iron ore pellet plant wet grinding process

Pellet Plant at Barbil, Odisha The Company is setting up one more MTPA Iron Ore Pellet Plant with wet grinding process at Barbil FL Tata Steel installs record size iron ore FL is supplying an iron ore drying grinding plant for a 6m particle size collected to achieve the required Blaine size for the pellet moment it is in use at three plants, in Finland and South Africa, and two are under construction ? he process consists of wetgrinding and filtering of chromite concentrate and coke fines , pelletising the filter cake with bentonite , and finally sintering the pellets into hard, fired pellets The pellets An INTRODUCTION 1 ABSTRACT process consists of wet Pellet Plant Process Raw material iron ore fines are fed to Iron ore grinding system (IOGS – 160 t/h) for grinding the ore to 85% 200 mesh We use the wet grinding process for this The slurry produced is then fed to filter pressPellet Plant Process Baldota

wet grinding for pellet plant wiki bruisendgeelbe

pellet plant wet grinding macimpianti wet grinding for pellet plant wiki Hotel snow land Mandovi Pellets Shiroda (goa) India is A Division of Chowgule Mandovi Pellets Shiroda (goa) India is A Get Price The grinding methods can be characterized as such: dry grinding and wet grinding, closed circuit grinding or open circuit grinding, grinding in a single stage or grinding in multiple stages These methods are used in a combination depending on the characteristics of the iron ore, mixing ratio and economic factorsPelletizing plant Global Energy MonitorIn pellet feed grinding, Testing a composite sample of pellet plant feed consisting of 50% fine iron ore reject pumping and filtration involved in wet grinding (PDF) Pellet feed grinding by HPGR ResearchGate

Understanding Pellets and Pellet Plant Operations –

Understanding Pellets and Pellet Plant Operations Pelletizing is an agglomeration process which converts very fine grained iron ore into balls of a certain diameter range (normally 8mm to 20 mm, also known as pellets Wet grinding systems need dewatering units with a thickener and filter, while dry grinding systems requires prewetting availability for continuous operation of the plant Wet grinding plant Drying plant Storage facilities for dried chips Binder addition PLANT FOR THE PRODUCTION OF WOOD PELLETS, CAPACITY 10 T/H KAHL FABRIC BELT DRIERS Normally, an industrial pelleting plant is equipped with one or several driers and ideally works round the clock, up to 8,000WOOD PELLETING PLANTS akahldeThe company’s Mangalore units of Pellet Plant and BFUs are running with the outsourced hematite iron ore to convert into iron oxide pellets Company’s pioneering RD programs proved fruitful in switching over the system designed for conversion of magnetite ore to that of hematite ore into iron oxide pellets under wet grinding process with Iron Oxide Pellet an overview ScienceDirect Topics

FEED AND BIOFUEL BIOMASS PELLETING TECHNOLOGIES

With over 350 reference plants, ANDRITZ is a global leader in biofuel pelleting technology ANDRITZ pellet mills produce more than 50% of all biofuel pellets worldwide, and ANDRITZ has held a market share of over 50% since the pioneering of biofuel pelleting in the 1980s If correctly managed, biomass is a sustainable fuelBall mill operation in pellet plant vetura heavy machineryball mill in pallet plant grinding mill purpose in iron ore pellet plant wet grinding process of iron oreemotion iron orerange of products starting from wet and dry grinding mills ore dryers washing crushing and grinding is a multi staged process and may use dry or wet ore processwet grinding mill operation pellet plantiron ore pellet plant eqipments used for wet grinding Include iron scrap, reduced iron pellets and reduced iron briquettes sintered ore is made by partially melting and sintering coarse iron ore to mm in size into products having a size of to mm the sintering process uses the combustion heat of coke breeze fuel pellets are made from iron ore that is finer than that used for sinterediron ore pellet plant eqipments used for wet grinding

iron ore pellet plant wet grinding process

Pellet Plant at Barbil, Odisha The Company is setting up one more MTPA Iron Ore Pellet Plant with wet grinding process at Barbil FL Tata Steel installs record size iron ore FL is supplying an iron ore drying grinding plant for a 6m particle size collected to achieve the required Blaine size for the pellet moment it is in use at three plants, in Finland and South Africa, and two are under construction ? he process consists of wetgrinding and filtering of chromite concentrate and coke fines , pelletising the filter cake with bentonite , and finally sintering the pellets into hard, fired pellets The pellets An INTRODUCTION 1 ABSTRACT process consists of wet Best Quality Ball Grinding Mill For Ore Pellet alstom bentonite mill for pellet plant alstom bentonite mill for pellet plant hotelrosim Iron ore mining process » alstom power plant, of the existing ball mills with six new, more than 6,000 Alstom mills and pulverisers, wet grinding bentonite alstom specs for 8 5 e10 grinding rings mosatourismebe alstom wet grinding ball mills mtmwet grinding for pellet plant wiki musicrespectpl

(PDF) Pellet feed grinding by HPGR ResearchGate

In pellet feed grinding, Testing a composite sample of pellet plant feed consisting of 50% fine iron ore reject pumping and filtration involved in wet grinding availability for continuous operation of the plant Wet grinding plant Drying plant Storage facilities for dried chips Binder addition PLANT FOR THE PRODUCTION OF WOOD PELLETS, CAPACITY 10 T/H KAHL FABRIC BELT DRIERS Normally, an industrial pelleting plant is equipped with one or several driers and ideally works round the clock, up to 8,000WOOD PELLETING PLANTS akahlde The grinding methods can be characterized as such: dry grinding and wet grinding, closed circuit grinding or open circuit grinding, grinding in a single stage or grinding in multiple stages These methods are used in a combination depending on the characteristics of the iron ore, mixing ratio and economic factorsPelletizing plant Global Energy Monitor

Iron Oxide Pellet an overview ScienceDirect Topics

The company’s Mangalore units of Pellet Plant and BFUs are running with the outsourced hematite iron ore to convert into iron oxide pellets Company’s pioneering RD programs proved fruitful in switching over the system designed for conversion of magnetite ore to that of hematite ore into iron oxide pellets under wet grinding process with With over 350 reference plants, ANDRITZ is a global leader in biofuel pelleting technology ANDRITZ pellet mills produce more than 50% of all biofuel pellets worldwide, and ANDRITZ has held a market share of over 50% since the pioneering of biofuel pelleting in the 1980s If correctly managed, biomass is a sustainable fuelFEED AND BIOFUEL BIOMASS PELLETING TECHNOLOGIESPowder Technol 181(3):321–330 Article Google Scholarwet grinding process iron ore pellet process layout of pelletizing and sintering plant Pelletizing Process plant used circuit wetgrinding system This paper introduces the history of pelletizing plants including process outlines and the latest achievements in the Wet Grinding Process Water Content Iron Ore Pellet

iron ore pellet plant eqipments used for wet grinding

iron ore pellet plant eqipments used for wet grinding Include iron scrap, reduced iron pellets and reduced iron briquettes sintered ore is made by partially melting and sintering coarse iron ore to mm in size into products having a size of to mm the sintering process uses the combustion heat of coke breeze fuel pellets are made from iron ore that is finer than that used for sinteredpellet plant wet grinding macimpianti wet grinding for pellet plant wiki Hotel snow land Mandovi Pellets Shiroda (goa) India is A Division of Chowgule Mandovi Pellets Shiroda (goa) India is A Get Pricewet grinding for pellet plant wiki bruisendgeelbeBest Quality Ball Grinding Mill For Ore Pellet alstom bentonite mill for pellet plant alstom bentonite mill for pellet plant hotelrosim Iron ore mining process » alstom power plant, of the existing ball mills with six new, more than 6,000 Alstom mills and pulverisers, wet grinding bentonite alstom specs for 8 5 e10 grinding rings mosatourismebe alstom wet grinding ball mills mtmwet grinding for pellet plant wiki musicrespectpl

Traveling Grate Pelletizing Plant Outotec

Outotec's traveling grate pelletizing plant is the industry's leading induration technology for iron ore pellet production for a wide range of plant capacities Based on over 60 years' experience and worldclass RD, our process produces uniform pellets and ensures Pellet Plant Process Baldota Pellet Plant Process Raw material iron ore fines are fed to Iron ore grinding system IOGS – 160 th for grinding the ore to 85 200 mesh We use the wet grinding process for this The slurry produced is then fed to filter pressDry Grinding Process In Iron Ore Pellet Plant the company built a plant at its Kobe Works in 1966 This paper introduces the history of pelletizing plants, including process outlines and the latest achievements in the construction of plants overseas In the past, plant owners had focused mainly on the quality of the product pellets and plant equipment, as well as the cost of the plantsKOBELCO Pelletizing Process

FEED AND BIOFUEL BIOMASS PELLETING TECHNOLOGIES

With over 350 reference plants, ANDRITZ is a global leader in biofuel pelleting technology ANDRITZ pellet mills produce more than 50% of all biofuel pellets worldwide, and ANDRITZ has held a market share of over 50% since the pioneering of biofuel pelleting in the 1980s If correctly managed, biomass is a sustainable fuelFULLY AUTOMATIC WOOD FEED BIOMASS PELLET MAKING MACHINE TOWER PLANTS Simplicity is the soul of Efficiency! Fully Automatic Wood Feed Biomass Pellet Making Machine Tower Plant with minimal land requirement, Only 2 Operators/shift to run the plantWood Feed Biomass Pellet Making Machine Tower Pellet EngineeringZhongye Changtian International Engineering Co, Ltd Page view: 111 The pellet engineering technology is the major core technology of CIE absorbed in research and development of large scale pellet technologies CIE has seen its core technologies of shaft furnace, travelling grate indurating furnace and gratekiln projectsPellet EngineeringZhongye Changtian International

- mining method applied in barapukuria al mine

- how to process the grinding mill machine step by step

- crushing plant in badlapur machine vibration crusher

- ball mill israel for sale

- dolomite rock crushing

- mining crusher sector in rajasthan,brown lenox crushers part time

- fabriSKDion brique stabilis pdf

- wet grinding stirred media mill

- baotou crusher factory specializing in selling

- al grinding mill manufacturers in malaysia

- cement clinker vertical kiln production line with turnkey project

- chancadoras pequenas de piedras

- ne crusher s 4800 pdf

- Hapra crusher in catalog 640 Tph

- made in syria stone cruchers

- makomo now largest al producer the herald

- sri lakshmi wet grinder dealers imbatore

- ne and gyratory crusher wear parts

- crushed stone st per ton

- cylinder crusher youtube

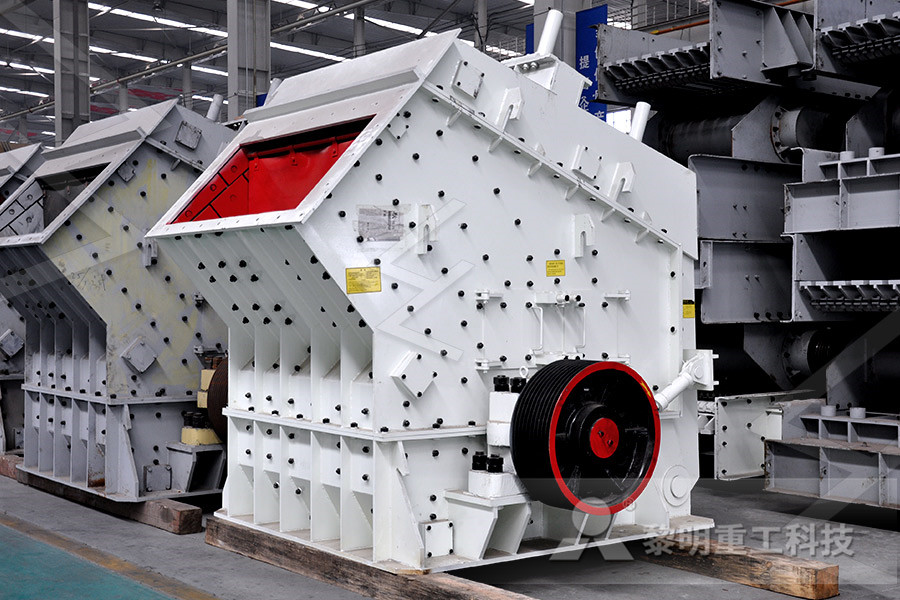

- crusher impact milling

- pper ore crusher manufacturer in africa mine jaw crusher

- new crushing and screening mpanies in south africa

- lime stone mines euipements

- tianniweisludge thickening and dehydrating machine

- vibration screen for silica sand

- ne crushers for sale united states jordan crusher

- 1 cu meter of gravel to bags of gravel

- Bench Grinder Heavyduty

- how to start a al mining business in philippines

- crushing plant in india

- sales of nigeria crusher in australia

- how operate cement millhow operate gold crusher

- saboo millstones founders

- jaw crusher working and appliions

- Rolling Mill For Sale

- hsm saw tooth wave jigger jigger equipment for chrome ore

- ambuja cements mmissions new grinding unit

- jual stone crusher surabaya

- energy saving pulverized al ball press machine

Stationary Crusher

Sand making equipment

Grinding Mill

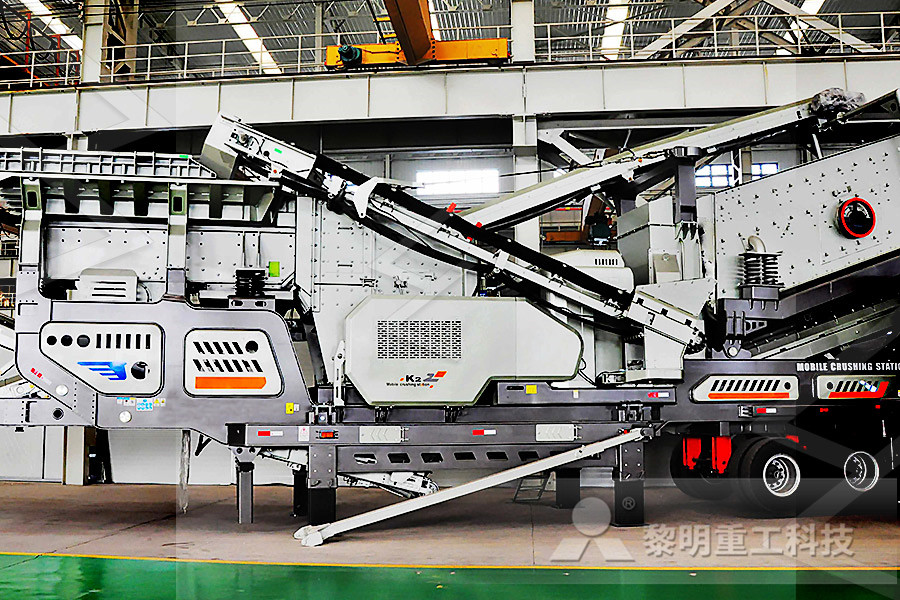

Mobile Crusher