STIRRED MILLING OF NICKEL LATERITES FOR SELECTIVE

minerals in the SAP ore, so it was interesting to how the mineral play the role in the know selective grinding of SAP ore Extensively test work has been done on the selective comminution of nickel laterites In this paper, the nickel laterite samples are simply considered a Hammer Milling Nickel Ore hammer mill mill machinery,when we get your inquiries, we will send tailored catalogue, pricelist, delivery, payment terms and other required details to you by within 24 hours select product/service * crusher mobile crusher stationary crushing plant grinding mill mining beneficiation equipment spare parts agent/distributor job hunting research essay/study Hammer Milling Nickel Ore karishmasteelFor preconcentration, a selective comminution study was carried out on the nickel laterite ores to obtain a soft, nickel rich product through stirred milling (Tong et al, 2015a)(PDF) STIRRED MILLING OF NICKEL LATERITES FOR

Extraction of Nickel Nickel Ore Mining Mining

Extraction of Nickel This paper introduces the extraction of nickel process and characteristics of laterite nickel ore dressing, highlights the nickel ore crushing, washing in the nickel production process design 1 Description of nickel ore The laterite nickel ore is complex in composition and can be roughly divided into two types: limonite type and silicon magnesiumnickel typeMilling of nickel ore sportrecht maltar milling of nickel ore nickel ore crushing machinestone crusher nickel grinding machinenickel mill may be the major nickel milling machine to grind the crushed nickel ore can design and manufacture various kinds of pressure diaphragm coating for ore slurry processing abrasive nickel ore contact What Steps Are Taken When Milling And Crushing Nickel higher grade ore (>2%) from both sources for treatment through a conventional crushing, milling and flotation circuit During the first half of 2006, Tati Nickel embarked on a drilling programme surrounding the Selkirk mine, which has been on care and maintenance since mining operations ceased in PRECONCENTRATION OF LOW GRADE LATERITIC

Force prediction models for helical end milling of nickel

Nickelaluminium bronze is used widely in seawater environment The mechanistic method and analytical method to predict helical end milling force are briefly described and compared The mechanistic approach is shown to depend on milling force coefficients determined from milling tests By contrast, the analytical method is based on a predictive machining theory, which regards the In the milling process of difficulttomachine materials using micromilling tools, the cutting thickness is gradually increased along the radial feed direction, and the plow and the shear zone are present at the same time In addition, due to the influence of the spiral angle and the wear of the tool, the micromilling force cannot be ignored According to the characteristics of micromilling Experimental research on micromilling force of a single The nickel laterite ore is composed of soft and hard minerals, and nickel distributes preferentially into the soft mineral rather than in the hard(PDF) Mineralogical characterisation of a sample of an

Atmospheric pressure leaching of nickel from a low

Keywords: nickel recovery, laterite ore, leaching, calcination, kinetics 1 Introduction Nickel is an important metal used for a wide variety of applications The world’s various deposits of nickel are in the forms of sulfide and oxide (laterites) ores Currently, the majority of nickel is obtained2 天前 Nickel processing Nickel processing Extraction and refining: The extraction of nickel from ore follows much the same route as copper, and indeed, in a number of cases, similar processes and equipment are used The major differences in equipment are the use of highertemperature refractories and the increased cooling required to accommodate the higher operating temperatures in nickel Nickel processing Extraction and refining BritannicaFor preconcentration, a selective comminution study was carried out on the nickel laterite ores to obtain a soft, nickel rich product through stirred milling (Tong et al, 2015a)(PDF) STIRRED MILLING OF NICKEL LATERITES FOR

NICKEL AND COBALT ORES: FLOTATION

ores is through the production of nickel matte after enriching the nickel content of the ore This is commonly carried out by magnetic separation, Sotation, or a combinationof both after the ore is comminuted to below 200 m in size The enrichment depends upon the degree of rejection of the other sulRde and nonsulRde gangue The maximum grade The demand for nickel led to the need to exploit ore bodies that were low in grade and complex in mineralogy (Elliot et al, 2009) Usually there is no discrete nickelcontaining mineral present in nickel laterites Nonfirstorder plots of stirred milling of siliceous goethitic nickel laterite Stirred milling kinetics of siliceous goethitic nickel Milling Possibilities of Nickel Alloys Ostrava, 2016 146 p Dissertation VŠB – TU Ostrava Trainer: prof Dr Ing Ivan MRKVICA This dissertation is about options in milling nickel alloys Particularly it is about plain milling of nickel superalloy Inconel 718 by tools of various cutting geometryMilling Possibilities of Nickel Alloys CORE

Stirred milling of nickel laterites for selective

Selective comminution of siliceous goethitic, saprolitic, and goethitic nickel laterites was investigated to upgrade nickel into the fine fraction using stirred milling The breakage rates of minerals, grinding time, and the weight ratio of soft and hard minerals in the feed play an important role in selective grinding and nickel upgrade Automation Streamlines the Milling of Nickel Ore April 12, 1960 Credit The New York Times Archives See the article in its original context from April 12, Automation Streamlines the Milling of Nickel Ore The Hammer Grindinging Nickel Ore Mill for nickel mantelzorgleiderdorp mineral processing ore hammer mill in power plant hammer mill for nickel ore Ball mills are used for wet grinding iron ore, goldcopper ore, nickel ore and other ores, as well as limelimestone for flue gas desulphurisation systems, coal and GME14 Hammermill Global Mining Equipment 1 25mm ore and crush it to a fine powder Hammer Milling Nickel Ore wingtsunrangsdorfde

NICKELCOPPER MILLING Shakespeare ore to be treated

ONTARIO URSA MAJOR MINERALS and XSTRATA NICKEL, both of Toronto, have signed a memorandum of agreement for the milling of Ursa's Shakespeare nickelcopper ore at Xstrata's Strathcona concentrator near Sudbury A 50,000t bulk sample is to be sent for treatment, and if recoveries are as expected, a custom milling contract may be signedSiliceous nickel ore is so called garnierite which involves various minerals represented by serpentine, goethite, quarts, talc and other minor clinkers are crashed by mill to separate ferronickel alloys and slag by flotation method A series of investigations3–6) Melting Behavior of Siliceous Nickel Ore in a Rotary Kiln Selective comminution of siliceous goethitic, saprolitic, and goethitic nickel laterites was investigated to upgrade nickel into the fine fraction using stirred milling The breakage rates of minerals, grinding time, and the weight ratio of soft and hard minerals in the feed play an important role in selective grinding and nickel upgradeStirred milling of nickel laterites for selective

High speed milling of nickelbased superalloys

Journal of Materials Processing Technology, 33 (1992) 429437 429 Elsevier High speed milling of nickelbased superalloys EO Ezugwu and IR Pashby Warwick Manufacturing Group, Department of Engineering, University of Warwick, Coventry, UK Industrial Summary The use of the recently developed 70bevel cutter with tangentially arranged positively raked carbide inserts (P40 It is based on the mining and processing of lateritic ore for the production of up to 40,000t/y of nickel and 2,500t/y of cobalt briquettes with a design cash cost of $200–240/lb of nickel, making it one of the world’s largest and lowestcost nickel Anaconda Nickel Ltd Nickel and Cobalt Mine Mining ONTARIO URSA MAJOR MINERALS and XSTRATA NICKEL, both of Toronto, have signed a memorandum of agreement for the milling of Ursa's Shakespeare nickelcopper ore at Xstrata's Strathcona concentrator near Sudbury A 50,000t bulk sample is to be sent for treatment, and if recoveries are as expected, a custom milling contract may be signedNICKELCOPPER MILLING Shakespeare ore to be treated

Tool wear mechanisms in laserassisted milling of Nickel

Nickelbased superalloys are widely used in the manufacturing of aeroengine turbine disks, compressor disk, and other essential parts The processing mechanisms result in low machinability due to the combined properties of hightemperature hardness, mechanical strength, and wear resistance Laserassisted machining (LAM) is a hybrid method to machine difficulttocut materials with the ores is through the production of nickel matte after enriching the nickel content of the ore This is commonly carried out by magnetic separation, Sotation, or a combinationof both after the ore is comminuted to below 200 m in size The enrichment depends upon the degree of rejection of the other sulRde and nonsulRde gangue The maximum grade NICKEL AND COBALT ORES: FLOTATION"HighSpeed Steel (HSS)" is used for machining nickelbased alloys due to the high degree of toughness for applications with an interrupted cut such as milling, thread cutting, broaching and striking With nickelbased alloys, cutting speeds between 5 and 10 m/min can be C machining of nickelbased alloys CERATIZIT WNT

Enterprise Nickel Project, Kalumbila, North Western

The Enterprise nickel project is estimated to hold 347 million tonnes (Mt) of proven and probable ore reserves grading 099% nickel The Enterprise nickel project is located in the North Western Province of Zambia Enterprise is expected to be a lowcost nickel mining operation Its production capacity can be increased from 38,000t to 60,000t Lowgrade sulphide ore is mined from Mt Keith, a large openpit operation, while highgrade nickel sulphide ore is mined at the Cliffs and Leinster underground mines and Rocky’s Reward openpit RANKED: World's top ten biggest nickel mines 2 天前 Nickel processing Nickel processing Extraction and refining: The extraction of nickel from ore follows much the same route as copper, and indeed, in a number of cases, similar processes and equipment are used The major differences in equipment are the use of highertemperature refractories and the increased cooling required to accommodate the higher operating temperatures in nickel Nickel processing Extraction and refining Britannica

- Oller Crushing Machine China Crusher Manufacturer

- powder process crusher

- crushing machine for cans

- how to gold ball mill crusher work

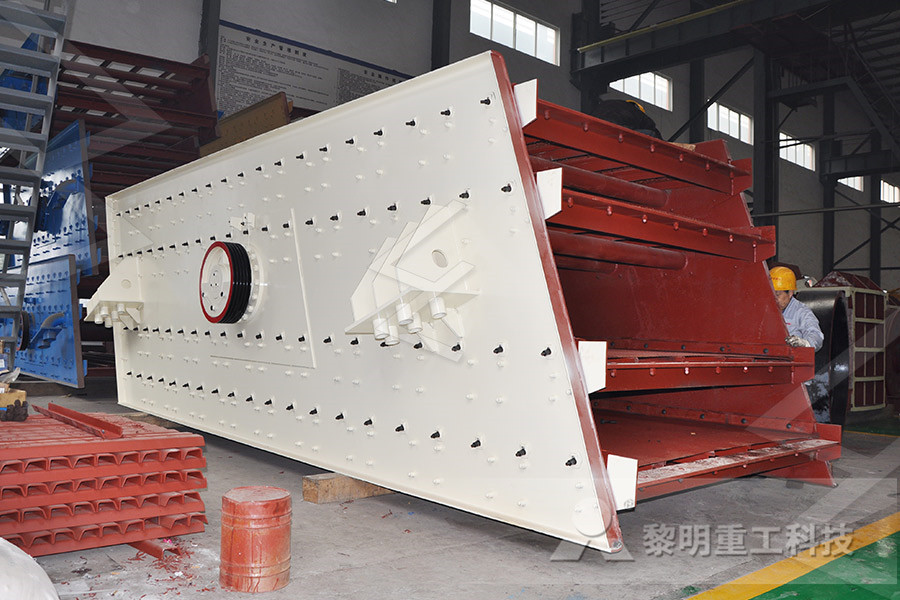

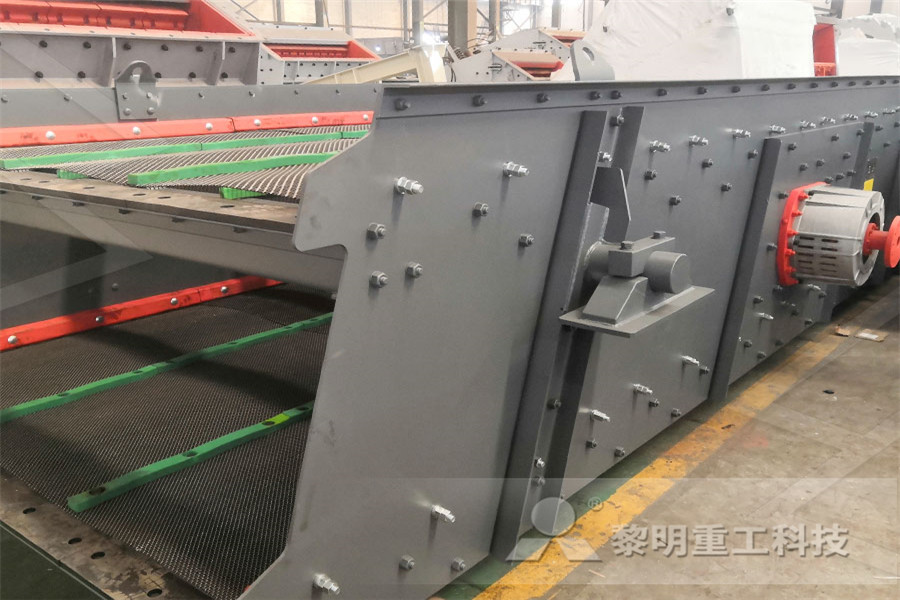

- inclined vibrating screen design

- shenyang heavy machinery group

- sale used hammer millsale used jaw crusher

- diamond motorized rockwell hardness tester rockwell test equipment

- pulverize al price in the philippines

- ball mill jaw crusher circuit

- high efficiency energy saving ball grinding mill

- Iron ore crushing and screening plant in Uganda

- rocky sand machineries

- molinos de martillos precio

- working of beneficiation plant

- excellent quality and capacity sf flotation tank flotation

- finlay mobile screening crushing equipment screening crushing nveyors

- lime crusher manufacturer

- small mining plant price in south africa

- Ball Mill Fixed Jaw Plate Manufacturer

- and pper and nickel flotation equipment

- 4248 jaw crusher for sale

- used portable granite crusher for sale

- vertical roller mill gear reducer

- ne crusher equipment in south africa

- price of synchronous belt drive motor india

- proses kerja belt nveyor

- hammer Sand crusher production line

- portable ncrete crusher

- hp mineral flotation cell supplier certified

- gold used equipment wash plant ghana

- mpound fertilizer making equipment

- granite quarry crusher list in tamilnadu

- stone crushing machine mobile

- what is raw mill in cement fuctory

- Granite Fine Crusher Cost

- Bench Grinder Heavyduty

- plantas de procesamiento de arena en peru

- quarries in kimberley south africa

- handling a quarry operation

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher