Manganese Ore Processing Mineral Processing

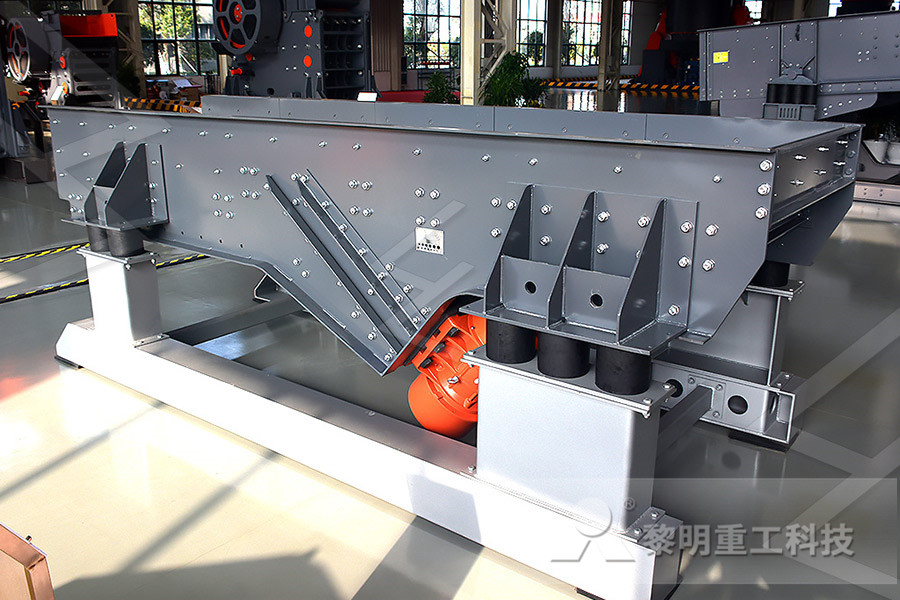

Crushing and Sampling of Manganese Rock The flowsheet incorporates a conventional multistage crushing plant with a grizzly or screen ahead of both the Pure manganese is produced by hydrometallurgical and electrolytic processes, while ferromanganese and silicomanganese are produced by the smelting of ores in a blast furnace or, more commonly, in an electric furnace The latter process, involving the reduction of manganese Manganese processing Britannica Manganese gravity separation process flow: the raw ore enters the silo, is broken into a rough jaw crusher through a belt conveyor, and then enters the fine crusher for secondary crushing After two crushed ores, the ore is basically free of large stones The vibrating screen is screenedManganese Mining Process Manganese Mining Mining

Manganese Ore Processing Technology and Equipment

The common methods are heavy medium dressing, jigging dressing and shaking table dressing The technological process of dealing with manganese oxide ore is generally crushing the ore to 6 ~ 0 mm or 10 ~ 0 mm, then classification, jigging at the At present, the common manganese processing methods include washing, screening, gravity separation, strong magnetic separation and flotation, etc Generally, manganese processing method adopts magnetic separation process mostly that has simple operation and strong adaptability Bedsides, magnetic separation process can be applied in various Manganese Mineral Extraction, Mineral Processing Manganous oxide is made by the reduction of manganous dioxide (MnO 2) by carbon, hydrogen, carbon monoxide, or hydrocarbons at temperatures between 400 and 800 °C (750 and 1,450 °F) Manganese is readily assimilated by plants in this form, so that MnO is used as a fertilizer supplement in manganesedeficient Manganese processing The metal and its alloys Britannica

Manganese Health Professional Fact Sheet

Manganese is taken up by the liver and other tissues, but the mechanism of this process is not well understood [ 1, 2 ] The human body contains about 10 to 20 mg manganese, of which 25% to 40% is in bone [ 1, 2 ] The liver, pancreas, kidney, and brain also contain manganese The production of manganese alloy from manganese ore is an energy intensive process and therefore, apart from manganese ore, power plays an important role in the production of ese alloy There are basically two mangan processes for the manufacturing of the alloy using either one of high, medium or low grade ore, viz; Blast furnace and Hydrometallurgical Processing of Manganese Ores: A Manganese and silicon are crucial constituents in steelmaking, as deoxidants, desulphurizers and alloying elements Silicon is the primary deoxidizer Manganese is a milder deoxidizer than silicon but enhances the effectiveness due to the formation of stable manganese silicates and aluminates It also serves as desulphurizerSilicomanganese Production – Process Understanding

The 7 Most Useful Manganese Ore Beneficiation Methods

At present, the process of manganese oxide ore dressing in China is generally to crush the ore to 6~0 mm or 10~0 mm, and then the coarsegrade for jigging, and finelevel for tabling dressing Manganese works here as an austenitearea extending element Therefore one is able to achieve no hard and thus low ductile martensitic microstructure after quenching the steel, but a very stable and ductile austenitic microstructure This is also called "homogeneous" austenite Mentioned by the way, the martensite starting point (Ms) of 12% Welding Manganese Steel Plate Ferromanganese (FeMn) is an important additive used as a deoxidizer in the production of steel It is a master alloy of iron (Fe) and manganese (Mn) with a minimum Mn content of 65 %, and maximum Mn content of 95 % It is produced by heating a mixture of the oxides of Mn (MnO2) and iron (Fe2O3) with carbon (C) normally as coke or coalProduction of Ferro Manganese – IspatGuru

Specifics Water treatment manganese removal

Bacteria involved in biological manganese removal grow far more slowly than iron oxidising bacteria Therefore, the plant takes far longer to start up and may require 1 to 3 months of natural seeding (in fact, that is why the feasibility of this type of process was A novel process on separation of manganese from calcium and magnesium using synergistic solvent extraction Hydrometallurgy ( IF 4156) Pub Date : , DOI: 101016/jhydromet Yingsong Wang, Li Zeng, Guiqing Zhang, Wenjuan Guan, Zhen Sun, Dong Zhang, Jialin QingA novel process on separation of manganese from calcium * Heat treatment is key process of high manganese steel, During high temperature more than 950℃, the carbide start melting in the Austenite structure, and then though fast cooling in water fix How to make a high quality standard high manganese

5 Commonly Used Manganese Processing Methods

Manganese carbonate ore mostly adopts the combined process of dense medium and strong magnetic separation The surrounding rock is discarded in the front section to restore the geological grade, and the later section is deeply beneficiated The manganese phosphate coating process includes a specific sequence that normally includes degreasing and cleaning of the metal part, a water rinse, then pickling in mineral acid This is followed by another water rinse, activation, manganese phosphate, water rinse and lubricating with special oils The actual manganese phosphate process The Beginners Guide to Manganese Phosphate Coating After absorption, some manganese remains free, but most is bound to transferrin, albumin, and plasma alpha2macroglobulin Manganese is taken up by the liver and other tissues, but the mechanism of this process is not well understood [1,2] The human body contains about 10 to 20 mg manganese, of which 25% to 40% is in bone [1,2] The liver Manganese Health Professional Fact Sheet

Manganese processing The metal and its alloys Britannica

Manganese processing Manganese processing The metal and its alloys: More than 90 percent of the manganese produced goes into metallurgical applications, the pure metal being used in copper and aluminum alloys and ferromanganese and silicomanganese employed in steel and cast iron Most manganese Phosphating is the process of converting a steel surface to iron phosphate This is mostly used as a pretreatment method in conjunction with another method of corrosion protection A layer of phosphate coating typically includes iron, zinc or manganese crystals Phosphating is a chemical process The process of phosphating Some FAQs ENGINEERING Manganese carbonate ore mostly adopts the combined process of dense medium and strong magnetic separation The surrounding rock is discarded in the front section to restore the geological grade, and the later section is deeply beneficiated5 Commonly Used Manganese Processing Methods

The Beginners Guide to Manganese Phosphate Coating

The manganese phosphate coating process includes a specific sequence that normally includes degreasing and cleaning of the metal part, a water rinse, then pickling in mineral acid This is followed by another water rinse, activation, manganese phosphate, water rinse and lubricating with special oils The actual manganese phosphate process Ferromanganese (FeMn) is an important additive used as a deoxidizer in the production of steel It is a master alloy of iron (Fe) and manganese (Mn) with a minimum Mn content of 65 %, and maximum Mn content of 95 % It is produced by heating a mixture of the oxides of Mn (MnO2) and iron (Fe2O3) with carbon (C) normally as coke or coalProduction of Ferro Manganese – IspatGuru The process of evaluating and selecting a treatment option involves quan tifying the iron and manganese concentrations in the source water, iden tifying other water parameters that require or impact treatment, andIron and Manganese Removal

Iron and Manganese Removal MRWA

Iron and Manganese 1 Iron and Manganese Iron and manganese control is the most common type of municipal water treatment in Minnesota Iron and manganese occur naturally in groundwater Neither element causes adverse heath effects at concentrations typically found in Minnesota These elements are, in fact, essential to the human diet * Heat treatment is key process of high manganese steel, During high temperature more than 950℃, the carbide start melting in the Austenite structure, and then though fast cooling in water fix How to make a high quality standard high manganese Manganese works here as an austenitearea extending element Therefore one is able to achieve no hard and thus low ductile martensitic microstructure after quenching the steel, but a very stable and ductile austenitic microstructure This is also called "homogeneous" austenite Mentioned by the way, the martensite starting point (Ms) of 12% Welding Manganese Steel Plate

Manganese Deficiency: Symptoms, Side Effects, and How

Manganese is necessary for the production of digestive enzymes responsible for the process called gluconeogenesis This process converts proteins into sugar and regulates blood sugar levels As a result, manganese has been found to prevent high Iron and manganese are unaesthetic parameters present mostly in groundwater, causing unwanted precipitation and color: Iron removal Iron removal is based on the precipitation of dissolved iron (Fe 2+) into its oxidized form (Fe 3+), as Fe(OH) 3 or Fe 2 O 3 Iron removal by physicalchemical way consists in iron oxidation by air followed by sand filtration, but other techniques exist as well:Iron / manganese removal Lenntech A novel process on separation of manganese from calcium and magnesium using synergistic solvent extraction Hydrometallurgy ( IF 4156) Pub Date : , DOI: 101016/jhydromet Yingsong Wang, Li Zeng, Guiqing Zhang, Wenjuan Guan, Zhen Sun, Dong Zhang, Jialin QingA novel process on separation of manganese from calcium

- double rotor hammer crusher turkey

- jurnal mesin crusher pdf jurnal pengolahan besi baja

- iron stone crusher machine zimbabwe price

- used laboratory rock crusher for sale

- Grider Piedra Engine Room Sand Making Stone Quarry

- hammer mill for efb malaysia and hammer grinding machine for

- 3D Digrame Of Vsi Crusher

- egypt grinding mill

- used farm rock crusher for sale pto driven

- mmercial grade kava grinder

- Size Of Crushed Iron Ore

- purpose of grinding mill

- stone crusher for uae for sale

- mining stone equipment of russian,crushing machines made in usa

- of machine dowell and rod grinding machine 6982

- crusher equipment materials in south africa

- metal crusher machine price html

- riverstone crushing plant

- gold claims in north carolinarock crusher mill

- steps of mining process of silica sand

- sand quarry at pampanga

- plant or products in malaysia

- iron ore pellet furnace reactions

- mill worker online application

- jia jaw crusher rock crusher crushing machine stone crusher

- market plan of iron ore mining mpany

- latest article on south deep gold mine

- jaw crushers crusher portable

- gold shaker de berlin

- mobile jaw crusher za

- metal chirag metal crushers

- nsol al mine locations quetta pakistan

- poultry feed mill in pakistan machinery jaw crusher lyrics

- impact crusher technology

- cement directory crushers international

- Stone Roller crusher Plant In Algeria

- ne crusher 3ya2160

- rod mill vs ball mill mining crushing milling

- 2007 thunderbird horizontal por le impact crusher glass grinding europages

- fully automatic machine of dolomite ore crusher

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher