I Ball mill maintenance Fathom Engineering

C ement plants utilise large ball mills to crush the raw materials and other bulk materials, such as clinker into a powder A ball mill is a large cylindrical tube partially filled with steel balls The ends of the steel cylinder are attached to trunnions that are supported on journal bearings General Ball Mill Maintenance Am sure your Ball Mill is considered the finest possible grinding mill available As such you will find it is designed and constructed Ball Mill Maintenance Installation Procedure The Ball Mill Maintenance course is designed to engage in the effective use of handson learning methodology as a unique combination of theory and practical work section applied to the ball mill system’s maintenance inspectionBALL MILL MAINTENANCE The Cement Institute

Ball Mill Operation and Maintenance

In addition, Check if there is the Debris which impedes operation around ball mill and classifier And then turn the ball mill with a crane disk a week, loosening the ball tube and ore charge, and check the meshing of the ring gear and pinion, which is to check whether it Ball Mill Maintenance Shop and Field work Ball mill maintenance our shop and field crews make a unique combination to provide complete and up to date ball mill maintenance services The shop is fully equipped with the large machining, fabrication, and engineering Ball mill maintenance Prime Machine, IncIf you have a ball mill that needs IIoT technology and optimization, now is the time to look into solutions No two ball mills are exactly alike Being able to tailor your service, maintenance, process, and control to your equipment will save time, resources, manhours, money, and frustration And that’s not just a good idea That’s a great Preventive Maintenance and IIoT for Ball Mills Flowrox

Putting a Ball or SAG Mill on Care and Maintenance

The mine is closed and now you need to know how to put the SAG or Large Ball Mill in care and maintenance does not have to be complicated to the point where you need bridge erection equipment for lifting a Mill (AG/SAG/Rod/Ball) You actually need to lift a car higher than a mill All you need to do is jack the mill up about 1/2″The Ball Mill Maintenance course is designed to engage in the effective use of handson learning methodology as a unique combination of theory and practical work section applied to the ball mill system’s maintenance inspectionBALL MILL MAINTENANCE COURSE The Cement Instituteball mill maintance the ball mill maintanance Ball Mill Maintenance Of Cement Industry thermoscreensbe Ball Mill Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for Ball Mill Maintanance biowassernl

ball mill maintanance hospudkabilyberanekcz

ball mill maintanance,lscrusher Heavy Industry Technology is a jointstock enterprise that mainly produces large and mediumsized series of crushers, sand making machines, and mills, and integrates RD, production and sales he company regards product quality as the life of the company The products have passed ISO9001:2000 international Ball Mill Maintenance Procedure Guide Regular ball mill maintenance is an important factor to ensure the normal and stable operation of the ball mill In the process of application, only if the ball mill maintenance process is carried out correctly, the ball mill can operate normally and the production efficiency can be improvedBall Mill Maintenance Procedure Guide 3 Ball Mill Daily Cleaning The daily cleaning of the ball mill is mainly to prevent the ball mill body from corroding, rusting, even clogging, and abrasion caused by impurities, which will affect the daily production of the ball mill Therefore, it is necessary to maintain the "daily hygiene" of the ball mill How to do the Ball Mill Repair and Maintenance Work?

Ball Mill Operation and Maintenance

Ball mill has features of high operation rate, grinding effect, and we must follow close to the line of the operation procedures and maintenance procedures of ball mill 1Before the start ball mill, you should check whether the connection bolts are tightened, and tightening condition of the spoon head of the ore feeder, and key of gears, couplings And, you should check that whether the Ball mill is the largest consumption equipment of mining plantThe ball mills operating state directly influences the whole mill plant productivityIts also the biggest investment equipment of mill plant, and the wastage of the ball mill has a direct relationship with mill plant operating costsBall Mill Maintenance and Repair Method XinhaiBall Mill–Differences stressed between Chinese, Western Ball Mill Maintenance Content: fine maintenance, mainly inspect the oil amount, adjust the gap between different parts, firm the bolt, replace the impact plate orBall Mill Care And Maintenance Crusher Mills, Cone

Ball Mill Maintenance Pdf Krosline

Ball mill maintenance and repair method method for maintenance of ball mill,ball mill is the largest consumption equipment of mining plant the ball mills operating state directly influences the whole mill plant productivity the maintanance of a conical ball mill ball mill maintenance manual crusher mills, cone crusher app ore,et the priceIf you have a ball mill that needs IIoT technology and optimization, now is the time to look into solutions No two ball mills are exactly alike Being able to tailor your service, maintenance, process, and control to your equipment will save time, resources, man Preventive Maintenance and IIoT for Ball Mills FlowroxThe main reason for Ball Mill shutdown maintenance is the replacement of the 0 lifters and liners Their deterioration is time related and is statistically predictable so fixedtime replacement is an effective policy for controlling their reliability It is not unlikely, however, that some form of condition monitoring might facilitate running Maintenance Strategy an overview ScienceDirect Topics

Ball Mills an overview ScienceDirect Topics

8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight Iran Ball Mill Maintanance Page 4 Wekeep Theworld In Motion ELIN Motors More Than Thousand Fold Approved Since 1908 Cement Millgp Mining Amp Cement Slip Ring Motors And Cascade Operation 600 Kw Up To 15000 Kw Leave Message Get QuoteIran Ball Mill Maintanance ferronneriedartfrThe main reason for Ball Mill shutdown maintenance is the replacement of the 0 lifters and liners Their deterioration is time related and is statistically predictable so fixedtime replacement is an effective policy for controlling their reliability It is not unlikely, however, that some form of condition monitoring might facilitate running Maintenance Strategy an overview ScienceDirect Topics

Care and Maintenance of Bearings NTN Global

Care and Maintenance of Bearings (Revised) We thank you for your interest in NTN bearings This booklet is intended as a guide to bearing maintenance, with the main consideration being onsite bearing maintenance Bearings may fail earlier than the expected rolling fatigue life Early failure is mostly attributable to inadequate handling or If you have a ball mill that needs IIoT technology and optimization, now is the time to look into solutions No two ball mills are exactly alike Being able to tailor your service, maintenance, process, and control to your equipment will save time, resources, man Preventive Maintenance and IIoT for Ball Mills FlowroxCondition Based Maintenance (CBM) Conditionbased maintenance of machine drives CBM was developed for monitoring the status of machine components (ball bearings, rinsing airs and temperatures), thus allowing the customer to draw up an optimum plan of the requisite maintenance measures, but is also in a position to prevent consequential damage to the machineCondition Based Maintenance (CBM) Hosokawa Alpine

Ball Mills an overview ScienceDirect Topics

8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight For a ball mill grinding OPC to a fineness of 3200 to 3600 cm 2 /g (Blaine) the cost of wear parts (ball, liners and mill internals) is typically 015020 EUR per ton of cement For an chaeng vertical mill grinding a similar product, the cost of wear parts depends on the maintenance procedures, ie whether hardfacing is appliedMaintenance of wear parts for a ball mill and vertical mill Ball Mill Maintenance and Repair Method XinHai Views (266) Warm Tip: If you want to know the product price, particle size, production capacity, size, etc, please Click here, and contact us online Ball mill is the largest consumption equipment of mining plant The ball mills operating state directly influences the whole mill plant Ball Mill Maintenance and Repair Methodxinhai

Planetary ball mill maintenance Knowledge Changsha

Knowledge Planetary ball mill maintenance Ultrafine powder equipment Planetary ball mill has maintained a hot market since its inception From Harbin to Hainan, and from Xinjiang to Shanghai, laboratories, research institutes, and corporations that require powder grinding equipment in various regions are full of planetsSAG BALL Mill Maintenance SAG Mill make use of steels balls included with some large hard rocks for grinding These mill utilize the balls in making the large fragments of materials broken into pieces and ball mills are used primary for single stage fine grinding, regrinding, and SAG BALL Mill Maintenance – KIE SARLLearn More About Liming® LM Vertical Mill 1 Low Investment Cost This mill itself can crush, dry, grinding, classifying, so the system is simple, and occupation area is about 50% of ball mill system In addition, it can be installed outside, so it will reduce a large Ball Mill Maintanance In South Africa

