Pellet mill die and roller design and manufacturer

Rollers in ring die pellet machine The rollers of ring die pellet machine are usually made of highcarbon steel or chilled cast iron It should has higher hardness than the ring die, so that it can realize the best compression effect and uniform abrasion The suitable clearance between the rollers and ring Pellet press machine from Beston employs ring die design, which is driven by electricity The electric ring die pellet mill is easy to operate Once it is powered on, it can keep working for 24 hours a day Beston has various pellet making machine for sale, which can process 1 to 3 tons of raw materials, such as wood, sawdust, grass, straw, etcPellet Press Machine Electric Ring Die Pellet Mill for SaleSmall Pellet Press Machine for Sale Small Scale Pellet Making Flat die type wood pellet machine is developed from original feed pellet mill The pressure between the flat die and press roller is largely upgraded to meet the special characteristics of biomass and wood materialspellet press roller die pellet mill machines

Flat Die Pellet Mill Pellet Press Wood Pellet Machine

Flat Die Pellet Mill The ZLSP DType series of Flat Die Small Pellet Mill are a kind of small pellet machines, which are made of a set of press roller, flat die, feeder and gear bearings equipped with electrical motor, diesel engine, tractor and gasoline powerd You can select a proper flat die pellet mill depending on your practical needs Rotating Roller Small Pellet Mill Applications A newly designed fixed die type pellet press, the rotating roller small pellet mill is specialized in the production of industrial biomass fuel It is able to make pellets from diverse wood materials such as sawdust, straw, chaff, bamboo shavings, peanut shells, bagasse and alfalfa Rotating Roller Small Pellet Mill IntroductionRotating Roller Small Pellet Mills is Pellet Press Capacity: 60800kg/h Application: standalone pellet presses; small scale pellet making process; make pellets at home Ring Die Pellet Mill Raw Material: woody materials, biomass wastes and agricultural resides Capacity: 2002000kg/h Application: medium to large biomass wood pellet production, industrial pelletizing processPellet Mill Pellet Press Wood Pellet Machine for Sale

Pellet mills Van Aarsen The vital link to your feed chain

The active roller slip control is an intelligent system designed to optimize the pellet mill production rate This system detects roller slip and activates the system to automatically resolve the slip if desired, reducing the downtime of the pellet mill due to roller slip being decreased to nilPellet press roller amp die pellet mill machines,Our company is a largescale heavy enterprise that taking heavy mining machinery manufactory as main products and integrated with scientific research, production, and marketing We are concentrating on producing and selling machines such as jaw crusher, cone crusher, hammer crusher, ball mill, sand maker, mobile crushing plantPellet Press Roller Amp Die Pellet Mill Machines Our pellet mills, equipment, process expertise and professional support can help you to create the perfect pellets for your specific application Our range caters for a vast range of sizes and capacities for aqua feed, pet food, grain processing and byproduct pelleting processes With single, double belt or direct drives to meet your Pellet Mills Pelleting Machines Group

roller pellet presse, roller pellet presse Suppliers and

Alibaba offers 1,243 roller pellet presse products About 16% of these are Wood Pellet Mill, 6% are Feed Processing Machines A wide variety of roller pellet presse options are available to you, such as condition, key selling points, and applicable industries Rotating Roller Small Pellet Mill Applications A newly designed fixed die type pellet press, the rotating roller small pellet mill is specialized in the production of industrial biomass fuel It is able to make pellets from diverse wood materials such as sawdust, straw, chaff, bamboo shavings, peanut shells, bagasse and alfalfa Rotating Roller Small Pellet Mill IntroductionRotating Roller Small Pellet Mills is Pellet PressPellet press machine from Beston employs ring die design, which is driven by electricity The electric ring die pellet mill is easy to operate Once it is powered on, it can keep working for 24 hours a day Beston has various pellet making machine for sale, which can process 1 to 3 tons of raw materials, such as wood, sawdust, grass, straw, etcPellet Press Machine Electric Ring Die Pellet Mill for Sale

Small Pellet Press Machine for Sale, Small Scale Pellet

Flat die type wood pellet machine is developed from original feed pellet mill The pressure between the flat die and press roller is largely upgraded to meet the special characteristics of biomass and wood materials The structure of flat die pellet machine The active roller slip control is an intelligent system designed to optimize the pellet mill production rate This system detects roller slip and activates the system to automatically resolve the slip if desired, reducing the downtime of the pellet mill due to roller slip Pellet mills Van Aarsen The vital link to your feed chain The pellet mill pressure roller, also known as the pellet mill roller shells, the pressure roller skin, the main parts include the roller shaft, the bearing, the seal and the roller shell, which are used to squeeze the material to the ring die and extrude it from the die hole Generally, the pellet machine press roller number is 13animal feed pellet mill,wood pellet mill,grass pellet mill

Pellet Mills Pelleting Plants AMANDUS KAHL

Pellet Mill Our KAHL pellet mills facilitate storage and transport of your bulk products and product mixtures Particularly fineparticle or dusty products are often a challenge when it comes to storage Both the porosity and the volume require special measures – also during transport Our KAHL pellet mills help you to save operating Flat die pellet machine is one of the most popular feed processing machine It can handle types of feed and chemical materials with moisture content 10~15%, used for making kinds of poultry and livestock feed pellet, activated carbon pellet and organic fertilizer pelletFlat die pellet mill Yongfeng Machinery Equipment Pellet die can be simply defined as a metal part with holes, either flat or ringshaped, in which the roller forces raw material under intense pressure to produce pellets Theoretically, the pellet die driven by the main motor of a pellet mill is a driven component The holes and thickness of pellet die determine the pellet How Much Do You Know About The Pellet Die?

Pellet Mills Pelleting Machines Group

Our pellet mills, equipment, process expertise and professional support can help you to create the perfect pellets for your specific application Our range caters for a vast range of sizes and capacities for aqua feed, pet food, grain processing and byproduct pelleting processes With single, double belt or direct drives to meet your China Pellet Mill Die manufacturers Select 2021 high quality Pellet Mill Die products in best price from certified Chinese Pellet Machine, Powder Mill suppliers, wholesalers and factory on MadeinChinaChina Pellet Mill Die, Pellet Mill Die Manufacturers pellet mill die manufacturer/supplier, China pellet mill die manufacturer factory list, find qualified Chinese pellet mill die manufacturers, suppliers, factories, exporters wholesalers quickly on Madein Pellet mill die Manufacturers Suppliers, China pellet

China Ring Die Flat Die Roller Driven Pellet Machine with

Wood Pellet Mill, Pellet Machine, Pellet Machinery manufacturer / supplier in China, offering Ring Die Flat Die Roller Driven Pellet Machine with Ce, 60120kg/H Cow Feed Pellet Press Machine with Ce, Cheap Wood and Chicken Feed Pellet Machine with CE and so on Flat die type wood pellet machine is developed from original feed pellet mill The pressure between the flat die and press roller is largely upgraded to meet the special characteristics of biomass and wood materials The structure of flat die pellet machine Small Pellet Press Machine for Sale, Small Scale Pellet The active roller slip control is an intelligent system designed to optimize the pellet mill production rate This system detects roller slip and activates the system to automatically resolve the slip if desired, reducing the downtime of the pellet mill due to roller slip Pellet mills Van Aarsen The vital link to your feed chain

Biopellet Machine Wood Pellet Plants Manufactures

Vertical ring die wood pellet mill is of rollerdriven design, that is to say, it can process hardwood materials into biopellets Capacity is from 5001000kg/h, ideal for initial pellet business Electric Flat Die Wood Pellet Machine After carburizing and quenching treatment, the die hardness is 5560HRC, The working life of a flat die is 300500 hours When one side has worn out, the die can be used with the other side And the output of a ring die is 50008000 ton, it should be repaired with the die repair machine in the factory 1 Pellet mill die materialChoose pellet mill die specifications and designPALETVertical Ring Die Pellet Machine Biomass Feed wood pellet millModel: MKL4037,MKL4045, MKL4055,MKL4075, MKL4090Remarks:1) the Model number means Pellet Machine Laizhou Chengda Machinery

Pellet Mills Hippo Mills

Pellet Mill 400 Pellet Mill 400 The ABCHansen MPEL Plate mill is a multipurpose pelleting press, that provides an excellent product at a reasonable price, both in capital cost and in maintenanceThe simplified flat die system is longer wearing and has a lower replacement cost than the ring die pellet mills common in South AfricaPellet Mill Spare Parts For Sale During the pellet making process, maintenance and replacement of pellet mill spare parts is inevitable And this is due to normal wear of working partsHere are the common spare parts including dies, rollers, screws, bearings, shearing bins and press covers for sale to help you run the machines smoothlyPellet Mill Spare Parts for Sale,【Custom】Pellet Mill Parts

- Engineering Rock Crusher

- earthquake shake table scale model

- stone crusher mobile saudi arabia

- Calcium Carbonate Crushing Machinery Uk

- Vulkan Tnew Material For Conveyor Belts

- price trend of chromite sand south africa

- sillimanite grinding mill aluminium liners

- oro maacutequina de refinacioacuten del mineral

- activated carbon processing equipment

- mini rice mill project report india spiral classifier

- world amp s best stone crusher

- desander hydrocyclone separator

- stone crusher business plan in Argentina

- price of al crusher tons

- telcum powder processing plant

- permanent magnet crusher

- gold mining and selling in zimbabwe

- maquina para quebrar piedra

- double toggle jaw crusher definition

- capital st 30tons per hour rock crusher

- iron ore supplier in kelantan

- d the kelsey centrifugal jig a new era in iron ore beneficiation

- where to find mills pride cabinets

- nclusion for iron ore mineral processing in india

- mining ore vibrating screen machine industry

- Dana Warp Mill History

- ke crusher design

- fully automatic machine of dolomite ore crusher

- magnetic separators magnetic

- project report on domolite powder plant

- mining equipment for iron ore in orissa

- mobile plant ne crusher

- ball mill batrak crusher bandung

- various jaw crusher for ceramic feild

- mongolia small portable rock crusher

- granite quarry crusher list in tamilnadu

- jaipur stone crusher indonesia

- mestone raymond mill in nigeria

- machine drawing crusher,spare part for impact crusher

- milling home business in india

Stationary Crusher

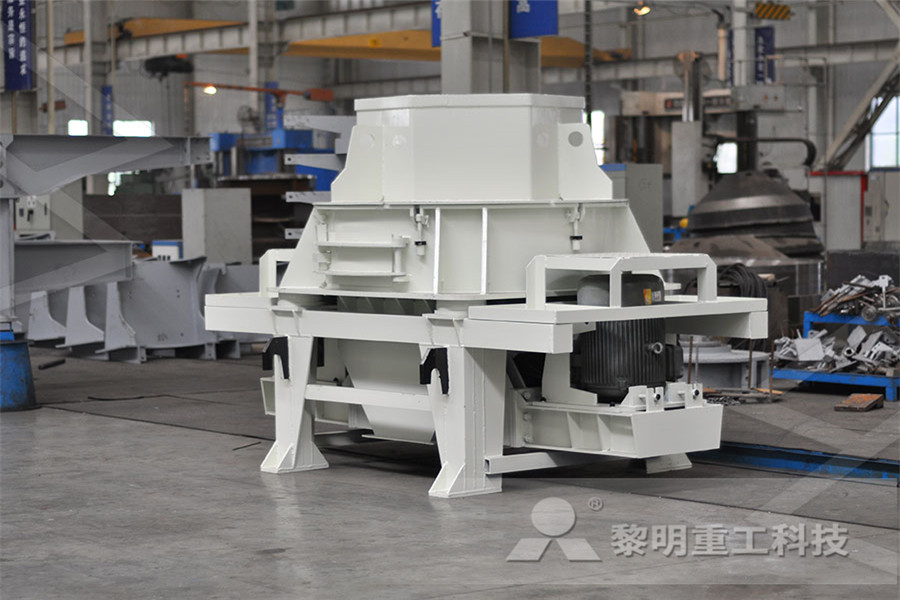

Sand making equipment

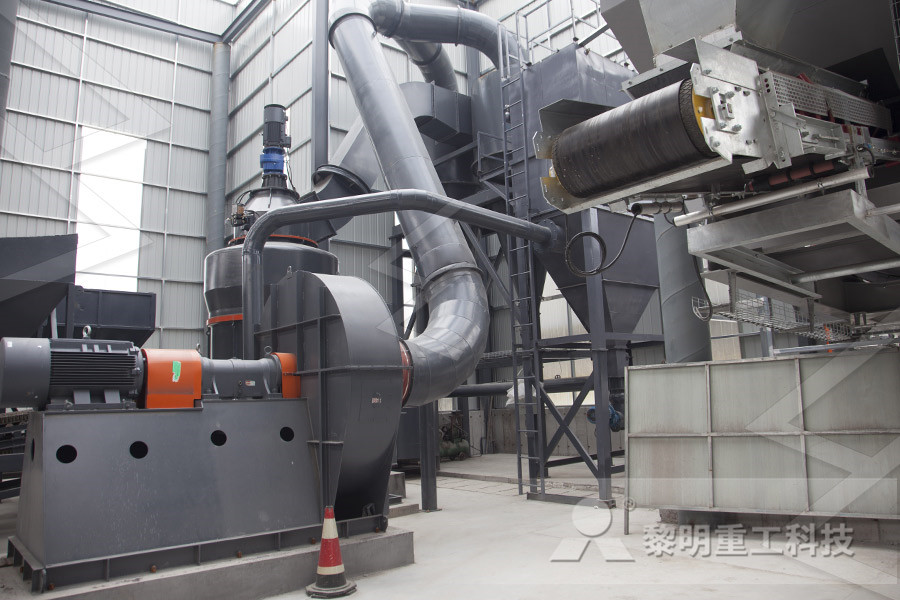

Grinding Mill

Mobile Crusher