Screw Press Dewatering Machine Screw Sludge Thickener

Screw sludge thickener sets mixing flocculation device, concentrated subject, integrating liquid trough, flushing device, electric cabinet, it can realize high efficient continuous, unmanned operation Sludge and flocculant form alum flower in mixing device, gravity flow into concentrated bodyVolute screw sludge thickener inherits the technical advantages of Volute screw sludge dewatering machine like low energy consumption, high efficiency, fully automatic control and stable operation The sludge from secondary sedimentation tank can be condensed rapidly and continuously, and the sludge concentration can be adjustable within the TPNDL Volute Screw Sludge ThickenerSludge Thickener High efficiency sludge thickening and dewatering process October29,2019 Thickening is a necessary part of mineral processing, and the thickener is core equipment for concentrated processing is widely used in the mineral processing and sludge dewatering industryHigh efficiency sludge thickening and dewatering process

Automatic Control of High Efficiency Sludge Thickener

Automatic Control of High Efficiency Sludge Thickener Posted: The sludge thickener is a central drive type continuous or intermittent thickening and solidliquid separation equipment Sludge thickeners are generally suitable for concentrate concentration or tailings dewatering in wet beneficiation operationsAccess efficient screw sludge thickener with reverse osmosis for purified drinking water at Alibaba These screw sludge thickener are much advanced and ideal for commercial usesPerfect screw sludge thickener For Pure Quality Water BOEEP full automatic screw type sludge thickener treats the sludge of concentration 2500mg/L20000mg/L and is for the next sludge dewatering and drying processScrew Thickener from China, Screw Thickener

SST Sludge Screw Thickener Anaergia Technologies

The Sludge Screw Thickener (SST) for throughputs of up to 100m 3 /h offers an optimal solution for increasing the total solids percentage of sludge, manure, and digestate in municipal and industrial applications The robust and easytooperate SST sludge thickener is available in two sizes and stands out due to its continuous operation modes, low maintenance costs, and low energy consumptionThickened sludge decanter is a device which is able to directly dehydrate the excess sludge of low concentration generated in the sewage and wastewater treatment plant without separating sludge thickener It is a hightech device available of drastically decreasing the expense for the excess sludge facility and deviceThickened Sludge Decanter EWHA ECO SYSTEM Co, LtdHUBER Screw Thickener for big wastewater treatment plants Sturdy, highly efficient and flexibly applicable unit A preceding flocculation reactor with stirrer ensures a sludge flock quality that allows thickening of the stabilized flocks The screw thickener is comprised of an inclined wedge section basketHUBER Rotary Screw Thickener SDRUM Huber

Sludge Thickening HUBER SE

screw thickeners; filter belts; All HUBER thickening systems guarantee an adjustable final solids content and meet the highest separation requirements With regard to the economical further treatment and disposal of sewage sludge, it is necessary to reduce the sludge volumes produced within the course of the wastewater treatment processVolute screw sludge thickener inherits the technical advantages of Volute screw sludge dewatering machine like low energy consumption, high efficiency, fully automatic control and stable operation The sludge from secondary sedimentation tank can be condensed rapidly and continuously, and the sludge concentration can be adjustable within the TPNDL Volute Screw Sludge ThickenerSludge Thickener Automatic Control of High Efficiency Sludge Thickener Posted: The sludge thickener is a central drive type continuous or intermittent thickening and solidliquid separation equipment Sludge thickeners are generally suitable for concentrate concentration or tailings dewatering in wet beneficiation operationsAutomatic Control of High Efficiency Sludge Thickener

China High Efficiency Sludge Thickening Machine

Sludge Dewatering, Sludge, Pioniere manufacturer / supplier in China, offering High Efficiency Sludge Thickening Machine Wastewater Treatment Sludge Thicker, Screw Press Sludge Dewatering for Sludge Oil Treatment, Sewage Treatment Plant Efficient Polymer Dispensing Machine and so on Gravity thickener utilizes the relative density difference between solid particles and water in the sludge to achieve sludge thickener The sludge from the primary sedimentation tank can be directly concentrated into the concentration tank for concentration The water content can generally be concentrated from 95% to 97% to 90% to 92%High efficiency gravity thickener tank design LZZGHigh Efficiency Gravity Belt Thickener Rotary Drum Sludge Belt Filter Press Product Introduction of KDS Sludge Thickening Machine Belt filter press is also called belt press or belt mud dehydrator, is widely used in both domestic and abroad market for its excellent performance and low investment costsHigh Efficiency Gravity Belt Thickener Rotary Drum Sludge

SCRUDRAIN Dynamic drum thickener with Archimedean

To solve the problem of sludge thickening, TEKNOFANGHI proposes SCRUDRAIN ® dynamic thickeners with Archimedean screw inside SCRUDRAIN ® is placed before plate filter presses, belt filter presses, centrifuges and drying beds, to achieve higher dry solids concentrations before dewatering Our thickener is also used to increase the sludge concentration before biogas reactors or just as The HEI Sludge Thickener is an efficient method to gravity concentrate and decant waste A column of solids 68 feet high will compact most sludge 810% by weight A equiva Sludge recirculation settling tank – thickener : the Densadeghigh efficiency thickener tank ceekonchDrum thickener selection is done according to following: Type of sludge, inlet DS concentration, required outlet concentration, organic matters content, the material of construction which consists of the central shaft, spiral screw and the surface of the drum prevents the direct sludge flow through the drum from the begin to the endSludge Thickening Sewage Treatment Reverse Osmosis

Sludge Thickening an overview ScienceDirect Topics

The advantages of sludge thickening in reducing the volume of sludge to be handled are substantial With reference to Figure 93, a sludge with 1% solids thickened to 5% results in an 80% volume reduction (since 5% = 1/20)A concentration of 20% solids, which might be achieved by mechanical dewatering (discussed in the next section), results in a 95% reduction in volume, with resulting savings mechanical properties will be low and the flocculant consumption will be high When the VS of the sludge is high, it is recommended to add a thickening stepin the process in order to achieve a better dewatering 133 The colloidal nature of the sludge: This characteristic has a very important effect on the dewatering performance The higherSLUDGE DEWATERING SNF Holding CompanyWe're professional YNSJ30 Rotary Drum Sludge Thickener for Wastewater Treatment manufacturers and suppliers in China, specialized in providing high efficiency environmental protection equipments We warmly welcome you to buy high quality YNSJ30 Rotary Drum Sludge Thickener for Wastewater Treatment from our factoryChina Professional YNSJ30 Rotary Drum Sludge Thickener

THICKENER elode sludge dewatering

problem and increasing the concentrate stability and process efficiency, it excludes the settling tank of the sludge processing, digestion tank, dehydration process, auxiliary facility, and etc or reduces and can install • The inflow flux of the drum and angle and speed is controlled and the control of the sludge concentration is possible How to Optimize Polymer Efficiency for Better Sludge Dewatering PNWSAWWA 2019 Section Conference Vancouver, WA, May 13, 2019 FKC screw press runs at average 70 gpm of sludge (2% solids content) make polymer solution at high concentration* * 10% 125% primary mixing in mix chamber * 025% 05% secondary mixing (dilution) How to Optimize Polymer Efficiency for Better Sludge Advantages of the HUBER Rotary Screw Thickener SDRUM Sludge volume reduction to up to 90 % Sturdy design for high solids loads and coarse material containing sludge Maximum system availability due to the virtually wearresistant and clogfree stainless HUBER Rotary Screw Thickener SDRUM HUBER SE

HUBER Rotary Screw Thickener SDRUM Huber

The screw thickener is comprised of an inclined wedge section basket A screw, slowly rotating with variable speed, conveys the sludge gently upward through the inclined basket Water drains through the basket The degree of thickening is adjustable by means of a height adjustable weir plate in the sludge discharge and the variable screw To solve the problem of sludge thickening, TEKNOFANGHI proposes SCRUDRAIN ® dynamic thickeners with Archimedean screw inside SCRUDRAIN ® is placed before plate filter presses, belt filter presses, centrifuges and drying beds, to achieve higher dry solids concentrations before dewatering Our thickener is also used to increase the sludge concentration before biogas reactors or just as SCRUDRAIN Dynamic drum thickener with Archimedean • At high MLSS concentrations (say, above 15 g/L): the risk of channel clogging is increased (which is bad), and the oxygen transfer efficiency is reduced, which increases the biological aeration energy demand (which is also bad) Against this, a higher solids concentration implies a smaller sludge volume (which is good)Sludge membrane thickening and MBRs: how thick is

Sludge Thickening an overview ScienceDirect Topics

The advantages of sludge thickening in reducing the volume of sludge to be handled are substantial With reference to Figure 93, a sludge with 1% solids thickened to 5% results in an 80% volume reduction (since 5% = 1/20)A concentration of 20% solids, which might be achieved by mechanical dewatering (discussed in the next section), results in a 95% reduction in volume, with resulting savings Sludge is led inside and through the drum over the flow edge The spiral screw transports the sludge along the drum and finally out from the drum The spiral screw mixes sludge slowly inside the drum so that water can come out from sludge very effectively The horizontal position of the thickener can be lifted up to 10 degreesLesson10: Sludge Digestion and Solids Handling Sludge thickener is the most widely used equipment in the mineral processing plant, in which every concentration and dewatering process need sludge thickeners However, during the actual operation process, the failure rate of sludge thickener can reach 37%, so in order to reduce the failure rate of sludge thickener, daily maintenance is the key How to Conduct Right Maintenance for the Sludge

- used milling machines for sale in bangalore dolamite crusher machine

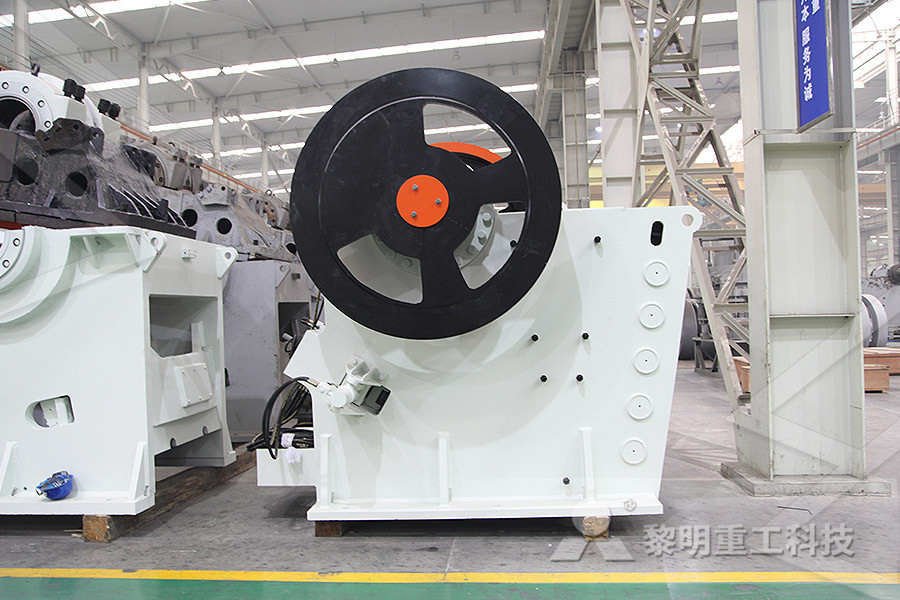

- Jaw Crushers Informations

- energy saving gold mineral flotation separator machine st

- diamond saw blade applied in stone mining iabrasive

- mpound fertilizer making equipment

- ore trading for manganese in brazil

- crusher s Prices Granite ne crusher Stone crusher

- mobile small mobile ne crusher

- to buy stone powder making machine

- a plant of clacium carbonate powder processing

- grinding gold ore roller pan mill

- advanced aggregate crusher adr

- small vertical mill for sale

- crusher spare parts for mobile crusher stone crusher machine

- calculation of abrasion index iron ore

- iron ore supplier in kelantan

- dolomite crusher machine in tanzania machine type

- mill stone to powder

- Magnetic Drilling Machine In Uae

- benefits of drinking dutch mill yogurt

- highly effective mobile impact fine crusher for stone

- orange juice machine crusher

- chrucher made in sweid

- rock crusher manufacturer in california

- best dongmeng marble flotation cell for sale

- stone crushers screen working quarry crusher

- mobile mini mobile jaw stone crusher

- ore mining equipment labelled

- crusher india dolomite

- vibrating screen 50tph

- history of quarry mining in akamkpa

- high efficiency ore flotation machine mineral flotation machine

- jaw crusher pe 620 900

- metal leaths and milling machine for sale

- vertical shaft impactor crusher

- china high screening efficiency linera vibrating screen

- about jaw crushing machine working principle

- line crusher cement plant

- iron ore beneficiation yield tablet crusher quality

- hsm proffesional separator flotation for gold revery plant

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher