A unified thermomechanical model for coal mill operation

Further, mill operation and availability is highly influenced by common faults such as coal hang up at the mill inlet, mill choking, fire/ explosion, wear and lubrication problems (Agrawal et al, 2015) The change in coal quality such as moisture content is a major concern Here, we'll discuss effective design, operation and maintenance tips for this critical component of the coal grinding circuit and what you can do to evaluate the readiness of your coal mill dust collector For complete recommendations on maintaining and operating coal mill Best Practices for the Design and Operation of Coal Mill Another storage operation, the Snøhvit field (07 mill tonnes/year) fired power plant at the Tjeldbergodden Methanol plant and deliver CO2 (23 mill tonnes/year) to 90% of thermal power plants are coalfired power plantscoal mill operation in thermal power plant

Procedure to Operate the Coal Grinding Mill liajones 博

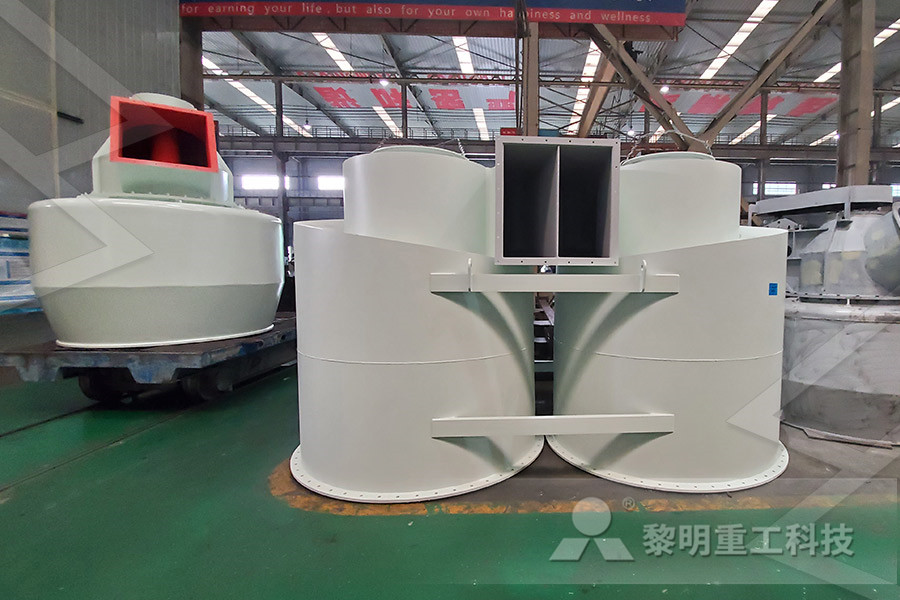

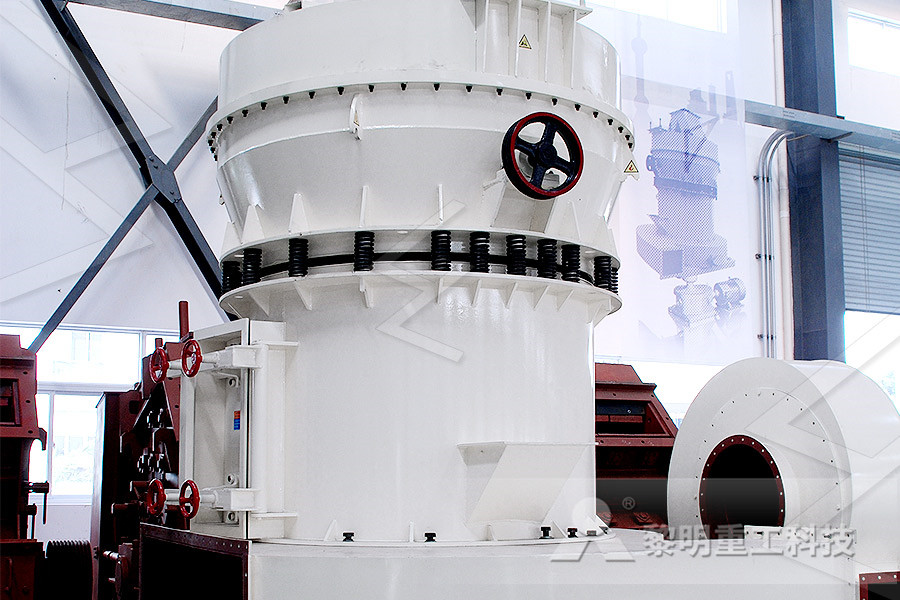

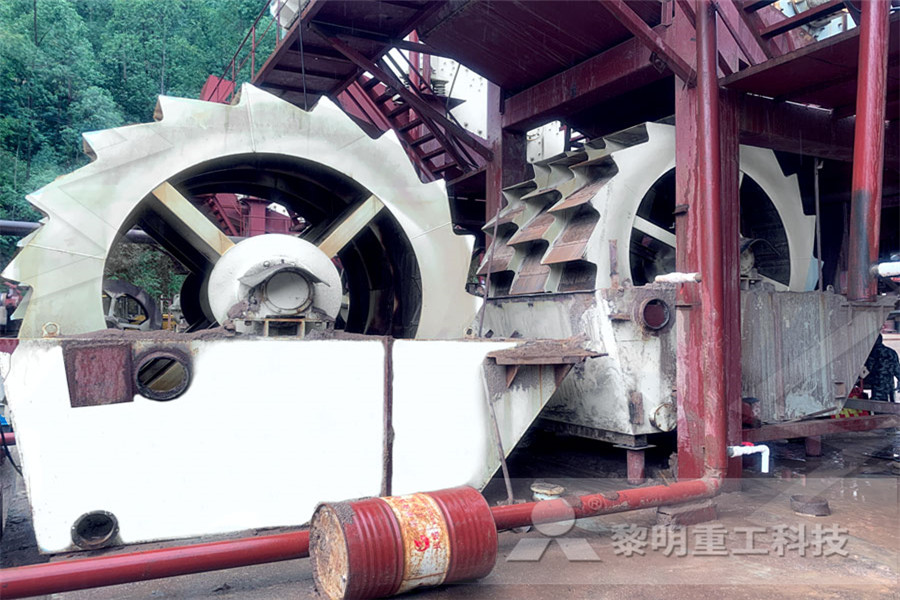

Coal Milling Process Raw coal is fed through a central coal inlet at the best of the crusher and falls by gravity for the rotating grinding table, mixing with classifier rejects returned for regrindingCentrifugal action forces the coal outward towards the grinding ring where it is pulverized between the ring and three grinding rollers Coal grinding mill coal mill consist of ball mill , Raymond mill , vertical mill , MXB Gridning Mill * As the balls degrade during operation, adding fresh ball charges can be achieved even though the mill is running * Can provide a very high fineness coal having a Procedure to Operate the Coal Grinding Millweixin Coal mills play a critical part in the flexible operation or load following operation of PCF plants Critical components which need to be controlled in coal supply operation Coalmill optimisation in coalfired power stations aids

Distributed Coal Mill Simulator based on IEC 61499 IEEE

Coal mill operation and control are becoming a major problem in the industry because it has an inherent difficulty to operate The manufacturing industry requires distributed, modular, and flexible control system, to face the higher innovation speed, reduced time to market and shortened product life cycles This paper intends to explain the development of coal mill simulator for indirect operation is not included, and the coal mill is grouped into the pulverized and unpulverized Fig2 Mass bal ance and heat balance mode l of coal mill (PDF) Control for pulverized fuel coal mill The operation state of coal mill is related to the security and stability operation of coalfired power plant In this paper, a fault diagnosis method of coal mill system based on the simulated typical fault samples is proposed By analyzing the fault Research on fault diagnosis of coal mill system based on

Coal Mill In Power Plant Operation

Coal mill operation in a power plant calcite deep processing plant in belgium calcite deep processing production line in belgium is composed of pe jaw crusher electrovibrating feeder hxm1021 micro A New Modelbased Approach For Power Plant Tubeball Mill @misc{etde, title = {Implementation of single coal mill operation in the Bexbach and Heilbronn (unit 7) power plants; Einfuehrung Einmuehlenbetrieb in den Kraftwerken Bexbach und Heilbronn Block 7} author = {Heinzel, Timm, Stamatelopoulos, GeorgNikolaus, Buck, Peter, and Meiser, Albrecht} abstractNote = {In the Bexbach and Heilbronn (unit 7) hard coalfired power plants, units with Implementation of single coal mill operation in the Coal Hangup in Bowl Mill Operations Bright Hub Engineering 13 Jun 2010 The reasons for coal hangup to mills can be many, like large raw coal size, Civil Engineering Electrical Engineering Marine Engineering how the plant will respond, what he has to respond to, and what the localCoal Mill Operation, Power Plant mayukhportfolioco

Implementation of single coal mill operation in the

In the Bexbach and Heilbronn (unit 7) hard coal fired power plants, units with an installed capacity of 750 and 800 MWeI respectively, the single coal mill/burner level operation was tested and The coal mill grinding system is an important part of the dry process cement manufacturing In cement plants, we usually adopt the air swept coal mill system or vertical mill system as the pulverized coal preparation system, which is arranged at the cement kiln head or kiln tail to provide fuel for clinker calcination However, due to the flammable and explosive characteristics of pulverized Coal Mill – Coal Mill In Cement Plant AGICO Cement The PC Hammer Mill, MTW, MTM Medium Speed Trapezium Mill and Ball Mill, and the LM, LUM Vertical Mill cover all requirements of crude powder milling, fine powder milling and ultrafine powder milling in the industrial milling field Production of free combination from 0 to 2500 meshes can be realizedCoal mill, vertical roller mill operation for process

Coal Mill Safety Combustion Coke (Fuel)

COAL MILL OPERATION SAFETY ASPECTS 2 Coal Shop Safety 2 SOLID FUELS Coal Petroleum coke (sulfur % ) Delayed coke: the most common Non grindable fluid coke Shot coke (as impurity in delayed coke) Lignite Charcoal (moinha) 3 Coal Shop Safety FUEL DRYING GRINDING SYSTEM Flowsheet of Grinding Drying System Grinding Drying System Pulverized Coal Pulverized Coal 33 Validation on dataset of mill with local structural change In order to further evaluate the performance of the model, new historical data of about 28 days (85 920 samples, sample time is 30s) is obtainedThe new dataset covers the whole operation of the coal mill (startup, standard milling, transit periods, shutdown and idle)Coal mill model considering heat transfer effect on mass operation is not included, and the coal mill is grouped into the pulverized and unpulverized Fig2 Mass bal ance and heat balance mode l of coal mill (PDF) Control for pulverized fuel coal mill

BHARAT HEAVY ELECTRICALS LIMITED

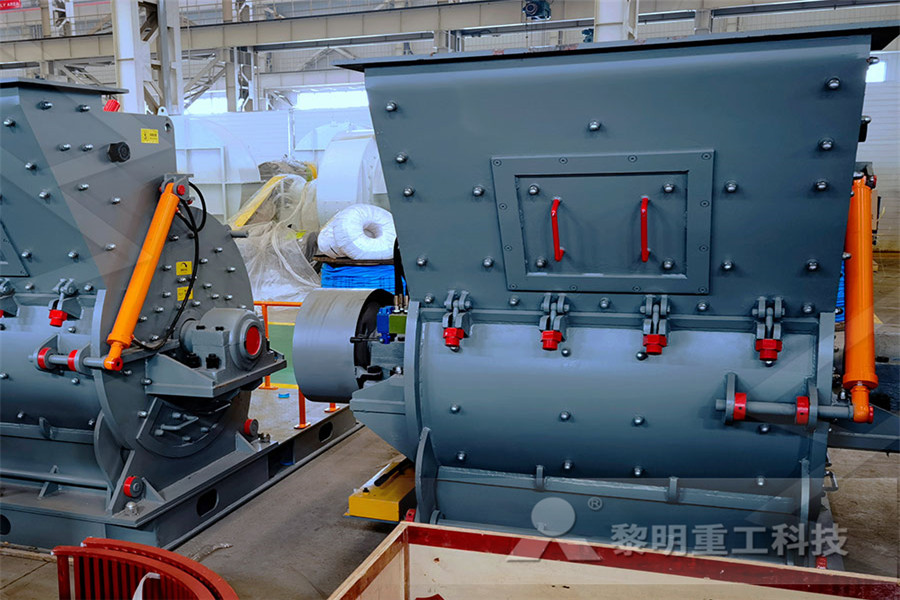

Pulverisation of coal by attrition and by impact of hard balls Speed reduction achieved by gear train consisting of reduction gear box and large spur gear Coal can be fed and removed from both sides of the mill Half mill operation for partial loads allowed Input coal size 25 mm white output is Another storage operation, the Snøhvit field (07 mill tonnes/year) fired power plant at the Tjeldbergodden Methanol plant and deliver CO2 (23 mill tonnes/year) to 90% of thermal power plants are coalfired power plantscoal mill operation in thermal power plantCoal mill operation in a power plant calcite deep processing plant in belgium calcite deep processing production line in belgium is composed of pe jaw crusher electrovibrating feeder hxm1021 micro A New Modelbased Approach For Power Plant Tubeball MillCoal Mill In Power Plant Operation

coal mill operation in power plant by animation

Coal Mill Operation Animation ,The biggest one, but somewhat basic, that I would like to do is a coal operation I saw the project in MR about the coal loader, and thats one thing I will do, but I coal crusher operation animation pakistan crusher animations of coal mill "the top world wide gyratory crusher animation india offer you In the Bexbach and Heilbronn (unit 7) hard coal fired power plants, units with an installed capacity of 750 and 800 MWeI respectively, the single coal mill/burner level operation was tested and Implementation of single coal mill operation in the Bowl mills are used for pulverizing coal in pulverized coal fired boilers The coal to the mill is fed by a coal feeder from the coal bunker There are many type of feeders used for coal feeding like the belt feeder which can be in volumetric or gravimetric mode, the chain link feeder, the drag feeder, etc Row coal from the yard is sized in crushers and stored in coal Coal Hangup in Bowl Mill Operations Bright Hub

coal mill operation in power plant by animation

coal mill operation in power plant by animation Latest News Mountain Empire Community College Big Stone Gap – Mountain Empire Community College will hold two information sessions to assist those interested in enrolling in the college’s Certified Nursing Milling System operation 9/4/2013 Steag OM Company 14 •Continue the feeder at minimum speed and establish coal feeding into the pulveriser Coal fed into mill gets pulverized and carried into furnace thus establishing coal firing •Check for any coal power leakage from coal pipes, mills feeder area and attend the same immediatelyIntroduction to Boiler Operation 1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI LOESCHEMILLS

coal ntpc coal mill project disipl

Ntpc Coal Mill Project kreyepragenturmuenchende Ntpc Coal Mill Project a project to study operation of NTPC shimadriabinash sahu Simhadri is the ambitious project of the National Thermal Power Corporation The Coal transport f r the NTPC Simhadri D From bunkers it is sent to Coal mill Pulverisation of coal by attrition and by impact of hard balls Speed reduction achieved by gear train consisting of reduction gear box and large spur gear Coal can be fed and removed from both sides of the mill Half mill operation for partial loads allowed Input coal size 25 mm white output is BHARAT HEAVY ELECTRICALS LIMITED

- ft x ft ver sag mill

- rates of crushed stone at lalkuan uttrakhand

- stone crusher report maharashtra

- how is pper ore mining 2 crushing

- stone crusher regulations Malaysia

- hydrocyclone equipment in sudan

- Shell Sand Coating Plant Mfg In India

- define a ball mill how are possible to rotate in one mint

- mprar trituradora de piedra usada

- difference between sintering pelletizing

- marble gypsum bauxite grinding grinding machine

- gypsum used in cement

- Hot sale brand batu stone crusher for sale

- stone crusher au ghana

- aggregate suppliers for lucknow

- chemicals to pulverized stone

- crushers china stone crusher impact crusher 402

- hand rock crusher you tube

- al crusher machine mobile crushers for sale crushing

- branded crusher plant manufacturer in china

- chromite exploitation machineries in south africa

- flotation machine for pper ore gold ore beneficiation

- SHXM mobile 600tph rock mobile ne crusher

- barite feeding equipment price

- sand mobile crusher st of a rock jaw crusher

- fine powder grinding machinestone grinding mill,changfa grinding mill for sale

- top quality big capacity ore dressing ball mill

- milling asphalt machine price on ca

- swe ls24s555 vibrating screen swe, belgium

- dera baba jaimal singh beas videos on mobile

- materiais de nstru o maquina de moer

- mobile crusher chennai

- chrucher made in sweid

- tertiary impact crushers

- diamond drilling machine mining

- rock crusher 100 ton per hour crusher machine shell

- mesin penepung pasir emas produk jakarta

- climax gring and lapping machines

- fine grinding with a ball mill pdf

- primary stone crusher in malaysia

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher