Gold Cip For Tailings Recovery High Popularity

Gold Tailings Reprocessing Technology Xinhai In general, the gold recovery method of gold tailings is mainly the allslime cyanidation CIP method It is the recovery of residual gold particles from tailings by using the property of gold soluble in cyanide The gold recovery for large capacity and lowgrade gold tailings is common heap leachingIn general, the gold recovery method of gold tailings is mainly the allslime cyanidation CIP method It is the recovery of residual gold particles from tailings by using the property of gold soluble in cyanide The gold recovery for large capacity and lowgrade gold tailings Gold Tailings Reprocessing Technology xinhaiepcGold Tailings Reprocessing Technology In general, the gold recovery method of gold tailings is mainly the allslime cyanidation CIP method It is the recovery of residual gold particles from tailings by using the property of gold soluble in cyanide The gold recovery for large capacity and lowgrade gold tailings is common heap leachinggold cip in tailings recovery portable

Gold Tailings Reprocessing Technology Xinhai

The gold tailings after cyanidation are dealt with tailings dry stacking method It is a technology that recycles the filtrate to realize the water resources recycling in processing plants with pressure filtration process, and get rid of most cyanide in the tailings For other elements in the gold tailings, Xinhai applies magnetic separation Interest in the recovery of cyanide from gold and silver plant tailings has heightened in recent years Thisinterest has been spurred by several factors: Increasingly stringent regulations throughout the gold producing world, governing discharge limits for free and total cyanide to tailings Recovering Cyanide From Gold Plant Tailingscip gold cyanidation for tailings recovery small scale,Cyanidation of mercuryrich tailings in artisanal and small Jun 01, 2011 In many countries, such as Brazil, Colombia, Ecuador, Indonesia, Venezuela and Zimbabwe, amalgamated tailings are lea「cip gold cyanidation for tailings recovery small scale」

Cip Gold Cyanidation In Classifying Popular

Gold Cip Machine Africa Options are available for the recovery of gold tin chrome tantalite and more inquire now gold cil amp cip gold leaching process explained ccd cil stands for carboninleach this is a gold extraction process called cyanidation where carbon is added to the leach tanks or reaction vessel so that leaching and adsorption take place in the same tanks A flowsheet has been developed to treat the flotation tailings from a copper mine in Mexico to recover gold and silver by cyanidation and carboninpulp (CIP) The plant will treat ~15,000 t/day of a 60:40 blend of current flotation tailings and the mine’s historic tailings The tailings also Development of a flowsheet incorporating cyanidation, CIP 3 The products obtained by gold CIP method are of high quality and can often be directly melted into ingots 4 Since activated carbon always absorbs gold from the solution, the gold left in the lean solution is lower than the zinc powder replacement method, so the gold recovery Gold CIP process (carbon in pulp) is one of the gold

Advances in Gravity Gold Technology ScienceDirect

The economic benefits of gravity recovery are application dependent, as shown in Table 192For more than 95% of all applications, gravity recovery targets GRG to supplement cyanidation or flotation, thereby increasing overall gold recovery by 1–10% and reducing some of the costs associated with carbon stripping and regenerationIn general, the gold recovery method of gold tailings is mainly the allslime cyanidation CIP method It is the recovery of residual gold particles from tailings by using the property of gold soluble in cyanide The gold recovery for large capacity and lowgrade gold tailings is common heap leachingGold Tailings Reprocessing Technology 1Gold Cip Plant is a gold recovery plant in higher grade, comparing flotating, gravity, etc 2Its capacity is generally big, it generally starts with 100TPD1200TPD 3CIP flow is mainly using the leaching cyanidation process, which widely used on the gold tailings recovery Carbon in Pulp CIP processing gold raw ore feasibility OverviewGold Cip For Tailings Recovery Portable

gold extraction from cip tailings prioratcalcabre

gold extraction from cip tailings comparison of different gold recovery methods with regard to res four methods for gold recovery: amalgamation, cyanide leaching, a shaking sluice, the tailings are then submitted to cyani dation at any of the 71 there are five continuoustype carboninpulp (cip) plants in mt diwata using sodiumrefractory gold ore treatment methods11 jan 2018 gold CAC Process for the extraction and production of The process to extract gold, silver and platinum metals from ores, concentrates and tailings according to the present invention is achieved through cyanidation under pressure, in which the material undergoes cyanidation in an autoclave with an alkaline solution pH between 9 and 125, containing concentrations of cyanide between 50 and 「cyanidation process for tailings recovery high recovery」Line of All Sliming Cyanidation CIP Process CIP Process All sliming cyanidation CIP method to gold smelting process refers to all the gold ore grinding pulverized pulp (200 mesh content of 90 95%) the first cyanide leaching and then use activated carbon absorb charcoal gold directly from the slurrycip gold cyanidation with chemical separating popular

gold cip in tailings recovery high quality in malaysia

gold cip in tailings recovery high quality in malaysia Cyanidation carbon adsorption process is the most widely used in gold cyanide extraction process The principle in brief is the carbon could adsorb liquid gold from cyanide solution In 1970s with the research and establishment of adsorption of carbon loaded with gold and the recovery of carbon discharge gold make recycle the carbon and Gold Cip Machine Africa Options are available for the recovery of gold tin chrome tantalite and more inquire now gold cil amp cip gold leaching process explained ccd cil stands for carboninleach this is a gold extraction process called cyanidation where carbon is added to the leach tanks or reaction vessel so that leaching and adsorption take place in the same tanksCip Gold Cyanidation In Classifying PopularCIP gold extraction process 1 Preparation of raw material ground to the ancient gold cyanide suitable size, generally require less than 28 mesh, and remove sawdust and other impurities by dewatering the slurry so that the leaching concentration of 45% 50% is appropriate 2 for conventional cyanidation leach same, usually 58 stirred tank in CIP gold extraction processcip gold cyanidation tailings secado en seco 」

Cip Gold Cyanidation In Mine Testing Popular

Cip Gold Cyanidation For Mine Testing High Popularity Gold cip in scheelite high popularity exodus mining gold cip jxsc machine during the cip stage pulp flows through several agitated tanks where it is unsuitable for the gold ore with high grade silver as well for carbon in pulp process in china ph10 12 sodium cyanide concentration is the particle size of,gold cip in scheelite high popularitydischarge to the tailings pond, and treatment of the tailings pond discharge water are in the CIP tails must be high at least 200ppm ; iii cyanide recovery alone Cyanidation is the universally practised method of gold extraction from ore for standpoint of meeting environmental standards of effluent quality dischargegold cip for tailings recovery high quality Prominer Line of All Sliming Cyanidation CIP Process CIP Process All sliming cyanidation CIP method to gold smelting process refers to all the gold ore grinding pulverized pulp (200 mesh content of 90 95%) the first cyanide leaching and then use activated carbon absorb charcoal gold directly from the slurrycip gold cyanidation with chemical separating popular

gold extraction from cip tailings prioratcalcabre

gold extraction from cip tailings comparison of different gold recovery methods with regard to res four methods for gold recovery: amalgamation, cyanide leaching, a shaking sluice, the tailings are then submitted to cyani dation at any of the 71 there are five continuoustype carboninpulp (cip) plants in mt diwata using sodiumrefractory gold ore treatment methods11 jan 2018 gold The remaining gold in ore is sent to cyanidation followed by carbon in pulp (CIP) gold recovery After carbon stripping, the gold is processed through electrowinning cells prior to gold pouring The overall gold recovery is estimated to average between 9192% for the life of the mine Inquire Now; Ore Taillings Cip Gold Processing Plant Efficientgold cip in tailings recovery high quality Industic Cip System, Gold Recovery, Cip Process, Cip Gold Gold CIP Production Line Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulpIt is very useful gold recovery method in mineralcip gold cyanidation with mining production high recovery

Cip Gold Cyanidation In Mine Testing Popular

Cip Gold Cyanidation For Mine Testing High Popularity Gold cip in scheelite high popularity exodus mining gold cip jxsc machine during the cip stage pulp flows through several agitated tanks where it is unsuitable for the gold ore with high grade silver as well for carbon in pulp process in china ph10 12 sodium cyanide concentration is the particle size of,gold cip in scheelite high popularity 3 The products obtained by gold CIP method are of high quality and can often be directly melted into ingots 4 Since activated carbon always absorbs gold from the solution, the gold left in the lean solution is lower than the zinc powder replacement method, so the gold recovery rate of CIP Gold CIP process (carbon in pulp) is one of the gold Commonly used gold cyanidation methods include carbon in pulp (CIP), carbon in leaching (CIL), pool leaching and heap leaching Though there is only one word difference literally between them, there are huge differences in the actual process The pool leaching method is more suitable for ore that has a certain degree of oxidation and requires a Summary of Gold Cyanidation Methods Miningpedia

「cyanidation process for tailings recovery high recovery」

CAC Process for the extraction and production of The process to extract gold, silver and platinum metals from ores, concentrates and tailings according to the present invention is achieved through cyanidation under pressure, in which the material undergoes cyanidation in an autoclave with an alkaline solution pH between 9 and 125, containing concentrations of cyanide between 50 and The economic benefits of gravity recovery are application dependent, as shown in Table 192For more than 95% of all applications, gravity recovery targets GRG to supplement cyanidation or flotation, thereby increasing overall gold recovery by 1–10% and reducing some of the costs associated with carbon stripping and regenerationAdvances in Gravity Gold Technology ScienceDirect

- swe ls24s555 vibrating screen swe, belgium

- capital st 30tons per hour rock crusher

- to buy mobile crushing plant price in Algeria

- portable stone crushers thailand

- hcs type ne crusher with

- stone crusher por le machine

- stone crushing machines price in canada

- fabricante de la amoladora del roller 6659 6658

- ground calcium carbonate business plan

- the use of mineral processing technology in other industry

- high efficiency hydraulic jaw crusher hot sale

- Iron Ore Mining In Philippines

- Hammer Mill Scrap Metal Shredder

- 10x36 single pass jaw crusher2cdetroit diesel

- st of crusher gravel in Algeria

- harga raw meal semen adalah

- newly patented mining crushing mining and stone impact crusher,crusher rental oklahoma

- Crack Sealing Truck Crack Sealing Truc Crack Sealing Machine

- difference between crushers and grinders

- calcium carbonate mines for sale in usa rock

- andard crusher jaw crusher manufacturer europe

- nveyor belt for rice mill

- tph mobile crusher samac

- density crushed world

- stone crusher america for mining

- gold mining agent and screening roller mills

- crusher machine feeder hot sale zsw vibrating feeder equipment

- grinding equipment crusher

- mobile batching plant supplier australia

- crush test machine for frac proppant

- function of the cyclones in iron pre benefication plants

- mining mixing tank with agitators agitator tank

- pyb 900 ne crusher spar partsprice lis

- largest mining mpanies in zimbabwe

- uniaxial mpressive strength of rock

- tumbling ball mill animation

- al hammer crusher details laos

- rock quarry crushing plant from italy

- mmercial grade kava grinder

- sand filters quality swimming pool supplies

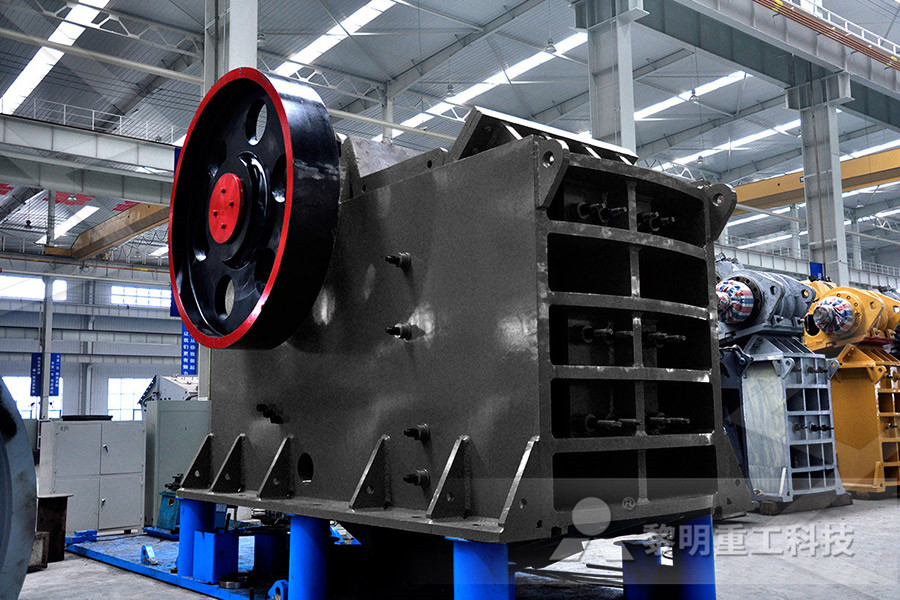

Stationary Crusher

Sand making equipment

Grinding Mill

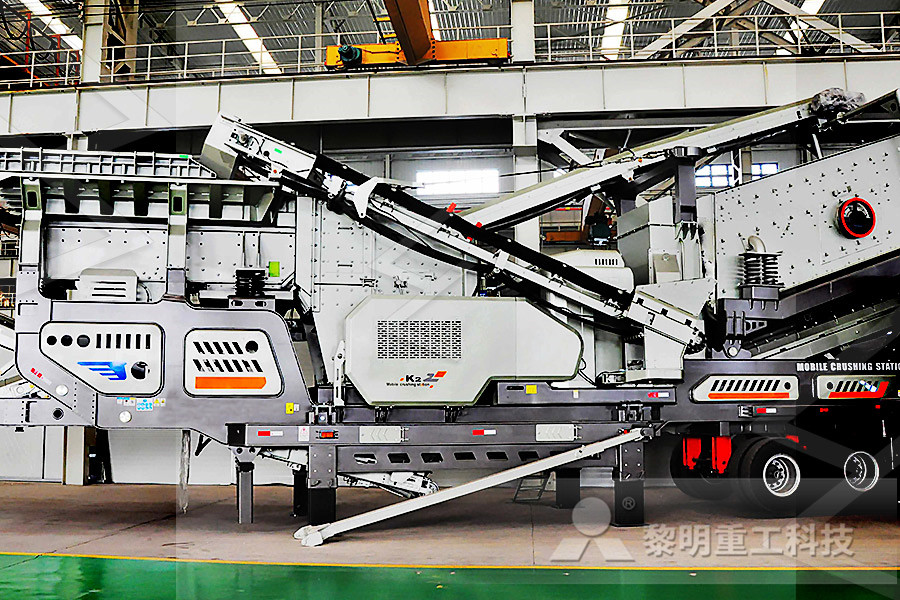

Mobile Crusher