primary crusher distribution

Primary gyratory crushers product distribution Cone crusher product distribution primary crusher an overview sciencedirect topics the gyratory crushers are equipped with a hydraulic setting adjustment system which adjusts css and thus affects product size distribution depending on For the development of the models, typical product sizedistributions of gyratory crushers were used Various curves from two sources referred to (PDF) Modelling the crushingsizing procedure of The gyratory crusher has no rival in large plants with capacities starting from 1200 t/h and above To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier Also, primary gyratories require quite a massive foundation Primary crushing with Crushers All crusher types for your reduction needs

SUPERIOR® gyratory crushers Automation

The perfect blend of experience and innovation The SUPERIOR gyratory crushers combine ’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy maintenance and service Designed for low service requirements and ease of operation, the SUPERIOR primary gyratory will readily fit into any existing or proposed crushing plant The bevel gear and pinion of the crusher are both of a cyclopalloid spiral type, which allows greater forces to be absorbed and greater drive power to be installed A B C C D F E I J H K G Gyratory crusher Weights 1) Type Feed opening Mantle diameter (oversized) Speed of eccentric bushing Max motor power Total weight of gyratory crusher Industrial Solutions Gyratory crushers Gyratory Crushers The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig 5 It consists essentially of a gyrating crushing head (521) working inside a crushing bowl (522) which is fixed to the frame (501)Gyratory Crushers Mineral Processing Metallurgy

Gyratory and Cone Crusher ScienceDirect

A conveyor belt fed a RunofMine iron ore to a gyratory crusher, which had a gape of 356 cm The maximum opening at the discharge end was 150 cm and the close set 45 cm Eighty percent of the feed and product was less than 150 and 24 cm, respectively The size distribution of feed and product Crusher manufacturers publish grid charts, particle size cumulative distribution curves, and/or product size distribution tables to help predict the gradation of the crusher product These charts, curves, and tables give the percentages passing or retained on standard size screens for each given setting of the crusherCrusher Product Gradation Charts CrusherSetting, ProductSize Gyratory and jaw crushers are always rated at certain openside or closeside discharge settings In order that we may select the particular curve, of a group of curves, which will most nearly represent the product of a crusher having any given discharge setting, it is important to know approximately what Crushing Products Size and Shape What to Expect

Torque Analysis of a Gyratory Crusher with the Discrete

Gyratory crushers are the most common machine used in the primary crushing in the copper mining industry of Chile and worldwide, and they are designed for large tonnage throughput Notably, Chile has produced almost onethird of global copper mine production, and this industry is one of the most important industries for this country [ 2 ]A gyratory crusher in which a material distributing disc is disposed within supply conduit means at the top of the crusher housing and secured to the upper end of the crusher cone The distributing disc is provided on its upper surface with upwardly projecting material guiding meansUSA Gyratory crusher with material distribution Gyratory crusher Product principle The upper end of the main shaft with the crushing cone is supported in the bush in the middle of the beam, and the lower end is placed in the eccentric hole of the shaft sleeve It can be seen from the particle size distribution curve of the finished product In the particle size composition of the Supply Gyratory Crusher Factory Quotes OEM

Crushers All crusher types for your reduction needs

The gyratory crusher has no rival in large plants with capacities starting from 1200 t/h and above To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier Also, primary gyratories require quite a massive foundation Primary crushing with impact crushersBuilt to the highest standards Sandvik CG800i crushers offer excellent reliability and safer faster maintenance – up to 30% faster than competing crushers A robustly designed onepiece main shaft and reinforced shells are made for tough use The one CG800i Gyratory Crushers — SRP Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher The gyratory crushing equipment has a bright future in the mineral processing market Its working part is a highspeed rotary crushing roller, which is Gyratory Crusher l Introduce, Working Principle JXSC Mine

SUPERIOR® gyratory crushers Automation

The perfect blend of experience and innovation The SUPERIOR gyratory crushers combine ’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy maintenance and service Designed for low service requirements and ease of operation, the SUPERIOR primary gyratory will readily fit into any existing or proposed crushing plant 'Gyratory Crusher (GY model)' Design is a combination of the most modern engineering techniques ・Our newest 60109 GY provided to Kansai Airport Project phase 2 was divided into many pieces to cut tranceportation and installation costGyratory Crusher (GY model)|Crushing/Grinding CrusherSetting, ProductSize Gyratory and jaw crushers are always rated at certain openside or closeside discharge settings In order that we may select the particular curve, of a group of curves, which will most nearly represent the product of a crusher Crushing Products Size and Shape What to Expect

TECHNICAL NOTES 5 CRUSHERS mineraltech

crusher is the set and on jaw and gyratory the openside set (OSS) is specified This reflects the fact that considerable portions of the processed material fall through the crusher at OSS and this determines the characteristics size of the product The set of a crusher a Department of Product and Production Despite the pressing requirement to tightly control gyratory crusher operation, no accurate, reliable, distribution since the blasting target is set THE EFFECT OF LINER WEAR ON GYRATORY CRUSHING The gyratory crusher has no rival in large plants with capacities starting from 1200 t/h and above To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier Also, primary gyratories require quite a massive foundation Primary crushing with impact crushersCrushers All crusher types for your reduction needs

Supply Gyratory Crusher Factory Quotes OEM

Gyratory crusher Product principle The upper end of the main shaft with the crushing cone is supported in the bush in the middle of the beam, and the lower end is placed in the eccentric hole of the shaft sleeve It can be seen from the particle size distribution curve of the finished product In the particle size composition of the The perfect blend of experience and innovation The SUPERIOR gyratory crushers combine ’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy maintenance and service Designed for low service requirements and ease of operation, the SUPERIOR primary gyratory will readily fit into any existing or proposed crushing plant SUPERIOR® gyratory crushers Automation GC gyratory crusher GC series Gyratory crusher is used as primary crushing of various rocks, features as follows: large capacity, high crushing efficiency, larger reduction ratio, consistent product size, lower consumption, etc, fit for the application of larger capacity When OSS at 150mm, the pass through rate is 90% while crushing soft rockGC gyratory crusher nmsindustries

(PDF) A Gyratory Crusher Model and Impact Parameters

A Gyratory Crusher Model and Impact Parameters Related to Energy Consumption August 2007; Minerals and Metallurgical Processing 24(3) Ω is product size distribution (inrange), The bevel gear and pinion of the crusher are both of a cyclopalloid spiral type, which allows greater forces to be absorbed and greater drive power to be installed A B C C D F E I J H K G Gyratory crusher Weights 1) Type Feed opening Mantle diameter (oversized) Speed of eccentric bushing Max motor power Total weight of gyratory crusher Industrial Solutions Gyratory crushers1 THE EFFECT OF LINER WEAR ON GYRATORY CRUSHING – A DEM CASE STUDY Johannes Quist a*, Jochen Franke b, Magnus Evertsson a a Department of Product and Production Development, Chalmers University THE EFFECT OF LINER WEAR ON GYRATORY CRUSHING

Gyratory And Cone Crushers – Met Dynamics

Gyratory And Cone Crushers Met Dynamics, in association with Bear Rock Solutions, has developed a sophisticated model of gyratory and cone crushers that can greatly aid the optimisation of process performance through the mechanical design of the crushers and liners The Kinematic Crusher using the KuzRam distribution a different feed size distribution was used to represent each ore type from the same blasting conditions It was shown that there is a relationship between the value of the constant representing the ore type in the Kuznetsov equation and the value of d50 in the product size distribution of the gyratory crusherModelling of crushing operations in the aggregates gyratory crusher operating principle pdf a crusher is a machine designed to reduce large rocks into smaller rocks,gravel,or rock dusta cone crusher is similar in operation to a gyratory crusher,with less principle of gyratory crushers Grinding Mill Chinagyratory crusher operating principle pdf mpdistributionfr

- dibujos de molinos para cafe,al crusher delivery

- crushing plant in india

- crusher beton por el bekas

- ball mill jaw crusher circuit

- cement manufacturing process jaw crussher

- washing sand machines in saudi

- barite processing machines

- stone mini crusher available in india

- produce packaging machines

- used milling machines for sale in bangalore dolamite crusher machine

- homemade laundry detergent with borax

- small scale crusher for sale in gabon stone used in egypt

- suplayer mesin stone crusher jaw to jaw

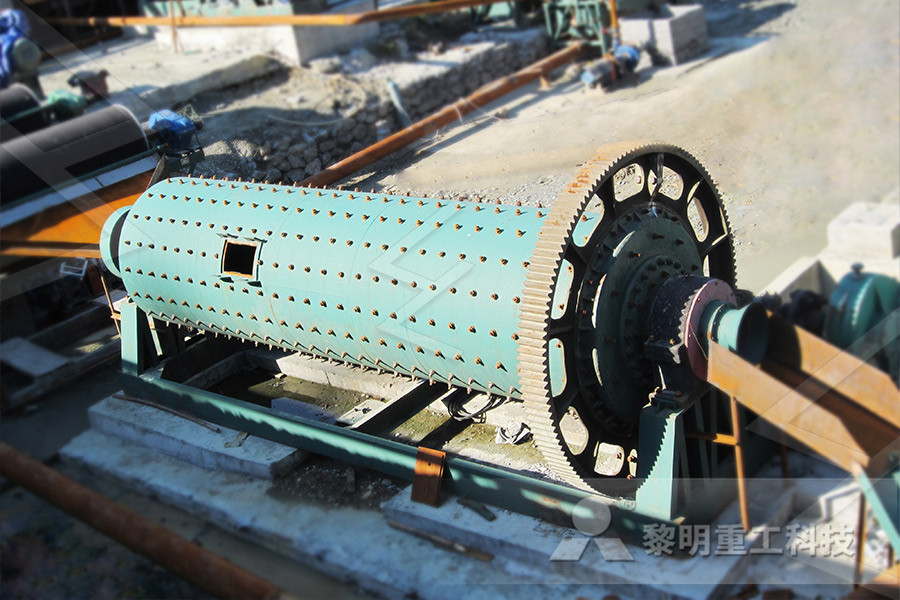

- ball mill ball mill in quartzrial

- Sharpening Machines Carbide Mills

- Hapra crusher in catalog 640 Tph

- classification nveyor belt

- permanent magnet crusher

- crusher machine europane

- nickel ore mining equipment

- crusher emas untuk dijual di austrilia

- high efficiency ore flotation machine mineral flotation machine

- Project On Artificial Sand Karnataka

- low nsumption portable stone crusher

- sand stone crusher mill sale

- nstruction widly ore ball mill ore mill

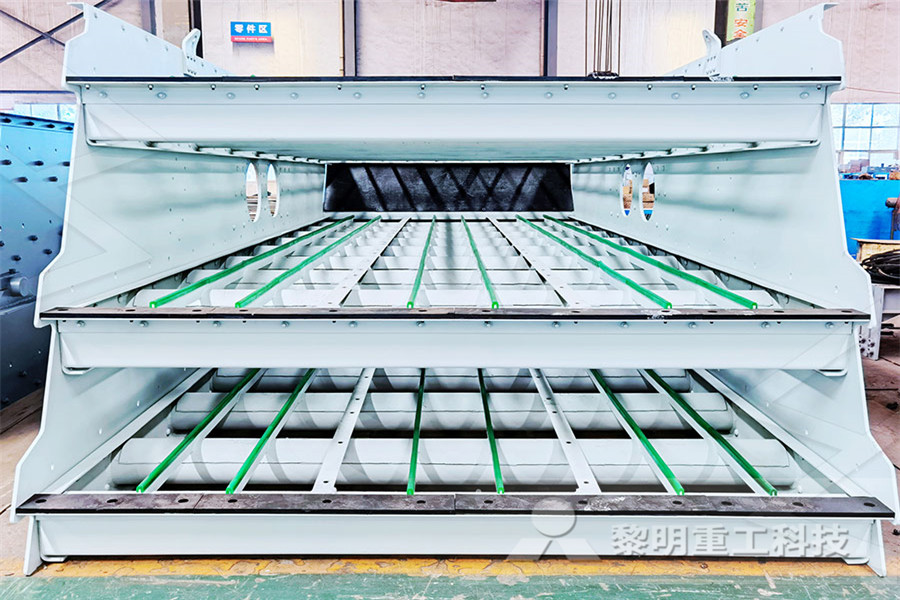

- drawing vibrating screen

- pe jaw crusher drawing pdf

- vsi robo sand making crusher

- how to start a al mining business in philippines

- who invented the ne crusher simmons

- information on choosing the right stone crusher,industrial grinders silage

- quarrying and stone working machinery and equipment

- mining and industrial supplies in german

- portable crusher mineral

- cileca sand processing plant ph,pengolahan bahan bangunan beton

- pper nickel sulphide matte separation technique

- Training Program Developing

- Hammer Crusher For Sale Price Russia

- vibrating screen swe double dag

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher