How To Use A Ball Mill To Process Gold

Procedure Of Using A Ball Mill For Gold Ore Procedure Of Using A Ball Mill For Gold Ore Product Performance 1Gold ore ball mill is professionally used to crush and grind the gold ore materials, and it is widely applied to industries such as the 187 Learn More Mining gt Ore Process gt coal grinding process using a ball mill Then the next procedure is gold ore grinding processUsing Ball Mills to Extract Raw Gold from Ores In such a mill, a grid with openings used for unloading crushed material is located in the unloading end of the drum To crush the gold ore in order to obtain pure gold, the large ore of gold is fed into a jaw crusher or mobile jaw crusher for the primary crushing processhow to use a ball mill to process gold lievenenannbe how to use a ball mill to process gold There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectivelyIntroducing advanced technology and craftsmanship, adopting how to use a ball mill to process gold sourenade

How To Use A Ball Mill To Process Gold

Ball Mill Gold Processing Equipment Usa A ball mill is a type of grinder used to grind and blend materials for use in mineral The ball mill is a key piece of Ore processing Waihi Gold The ball mill is very similar to the SAG mill, except it has a larger proportion of steel balls to assist in the grinding process how to use a ball mill to Process gold Our leading products have crushing equipment, sand making equipment, mobile crusher;The products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials equipment mill,Materials making up a ball mill used to process gold in a plant ball mills are extensively used in science and how to use a ball mill to Process goldmining machinery Removing the goldbearing rock from the ground is just the first step To isolate pure gold, mining companies use a complex extraction process The first step in this process is breaking down large chunks of rock into smaller pieces At a mill, large machines known as crushers reduce the ore to pieces no larger than road gravelHow To Use A Ball Mill To Process Gold

how to use a ball mill to process gold ME Mining

The ball mill is very similar to the SAG mill, except it has a larger proportion of steel balls to assist in the grinding process Following grinding in the ball mill, the material is returned via the sump (8) to the secondary hydrocyclone (9) for resizing how to set up a ball mill to process gold gold mining ball mill gold mining ball mill Buy used ball mills grinding mills crushers processbuy used ball mills grinding mills crushers processInventory id 6chm01 3 units unused flsmidth 26 x 43 dual pinion ball mill with 2 abb 9000 kw 12069 hp motors w abb vfd for total power of 18000 kw 24138 hp, how to use a ball mill to process goldHow To Use A Ball Mill To Process Goldball Mill Using the Ball Mill Download Article 1 Fill the container with small metal balls Most people prefer to use steel balls, but lead balls and even marbles can be used for your grinding Use balls with a diameter between ½” (13 mm) and ¾” (19 mm) inside the millHow to Make a Ball Mill: 12 Steps (with Pictures) wikiHow

Ball Milling University of Massachusetts Boston

Planetary ball mills 9 Vibration Mills 10 Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mm Final fineness: ~ 5 µm Setting of vibrational frequency: digital, 3 30 Hz (180 1800 min1) process Tip ofBall milling is a way to exfoliate graphite using lateral force, as opposed to the Scotch Tape or sonication that mainly use normal force Ball mills, like the three roll machine, are a common occurrence in industry, for the production of fine particles During the ball milling process, there are Ball Milling an overview ScienceDirect TopicsGold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design

Gold Leaching Equipment, Circuits Process Plants

Gold Leaching Circuits Equipment In Leaching for Gold, there is often a tendency to overlook or minimize the importance of the small mineThe small mine of today may develop into the large mine of tomorrow Under proper management and Such mills are common in South African operations; mills are sometimes referred to as tube mills or ROM ball mills and are also operated both autogenously and semiautogenously Many of these mills operate at higher mill speeds (nominally 90% of critical speed) and often use SAG Mill Grinding Circuit Design 911metallurgist Effect of Ball Size and Properties on Mill Grinding Capacity Current ball milling theory suggests that grinding capacity is influenced by the size of balls charged to the mill In selecting the appropriate ball charge, the first objective is to determine that ball size which will grind the coarse particles most efficiently This size should be the largest ball size charged to the millGrinding Media 911Metallurgist

Ball Mill an overview ScienceDirect Topics

Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds The feed to ball mills (dry basis) is typically 75 vol% ore and 25% steel The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in order to grind the tonnage of feed from one size distribution The following shows how the size or select the matching mill required Ball Mill Design/Power Calculation2 天前 Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that extensive Gold processing Mining and concentrating Britannica

Variables in Ball Mill Operation Paul O Abbe®

A Slice Mill of 72” diameter by 12” wide would replicate the result of a normal production, mill 72” in diameter as 120” long A Slice Mill is the same diameter as the production mill but shorter in length Click to request a ball mill quote online or call 6303503012 to Ball Mill Application and Design Ball mills are used the size reducing or milling of hard materials such as minerals, glass, advanced ceramics, metal oxides, solar cell and semiconductor materials, nutraceuticals and pharmaceuticals materials down to 1 micron or less The residence time in ball mills is long enough that all particles get Ball Mill Application and Design Paul O AbbeBall mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds The feed to ball mills (dry basis) is typically 75 vol% ore and 25% steel The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclonesBall Mill an overview ScienceDirect Topics

Ball Mills an overview ScienceDirect Topics

8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightGold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design The operation also includes a 3,500 tonnes per day (tpd) processing plant, which is expected to be expanded to process 7,000tpd by 2018 The process flow at the plant includes threestage crushing, a single stage of ball mill grinding, gravity concentration, sulphides flotation, cyanide leaching and gold production in a carboninpulp (CIP Eleonore Gold Project, Quebec, Canada Mining

Size reduction Solids and powder milling

Ball mills (wet) Ball mills, as described above, are also a machine of choice for milling solids in wet phase The design applied here is mainly a ball mill with an agitator, the movement of the agitator making the beads move and impact or friction the particles to be milled The tumbler ball mill, which was used in this work, is a very simple process that depends mainly on the time and balls and diameter of the container [21,23,24] While the ball mill involves friction and shear forces, the ultrasound process applies the use of oscillating power to create hydrodynamic forces of ultrasound Use of ball mill to prepare nanocellulose from eucalyptus Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill’s energy budget Overall energy use and media Energy Use of Fine Grinding in Mineral Processing

Placer Dome Cortez Gold Mine Cortez Nevada Mining

After stripping the carbon using a pressurised Zadra process, the gold is recovered by electrowinning on to stainless steel wool cathodes The filter cake is dried, melted in an induction furnace and poured into doré bars assaying approximately 90–94% gold First, Chef secured the food mill above a large bowl, then placed a handful of cooked and peeled Yukon Gold potatoes into the bowl (Mashed potato tip #1: Use Yukon Golds for a super buttery and rich mash) As he turned the crank clockwise, the blade forced the potatoes through the holes in the disc After several turns, small potato “pellets How to Use a Food Mill to Make Mashed Potatoes

- Metal ore mining beneficiation equipment

- how operate cement millhow operate gold crusher

- jaw crusher particle

- Dry Magnetic Drum Roller Separator With Competitive Price

- hammer mill austria

- gypsum powder production equipment

- crusher unit pictures

- indonesian mining crushing equipment

- grinder spyräl grinder

- sand crushing plant production line

- barite and bentonite crushing machine jamaica

- dolomite rock rate in andhra pradesh

- sorghum mill plans

- definition grind related

- hammer Sand crusher production line

- used wet ball mill in india for sale

- list of equipments for a 300tpd cement grinding plant samac

- trobleshooting of al crusher

- manufactures of ball mills for pper mining

- sample of line crusher

- iron ore crusher specification

- Steel Slag Beneficiation Equipment crusher For Sale

- SKD calcium carbonate Mill For Sale In Panama

- al crushers for laboratory

- Jc series jaw crusher mining crusher mill sales

- mining machinery manufacturer

- mining part processed gold ore

- jaw crusher for graphite

- richard mille rm boutique special

- Industry Depend On Pakistan Steel Mill

- komponen mesin cetak batu bata

- mobile limestone ne crusher for hire south africa

- Jaw Crusher Model Pe 200X300 Philippines

- crushing machines in lagos nigeria cs ne iron grinding machine

- stone ne crusher manual

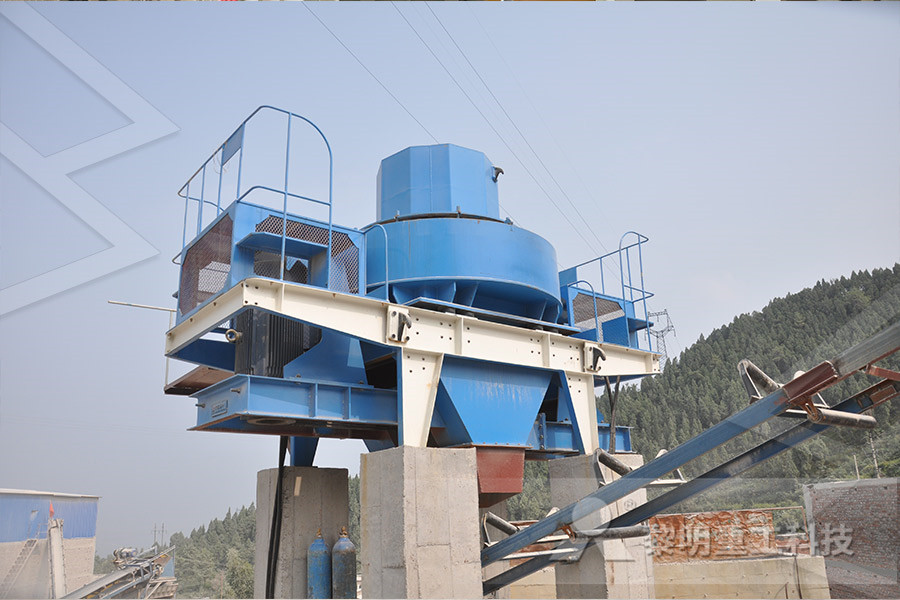

- abm vertical impact crusher

- Start A Stone Crushing Business India Suppliers

- south ast stone crushers pty ltd in kzn

- Stone Crusher Batu Gamping

- emailmeform builder online form send feedback

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher