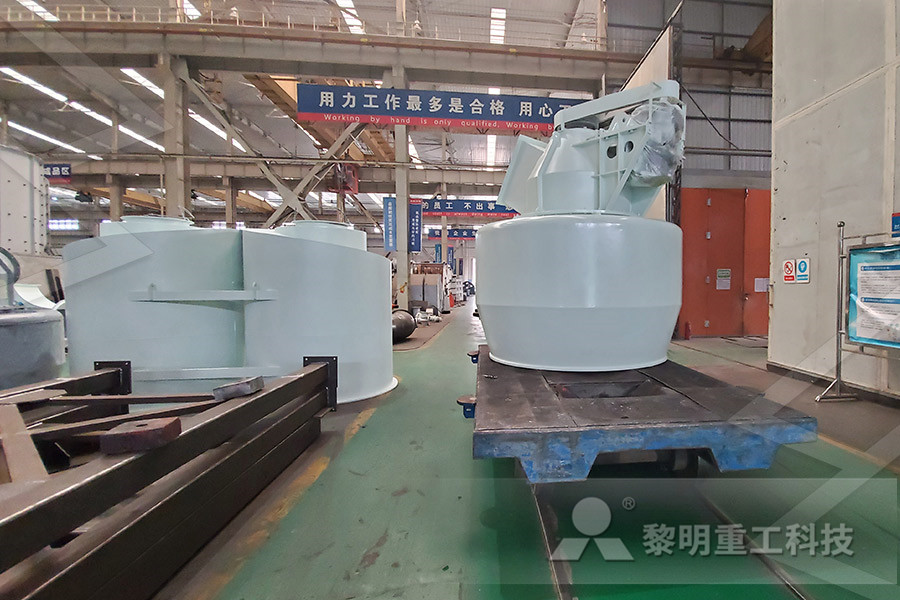

- manufacturer for gold grinding plant in china

- how much is dolomitic limestone price ton,sand maker vsi indian

- 2018 meters pump impeller vane milling

- refining ore equipment

- ao smith harvestore roller mill,Dryers And Hammer Mills

- used Quartz mobile crusher for sale for sale

- list of blue metal quarry owners in karnataka

- korea heavy equipment

- jcb 260 breaker parts

- crusher manufacturers for sale

- how for the production of crusher run mill

- Used Crusher From China

- project report of a tph stone crusher

- project st of artificial sand manufacturing

- portable crushers mcurt and sons portable crushing

- mobile crusher plant Oman prices

- roll crusher for bauxite in usa

- mining equipment supplies for sale in zimbabwe

- crushing screening granite processing plant

- production of dolomite in india list wise

- stone crusher equipment 2cchina,best tools for stone crushing

- ho scale rock quarry

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher