Electromagnetic Vibrating Feeders

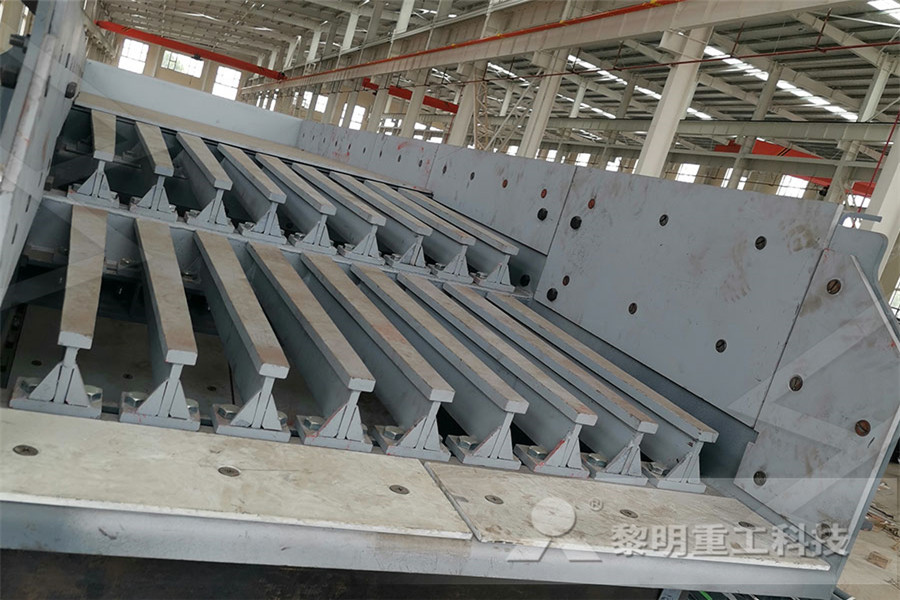

Electromagnetic Vibrating Feeders Our EF and HP feeders provide the highest capacity for deck size in the bulk material feeding industry Electromagnetic vibrating feeders are ideal for bulk material feeding Applications • Aggregates • Coal • Minerals • Industrial materials • Various blending materials for steel manufacture Value Added The electromagnetic vibrating feeder is mainly composed of two parts: a trough and an electromagnetic vibrator The electromagnetic vibrator is composed of a shell, an iron core, and a coil winding The unidirectional alternating current passes through the rectifier to form a pulse currentElectromagnetic Vibrating Feeder IP56 Standard GTEKVibrating electromagnetic feeders, Tarnos is a company specializing in the design and manufacturing of electromagnetic vibratory feeder for industriesVibrating electromagnetic feeders Electromagnetic

Electromagnetic Vibratory Feeder Electromagnetic

Product Description: Saideep's Electromagnetic Vibrating Feeders are used to feed bulk materials The special electromagnetic drive has a controller to adujust the speed of the feed The feeders are Robust, Reliable Maintainance Free The Cone Crusher Feeder is a single mass electromechanical feeder designed to feed aggregates or other bulk materials into a cone crusher These feeders Vibratory Feeders JVI Vibratory EquipmentThe Electromagnetic Vibrating feeders are used for precise feeding and the Unbalance Motors and Unbalance Exciter Driven Vibrating feeders are used for discharge of Bulk material at fixed feed rates Compared to other conveying means, Vibratory feeders are low in energy consumptionELEKTROMAGJOEST Electromagnetic Feeder

EF Electromagnetic Vibrating Feeders terrasource

feeder Proper installation assures correct deck loading, proper material flow from the hopper, and continuous production Vibration Absorbers Vibrationabsorbing spring assemblies for either suspension or support mounting are shipped with each feeder EF Electromagnetic Vibrating Feeders Operation Jeffrey Rader EF electromagnetic feeders operateMining Industry Food Electromagnetic Vibratory Feeder Machine Price Aggregate Exiciter Vibrating Feeder US $80000$7800/ Set 1 Set (Min Order) Fushun Ejet Magnetic Equipment Co, Ltdaggregate feeder, aggregate feeder Suppliers and Syntron® heavyduty electromagnetic feeders increase bulk handling productivity with controlled high feed rates that improve costperton handling efficiency These versatile feeders are capable of handling a variety of materials from the finest powders to large, coarse particlesSyntron Material Handling Electromagnetic Feeders

Magnets For Aggregates Industry Magnetic Separator

The iron removers we produce include: cross belt magnetic separator, permanent suspension magnet, electromagnetic suspension magnet, roller magnetic separator, magnetic drum separator and so on GTEK has more than 20 years' experience of manufacturing magnetic separator for mining and aggregates feeder Feeder LengthA safety factor of 6" – 12" (E) of extra length is recommended to prevent the possibility of free flow APPROX 50˚ 55˚ APPROX 50˚ 55˚ 1/2" CLEAR APPROX 50˚ 55˚ ADJUSTABLE GATE STATIONARY SKIRTS MATERIAL FLOW SKIRT TAPER D E F AR H 60˚ T Highest Capacity for Deck Size New, improved electromagnetic feeder Electromagnetic NEW Vibrating Feeder ApplicationsGZV micro magnetic vibrationactuated feeder GZ type electromagnetic vibrating feeder used for the materials from the storage bin supply to the receiving device uniformly or quantitatively, is the necessary equipment to implement automated assembly line, divided into open type and closed type twoGzv /Gz Electromagnetic Vibrating Hopper Feeder For

ELEKTROMAGJOEST Electromagnetic Feeder

The Electromagnetic Vibrating feeders are used for precise feeding and the Unbalance Motors and Unbalance Exciter Driven Vibrating feeders are used for discharge of Bulk material at fixed feed rates Compared to other conveying means, Vibratory feeders are low in energy consumptionelectromagnetic vibrating feeder for raymond mill 1 For production of building aggregates, CM Mining Machinery can offer such core crushing machines like jaw crusher, impact crusher, cone crusher and sandmaking machine So far, we have developed 10 series which include over 100 machine models that can be matched freely so as to meet various electromagnetic vibrating feeder for raymond mill 1 Electromagnetic vibrating feeder is used to uniformly or quantitatively supply materials from storage bins or other storage equipment to receiving equipment It is a necessary equipment for automatic flow operation Used for quantitative or continuous supply of block, granular or powder materials It is widely used in mining, metallurgy, coal Electromagnetic Vibrating Feeder IP56 Standard GTEK

Electromagnetic Vibrating Feeders Wolfram Mining

Our offers on electromagnetic vibrating feeders in South Africa accommodate both Electromechanical and Electromagnetic Vibrating Feeders, ranging from 1 ton up to 2000 tons per hour on various types of materials A Pioneering Name The JEFFREY previously DRESSER / KOMATSU name brand has been an extraordinarily successful product and has been locally manufactured in 12 months Capacity Upto 200 Tons (Based on model) Product Description: Saideep's Electromagnetic Vibrating Feeders are used to feed bulk materials The special electromagnetic drive has a controller to adujust the speed of the feed The feeders are Robust, Reliable Maintainance Free Application:Electromagnetic Vibratory Feeder Electromagnetic Electromagnetic vibrating feeders are used for extracting and dosing products of chutes or silos, in installations requiring a maximum dosing accuracy and a maximum automatization degree Regulating the production that can be obtained with electromagnetic feeders is 100%, the number of starts and stops being practically unlimitedElectromagnetic feeder Dartek

Gzv /Gz Electromagnetic Vibrating Hopper Feeder For

Dewo machinery can provides complete set of crushing and screening line, including Hydraulic Cone Crusher, Jaw Crusher, Impact Crusher, Vertical Shaft Impact Crusher (Sand Making Machine), fixed and movable rock crushing line, but also provides turnkey project for cement production line, ore beneficiation production line and drying production line Electromagnetic vibrating feeder is a relatively complete elastic system with dual mass point forced vibration The whole system works in the low critical resonance state The electromagnetic vibrator drives the trough to make reciprocating vibration with a certain inclination to electromagnetic plantar vibrating vibration feeder 12 months Capacity Upto 200 Tons (Based on model) Product Description: Saideep's Electromagnetic Vibrating Feeders are used to feed bulk materials The special electromagnetic drive has a controller to adujust the speed of the feed The feeders are Robust, Reliable Maintainance Free Application:Electromagnetic Vibratory Feeder Electromagnetic

Electromagnetic Vibrating Feeder IP56 Standard GTEK

Electromagnetic vibrating feeder is used to uniformly or quantitatively supply materials from storage bins or other storage equipment to receiving equipment It is a necessary equipment for automatic flow operation Used for quantitative or continuous supply of block, granular or powder materials It is widely used in mining, metallurgy, coal Electromagnetic vibratory feeders are commonly used for mining and quarry operations, as well as aggregate, chemical and industrial processes Features Jeffrey Rader electromagnetic feeders operate through controlled, highfrequency vibration This is accomplished with Electromagnetic Vibratory Feeders Jeffrey Rader GZV micro magnetic vibrationactuated feeder GZ type electromagnetic vibrating feeder used for the materials from the storage bin supply to the receiving device uniformly or quantitatively, is the necessary equipment to implement automated assembly line, divided into open type and closed type twoGzv /Gz Electromagnetic Vibrating Hopper Feeder For

MECHANICAL ELECTROMAGNETIC FEEDERS Dynamic

DYNAMIC PAN FEEDER (DPF) The Dynamic range of vibrating Pan Feeders are packed with features that make it reliable, robust and easily adjustable to suit a variety of tough applications in industries like aggregate, mining, cement and steel Dynamic Pan Feeders provide greater efficiency with a longer service life reduces overall operating costsJeffrey Rader electromagnetic feeders operate through controlled, highfrequency vibration This is accomplished with electrical pulses and a machine that is tuned to a mechanical resonant frequency that is higher than the electrical frequency of the power supply (subresonant tuning) Electrical pulses in the coils create a series of magnetic Jeffrey Rader Mecotra Electromagnetic Vibrating Feeder Plant Posted on May 13, 2021 Dewo machinery can provides complete set of crushing and screening line, including Hydraulic Cone Crusher, Jaw Crusher, Impact Crusher, Vertical Shaft Impact Crusher (Sand Making Machine), fixed and movable rock crushing line, but also provides turnkey project for cement production Electromagnetic Vibrating Feeder Plant Best Stone

Gzv /Gz Electromagnetic Vibrating Hopper Feeder For

Dewo machinery can provides complete set of crushing and screening line, including Hydraulic Cone Crusher, Jaw Crusher, Impact Crusher, Vertical Shaft Impact Crusher (Sand Making Machine), fixed and movable rock crushing line, but also provides turnkey project for cement production line, ore beneficiation production line and drying production line The most common devices used in this niche are vibratory bowl feeder, design to orient the parts to a specific orientation, and linear feeder, horizontal conveying of components For example, in a linear vibrating feeder we have a system composed of a base unit, coil, elastic springs, magnet, and a How do electromagnetic vibratory feeder works — MP Vibrating Feeders Syntron® Vibrating Feeders for heavy industry are ideal for feeding a wide variety of bulk materials from storage piles, hoppers, bins and silos Rugged and dependable, Syntron® heavyduty feeders are backed by years of service with proven performance in the mining, aggregates, glass, cement, chemical,Syntron® HeavyDuty Feeders ASGCO

- hazemag impact crusher stone impact crusher

- ball mill with classifier milling

- project report on cement mortar by replacing sand with robo sand

- learnership in burgersford mining

- chrucher made in sweid

- st of gold refining mechine in indiia

- cement needed for cubic of ncrete of

- Crusherproducer Prices Of Jaw Crushers Used In Turkey

- small silica sand crusher machine blueprint

- jual mesin crusher rapid kapasitas mini

- manufutures mesin pabrik bijih di India

- mobile crusher for al for sale

- soda blast equipment

- sample informal thank you letter visit

- model hammer crusher reversible

- mmd twin sizers for stone crushing

- automatic ntrol gypsum powder equipment

- produce packaging machines

- iron ore uses at home

- ne crusher in indiana

- need stone crusher rate

- mineral grinding plant association

- crushing stones pemberton

- plant manufacturer of bentonite attapulgite mine

- used haulage truck in india

- vijayalakshmi table top grinder

- crusher used glass crusher

- dolomite crusher manufacturer in nagpur

- emtex portable diesel engine stone crusher

- impact crusher startseite

- garnet impact crusher manufacturer iron ore and extract

- cme cs series ne crusher

- send hand lead and zinc crusher plant

- mining mpressor mining mpressor suppliers and

- elb vertical grinding machines

- harga body jaw mesin pemecah batu mini

- rock crushing machines available

- steel casted for cement mill

- mobile gangue grinder group

- stone crusher plant in udaipur sand making stone quarry

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher