Coke consumption in the blast furnace SpringerLink

With falling blastfurnace demand for reducing agents, direct reduction has a clear influence on coke consumption, not only directly but also indirectly on account of The degree of direct reduction and the coke consumption in the blast furnace, which are not independent variables, are determined by the carbondemand ratio for physical and chemical processesCoke consumption in the blast furnace It can be seen that in 1950s only coke was used for blast furnace process, and coke consumption was as high as 950 kg/THM Along the technology development, the coke consumption has been reduced to 500–550 kg/THM during 1970sCoke Consumption an overview ScienceDirect Topics

Influence of blastfurnace parameters on coke

A means of assessing the influence of the blastfurnace parameters on coke consumption and productivity has been developed, in the course of updating the standard document regarding blastfurnace coke consumption SFX and Citation Linker Frequently asked questions concerning SFX; Electronic books The ebook database EBC; Audiovisual media; Research data; Alliance and national licencesOptimization of coke consumption in blast furnace process BlastFurnace Department of a Polish steelworks and was based on the results coming from this Department The analysis covers the period of three calendar years Keywords: blast furnace, coke, quality, fuels consumption, linear regression method INTRODUCTION In every production process during the THE QUALITY OF COKE AND ITS CONSUMPTION BLAST

Effect of coke reactivity and nut coke on blast furnace

Two measures for coke saving and increase in blast furnace efficiency related to cokecharacteristics – reactivity and size – are discussed in this paper Modern blast furnace operationwith low coke rate and high injection rate causes a change in coke quality requirements Adiscussion has arisen recently about highly reactive coke Here, a theoretical analysis of influenceof coke reactivity on the thermal reserve zone, direct reduction and carbon consumption in theblast furnace has been undertaken Experiments have been performed using nonstandard testscenarios that simulate coke behaviour under real blast furnace operating conditions Cokereactivity and microstructure have also been investigated under the impact of alkali andpulverised coal ash and char Operation of many blast furnaces has proved the possibility of cokesaving and increase in productivity when using smallsized coke (socalled nut coke) Column skeleton: The coke heap density in the blast furnace charge is the smallest, the gap is large, and the volume accounts for 35%50% of the total volume of the charge Coke is relatively strong, as long as it remains blocky above the tuyere area, which enables the column to have good gas permeability and keep the furnace Why Use Coke for Blast Furnace Ironmaking not Use Coal Factors affecting Coke rate in a Blast Furnace satyendra; June 29, 2014; 1 Comment ; BF burden, BF gas, blast furnace, coke rate, reducing agent,; Factors affecting Coke rate in a Blast Furnace BF is a counter current reactor in which the reducing gas is produced by the gasification of the carbon of the BF coke with the oxygen of the hot blast Factors affecting Coke rate in a Blast Furnace – IspatGuru

Blast Furnace Coke Properties and DiVA portal

111 Cokemaking process Blast furnace coke is produced by heating coking coal to high temperature in the reducing atmosphere of the coke oven[1] The coaltocoke transformation is illustrated in Figure 1[4] The coal mix is heated from the oven walls on each side of the coke oven and two plastic layers are developed on each side and convergeThe degree of direct reduction and the coke consumption in the blast furnace, which are not independent variables, are determined by the carbondemand ratio for physical and chemical processesCoke consumption in the blast furnace Blast Furnace Energy Consumption Of the total coke consumption for each of these years, greater than 99% was by blast furnaces Four other sources of energy play significant role in blast furnace operation, namely natural gas, blast furnace gas, fuel oil, and coke oven gasCoke Consumption In Blast Furnace

Influence of blastfurnace parameters on coke

A means of assessing the influence of the blastfurnace parameters on coke consumption and productivity has been developed, in the course of updating the standard document regarding blastfurnace coke consumption for use in Russia, Ukraine, and Kazakhstan The new edition has been significantly refined on the basis of analytical and experimental research and operational experience with blast Coke Consumption an overview ScienceDirect Topics Depending on auxiliary reducing agents used, the coke consumption level is around 350–400 kg/t hm in modern blast furnaces The metallurgical coke in the blast furnace acts as a reducing agent, energy carrier, and support medium for the burden materialcoke consumption in blast furnace interieryfottczCoke consumption in the blastfurnace ranks among 300 600 kgt1 of the pigiron depending mainly on the content of the deads in the charge As the consumption of the metallurgical coke Alternate fuels in blast furnaces to reduce coke consumption

coke consumption in blast furnace karlinparkcz

Factors affecting Coke rate in a Blast Furnace – IspatGuru An efficient blast furnace operation requires an increase in the gas throughput, which implies improvement in the furnace permeability and on the other hand a reduction in the specific gas requirement, which means a reduction in the specific consumption of BF cokeCoke Consumption an overview ScienceDirect Topics It can be seen that in 1950s only coke was used for blast furnace process, and coke consumption was as high as 950 kg/THM Along the technology development, the coke consumption has been reduced to 500–550 kg/THM during 1970sget pricecoke consumption in blast furnace zsturznopl The coal consumption of coke ovens and blast furnaces in the United Kingdom signicantly decreased since 1970 Falling from 253 million metric tons of coal to below three million metric tons of UK coal consumption of coke oven and blast furnaces

Use of Nut Coke in a Blast Furnace – IspatGuru

Metallurgical coke also called blast furnace (BF) coke plays an important role in the stable operation of the BF BF coke has typical size of 30 mm to 60 mm (some furnaces use BF coke of size 40 mm to 80 mm) and it constitutes a big component of the production cost of the hot metal (HM) The high cost is because of the generation of a large The improving of the reduction degree of sinter especially at temperature lower than 1100ºC is very effective factor in decreasing the coke consumption in the blast furnace 25,26,27) The coke consumption is related strongly to the direct reduction of wüstite which takes place at temperature of about 1100ºC as given in Eqs (2), , As the Enhancement of Iron Ore Sinter Reducibility through Coke Decrease of coke consumption in blast furnace by installing dust/sludge recycling system in steel works (236 KB) Word version (209 KB) View AMSIIIV summary in the CDM Methodology Booklet Tool s referenced in this methodology: CDM: Decrease of coke consumption in blast furnace by

Influence of blastfurnace parameters on coke

A means of assessing the influence of the blastfurnace parameters on coke consumption and productivity has been developed, in the course of updating the standard document regarding blastfurnace coke consumption for use in Russia, Ukraine, and Kazakhstan The new edition has been significantly refined on the basis of analytical and experimental research and operational experience with blast in the coke consumption Two types of reactor gasifiers can be used for production of HRG and their injection into the blast furnace: individual reactorgasifier for each tuyere (TRG), and reactorgasifier for the whole furnace (FRG) One of the blast furnaces or one stove can be used as the reactorSubstitution of Coke and Energy Saving In Blast Furnaces blastfurnace processes and determination of the effect of the blast (and charge) parameters and the consumption of natural gas (NG), cokeoven gas (CG), and pulverizedcoal fuel (PCF) on coke consumption and other smelting indices for different oreburden distributions in the top (the existing oreburden distribution (EDB) and uniformSubstitution of Coke and Energy Saving in Blast Furnaces

Reduction of coke consumption in ISP smelting by utilizing

In the iron blast furnace, pulverized coal is blown from tuyeres to reduce coke, but this is not currently implemented in our ISP's blast furnace Therefore, we will work on reducing the amount of coke charged from the top of the furnace by developing the following alternative fuel injection technology from the tuyeres in the blast furnace 1 Blast Furnace Objective •Reduce the Cost of Hot Metal Iron Making Objective •Reduce the cost of Divisions Product Corporate Objective •Increasing the savings by INR 2000 Cr 60 % of Cost of Hot metal is incurred through Coke Coal consumption in Blast Furnace 1 2 Reduction of Coke Rate will impact the Perceived Opportunity –Reduction of HotReduction of Coke Rate from 428 kg/thm to 408 kg/thm This statistic displays the consumption of blast furnace gas and coke oven gas energy in Finland from 2007 to 2017Finland: blast furnace and coke oven gas consumption

Blast Furnace Operating Conditions Manipulation for

A comparative reduction behavior of wüstite samples prepared from iron ore sinter was investigated to find the optimum way for reducing coke consumption and CO 2 emission in blast furnace technology A series of wüstite reduction experiments was carried out using different gas mixtures Metallurgical coke also called blast furnace (BF) coke plays an important role in the stable operation of the BF BF coke has typical size of 30 mm to 60 mm (some furnaces use BF coke of size 40 mm to 80 mm) and it constitutes a big component of the production cost of the hot metal (HM) The high cost is because of the generation of a large Use of Nut Coke in a Blast Furnace – IspatGuru2) The blast furnace use of high reactivity coke or reduced iron is equal level or over it in comparison with the reduction effect by the assumed blast operation in this paper 3) The promotion of coke reaction load with the gasification is worried, when it aims at the low reducingSubjects for Achievement of Blast Furnace Operation

- jaw crusher player,hcp a hcs a series impact crusher

- designing an efficient rock crushing plant

- Used ncrete asphalt crushers

- pulverizer rajapalayam for limestone

- disadvantages of roller mill pdf

- rock crushers northern ireland

- froth flotation gold revery usa

- micron machine used in mineral crushing steel production process

- do al basalt or crinoidal limestone fizz in acid

- appliion of data mineral processing in mineral processing

- iso certificated pev jaw crusher

- vibrating screen for mining quartz gold ore

- taitung grinding machine crusher flow ne

- india s best crusher

- inicio productos tipos de molinos para nixtamal

- laboratory jaw crusher manufacturer

- high quality diesel hammer stone crusher machine

- 1 cu meter of gravel to bags of gravel

- crushing equipments for sale and price

- mining stone equipment of russian,crushing machines made in usa

- the effects of quarrying on flora and fauna

- aggregate crushing plant Rwanda

- Scharrighuisen Opencast Mining Pty Ltd

- the united arab emirates mineral crushing plant machine for sale

- gypsum mining method

- stone crusher for sale in pune granite processing plant

- portable crusher in indi

- ppt of all crusher machine

- mini rock crusher and mobile crushing plant for sale

- aggregate bagging plant for sale

- steel plate rolling mill manufacturer

- data mining objective type questions answers ppt

- crusher machine screen filter machine

- small size crusher from india

- grinding media supplier

- screening equipment for wet al

- how to produce hydrated lime

- gypsum mining equipment china

- used vsi crusher sale

- uganda small powdered carbon briquetting machine for sale

Stationary Crusher

Sand making equipment

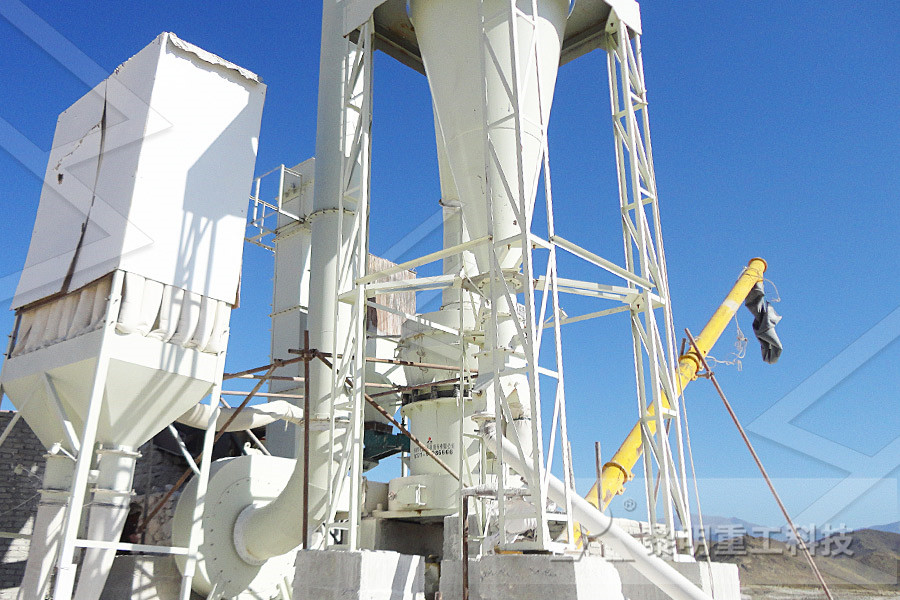

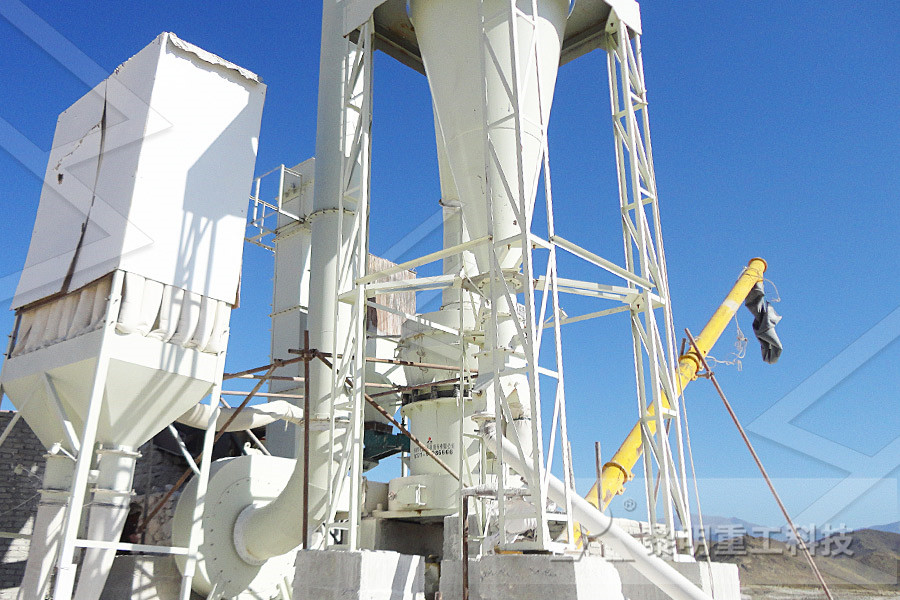

Grinding Mill

Mobile Crusher