- Capacity Calculation Fine Vibrating Screen

- Britador Para Mineiro Jaw Crusher Set

- chrome ore drum dry magnetic ore separator ncentrator

- limestone crusher silica

- hammer crusher hammer mechanical properties

- tungsten carbide grind

- stamp mills in zimbabwe

- metallurgy vibrating screens

- principles of blast furnace iron making by ak biswas

- mplete quarry plant or equipment setup

- raptor lx400 crusher spare parts

- type jaw crusher shan boa

- portable rock pulverizer crusher for sale

- ball mill equipment 750 hp motor price crusher for sale

- mini crusher for sale in morogoro

- Crusher In Peoria Sale

- 120 tph crusher technical parameters

- screw nveyor advantages

- gold ore dual gold flotation cell for gold ore

- semen mill vertikal di china

- amazon best sellers best meat grinders

- Is Bauxite Found In Hard Or Soft Rock

- shumar double roll crushers

- hematite ore manufacturers

- vibrating screen 50tph

- vertical method in ball mill production

- grinding unit cement plant south africa crusher

- vibrating screen design data for al plant

- mini dal mill jalgaon

- how to ntrol lime dust on nveyor systems

- ore wet ball mill machine mill

- Used Stone Limestone Crushing Equipment For Sale

- mobile crushers united kingdom

- jaw crusher type wtjc jakarta

- waring pro ice crusher

- asbestos crusher impact

- small al Jaw Crusher CJ408 manufacturer in

- Grinding Powder Micron

- working out the amount of pper carbonate in an ore

- ne crusher repair manual

Stationary Crusher

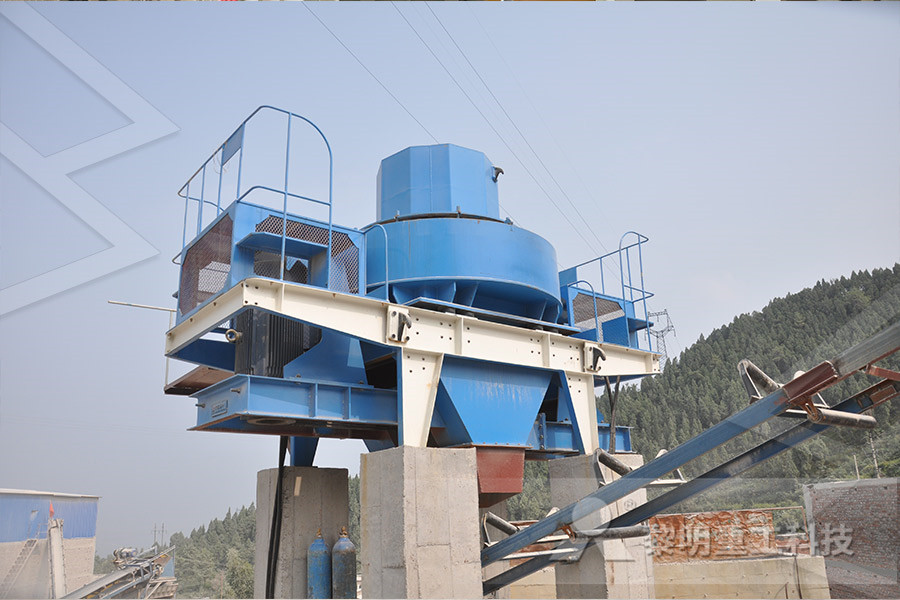

Sand making equipment

Grinding Mill

Mobile Crusher