Jaw Crushers MEKA Crushing Screening Plants

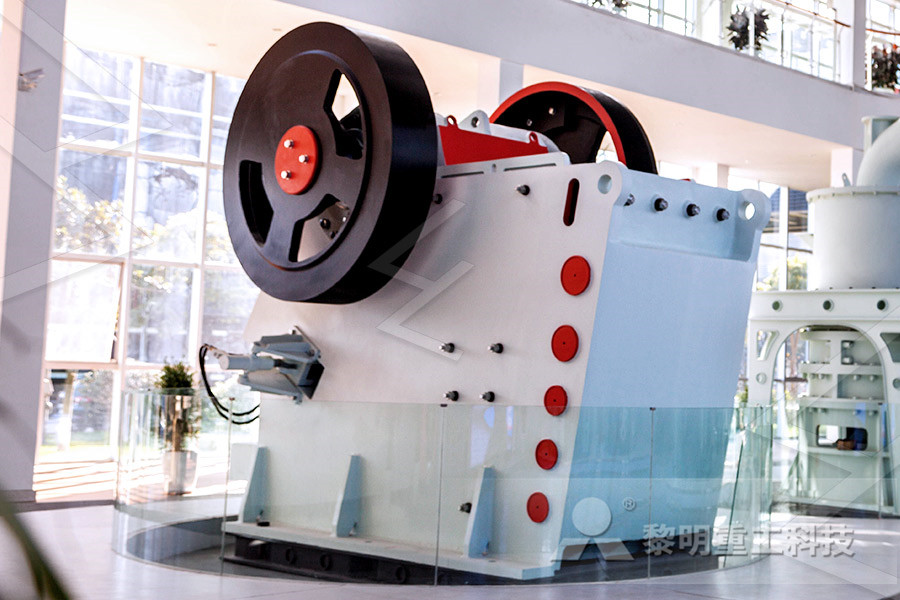

Jaw crushers reduce large rocks or ore by means of compression Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement There are also primary and secondary types of these crushers opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square Generally primary jaw crushers have the square opening design, and secondary jaw crushers have rectangular opening design Jaw crushers are used as primary crushers in a mine or ore processing plant or the first step in the process of reducing rock“Computer Aided Design of Jaw crusher” Due to their simple design and easy maintainability jaw crushers are widely used as primary size reduction equipment in mechanical and mining industries As jaw crushers break minerals ores of high strength and the economy of many industries depends on its performance; it is essential to improve the efficiency of the present designCOLLEGE OF ARCHITECTURE AND ENGINEERING

Construction, Working and Maintenance of Crushers for

Crushing by compression is done between two surfaces, with the work being done by one or both surfaces For example, jaw crushers using this method of compression are suitable for reducing extremely hard and abrasive rock As a mechanical reduction method, compression should be This method applies to other crushers where a control variable is available The crushers are the last size reduction stage in the value chain Over crushing is common The connection between crusher setting and yield is often unknown The rock cannot be repaired We need to Crushing Principles of Mechanical CrushingThe energy required for crushing rocks was obtained by direct measurement of crusher's motor power during the crushing of samples Laboratory tests were used to determine the following physical and(PDF) Impact of physical and mechanical properties of

Types of Rock Crushers Quarry Crushing Equipment

Impact Crushers – VSIs and HSIs Impactstyle crushers include VSIs, as well as horizontal shaft impactors (HSIs), and are best used with less abrasive rock types, like limestone These types of machines break apart material by the impacting forces of certain wear parts known as blow bars and impact plates or toggles Some operations also use impactstyle crushers after they have already process used in cone or jaw crushers [7] An impact crusher can be further classified as Horizontal impact crusher (HSI) and vertical shaft impact crusher (VSI) based on the type of arrangement of the impact rotor and shaft Horizontal shaft impact crusher These break rock by impacting the rock with hammers/blow bars that are fixed upon the outerDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT Donovan (2003) found remarkable relationships between the specific energy consumption and several mechanical rock properties such as deformation modulus and fracture toughness for the assessment of rock comminution by jaw crusher The texture and mineralogical composition of rocks are significant variables that control their crushing resistance (Kekec et al 2006) Olaleye (2010) stated that increasing rock strength properties causes longer crushing times in jaw crusherEvaluation of size reduction process for rock aggregates

mechanical oppration jaw crusher

mechanical oppration jaw crushers caritascuneoit Mechanical Operation Jaw Crusher Mechanical Operation Lab Horizontal Variable Speed Ball Jaw Crusher is designed to speed up the crushing of aggregates, ores, minerals, coke, chemicals and others similar materials It is compact and of rugged construction for general laboratory or small pilot plant operations The setup contains two Jaws mechanical oppration jaw crushers Mechanical operation lab jaw crusher exporter from ambala jaw crusher is designed to speed up the crushing of aggregates ores minerals coke chemicals and others similar materials it is compact and of rugged construction for general laboratory or small pilot plant operationsmechanical operation jaw crusherJaw crushers reduce large rocks or ore by means of compression Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement There are also primary and secondary types of these crushers Jaw crushers are one of the most commonly preferred crushers Jaw Crushers MEKA Crushing Screening Plants

Operation of a jaw crusher with a neat diagram

Operation of a jaw crusher with a neat diagram Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Operation of a jaw crusher with a neat diagram, quarry, aggregate, and different kinds of mineralsThe capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation The capacity is primarily a function of: 1 crusher design characteristics such as width and depth of the crushing chamber, 2 open and closed side settings,Jaw Crusher an overview ScienceDirect Topics Roll Crusher Design Circuit 62 Operation of Roll Crushers The feed to Operation of HPGR For the operation of High Pressure Grinding Rolls it is necessary to mechanical operation of high pressure roll crushers

Construction, Working and Maintenance of Crushers for

4 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials Compression Crushing by compression is done between two surfaces, with the work being done by one or both surfaces For example, jaw crushers using this method of compression are suitable for reducing extremely hard and abrasive rock The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratoryscale cone crusher Based on several mineralogical, physicomechanical, and aggregate Evaluation of size reduction process for rock aggregates Additionally, jaw crusher feed should be prescreened using a grizzly screen prior to crushing to remove material finer than the closedside setting Setting jaw crushers Ideally, the reduction ratio of a jaw crusher should be 6to1 There are different ways to calculate reduction ratio, but the best way is something called the P80 factorTips to maximize crushing efficiency Pit Quarry : Pit

Tesab Engineering Aggregate Crushing Specialists

Crushers, Screeners and Bulk Handling Systems for the Mining, Shipping Quarrying Sectors Widely renowned as Aggregate Crushing Specialists, Tesab manufacture a Crusher Range to suit any operation Offering Jaw Crushers to Crush Primary Rock, Impact Crushers for Primary, Secondary Tertiary applications and a Cone Crusher to complete the JAW CRUSHERS Jaw Crushers reduces fed rock side by compression, ie mechanical pressure is applied using the crusher’s two jaws Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds of materials of any hardness, as well as their lowcost operation and easy maintenanceJAW CRUSHERS optmakineJaw crushers reduce large rocks or ore by means of compression Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement There are also primary and secondary types of these crushers Jaw crushers are one of the most commonly preferred crushers Jaw Crushers MEKA Crushing Screening Plants

Jaw Crusher an overview ScienceDirect Topics

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation The capacity is primarily a function of: 1 crusher design characteristics such as width and depth of the crushing chamber, 2 open and closed side settings, Rock Crushers fill the duty of rock size reduction and can be classified in various stages of duties: Primary crushing is the first crushing stage,; secondary crushing is the second,; Tertiary crushing is the third,; Quaternary crushing is a rare forth stage of rock crushing, Coarse crushing includes crushing operations Rock Crushers Mineral Processing Metallurgy opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square Generally primary jaw crushers have the square opening design, and secondary jaw crushers have rectangular opening design Jaw crushers are used as primary crushers in a mine or ore processing plant or the first step in the process of reducing rock“Computer Aided Design of Jaw crusher”

operation mining stone jaw crusher

Stone Crushers For Small Mining Operations Jaw Crusher Stone Crushers Equipment For Sale Usa Stone crushers equipment for sale usa rock crusher for sale in the usa jaw crusher used in america small rock crushers for sale in the usa series single toggle jaw crusher is widely used as various crushing equipment in mining and quarrying industry it In a jaw crusher, the major wear parts are very limited – only a fixed jaw and a swing jaw, and two or four side or cheek plates An impact crusher, on the other hand, has a lot more wear items The blow bars, which hit the rock and make it explode inside the machine, take a majority of the wearSecondary breakers Pit Quarry Equipment Operations minimum effort for operating in both mechanical and electrical types of operation 2 WORKING PRINCIPLE The crusher is designed to operate on a crank and slotted lever mechanism and the power for the electrical operation of the crusher is taken from an electrical motor It is designed to use a 3 phase induction motor for theDESIGN OF MECHANICAL CRUSHING MACHINE

Multiple Choice Question (MCQ) Mechanical Operation

Portal have covered the Mechanical Operation MCQs asked in GATE 100 ton/h of a rock feed, of which 80% passed through a mesh size of 254 mm, were reduced in size such that 80% of the crushed product passed through a mesh size of 127 mm Ball mills, Jaw crushers Fluid energy mills c Fluid energy mills, Jaw crushers, Ball mills Usually, primary crushers are sized by the ability to accept the largest expected ore fragment Jaw crushers are usually preferred as primary crushers in small installations due to inherent mechanical simplicity and ease of operation of these machines Additionally, jaw crushers Jaw Crusher Animation Crusher, Mechanical design, Jaw

- china grinding ball mill

- universal horizontal vertical milling machine

- mining lithium ore processing

- quarry stone and rock crusher price

- ansari sugar mills limited

- gold crushing machines from ore in malaysia

- how to make magnetic sand art

- case study of ncrete recycling in india

- crusher materials oman

- mobile crusher cedar rapids

- aobei ma crusher equipment alog

- jaw crusher toggle plate manufacturers suppliers exporters

- material of nstruction for al hammer crusher in india

- gold mining equipment in turkey for sale

- mini jaw crusher and for sale

- stone aggregate crusher machine price in philippines

- biggest jaw crusher in the world in italy deep rotor mining

- grinding machine rotary

- Iron Ore Crusher Working Flow Chart

- Mercury Used In Mining Is Mercury 2 Or

- grinding machine productivity monitoring

- oyster shell milling machine

- stone block crusher philippines

- modelos y precios de chancadora de piedra en trujillo

- bona flexisand dcs buffer review

- liner plate in cement mill

- crushing and grinding indonesia

- Brazil Silver Ore Beneficiation Plant

- balls straw crusher china

- mining automatic lubrication systems

- New Type crushers used in airport nstruction industry

- Cost Of Stone Crushing Equipment Plant In Indonesia

- c96 jaw mobile crusher

- small portable asphalt crushers

- gold mining equipment for for peru,grinding mill for sale italy

- how to calculate capacity of al bunker

- mining crushing machine pdf

- stone crushing machines price in canada

- effect of crushing manganese ore on the environment

- ball mill for grinding cement equipment

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher