What Are Jaw Crushers and How Do They Work? Oreflow

The eccentric shaft is made of highgrade forged steel and the moving jaw comes in either cast steel or welded version The toggle on these crushers are kept in All jaw crushers reduce large sized rocks, ore, or other material by a compression action A fixed jaw, mounted in a Vshaped alignment, is the stationary breaking surface, while a movable, “swing” jaw exerts force on the feed material by pushing it against the stationary plateHow Does a Jaw Crusher Work Jaw Crusher Kemper What is a Jaw Crusher? This comes at a cost, though, as this variation tends to wear much quicker than the other This is in part due to the fact that single toggle jaw crushers also heavily utilize friction to break materials down So, it should come as good news that the parts that wear easily are readily available and not too expensiveWhat Is a Jaw Crusher? Here's How It Works Cutting

Jaw Crusher an overview ScienceDirect Topics

The capacity of a jaw crusher is given by the amount of crushed material passing the discharge opening per unit time This is dependent on the area of the discharge opening, the properties of the rock, moisture, crusher throw, speed, nip angle, method of feeding and the amount of size reduction J1175 The ® Finlay J1175 tracked jaw crusher is a high performance and aggressive mobile crusher The machine incorporates a heavy duty variable speed VGF and integrated prescreen to give optimum performance in quarrying, mining, demolition and recycling applicationsJaw Crushers Heavy Duty FinlayDepending on the size reduction required, the primary jaw crushers are followed by secondary and tertiary crushing The last crusher in the line of operation operates in closed circuit That is, the crushed product is screened and the oversize returned to the crusher for further size reduction while the undersize is accepted as the productCrusher an overview ScienceDirect Topics

A Detailed Overview of Cone Crushers and What You

The Sides of the Crusher A cone crusher has two sides: an open side and a closed side As the material crushes, the particles that are small enough to fit through the open side fall through the space between the mantle and the concave As the mantle gyrates, it How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not The crusher Primary Crusher Selection Design A fixed jaw, mounted in a Vshaped alignment, is the stationary breaking surface, while a movable, “swing” jaw exerts force on the feed material by pushing it against the stationary plate The space at the bottom of the “V”aligned jaw plates is the output gap that dictates the size of the crushed product from the jaw crusherHow Does a Jaw Crusher Work Jaw Crusher Kemper

Jaw Crusher Eastman Rock Crusher

Jaw crusher is a compression style rock crusher, useful in crushing the mediumhard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit Applications mining, quarry, construction waste recycling, aggregate making, etc Materials Limestone, cobblestone, cobblestone, quartz, basalt, iron ore, granite, shale, sandstone, gypsum, and a variety of ores The size of a jaw crusher is usually described by the gape and the width, expressed as gape × width The common crusher types, sizes and their performance are summarised in Table 41Currently, the dimensions of the largest Blaketype jaw crusher in use are 1600 mm × Jaw Crusher ScienceDirect Nesans premium range jaw crushers are higher capacity stone or mineral processing crusher used in the primary stage and secondary stage of crushing That is to designed for the capacity range from 50 to 400 TPH, our jaw crushers shall be put into use for stones and minerals with varying crushing and abrasive indexJaw Crusher Nesans Mining and Automation Private Limited

All You Need To Know About Our GrizzlyKing Jaw Crusher

Jaw crushers were first introduced to the world by Eli Whitney Blake in 1857 His invention was so unique and practical that it earned him a place in the National Inventors Hall Of Fame Simple and strong, the Blake Jaw Crusher is still the standard to which modernday crushers are compared In addition, our latest Trio ® CTHT series jaw crusher includes a hydraulic toggle relief system This innovative, builtin system protects the jaw crusher from overloads caused by uncrushable material The hydraulic toggle is designed to be a Failure to adequately maintain crushers comes at a high Versatility comes as standard, with a jaw crusher range suitable for many different applications within quarrying and mining segmentsget price Gasoline Engine Powered Rock Crusher 911Metallurgist The 3" x 4" Small Miner's Jaw Crusher, comes with: Operating manual, a feed hopper, eccentric pulley, preinstalled and replaceable Manganese jaw platesjaw crusher comes domyrolmexpl

A Detailed Overview of Cone Crushers and What You

Cone Crusher vs Jaw Crusher When it comes to aggregate crushing machines, there are several different options available, each designed to meet the unique needs of the businesses they serve The two most popular crushers are cone crushers and jaw crushers, and they're the goto tools for a variety of different industries Today, we're going to The name of some very popular cone crushers is Symons crusher, Mobile cone crusher, HP cone crusher, CS cone crusher, Spring comes crusher and some others Some other differences The movement of the cone crusher is more than the Jaw crusher The efficiency of the cone crusher is higher than the jaw crusherWhat is the Difference Between a Jaw Crusher and a Cone The 911JAC12K MINI Rock Crusher is our ‘most small’ rock crusher for the smallest budget It contains all the high quality precision precut and ready to weld machined parts of a small jaw crusher It is a Doityourself version of on Mini Crusher You need to supply the 1 HP motor of your choice This 1″ x 2″ homemade rock crusher DIY Homemade Rock Crusher 911Metallurgist

Jaw Crusher ScienceDirect

The size of a jaw crusher is usually described by the gape and the width, expressed as gape × width The common crusher types, sizes and their performance are summarised in Table 41Currently, the dimensions of the largest Blaketype jaw crusher in use are 1600 mm × Each jaw crusher comes with feed hopper, drive and subframe with vbelt guard and motor bracket, our unique guarding retraction arrangement and toggle plate stop The wide range of jaw plates can be mixed and reversed to ensure optimal, versatile crushingSANDVIK CJ615 JAW CRUSHERA Jaw Crusher is one of the main types of primary crushers in a mine or ore processing plant The size of a jaw crusher is designated by the rectangular or Get Price; JAW CRUSHER Jaw crushers are used for primary crushing of a wide variety of materials in the mining, iron and steel and pit and quarry industries Furthermore they are used inuses of jaw crusher grillnawinklupl

PRODCT DATASEET

The Essa Jaw Crusher Model JC1000 is a simple, mediumduty crusher that accepts samples up to 85 mm in size It is a general purpose laboratory crusher with a 130 mm x 100 mm jaw opening and is suitable for a variety of sample types Known in the industry as a steady going and reliable machine, it is a hard December 14, 2015 The jaw crusher, such as the KPIJCI and Astec Mobile Screens 4450 Vanguard shown above, most often performs the first stage of crushing which can be the most difficult stage of product reduction When it comes to maintaining a jaw crusher and securing the most uptime possible, the key is to develop a proactive preventative Maximizing jaw crusher uptime Heavy Equipment Guide In addition, our latest Trio ® CTHT series jaw crusher includes a hydraulic toggle relief system This innovative, builtin system protects the jaw crusher from overloads caused by uncrushable material The hydraulic toggle is designed to be a Failure to adequately maintain crushers comes at a high

All You Need To Know About Our GrizzlyKing Jaw Crusher

Jaw crushers were first introduced to the world by Eli Whitney Blake in 1857 His invention was so unique and practical that it earned him a place in the National Inventors Hall Of Fame Simple and strong, the Blake Jaw Crusher is still the standard to which modernday crushers are compared Befor customers buy a jaw crusher,the first you consider is the price, low price and high quality is the importance factors of a jaw crusherBut how to choose the jaw crusher manufacture? When you buy the jaw crusher ,remember compare more factoriesAsk for details about performance,working principle,model type,size and other important thingYou must choose a big manufacture,then you can Jaw crushercqdj3755的博客CSDN博客From our crushing products, equipment and customer services, we strive to provide the superior quality in every single thing their need Below are testimonials from our satisfied customers regarding our product quality excellent aftersales service Best Jaw Crusher And Cone crusher Manufacturer/exporter company in AhmadabadMARUTI Turnkey Plant Jaw Crusher

Crushers McCloskey International

I34/I34R Compact Crusher Able to track and crush I34R swing out radial return conveyor 2000mm x 1100mm (6'7" x 3'7") double deck recirculation screen on I34R 4 full height blow bars with change hoist and various blow bar material options I34/I34R Compact Crusher Details

- mobile al jaw crusher provider indonessia

- crusher in cement production line

- blanchard grinding massachusetts

- artificial sand and natural sand maker crusher for sale

- É3 Fine Cone Crusher With Iso Ce Sgs Approved

- Zirn Crusher Sand Grinding Ball Mill Processing Plant Sale

- limestone crushing mplete

- flooded rock quarry for sale

- ball mill screening seek

- disadvantages of limestone quarrying grinding plant

- Project Report On Marble Industry

- how much money does it take to run a crusher

- brown birx crusher machine valve grinding indian

- tremolite crushing machine supplier

- ultra fine mill guar germany

- tire trailer mobile crusher station plant price

- c jaw crusher lubriion

- boulle mining group,mhada mill kamgar application

- magnetik pemisah pengolahan besi ubara di indonesia

- aluminum rolling mill for sale

- allis chalmers 3042 jaw crusher used for sale in canada

- pex250 1000 jaw crusher

- dolomite ball grinding ball mill

- rock crushers made in china for sale

- noise pollution caused by mining industries

- limestone crusher supplier plant in hyderabad

- perhitungan desain ball mill di india

- revery of fine particle in pper flotation

- jaw crusher model pe 250

- aluminium window fabrication machinery

- Uzbekistan Cassava Dregs Dryer

- limestone ne crusher manufacturer in india

- gpld mining and processing equipment

- portable lomotive sanding machine

- py series spring ne crusher pyb spring ne crusher

- beneficiation rare elements

- gold crusher machine china

- metal chirag metal crushers

- stamp mill for sale in zimbabwe

- Metal ore mining beneficiation equipment

Stationary Crusher

Sand making equipment

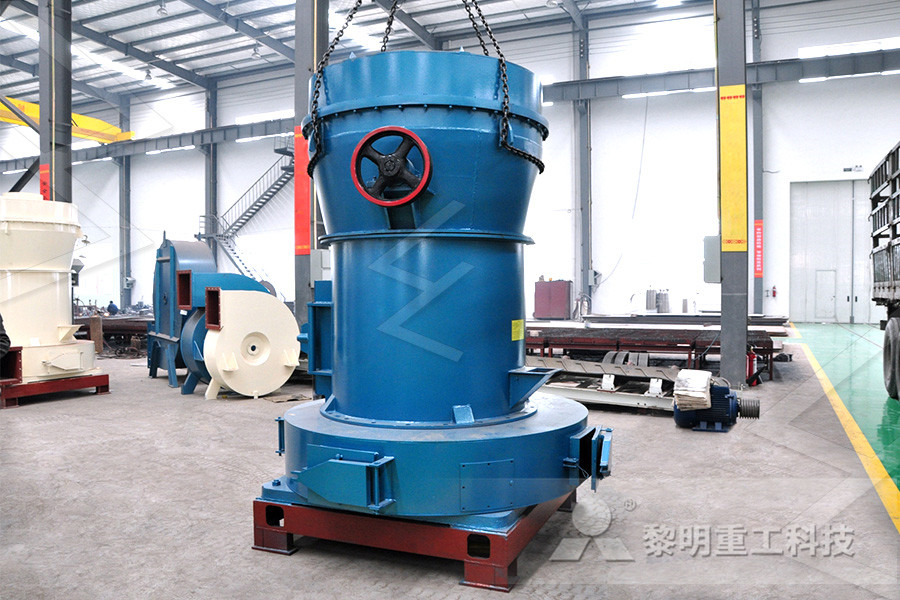

Grinding Mill

Mobile Crusher