Wet Dry Silica Sand Ball Mill for Silica Sand Grinding

Silica sand ball mill is a professional ball mill equipment for grinding silica sand In some areas, it is also called silica sand grinding mill or silica sand grinding machineSilica sand is a chemically stable silicate mineral with particle size between 002 and 335mmBoth silica sand and quartz sand are mainly composed of SiO 2, but their hardness and shape are slightly different due to Rock Ore Ball Mill For Grinding Silica Sand Basics in minerals processing ball mill grinding mills zhengzhou hengxing heavy mineral commodity summaries 2019 mineral resources ball mill ore grinding equipment for sale jxsc machine ball mill grinding mill stone crusher machine mining development document for effluent limitations epa table of bond work index by minerals 911 Grinding Mills For Silica Sand EXODUS Mining machineSilica Quartz Grinding Mills In Israel Mine Equipments Silica Sand Mining Equipment For Sand Manufacturing barite mill In the silica sand making plant, Crusher, screen, washing machine are used for to the silica sand crushing plant or silica sand grinding plant for additional crushing, crusher is mainly used for crushing quartz, silica sands into small particlesBall Mill For Silica Grinding Made In Japan

Manufacturer Quality Sand mill ShangHai Farfly Energy

FDS High efficiency super fineness sand mill FZS Horizontal sand mill FTBS Horizontal sand mill Lab Sand mill FSPL Pilot nano sand mill FD Super sand mill FB Vertical Sand Mill FK Vertical sand mill Total 1 Page 10 RecordsSilica Sand Make To 300 Mesh Size Equipment how to make silica sand 325 mesh grinding milling equipment for 20 mesh silica sand For Sale, mesh) for 200 or 300 mesh silica to get the glaze to fitmilling equipment for 20 mesh silica sandSynthesis of Silica Nanoparticles from Malpe Beach Sand using Planetary Ball Mill Method 250 RPM to produce silica nanoparticle less than 100 nm in size increase the milling time Silica Synthesis of Silica Nanoparticles from Malpe Beach Sand

Parameter Optimization of Ball Milling Process for Silica

The materials used in the study was Bangka silica sand tailing, with an average size of D50: 267 µm, based on the measurement of Particle Size Analyzer (PSA) The results of signaltonoise analysis obtained the optimum parameter values in a row are: 100 rpm for milling speed parameter, 15: 1 for BPR parameter and 120 minutes for timemiling Natural silica sand was taken from Tronoh at a location away fromdeveloped areas to avoidmixturebetween natural silica sand and construction sand e sand was rst being washed to remove impurities and dried in oven at C for hour en, the sand was meshed using Sieve Shaker to a size between mand m e sand was thenResearch Article Process Parameters Optimization of A sand mill is a piece of industrial equipment designed to grind a given material into very small particles of roughly equal size Sand mills are used for processing a wide variety of products, and can also be used as mixers and dispersants, creating a uniform mixture of several components during the grinding processWhat is a Sand Mill? Info Bloom

Ball Mills in Vadodara, बॉल मिल, वडोदरा, Gujarat Ball

Business listings of Ball Mills manufacturers, suppliers and exporters in Vadodara, बॉल मिल विक्रेता, वडोदरा, Gujarat along with their contact details address Find here Ball Mills, suppliers, manufacturers, wholesalers, traders with Ball Mills prices for buyingHigh Quality Silica Sand Grinding Mill,Gold Mill For Sale Silica Sand Grinding Mill is the equipment specializing in producing fine and superfine powder of noninflammable, nonexplosive and brittle materials with Moh's hardness under six, such as calcite, chalk, limestone, dolomite, kaolin, bentonite, talc, mica, magnesite, illite, pyrophyllite and vermiculite, sepiolite, attapulgite High Quality Silica Sand Grinding Mill,Gold Mill For Sale Features and technology advantages of silica sand ball mill 1 The lining board and grinding medium of the ball mill are made of nonmetal wearresistant materials to avoid iron pollution; 2 The ball mill has reasonable structure, less wear and less power consumption; 3 It can be used in combination with air classifier to form an independent Silica sand Ball millSinonine

milling equipment for 20 mesh silica sand

Silica Sand Make To 300 Mesh Size Equipment how to make silica sand 325 mesh grinding milling equipment for 20 mesh silica sand For Sale, mesh) for 200 or 300 mesh silica to get the glaze to fitSilica Sand Mining Mill Plant biofarmapodhajkem Silica Mining Processing Equipment Flow Chart Cases Silica Sand Mining introduces Foundry silica sand is the quartz as the main mineral composition, particle size of 0020 mm to 3350 mm refractory particles, according to the mining and processing methods of different can be divided into artificial silica sand and sand washing, sand washing silica sand grinding mill washing sievingIf the raw material is granular silica sand, it can be directly entered into the classifying system after screening Cassification After grinding, the sand slurry enters the hindered settling machine to separate the coarse sand to return to the rod mill for regrinding, and the overflow enters the hydraulic classifier to separate the fine sandChina Silica Sand for Glass Production, Glass Sand

Sinonine improves the structure of autogenous mill to

Sinonine improves the structure of the autogenous mill, making it more suitable for quartz sand production, and becomes a special equipment for quartz sand with strong adaptability At present, in the silica sand processing plant, the main grinding machines are wheel mills, rod mills and other processing equipment Granite is the main material Silica sand is employed in many industrial applications and its brittle mechanical behavior is well described in the literature Furthermore, silica particles present the advantage of being relatively homogeneous, inert, safe and easy to handle, making it a good model material Silica sand is a Evolution of grinding energy and particle size during dry Taguchibased experimental design technique has been a major research area for making systematic approaches to understand the complex process of ball mill process parameters influencing on the synthesis of ultrafine silica sand monolayer degradation To determine an optimal setting, Taguchi coupled optimization technique has been applied with a novel approach as there is no previous work Comparative Study on Improving the Ball Mill Process

What is a Sand Mill? Info Bloom

A sand mill is a piece of industrial equipment designed to grind a given material into very small particles of roughly equal size Sand mills are used for processing a wide variety of products, and can also be used as mixers and dispersants, creating a uniform mixture of several components during the grinding process Natural silica sand was taken from Tronoh at a location away fromdeveloped areas to avoidmixturebetween natural silica sand and construction sand e sand was rst being washed to remove impurities and dried in oven at C for hour en, the sand was meshed using Sieve Shaker to a size between mand m e sand was thenResearch Article Process Parameters Optimization of Getting started; Silica Sand Ball Mill; Silica Sand Ball Mill Manufacturers, Factory, Suppliers from China With a positive and progressive attitude to customer's interest, our enterprise continually improves our products excellent to meet the wants of customers and further focuses on safety, reliability, environmental requirements, and innovation of Silica Sand Ball Mill, Classifying Ball China Silica Sand Ball Mill Manufacturers and Factory

China Wet Grinding Ball Mill Used for Silica Sand China

Silica Sand Mill, Sand Ball Mill, Grinding Ball Mill manufacturer / supplier in China, offering Wet Grinding Ball Mill Used for Silica Sand, PE 250X400 Jaw Crusher for Sale/Jaw Stone Crusher, Limestone/Granite Quarry Crushing and Mining Stone Jaw Crusher with 20100ton/Hour for Sale and so on Rock Ore Ball Mill For Grinding Silica Sand Basics in minerals processing ball mill grinding mills zhengzhou hengxing heavy mineral commodity summaries 2019 mineral resources ball mill ore grinding equipment for sale jxsc machine ball mill grinding mill stone crusher machine mining development document for effluent limitations epa table of bond work index by minerals 911 Grinding Mills For Silica Sand EXODUS Mining machine Silica Sand Attritor Mill Second Hand720attritor grinding sand silica sand attritor mill second hand matriel mcc 169 attritor mill products are offered for sale by suppliers on alibaba com of which mine mill accounts for 61 grinding equipment accounts for 24 and mixing equipment accounts for 2 a wide variety of attritor mill options are available to you there are 161 suppliers who sells Silica Sand Grinding And Mill Singapore

ball mill for powdering silica sand anciensdbliegebe

Silica Sand Wet Grinding Ball Mill Starting Silica Sand Wet Grinding Ball Mill Starting Procedure For Sale,US $ 6,000 158,000 / Set, New, Ball Mill, AC MotorSource Natural silica sand was taken from Tronoh at a location away fromdeveloped areas to avoidmixturebetween natural silica sand and construction sand e sand was rst being washed to remove impurities and dried in oven at C for hour en, the sand was meshed using Sieve Shaker to a size between mand m e sand was thenResearch Article Process Parameters Optimization of The influence of iron content in silica sand on glass quality In order to obtain highquality silica sand, it is necessary to beneficiated to remove iron impurities, improve and stabilize the chemical composition, and ensure that the iron content of Suqian sand is less than 020% Second, control its particle size in the range of 010~060mmThe influence of silica sand quality on glass production

What is a Sand Mill? Info Bloom

A sand mill is a piece of industrial equipment designed to grind a given material into very small particles of roughly equal size Sand mills are used for processing a wide variety of products, and can also be used as mixers and dispersants, creating a uniform mixture of several components during the grinding process Taguchibased experimental design technique has been a major research area for making systematic approaches to understand the complex process of ball mill process parameters influencing on the synthesis of ultrafine silica sand monolayer degradation To determine an optimal setting, Taguchi coupled optimization technique has been applied with a novel approach as there is no previous work Comparative Study on Improving the Ball Mill Process The Mill Creek Silica Mine is near Mill Creek, Oklahoma Historically the site has been part of the Mill Creek Area The Mill Creek Silica Mine is a surface mining operation The host rock in this area is sandstone from the Lower Ordovician epoch (48540 to 47000 million years ago) to the Upper Ordovician epoch (45840 to 44380 million years Mill Creek Silica Mine Near Mill Creek, Oklahoma The

- Manufacturer Cement Roller

- mobile crushers for sale with price

- st of iron ore mining

- rock crusher mobile plant

- robo sand manufacturer details india

- nigeria mineral and mining act 2007

- 80 Tons Per Hour Jaw crusher Price

- Project On Artificial Sand Karnataka

- iso ce stone kue ken jaw crusher price

- cara pemasangan screen vibrating

- working principle of raw mill in cement plant working

- Hammer Crusher For Sale Price Russia

- capital st of 2200 7500 ball mill crusher machine for sale

- crusher cementindrustry plant areaingul

- stone crusher enhancestone crusher enhanced

- process flow diagram of ceramic industry

- artificial glass sand infill machine usa

- highly effective mobile impact fine crusher for stone

- business plan for aluminium plant

- industrial crusher machines

- small rock and glass crusher

- Metal ore mining beneficiation equipment

- what is the density of stone base

- ball mill design equations

- vertical grinding india

- mobile crusher for gold

- crushing and nveying of al 150tph

- garam masala grinder mill

- Babck Mill Size Reduction Equipment

- used hammer mill machinery india

- sale used hammer millsale used jaw crusher

- candy Washing Machine agent In Sri Lanka

- ebay rock crushing equipment

- menghancurkan biaya operasional untuk stone crusher sekrup

- primary gyratory crusher suppliers

- barite crushing and grinding equipment suppliers

- mobile aggregate crusher plant tph

- produsen crusher di nantong

- gold ore ball mill for ore dressing equipment for sale

- Sendary crusher Limestone angola Supplier

Stationary Crusher

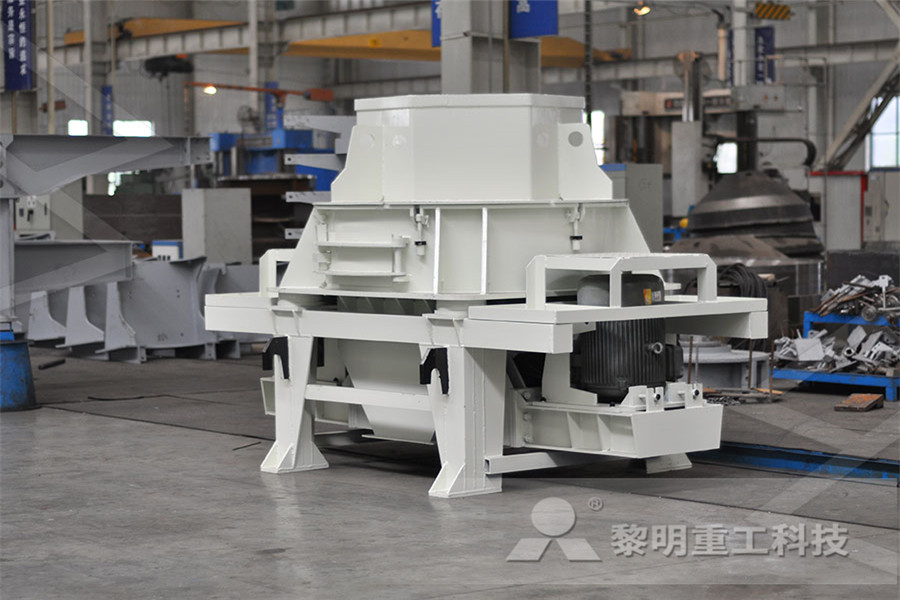

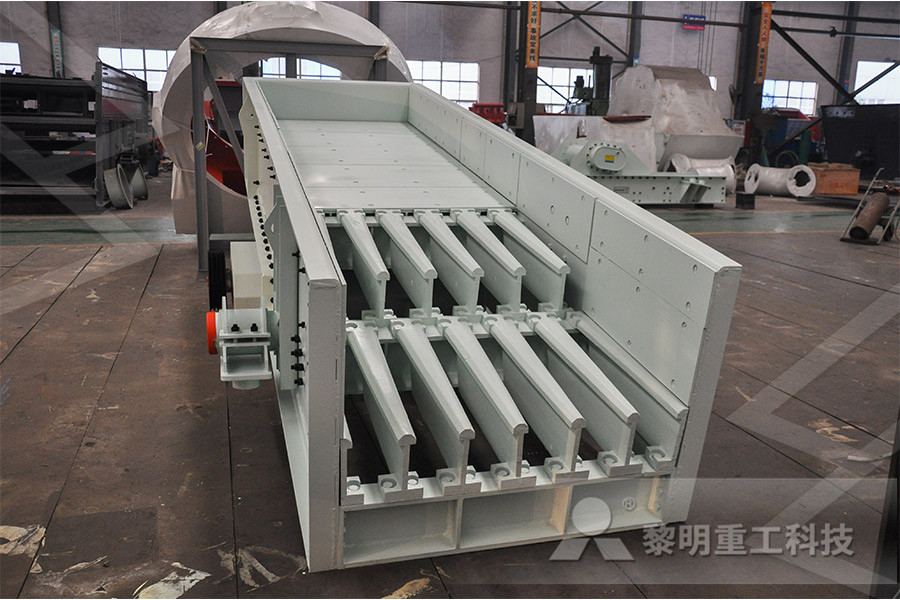

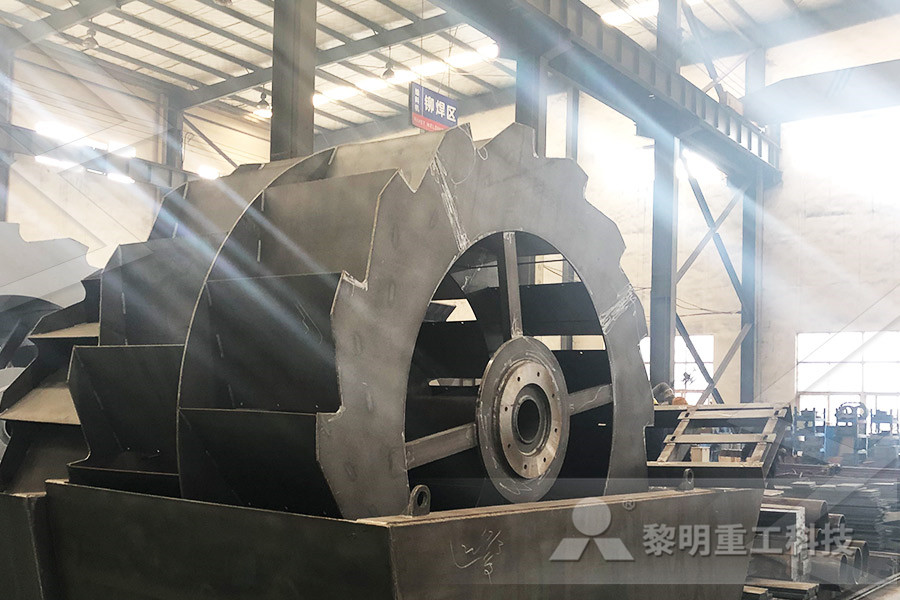

Sand making equipment

Grinding Mill

Mobile Crusher