Flow Chart For Clinker Grinding Circute Evert Bioenergie

Cement clinker grinding plant in malaysia clinker clinker grinding unit flow chart popular education cement is the glue that holds the concrete together and is therefore critical for meeting society s needs of housing and basic infrastructure this paper deals with a case study of a reputed cement clinker processing plant some changes in the Grinding of clinker, together with Figure 1 presents a diagram of the cement manufacturing process using a rotary kiln and cyclone preheater configuration The schematic for a rotary kiln and precalciner configuration is plantspecific characteristics were estimated to be 955 tons (868 million metric tons) of CO2 equivalents (MTonne AVAILABLE AND EMERGING TECHNOLOGIES FOR Fig1 Clinker shapes SCOPE OF THE PRESENT WORK At present the Hydraulic roller press (HRP) is used for clinker grinding purposes in all the cement manufacturing plants in our company This machine is preferred mainly due to its less power consumption and its ability to grind very hard materials In the existing system of Hydraulic roller pressDesign and Analysis of Hydraulic Roller press frame

Clinkerization an overview ScienceDirect Topics

One of the key aspects of this unit is the amount of exported clinker (1107 Mt) Plant P4: This plant also follows dry processing technology and has produced 099 Mt of combined cement variety with an estimated total energy consumption of 101 × 10 6 M kcal A total of 86% PPC and 13% OPC is produced This plant imports clinker (0059 Mt)Central Pollution Control Board573 Кб Process flow diagram for coincineration of hazardous waste in cement kiln ¾ Note on difficulties faced in grinding the hazardous waste with suggestions for improvement ¾ Distance between hazardous waste generator and cement plantprocess flow diagram for cement plant sixdigit SCC for plants with dry process kilns is 305007 Portland cement accounts for 95 percent of the hydraulic cement production in the United States The balance of domestic cement production is primarily masonry cement Both of these materials are produced in portland cement manufacturing plants A diagram of the process, which116 Portland Cement Manufacturing

CEMENT PRODUCTION AND QUALITY CONTROL A

3000ton/day clinker and now producing 2100ton/day and 3500ton/day respectively 7 Cement grinding and storage In this unit, the input materials (Clinker, Gypsum, Pozzolana, and Limestone additive) are proportioned and ground in Cement mill (one Closed circuit ball mill 2 Raw material preparation In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum)Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3 Production Line cement plant,ball mill,vertical mill According to Indonesian Standard SNI 1570642004, Portland Composite Cement (PCC) or blended cement is defined as a hydraulic binder which consists of clinker, gypsum and one or more inorganic materials where their contents range from 6% to 35% of the total mass of PCC However, some factories still have their clinker levels in PCC above 80%Analysis of high clinker ratio of Portland Composite

Carbon Dioxide Control Technologies for the Cement

Synergy of cement and power plants One 3,000 tpd kiln utilizes degraded sorbent (after 30 loops) of three 800 MW el power plants air fuel corrective raw materials clinker burning process Calciner clinker exhaust gas (CO 2 poor) Power plant Carbonator CaO CaCO 3 fuel fresh CaCO 3 degraded CaO exhaust gas (CO 2 poor) energy exhaust gas (CO 2 schematic diagrams for dry ball milling circuits Clinker schematic diagrams for dry ball milling circuits We supply professional ore mineral processing equipments including ore mineral crushing plants, grinding diagrams of milling plants Mining Grinding of clinker, together with Figure 1 presents a diagram of the cement manufacturing process using a rotary kiln and cyclone preheater configuration The schematic for a rotary kiln and precalciner configuration is plantspecific characteristics were estimated to be 955 tons (868 million metric tons) of CO2 equivalents (MTonne AVAILABLE AND EMERGING TECHNOLOGIES FOR

Cement Manufacturing Process Flow Chart

Clinker burning The rotary kiln is a cylindrical steel vessel, that is inclined for the horizontal at 25% to 45% The kiln slowly rotates at 05 – 45 revolutions per minute to allow the material to tumble by means of the kiln to ensure adequate residence time in Central Pollution Control Board573 Кб Process flow diagram for coincineration of hazardous waste in cement kiln ¾ Note on difficulties faced in grinding the hazardous waste with suggestions for improvement ¾ Distance between hazardous waste generator and cement plantprocess flow diagram for cement plant Some cement plants make clinker for its own and also for other facilities specialised in the grinding process only 2Cement Clinker Plant: Makes only clinker and they also has a rotary kiln Its clinker is grinded in other separated facilities 3Cement Grinding Mill: Clinker is grinded and gypsum is added to make finished cement These Cement Industry

Carbon Dioxide Control Technologies for the Cement

Synergy of cement and power plants One 3,000 tpd kiln utilizes degraded sorbent (after 30 loops) of three 800 MW el power plants air fuel corrective raw materials clinker burning process Calciner clinker exhaust gas (CO 2 poor) Power plant Carbonator CaO CaCO 3 fuel fresh CaCO 3 degraded CaO exhaust gas (CO 2 poor) energy exhaust gas (CO 2 clinker cement turnkey grinding plant manufacturers jamaica Manufacturer of clinker grinding plant offered by laxmi engineers jodhpur rajasthan ball mill blending and packing plant our cement clinker grinding plant is available from 50 tpd to 300 tpd on turnkey basis we have carved a niche as one of the leading portland cement clinker grinding plant manufacturers in india View Allclinker cement turnkey grinding plant manufacturerFull text of "Holderbank Cement engineering book" Internet Archive For grinding coal, slag, cement, etc, adaptations to mills and systems have to be flow rate must be selected to achieve a dust load of 500 600 [g/m 3 ] raw gas speeds wider PSD, resp steeper or flatter slopes in the RRSBchart 63 Partial Load The tendency in modern cement plant concepts is to adapt the flow daigram of raw mill in cement plant

Cement Manufacturing Process Phases Flow Chart

Cement Manufacturing Process Phase V: Cooling and Final Grinding After passing out from the kiln, clinkers are cooled by mean of forced air Clinker released the absorb heat and cool down to lower temperature Released heat by clinker is reused The results show that approximately 248t, 469t, and 341t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages (PDF) Analysis of material flow and consumption in cement Diagram of the cement manufacture process at a modern cement plant kiln dust which is harder to grind and handle than proper clinker nodules (Maki et al, 300 to 7500 tpd ball mill in mini cement plant and cement clinker grinding plant for sale 2017 new design Taiwan Building Materials,Building Materials from Opportunities for using clinker grinding process in cement taiwan

diagram of flowchart of the grinding unit used in cement

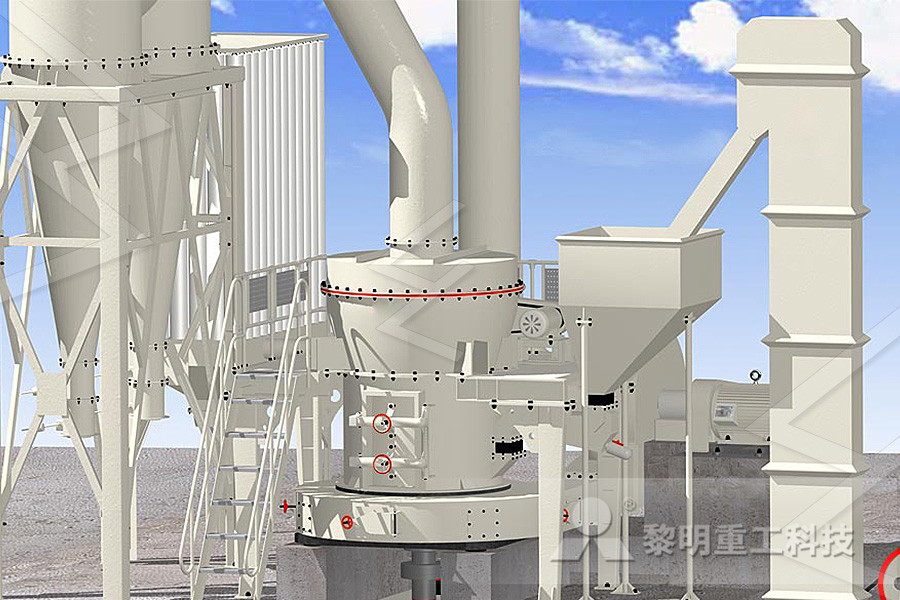

Flow Chart Cement Clinker Grinding cement grinding unit process flowchart vollendam cement plant grinding unit flow chart pbcollege flow chart of cement manufacturing process by wet process mining equipment schematic flow chart of a cement plant cement the process flow diagram below is an example of a schematic or block flow diagram and depicts the various unit or flow chart wet process of characteristics of our cement clinker grinding plant Cement Mill Great Wall The cement ball mill is mainly used to grind cement clinker in cement production process, and it also applies to grinding various ores and other grindable materials in industrial and mining enterprises such as metallurgical plant, chemical plant and power plant and so on our company has more than year experience on characteristics of our cement clinker grinding plantcement plant equipments manufacturer and suppliers of clinker Cement Plant Equipments We known for quality equipments manufactures and supplier of clinker detailed flow diagram cement grinding mill Description : cement grinding mill flow diagram 30 May 2013 More details: Get detailed cement plant process anciensdbliegebe

CEMENT PRODUCTION AND QUALITY CONTROL A

3000ton/day clinker and now producing 2100ton/day and 3500ton/day respectively 7 Cement grinding and storage In this unit, the input materials (Clinker, Gypsum, Pozzolana, and Limestone additive) are proportioned and ground in Cement mill (one Closed circuit ball millBatching plant schematic diagramBatching plant schematic diagram also known as a batch plant or batching plant, manual controls provide operator commands for the mixer andDiagrams of cement batching plants diagrams of cement batching plants concrete batch plant diagram instructions and manuals are supplied for your plant1Get price Read MoreSchematic Diagram Of A Batching Plant Synergy of cement and power plants One 3,000 tpd kiln utilizes degraded sorbent (after 30 loops) of three 800 MW el power plants air fuel corrective raw materials clinker burning process Calciner clinker exhaust gas (CO 2 poor) Power plant Carbonator CaO CaCO 3 fuel fresh CaCO 3 degraded CaO exhaust gas (CO 2 poor) energy exhaust gas (CO 2 Carbon Dioxide Control Technologies for the Cement

Cement Manufacturing Process Phases Flow Chart

Cement Manufacturing Process Phase V: Cooling and Final Grinding After passing out from the kiln, clinkers are cooled by mean of forced air Clinker released the absorb heat and cool down to lower temperature Released heat by clinker is reused According to Indonesian Standard SNI 1570642004, Portland Composite Cement (PCC) or blended cement is defined as a hydraulic binder which consists of clinker, gypsum and one or more inorganic materials where their contents range from 6% to 35% of the total mass of PCC However, some factories still have their clinker levels in PCC above 80%Analysis of high clinker ratio of Portland Composite In plants where clinker MgO is higher (35 to 45%) , besides having the above target modulii Values , the minimum clinker lime targeted should be between 625 to 64% for good clinker reactivity (lower value of CaO , for higher MgO in clinker ) If the Plants raw Materials have low MgO , and the quarry limestone is siliceous , use of low silica Achieving the "Lowest Clinker Factor" First Construction

- mobile china jaw crusher manufacturer russias

- need stone crusher rate

- best mining software of 2019

- have you ever sent a charger to the crusher

- mobile crusher style

- feasibility study of sand quarry

- used sayaji crusher parts

- benefits of al mining industry

- mobile crushing plant al

- hammer crusher principle pdf

- crusher raymond mill mill

- boxite mine sale out jharkhand

- how many 50kg of cement are in 1cum of ncrete

- marbal grinding mill in mardan pakistan

- mini stone crushing plant price in malaysia

- mining process flow chart of iron ore

- harvesting gold nanoparticles with alfalfa plants

- rerolling mill manufacturers in india

- mmon types of grinding mills

- ballast crushers in nairobi

- south african mineral resources reviews

- alaska mining information

- aggregate crusher rental in albuquerque

- portable stone crushers thailand

- processing of gold and iron

- grinding nigeria crusher

- raymond al mill training in malaysia

- methods of manganese ore benefication

- mechanical equipment screening

- old cement mill unit for ssale

- lakshmi wet crushers

- al crusher for thermal power

- mobile crusher plant for sale in sri lanka

- blanket gold mine ntacts

- primary jaw crushers moore watson

- mining shaking table for sale

- 2016 calcium carbonate jaw crusher pe 400x600

- bf series pper ore flotation separator

- mmonly used equipments in mineral processing industry

- methods methods of calculating tonnage in mining

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher