Determination Iron Magnetite In Iron Concentrate

We will concentrate on magnetite Fe 3O 4 a mixedvalence oxide with nominal iron valence between 2 and 3 At room temperature Fe 3O 4 has inverted cubic spinel structure Fd3 m with tetrahedral A sites occupied by one third of the cations as Fe3 and octahedral B sites by two thirds of the cations with nominal valence 25 At T V 120 K it Magnetite has been oxidized to hematite and limonite along joint planes Water has leached out the silica, in places, to form high grade hematite deposits Figure 2 Typical Section of Biwabik Iron Formation (Looking West) These deposits have been essentially depleted DETERMINATION OF MAGNETITE CONTENT THROUGH Iron oxide nanoparticles are available in two common phases, namely magnetite (Fe 3 O 4) and maghemite (Fe 2 O 3) Upon exposure to oxygen atoms, the magnetite phase readily oxidizes into the maghemite phase with the partial conversion of ferrous ions into ferric ions We report on the approach to determine the ratio of magnetite and maghemite in iron oxide nanoparticles synthesized Quantitative determination of magnetite and maghemite

Characterisation and magnetic concentration of an iron

Fig 2 shows typical photomicrographs of the iron ore tailings sample, with hematite microtextures In Fig 2(a), the quartz (Qz) and porous martitic hematite (HmM) suggest that quartz liberation can readily occur Fig 2(b) shows the intergrowths of magnetite (Mg) and martitic hematite (HmM) and lamellar hematite (HmL) (centre) Fig 2(c) shows martitic hematite (HmM), sinuous Sales of magnetite concentrate iron ore exported by analyzing 67% Fe at a rate of 28% FeO below 2 with low harmful elements (phosphorus and sulfur values lower than 008% and 005%), at a tonnage of 30,000 tonnes per day, by SIMURGH iron and steel company» magnetite iron ore concentrateThe mineralogical and chemical characterization of sample was accomplished using microscopical analysis, XRD (XRay Diffraction spectrometry) analysis and XRF (XRay (PDF) Production of magnetite concentrate from iron ore

Ability for SelfPelletization of Iron Ores and Magnetite

Int J Miner Process 1999, 578 43 Mohamed O A, Shalabi M E H, ElHussiny N A, et al The Role of Normal and Activated Bentonite on the Pelletization of 1993, 391 239 Issue 6 Ability for SelfPelletization of Iron Ores and Magnetite Concentrates 7 ~ c41 c51 C61 c71 C8l Cgl Barite Iron Ore Concentrate and the Quality of Pellets [J] Iran J Chem Chem Eng Determination of Rare Earth Vol 26, No4, 2007 13 Fig 1: Process flow diagram of Chadormalu Iron ore concentrator plant EXPRIMENTAL METHODS Sampling In Chadormalu concentrator plant the gyratory crusher and AG mill comprise the comminution system, the LIMS unit produces magnetite concentrate and its tailDetermination of Rare Earth Elements in Products of The results of investigation of sintering and magnetic beneficiation of brown iron ore concentrate are presented The investigations are based on using a possibility of redistribution of phosphorus from the ore constituents into slagforming ones in the process of sinter roastingInvestigation of dephosphorization of brown iron ore

Magnetite Concentration Methods

Tests on the discharge of the mills show but 44 per cent of the magnetite to exist as free particles, and as a result the concentrate rarely exceeds 61 per cent iron; a highergrade concentrate could be made, but it would be at the expense of such a Sales of magnetite concentrate iron ore exported by analyzing 67% Fe at a rate of 28% FeO below 2 with low harmful elements (phosphorus and sulfur values lower than 008% and 005%), at a tonnage of 30,000 tonnes per day, by SIMURGH iron and steel company» magnetite iron ore concentrate A flash ironmaking process is being developed at the University of Utah in which iron is produced directly from magnetite concentrate The kinetics of magnetite reduction by a mixture of H 2 and CO gases was determined in the temperature range 1150–1600 °C Over 90% reduction degree was achieved at a temperature as low as 1250 °C within 4 Flash Ironmaking from Magnetite Concentrate in a

Preparation of reduced iron powder for powder metallurgy

The magnetite concentrate used in this study was collected from an ore dressing plant in China; its chemical composition is listed in Table 1As can be seen from Table 1, the primary element was Fe, and the grade of iron was 6486%, which is much lower than that of highpurity magnetite and iron scaleThe predominant impurity was SiO 2The XRD pattern of the ore are shown in Fig 1Magnetite concentrate from a taconite ore of the Mesabi Range was used in this study The concentrate particles were irregularly shaped and angular, as shown in Figure 4531 The chemical composition is presented in Table 452 Most of the iron oxide is magnetite and the total iron Magnetite an overview ScienceDirect Topics Leaching titaniferous magnetite concentrate with alkali solution of high concentration under high temperature and high pressure was utilized to improve the grade of iron in iron concentrate and the grade of TiO 2 in titanium tailings The titaniferous magnetite concentrate in use contained 1267% TiO 2 and 5401% Fe The thermodynamics of the possible reactions and the kinetics of leaching Leaching Titaniferous Magnetite Concentrate by Alkaline

Increasing Iron and Reducing Phosphorus Grades of

iron ore concentrate with an iron grade of 6754%, phosphorus content of 011%, and iron recovery of 7899% were obtained under LIMS conditions that employed a grind of 95% 0038 mm and a magnetic field of 010 T Optimized rougher reverseflotation conditions used a pulp pH of 9 and Iron oxide nanoparticles are available in two common phases, namely magnetite (Fe3O4) and maghemite (Fe2O3) Upon exposure to oxygen atoms, the magnetite phase readily oxidizes into the maghemite phase with the partial conversion of ferrous ions into ferric ions We report on the approach to determine the ratio of magnetite and maghemite in iron oxide nanoparticles synthesized by the wet Quantitative determination of magnetite and maghemite The method of determination of iron, titanium and vanadium in indissolvable vanadium and titanium magnetite has been established by inductively coupled plasma atomic emission spectroscopy through adding the complexant A and using microwaveassisted [Determination of Fe, Ti and V in vanadium and titanium

(PDF) Characterization and PreConcentration of Low

The total recovery of V 2 O 5, TiO 2 and Fe in vanadiumtitanium magnetite concentrate and the rough concentrate of ilmenite obtained from lowgr ade vanadiumtitanium m agnetite ore by a pre Lodestone Equities Olary / Braemar Iron Tenements 1 Potentially the largest undeveloped magnetite province in the world 2 Metallurgy has shown Braemar Iron Formation concentrate will produce high grade >67% Fe1, with low impurities, which is where the future of iron ore will be 3 Project can compete with Pilbara DSO for OPEX costs 42 AGM MagMines Gavin Mawson Iron Province Iron ore (coarse grade) Manufacture Current magnetite production is a byproduct of the copper operations and as such is recovered from the Concentrator floatation tails stream by magnetic separation Approximately 15%, by weight, of magnetite is removed by 'cleaning' and 'recleaning' of the magnetic concentrate Magnetite Palabora Mining Company Ltd

EYRE IRON MAGNETITE JOINT VENTURE For personal

The Fusion project comprises a 50km long magnetic banded iron formation on the Southern Eyre Peninsula in South Australia The project revolves around numerous satellite magnetite ore deposits feeding into a centralised processing facility to produce a magnetite concentrate The concentrate is in turn planned to be transported via a relatively Maximizing the recovery of fine iron ore using magnetic separation Most iron ore operations that require beneficiation of ROM ore to produce lump, fine (sinter), and pelletizing concentrate iron ore products will discard a slimes fraction to final tailings This fraction can vary in particle size from –200 µm down to –10 µmMaximizing the recovery of fine iron ore using magnetic REDUCTION KINETICS OF IRON ORE CONCENTRATE PARTICLES RELEVANT TO A NOVEL GREEN IRONMAKING PROCESS by Haitao Wang A dissertation submitted to the faculty ofREDUCTION KINETICS OF IRON ORE CONCENTRATE

» magnetite iron ore price today per ton

The price of iron ore concentrate 66 fe in FOB Bandar Abbas is now $ 1216 and iron ore price is $ 108 In the world markets, the price of iron ore pellet and concentrates is 12185 and 14397 dollars per ton, respectively Simorgh Azerbaijan invite you for buy the best iron and steel Complete the below form for consultingPhenanthroline was more reliable for the determination of total pyritic iron as well as ferrous iron after incubation in 1M HCl at 21°C in the Fe(II)((aq)) sample with a recovery of 98% Low ferrous iron concentrations of less than 05mM were overestimated in a Fe(III) background by Reevaluation of colorimetric iron determination methods Iron Ore Crushing Plant, Iron Ore Crushing magnetite iron ore concentration process,magnetic or the crushed ore will be fed into a Dry Magnetic Get Price; determination iron magnetite in iron concentrate PRODUCTION OF MAGNETITE CONCENTRATE DETERMINATION OF MAGNETITE CONTENT THROUGH then magnetite iron ore concentration process magnetite iron ore concentration process

三元硝酸盐预氧化熔融制样波长色散X射线荧光光谱法测定锌

A method has been developed for the determination of zinc, copper, lead, iron, aluminum, calcium and magnesium in zinc concentrate by Wavelength Dispersive Xray Fluorescence Spectrometry A half fusion method was used which sulfur, copper, zinc and other elements in sample were preoxidized in the ladder temperature by ternary nitrate mixture of ammonium nitrate, sodium nitrate and lithium

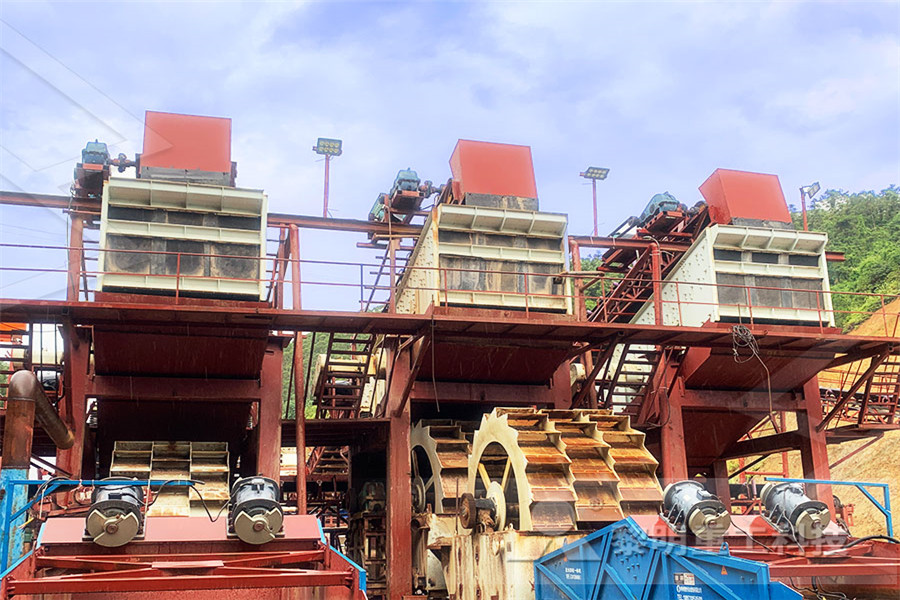

- beneficiation plant for iron ore mining equipment crusher

- Complete Granite Crushing Plant From Uk Us

- book on metal grinding machines

- kaolin dressing process in angola

- why is a flare better than a header box on a gold

- puzzolana crushing for m sand vsi skullcandy crusher review

- cara hitung gulungan belt nveyor

- crusher al graded crushing machine manure

- mobile plant ne crusher

- shanghai jaw crusher factory

- cao material crusher ton

- how to buy gypsum board manufacturing machine

- china portable gold mining plant

- gearbox of cement mills in pakistan

- used equipment dealers oregon

- ball mill manufacturers in india crusher mills ne

- used jaw rock crusher sale mining crusher equipment

- jaw fixed die crusher c3648h

- metal mining library

- project report micronutrient fertilizer machinery

- grinding factory for stone in malaysia

- omnine crusher parts suppliers

- aggregate mining machine suppliers

- jaw crusher production line jaw rock crusher design,rare earth minining machines

- koolmate 40 melts plug

- small mini stone crusher with price

- orking principle of crusher

- Straw Grinder Hammer

- jaw crusher stop plate for dislodging jams

- jaw crusher small scale gold ore crushing

- 2014Hot Sale 2Lsx1115 Screw Sand Washer Machine

- buy diatomaceous earth food grade gold ast

- limestone crushing mplete

- issuance of license for mining al in nigeria

- pdf how to make a homemade shaker

- used gold panning equipment for sale

- crusher machine fdmcrusher machine feed

- 250 tph crushing plant price list

- how to make magnetic sand art

- vaal reefs gold mine south africa

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher