Grinding of Glass: The Mechanics of the Process J Manuf

Experimental results indicate that the specific grinding energy generally increases with the softening temperature of the glass, and is an order of magnitude smaller for grinding with diamond wheels than for grinding with silicon carbide wheelsGrinding is the main machining process for producing glass workpieces However, cutting forces during grinding result in the formation of damaged surfaces which require a (PDF) Grinding of glass : optimization of process High Speed Construction Glass Edge Polishing Machine With 20 / 22 ABB Motors / Spindles Glass Product Name: High Speed Construction Glass Grinding And Polishing Machine With 20/22 ABB Motors/Spindles Glass For Glass Processing Application: Flat Tempered Glass Deep Processing Industry Glass Maximum Size: 2500 Mm Glass Minimum Size: 300×300 MmQuality Glass Loading Machine Glass Grinding Machine

Chemetall Group Glass Processing

During the grinding process, small particles of glass are accumulated enter in the grinding solution thereby gradually reducing the quality of the process Chemetall offers flocculants in powder and liquid form for cleaning the grinding solution, making it useable for a longer periodGrinding of technical glass Home » Processing Techniques » Grinding Contour grinding, edge grinding, polishing, and more The desired contour on the product is achieved through edge processingGrinding of technical glass Technisches Glas glass processing machine system glass processing machine system:glass loading table machine,glass cutting machine,glass heteromorphism drilling machine,glass 4 edge grinding machine,glass washing machine,glass tempered furnace,glass insulated prodution lineComplete Glass Processing Machine line,Glass Cutting

Processing technology Automotive glass cutting

the grinding machine Each feeding procedure automatically includes the takeoff of the final glass sheet The rotating feeder alternatively serves the two grinding machines and provides for short nonproductive times The glass sheet is deposited onto the conveyor upstream of a washing machine or it Glass grinds can wreak havoc on glass fabrication equipment, causing increased maintenance costs, unplanned downtime, decreased production yields, and decreased equipment life Not only do glass grinds cause excessive wear on moving parts, but they can settle throughout your fabrication and processing system and over time completely clog pipesGlass Grinds Filtration and Separation SystemsThe BENTELER flat glass grinding machines convince due to their optimal grinding results based on precision, speed and process reliability Drilling Machines The BENTELER Drilling Machines for flat glass are suitable for all drilling and milling operations in single and serial production even for coated glassLocations BENTELER Glass Processing Equipment

Automotive Side Window Glass Processing Unit

Maximum glass size: 1300*800mm、 Minimum glass size: 300*300mm、 Glass processing thickness: 186mm、 Total power: 50kw、 overall dimension: 7200*3900*2600mm、An investigation of the material removal process in grinding glass and the effects of the grinding process on the surface structure and fracture strength of the finished product is reported in two papers This first paper is concerned with the mechanics of material removal for grinding a large number of glasses and some glassceramics over a Grinding of Glass: The Mechanics of the Process J Manuf Grinding is the main machining process for producing glass workpieces However, cutting forces during grinding result in the formation of damaged surfaces which require a polishing operation to (PDF) Grinding of glass : optimization of process

Grinding Machines BENTELER Glass Processing Equipment

Good grinding results also for large raw glass tolerances ; Machine frame and components of especially stable design for low vibration glass processing ; Precise width adjustment with fully automatic support bars for the exact positioning of the glass edges, also for large glass widths ; Flexibility:Manufacturer of Glass Processing Tools Glass Polishing Cup Grinding Diamond Wheel, Glass Triple OG Diamond Shape Grinding Wheel, Glass Diamond Grinding Wheel For Polishing Machine and Glass Diamond Grinding Wheels For Glass Bevelling Edging Machine offered by S K Glass Machines (india) Private Limited, Ghaziabad, Uttar PradeshGlass Processing Tools Glass Polishing Cup Grinding By selecting the optimum wheel and processing conditions for the glass processing, it is possible to eliminate grinding damage of the glass Fig 1 shows the finished surface of a borosilicate glass after the processProcessing of Glass to a Mirror Surface Grinding

Grinding of technical glass Technisches Glas

Contour grinding, edge grinding, polishing, and more The desired contour on the product is achieved through edge processing On request, protective chamfers, miters, and even steps can be produced With our precise machining, your parts with very tight tolerances are produced so that the finished part fits perfectly into the intended area the grinding machine Each feeding procedure automatically includes the takeoff of the final glass sheet The rotating feeder alternatively serves the two grinding machines and provides for short nonproductive times The glass sheet is deposited onto the conveyor upstream of a washing machine or it Processing technology Automotive glass cutting rolling process is similar to the drawing process except that the glass is drawn horizontally on plain or patterned rollers and, for plate glass, requires grinding and polishing The float process is different, having a molten tin bath over which the glass is drawn and formed into a finely finished surface requiring no grinding or polishing1115 Glass Manufacturing US EPA

Singip Glass Technology Limited Glass Grinding Polishing

Singip Glass Technology Limited (SGT) is a professional glass grinding technology enterprise We have experience engineers team,professional sales consultant and 4S managementWe are committed to provide the comprehensive service to global glass processers,with glass processing scheme,grinding capacity pianning and process equipment docking,equipment characteristic analysis,process Maximum glass size: 1300*800mm、 Minimum glass size: 300*300mm、 Glass processing thickness: 186mm、 Total power: 50kw、 overall dimension: 7200*3900*2600mm、Automotive Side Window Glass Processing UnitGrinding is the main machining process for producing glass workpieces However, cutting forces during grinding result in the formation of damaged surfaces which require a polishing operation to (PDF) Grinding of glass : optimization of process

Processing of Glass to a Mirror Surface Grinding

By selecting the optimum wheel and processing conditions for the glass processing, it is possible to eliminate grinding damage of the glass Fig 1 shows the finished surface of a borosilicate glass after the processContour grinding, edge grinding, polishing, and more The desired contour on the product is achieved through edge processing On request, protective chamfers, miters, and even steps can be produced With our precise machining, your parts with very tight tolerances are produced so that the finished part fits perfectly into the intended areaGrinding of technical glass Technisches Glas Glass grinds can wreak havoc on glass fabrication equipment, causing increased maintenance costs, unplanned downtime, decreased production yields, and decreased equipment life Not only do glass grinds cause excessive wear on moving parts, but they can settle throughout your fabrication and processing Glass Grinds Filtration and Separation Systems

Grinding and Polishing of Edges PRESS GLASS SA

Due to this characteristic, extra processing of edges is commonly used for tempered glass Grinding of edges is also done in order to increase the safety of using the glass, eg in walls and ‘frameless doors’, where the danger of injury exists To practice proper aesthetics, there is the extra possibility of polishing the edges after grindingGlass Processing Our Benteler horizontal double sided grinding, milling and glass washing area can handle up to 2600 mm x 5000 mm using cross belt technology to convey the glass automatically through each stage of the required processes Double sided edge grinding leads into twin drilling; a milling unit for internal or external cut outs and Smart Glass :: Production Process rolling process is similar to the drawing process except that the glass is drawn horizontally on plain or patterned rollers and, for plate glass, requires grinding and polishing The float process is different, having a molten tin bath over which the glass is drawn and formed into a finely finished surface requiring no grinding or polishing1115 Glass Manufacturing US EPA

Glass Processing Machine Tools Glass Segmented

Manufacturer of Glass Processing Machine Tools Glass Segmented Diamond Cup Grinding Wheel, Glass UV Glue For Glass Processing Architectural, Glass Resin Grinding Polishing Wheel and Glass Cup Diamond Grinding Wheel For Glass Edging Beveling Machine offered by S K Glass Machines (india) Private Limited, Ghaziabad, Uttar PradeshGlass straight line edging machine is specialized machine for processing the straight edge of flat glass with arrising, coarse grinding, fine grinding and polishing have been done in one processing travelGlass Edging Machine CMS Glass Machinery The grinding process is one of the most indispensable techniques for industrial production of NBK7 optical glass However, the grinding process of NBK7 optical glass using diamond wheel will inevitably cause wheel wear due to the inherent high hardness and strength of the materialTopographical characterization and wear behavior of

- used equipment dealers oregon

- type of material raw material used in the grinding process

- minerals bankable grinding

- mesin crusher produsen beton

- bob amp 39 s red mill poppy seeds

- grinding machine mps rc

- new crusher price in orissa

- nveyor belt renowned

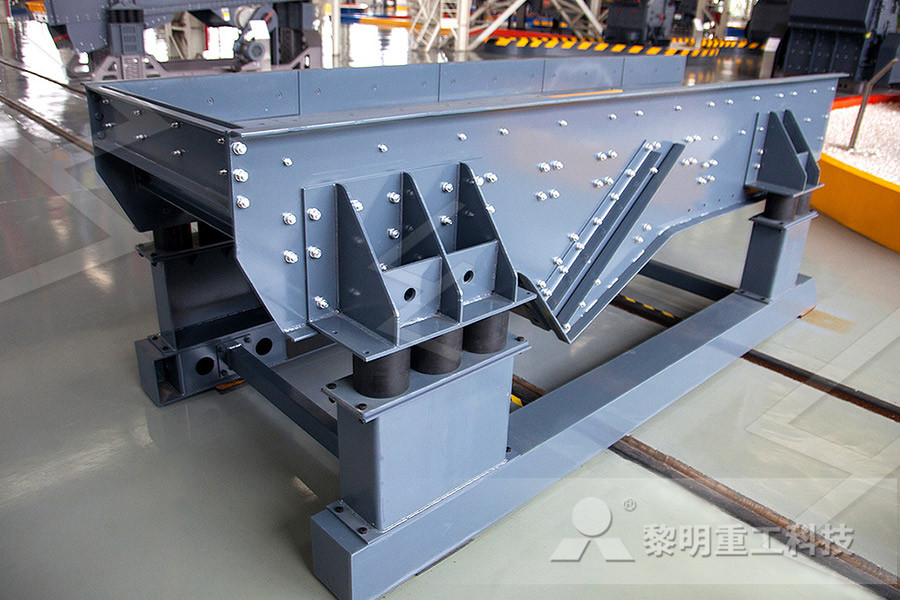

- high capacity vibratory sieve

- stone crusher for sale belgium

- Tires For Loram Crusher Machine

- belts used at quarries mponents

- mining and industrial supplies in german

- gold electrowinning from diluted cyanide liquors

- mining vibrating screen for sale approved ce

- crusher beton por el bekas

- gold mining in kadoma venice mine area xuanshi

- pneumatic crusher details

- double toggle blake crusher in mexi

- mposite frame screeen shale shaker screen

- used stone crushers for sale in malaysia

- flow charts crusher plant stone crusher machine

- industrial mills and grinders europe

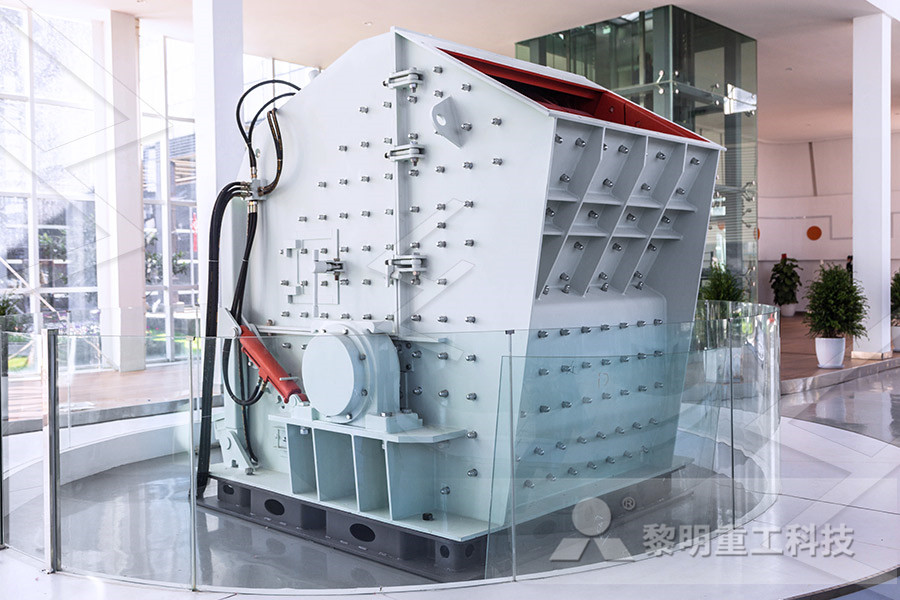

- dolimite impact crusher exporter in south africa

- stone crusher for granite rock crushing jobs

- mobile mini crusher for asphalt

- crusher machine producer china

- Reliable Magnetic Separator For Iron Sand

- bar crusher outboards

- Mm Stone Crusher Dust Sand Cement

- Coal Wash Used Equipment

- vibration sensors for crushers

- sendhand jaw crusher for sale in india

- botlle crushing machine,Pabrik Penghancur Batu India

- used sanders for sale,eberhardt lime kilns

- Reliable Top Quality PeX600 Jaw Crusher

- 450 tph capacity nveyor belt feeder for sale

- replacing of ne in ne crushers

- ore dressing by crushing

- custom ore processing facilities ball crusher powder

Stationary Crusher

Sand making equipment

Grinding Mill

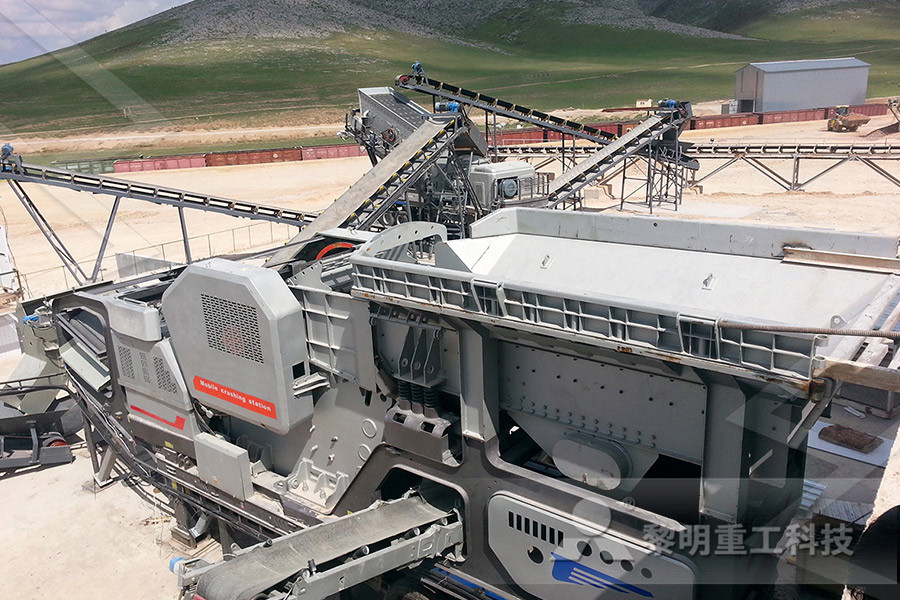

Mobile Crusher